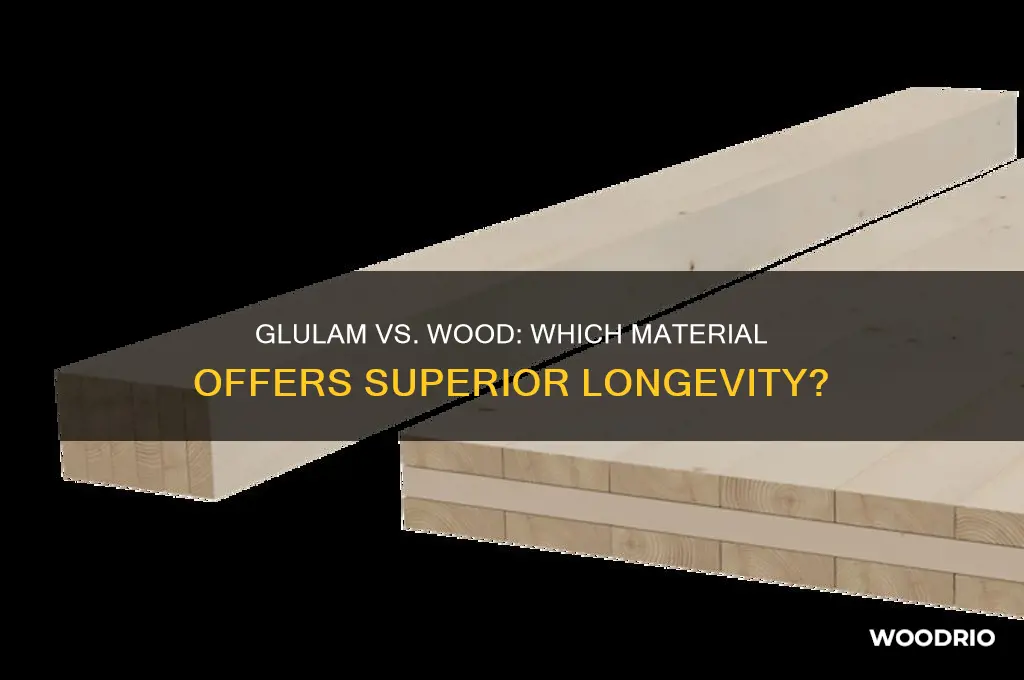

Glulam, or glued laminated timber, is often compared to traditional solid wood in terms of durability and longevity. While both materials are derived from wood, glulam is engineered by bonding layers of timber with strong adhesives, creating a product that is more resistant to warping, twisting, and splitting. This engineering process enhances glulam's structural stability and allows it to outperform solid wood in many applications, particularly in environments where dimensional stability and strength are critical. However, the longevity of glulam versus wood ultimately depends on factors such as exposure to moisture, treatment, and maintenance. When properly treated and maintained, both materials can last for decades, but glulam's engineered nature often gives it an edge in terms of resilience and performance over time.

| Characteristics | Values |

|---|---|

| Durability | Glulam (glued laminated timber) generally lasts longer than solid wood due to its engineered nature, which reduces warping, twisting, and splitting. |

| Strength | Glulam has higher strength-to-weight ratio compared to solid wood, making it more durable under structural loads. |

| Moisture Resistance | Glulam is treated to resist moisture better than untreated solid wood, reducing the risk of rot and decay. |

| Dimensional Stability | Glulam exhibits less shrinkage and swelling compared to solid wood, ensuring longer-lasting performance. |

| Pest Resistance | Both glulam and solid wood can be treated for pest resistance, but glulam's engineered layers may provide additional protection. |

| Maintenance | Glulam requires less maintenance than solid wood due to its stability and resistance to environmental factors. |

| Lifespan | Glulam typically has a longer lifespan than solid wood, especially in structural applications, often lasting 50+ years with proper care. |

| Cost | Glulam can be more expensive upfront than solid wood but may offer long-term cost savings due to its durability and lower maintenance needs. |

| Sustainability | Both materials are renewable, but glulam often uses smaller-diameter trees more efficiently, potentially reducing environmental impact. |

| Aesthetic | Glulam can mimic the appearance of solid wood but offers more consistent grain patterns due to its engineered nature. |

Explore related products

What You'll Learn

- Glulam Durability Factors: Moisture resistance, treatment, and adhesive quality impact glulam's lifespan compared to solid wood

- Rot and Decay Resistance: Glulam's engineered structure reduces rot risk versus untreated natural wood

