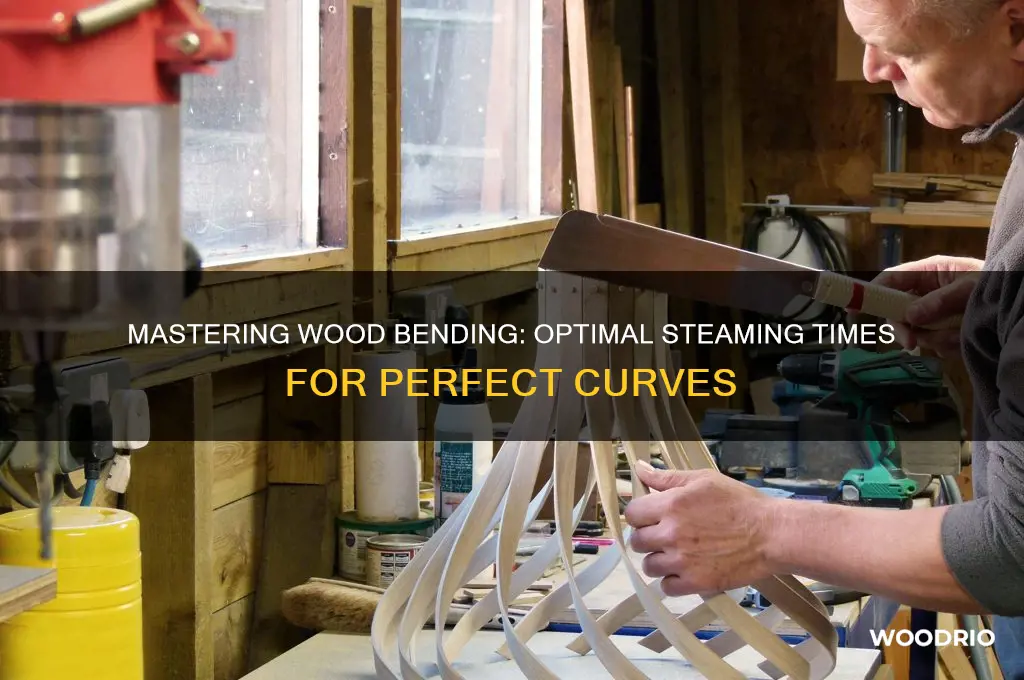

Steaming wood for bending is a traditional woodworking technique that involves softening the wood fibers by exposing them to steam, making the material pliable enough to shape without breaking. The duration required for steaming depends on several factors, including the wood species, thickness, and desired bend radius. Generally, hardwoods like oak or maple may need 30 to 60 minutes of steaming, while softer woods like pine or cedar may require less time, typically 15 to 30 minutes. Thicker pieces of wood will need more time to heat through, and tighter bends often necessitate longer steaming periods. It’s crucial to monitor the process carefully to avoid over-steaming, which can weaken the wood, and to ensure the wood is bent while still warm and pliable. Proper timing and technique are key to achieving a successful, durable bend.

| Characteristics | Values |

|---|---|

| Steam Temperature | 100°C to 120°C (212°F to 248°F) |

| Steaming Time (General) | 1 to 6 hours, depending on wood species and thickness |

| Softwoods (e.g., Pine, Cedar) | 1 to 2 hours |

| Hardwoods (e.g., Oak, Maple) | 2 to 4 hours |

| Tropical Hardwoods (e.g., Teak, Mahogany) | 4 to 6 hours |

| Thickness (1/4 inch) | 1 to 2 hours |

| Thickness (1/2 inch) | 2 to 3 hours |

| Thickness (1 inch) | 3 to 6 hours |

| Moisture Content Before Steaming | 8-12% for optimal bending |

| Bending Radius | Smaller radii require longer steaming times |

| Cooling After Steaming | 15-30 minutes, wrapped in cloth or plastic to retain moisture |

| Optimal Bending Time | Immediately after steaming while wood is still hot and pliable |

| Safety Precautions | Use heat-resistant gloves, avoid direct contact with steam |

| Steaming Vessel | Airtight container with a steam source (e.g., boiler or kettle) |

| Wood Preparation | End grain sealed to prevent excessive moisture absorption |

Explore related products

What You'll Learn

Ideal steaming duration for different wood types

Steaming wood for bending is both art and science, with duration playing a pivotal role in determining success. Hardwoods like oak and maple, known for their density, typically require 1 to 2 hours of steaming per inch of thickness. For instance, a 2-inch thick oak plank would need 2 to 4 hours of continuous steam to reach the necessary plasticity for bending. This longer duration ensures the lignin softens adequately without causing internal stress fractures. Conversely, softer woods such as pine or cedar, which are less dense, often achieve optimal flexibility within 30 minutes to 1 hour per inch. Oversteaming these woods can lead to brittleness, so precision is key.

The ideal steaming duration also hinges on the wood’s moisture content and grain orientation. Green wood, with its higher moisture levels, generally steams faster than kiln-dried wood, which may require an additional 30 minutes to 1 hour to absorb sufficient moisture. For example, a green ash plank might steam in 1.5 hours, while its kiln-dried counterpart could take up to 2.5 hours. Additionally, wood with straight grain bends more predictably than interlocked or wavy grain, which may require slightly longer steaming to ensure even softening. Always monitor the wood’s temperature—ideally between 180°F and 212°F—to avoid overheating or under-steaming.

For exotic woods like teak or mahogany, steaming durations can vary dramatically due to their unique cellular structures. Teak, prized for its durability, often requires 2 to 3 hours per inch, while mahogany, with its interlocked grain, may need up to 3.5 hours. These woods demand patience and careful observation; premature bending can result in cracks, while oversteaming risks weakening the fibers. A practical tip: insert a meat thermometer into the wood’s core to ensure it reaches 180°F, the threshold for lignin plasticity, before attempting to bend.

Steaming duration is not a one-size-fits-all solution; it must be tailored to the wood’s species, thickness, and intended bend radius. Thin strips of softwood for chair backs might steam in 20 minutes, while thick hardwood planks for boat frames could require 6 hours or more. A useful rule of thumb: start with the minimum recommended time and incrementally add 15-minute intervals until the wood bends smoothly without snapping. Always preheat the steamer to 212°F before introducing the wood to ensure consistent moisture penetration.

Finally, consider the cooling process as an extension of steaming duration. Rapid cooling can cause the wood to revert to its original shape or crack, so allow it to cool gradually under uniform pressure. For hardwoods, this might take 12 to 24 hours, while softwoods may stabilize in 6 to 8 hours. Applying a damp cloth or plastic wrap during cooling helps retain moisture, ensuring the bend sets permanently. By mastering these nuances, craftsmen can achieve precise, durable bends tailored to each wood type’s unique characteristics.

Understanding 3 Wood Shaft Length: A Comprehensive Guide for Golfers

You may want to see also

Explore related products

Effects of wood thickness on steaming time

Thicker wood requires longer steaming times to reach the necessary moisture content for bending. This is because moisture penetrates wood at a predictable rate, typically around 1 inch per hour for most hardwoods. A 1-inch thick board, therefore, would need at least an hour of steaming, while a 2-inch thick board would require double the time. This linear relationship is a fundamental principle in wood bending, ensuring the wood’s fibers soften uniformly without drying out or becoming brittle.

Consider a practical example: steaming oak for a chair leg. A ¾-inch thick oak board might steam adequately in 45 minutes, while a 1½-inch thick board of the same species would need closer to 90 minutes. However, steaming time alone isn’t the sole factor; temperature and humidity control are critical. Steam temperatures should remain between 180°F and 212°F (82°C to 100°C) to avoid scorching or case-hardening the wood’s surface. Monitoring these conditions with a thermometer ensures the wood reaches its fiber saturation point without overheating.

The relationship between thickness and steaming time also varies by wood species. Softwoods like pine or cedar, with larger cell structures, absorb moisture faster than dense hardwoods like maple or hickory. For instance, a 1-inch thick piece of pine might steam in 30 minutes, while a similarly sized piece of hickory could take up to 2 hours. This species-specific variability underscores the importance of testing small samples before committing to larger projects, especially when working with unfamiliar woods.

A cautionary note: over-steaming can be as detrimental as under-steaming. Prolonged exposure to steam can cause wood to become waterlogged, weakening its structural integrity. For thicker pieces, it’s better to steam incrementally, allowing the wood to rest briefly between sessions to distribute moisture evenly. For example, a 2-inch thick walnut board might benefit from two 45-minute steaming sessions with a 15-minute break in between, rather than a continuous 90-minute steam.