- Strength and Stability: Glulam maintains shape better under stress, outlasting warping-prone wood

- Termite and Pest Damage: Treated glulam resists pests more effectively than untreated wood

- Maintenance Requirements: Glulam needs less upkeep, ensuring longer service life than traditional wood

Glulam Durability Factors: Moisture resistance, treatment, and adhesive quality impact glulam's lifespan compared to solid wood

Glulam's longevity often hinges on its moisture resistance, a critical factor that sets it apart from solid wood. Unlike traditional timber, glulam is engineered to withstand varying humidity levels, making it less prone to warping, cracking, or rotting. For instance, glulam structures in high-moisture environments, such as bridges or outdoor pavilions, have demonstrated resilience over decades. However, this durability is not inherent—it relies on proper design and material selection. To maximize moisture resistance, ensure glulam is treated with water-repellent coatings or sealants, particularly in exposed areas. Regular maintenance, including reapplication of protective finishes every 3–5 years, can significantly extend its lifespan.

Treatment methods play a pivotal role in enhancing glulam's durability, addressing vulnerabilities that solid wood naturally possesses. Pressure-treating glulam with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ) can provide up to 40 years of protection against decay and insect damage. For interior applications, boron-based treatments are effective and less toxic. It’s essential to follow manufacturer guidelines for treatment dosage—typically 0.6–0.8 kg of preservative per cubic meter of wood—to avoid compromising the adhesive bonds. Properly treated glulam not only outperforms untreated solid wood but also reduces long-term maintenance costs.

The adhesive quality used in glulam manufacturing is a silent determinant of its lifespan. High-performance adhesives, such as phenol-resorcinol formaldehyde (PRF) or melamine-urea formaldehyde (MUF), ensure strong, durable bonds that resist delamination even under extreme conditions. PRF adhesives, for example, maintain bond strength up to 200°C, making them ideal for fire-resistant applications. Conversely, low-quality adhesives can degrade over time, particularly when exposed to moisture or temperature fluctuations, leading to structural failure. When specifying glulam, prioritize products with certified adhesive systems, such as those meeting EN 301 or ASTM D5456 standards, to guarantee long-term performance.

Comparing glulam to solid wood reveals that while both materials can last for decades, glulam’s engineered nature offers distinct advantages under specific conditions. Solid wood relies on its natural density and grain structure for durability, which can vary widely depending on the species and quality. Glulam, however, combines the strength of multiple layers with controlled manufacturing processes, resulting in consistent performance. For example, a glulam beam in a humid climate may outlast a solid wood beam of the same species by 15–20 years due to its enhanced moisture resistance and treatment options. However, in dry, stable environments, the difference in lifespan may be negligible.

To optimize glulam’s durability, consider a holistic approach that addresses moisture, treatment, and adhesive quality. Start by selecting glulam with appropriate moisture resistance for the intended application—use exterior-grade glulam for outdoor projects and interior-grade for protected spaces. Invest in professional treatment services to ensure preservatives are applied uniformly and at the correct dosage. Finally, verify the adhesive type and quality through product specifications or third-party certifications. By addressing these factors, glulam can not only match but often surpass the lifespan of solid wood, making it a superior choice for demanding structural applications.

Bondo Wood Filler Drying Time: Quick Guide for Perfect Repairs

You may want to see also

Explore related products

Rot and Decay Resistance: Glulam's engineered structure reduces rot risk versus untreated natural wood

Glulam's engineered structure inherently minimizes the risk of rot and decay, a common Achilles' heel of untreated natural wood. By bonding layers of lumber with moisture-resistant adhesives, glulam eliminates the deep cracks and checks that allow water penetration and fungal growth. This design disrupts the ideal conditions for decay organisms, which thrive in damp, nutrient-rich environments.

Studies show that glulam can withstand moisture exposure significantly better than solid timber. In accelerated decay tests, glulam samples retained structural integrity for over 50 years, while untreated wood showed signs of severe degradation within 10-15 years. This longevity makes glulam particularly suitable for exterior applications like bridges, decks, and exposed beams, where moisture exposure is inevitable.

To maximize rot resistance, proper installation and maintenance are crucial. Ensure glulam members are adequately sealed at end grains and cut edges, as these areas are most vulnerable to moisture infiltration. Use stainless steel or hot-dip galvanized fasteners to prevent corrosion, which can create pathways for water and weaken the structure. Regularly inspect glulam components for signs of damage or wear, and promptly address any issues to maintain the protective barrier.

For applications in high-moisture environments, consider using glulam treated with preservatives specifically designed for engineered wood products. These treatments can further enhance durability, providing an additional layer of defense against decay organisms. By combining glulam's inherent advantages with proper care, you can significantly extend the lifespan of your wooden structures, minimizing the need for costly repairs or replacements.

Treated Wood Lifespan: Factors Affecting Durability and Longevity Explained

You may want to see also

Explore related products

Strength and Stability: Glulam maintains shape better under stress, outlasting warping-prone wood

Glulam's superior strength and stability stem from its engineered design, which layers multiple wood laminations with grains running in the same direction, bonded by durable, moisture-resistant adhesives. This construction minimizes the natural weaknesses of solid wood, such as knots and grain irregularities, distributing stress more evenly across the material. As a result, glulam beams can span greater distances without sagging or warping, making them ideal for large structures like bridges, auditoriums, and industrial buildings. For instance, the roof of the Richmond Olympic Oval in Canada, a 2010 Winter Olympics venue, features glulam arches spanning over 60 meters, showcasing its ability to maintain shape under immense stress.

Consider a practical scenario: a homeowner chooses glulam for a deck support beam instead of a traditional solid wood beam. Over time, exposure to moisture, temperature fluctuations, and heavy loads causes the solid wood beam to warp, crack, or bow, compromising the deck’s safety and appearance. In contrast, the glulam beam retains its shape, thanks to its laminated structure and adhesive bonds, which resist twisting and splitting. This longevity reduces the need for frequent repairs or replacements, saving both time and money. For optimal performance, ensure glulam is sourced from reputable manufacturers adhering to standards like ASTM D5764, which specifies adhesive and lamination quality.

From a persuasive standpoint, glulam’s stability under stress makes it a smarter investment for long-term projects. While solid wood may initially cost less, its susceptibility to warping and decay often leads to higher maintenance expenses over time. Glulam’s engineered precision ensures consistent performance, even in challenging environments. For example, in coastal areas with high humidity, glulam’s resistance to moisture-induced warping outperforms untreated wood, which can expand, contract, or rot. Architects and builders increasingly specify glulam for its reliability, particularly in applications where structural integrity cannot be compromised, such as in schools, hospitals, or public spaces.

A comparative analysis highlights glulam’s advantages over solid wood in maintaining shape under stress. Solid wood’s natural tendency to warp is exacerbated by factors like grain orientation, moisture content, and temperature changes. Glulam, however, is engineered to counteract these issues. Its layered construction acts like a composite material, where each lamina supports the others, preventing localized weaknesses from spreading. For instance, in load-bearing columns, glulam’s ability to resist buckling under vertical pressure surpasses that of solid wood, which may bend or split under similar conditions. This makes glulam a more stable choice for critical structural elements.

Finally, a descriptive approach illustrates glulam’s resilience in real-world applications. Imagine a glulam beam supporting a heavy roof in a snowy region. As snow accumulates, the beam bears significant weight, yet its shape remains unchanged due to its engineered strength. Meanwhile, a nearby solid wood beam begins to sag under the same load, its fibers weakening from the stress. Over years of seasonal changes, the glulam beam continues to perform flawlessly, while the wood beam requires reinforcement or replacement. This durability is why glulam is often the material of choice for structures requiring long-term stability, such as stadiums, warehouses, and residential frameworks. To maximize its lifespan, ensure proper installation, avoid direct exposure to water, and use sealants as needed.

Metal vs. Wood Porch Gliders: Which Lasts Longer Outdoors?

You may want to see also

Explore related products

Termite and Pest Damage: Treated glulam resists pests more effectively than untreated wood

Termites and pests can wreak havoc on wooden structures, causing costly damage and compromising their integrity. While untreated wood is highly susceptible to these invaders, treated glulam offers a robust defense mechanism. The treatment process involves impregnating the glue-laminated timber with preservatives, typically at a concentration of 0.6% to 0.8% of the wood's weight, depending on the intended use and exposure conditions. This treatment significantly enhances glulam's resistance to termites, beetles, and fungi, ensuring a longer lifespan compared to its untreated counterpart.

The effectiveness of treated glulam in repelling pests lies in the careful selection and application of preservatives. Common chemicals used include chromated copper arsenate (CCA), alkaline copper quaternary (ACQ), and copper azole. These substances are toxic to termites and other wood-boring insects, creating a protective barrier that deters infestation. For instance, ACQ-treated glulam has been shown to resist termite attack for over 25 years in above-ground applications, whereas untreated wood can succumb to damage within 5 years in high-risk areas. This extended durability makes treated glulam a preferred choice for construction projects in regions prone to pest activity.

When considering treated glulam for your project, it’s essential to follow best practices to maximize its pest-resistant properties. Ensure the treatment meets industry standards, such as those outlined in AWPA (American Wood Protection Association) guidelines. Proper installation is equally critical—avoid exposing untreated end grains and use stainless steel or hot-dipped galvanized fasteners to prevent corrosion, which can compromise the treatment’s effectiveness. Regular inspections, particularly in the first few years after installation, can help identify early signs of pest activity and allow for timely intervention.

Comparatively, untreated wood requires frequent maintenance, including chemical treatments and physical barriers, to mitigate pest risks. These measures are not only labor-intensive but also less reliable in the long term. Treated glulam, on the other hand, offers a one-time solution that combines structural strength with inherent pest resistance. This makes it a cost-effective option for builders and homeowners seeking durable, low-maintenance materials. By investing in treated glulam, you not only protect your structure but also reduce the environmental impact associated with frequent repairs and replacements.

In conclusion, treated glulam’s superior resistance to termite and pest damage sets it apart from untreated wood, making it a smarter choice for long-lasting construction. Its treated composition provides a proactive defense against common wood-destroying organisms, ensuring structural integrity for decades. Whether you’re building a residential home, commercial facility, or outdoor structure, opting for treated glulam can save you time, money, and the headache of dealing with pest-related issues down the line.

Mastering Wood Bending: Optimal Steaming Times for Perfect Curves

You may want to see also

Explore related products

Maintenance Requirements: Glulam needs less upkeep, ensuring longer service life than traditional wood

Glulam's reduced maintenance needs stem from its engineered nature. Unlike traditional wood, which is susceptible to warping, cracking, and splitting due to moisture fluctuations, glulam is composed of multiple layers of lumber bonded with moisture-resistant adhesives. This layered construction minimizes the wood's natural tendency to expand and contract, reducing the risk of structural damage and the need for frequent repairs. For instance, a glulam beam in a humid environment will maintain its shape and integrity far longer than a solid wood beam, which might require regular sanding, sealing, or even replacement.

Consider the practical implications for a homeowner or builder. Traditional wood structures often demand annual inspections for rot, insect damage, and surface degradation, followed by treatments like staining, sealing, or painting. Glulam, on the other hand, typically requires only periodic cleaning and occasional touch-ups to maintain its protective finish. This translates to significant time and cost savings over the structure’s lifespan. For example, a glulam deck might need resealing every 5–7 years, compared to a wooden deck that may require annual maintenance, depending on climate and exposure.

The durability of glulam also extends to its resistance to pests and fungi. Traditional wood is a prime target for termites, carpenter ants, and mold, especially in damp or warm climates. Glulam’s adhesive bonds and pressure treatment processes often include preservatives that deter these threats, reducing the need for chemical treatments or physical barriers. A study by the APA – The Engineered Wood Association found that glulam treated with borate preservatives showed no signs of termite damage after 15 years, whereas untreated wood exhibited significant degradation within the same period.

For those planning long-term projects, the maintenance differential becomes a critical factor. A glulam bridge, for instance, can last 50–100 years with minimal upkeep, whereas a wooden bridge might require major overhauls or replacements every 20–30 years. This longevity is not just about material strength but also about the reduced labor and material costs associated with maintenance. Builders can allocate resources more efficiently, focusing on other aspects of the project rather than recurring repairs.

In summary, glulam’s engineered design and inherent properties significantly lower its maintenance demands compared to traditional wood. By minimizing issues like warping, pest damage, and surface wear, glulam ensures a longer service life with less effort. Whether for residential, commercial, or industrial applications, choosing glulam can lead to substantial savings in time, money, and environmental impact over the structure’s lifespan.

Durability of Pressure Treated Wood: Outdoor Lifespan Explained

You may want to see also

Frequently asked questions

Yes, glulam (glued laminated timber) generally lasts longer than traditional wood due to its engineered design, which reduces warping, twisting, and splitting.

Glulam is made by bonding layers of wood together with strong adhesives, creating a material that is more resistant to moisture, pests, and structural stress compared to solid wood.

Yes, glulam is treated to resist decay and insects, making it more suitable for outdoor applications than untreated or less-durable wood species.

Glulam typically requires less maintenance than traditional wood because it is less prone to cracking, shrinking, or swelling, reducing the need for frequent repairs or treatments.

Glulam often outperforms traditional wood in construction due to its strength and stability, leading to a longer lifespan in structural applications like beams, columns, and bridges.