In conclusion, understanding the effects of wood thickness on steaming time is essential for successful bending. By accounting for species, thickness, and environmental factors, craftsmen can achieve precise control over the process. Always err on the side of caution, testing and adjusting steaming times to suit the specific wood and project requirements. This methodical approach ensures both the durability and aesthetic appeal of the final bent wood piece.

How Long Does a Cord of Wood Last: Burning Time Explained

You may want to see also

Explore related products

Optimal temperature for effective wood bending

Steaming wood for bending is a delicate balance of temperature and time, with the optimal temperature range typically falling between 180°F and 212°F (82°C and 100°C). Below this range, the wood may not soften sufficiently for bending, while exceeding it risks drying the wood, making it brittle and prone to cracking. This temperature window ensures the lignin—the natural glue in wood—softens enough to allow fibers to stretch without breaking. For most hardwoods, such as oak or maple, 190°F to 200°F (88°C to 93°C) is ideal, while softer woods like pine may require slightly lower temperatures to avoid over-softening.

Achieving and maintaining this temperature range requires precise control. A steam box with a reliable thermometer is essential, as fluctuations can lead to uneven softening. For example, if the temperature drops below 180°F, the wood may not bend smoothly, while spikes above 212°F can cause steam pockets, leading to internal cracks. Monitoring the steam box every 15–20 minutes ensures consistency, especially when working with thicker pieces that take longer to heat through.

The duration of steaming depends heavily on the wood’s thickness and density. As a rule of thumb, 1 inch (2.5 cm) of wood thickness requires approximately 1 hour of steaming at optimal temperature. For example, a 2-inch thick oak board would need around 2 hours, while a ½-inch pine strip might only require 30 minutes. Over-steaming, even within the optimal temperature range, can weaken the wood’s structure, so timing should be adjusted based on visual cues—wood is ready when it feels pliable but not mushy.

Practical tips can enhance the process. Pre-heating the steam box to the desired temperature before introducing the wood reduces overall steaming time. Wrapping the wood in aluminum foil or damp cloth helps retain moisture and ensures even heat distribution. After steaming, the wood must be bent and clamped immediately, as it begins to cool and harden within minutes. For complex bends, consider using a series of shorter steaming sessions with gradual bending to avoid overstressing the fibers.

In conclusion, the optimal temperature for effective wood bending is not just a number but a critical factor that interacts with time, wood type, and thickness. Mastering this range—180°F to 212°F—along with precise timing and practical techniques, transforms rigid wood into a malleable material ready for crafting curves and shapes. Whether for furniture, boatbuilding, or artistic projects, understanding and controlling temperature is the key to success in wood bending.

Treated Wood Drying Time: Factors Affecting the Process and Duration

You may want to see also

Explore related products

Signs wood is ready for bending after steaming

Steaming wood for bending is a precise art, and knowing when the wood is ready is crucial for achieving the desired shape without breakage. One clear sign is the wood’s flexibility; when properly steamed, it should bend easily without snapping or cracking. Test this by gently applying pressure to a small section—if it yields smoothly, it’s ready. However, if it resists or shows signs of splitting, it may need more time in the steamer. This flexibility is the result of the steam breaking down the lignin in the wood fibers, making it pliable.

Another indicator is the wood’s surface appearance. Steamed wood often takes on a darker, slightly damp look, but it shouldn’t be saturated or dripping wet. Over-steaming can lead to a soggy, weakened structure, while under-steaming leaves the wood too rigid. Aim for a balance where the wood feels warm and moist to the touch but retains its structural integrity. For hardwoods like oak or maple, this typically occurs after 30–60 minutes of steaming, while softer woods like pine may require only 15–30 minutes.

Temperature and time are critical factors, but they’re not the only ones. The wood’s thickness and density play a significant role in determining readiness. Thicker pieces require longer steaming times—for example, a 1-inch thick hardwood board might need up to 90 minutes, while a ¼-inch strip could be ready in 20 minutes. Use a thermometer to monitor the steam temperature, ideally keeping it between 180°F and 212°F (82°C and 100°C). Steaming at lower temperatures may not effectively soften the wood, while higher temperatures can cause damage.

Finally, listen to the wood. As it steams, it may emit a faint hissing or popping sound as moisture escapes and fibers relax. This auditory cue, combined with visual and tactile signs, provides a holistic assessment of readiness. Once bent, the wood should hold its shape as it cools, gradually regaining rigidity. If it springs back or loses form, it wasn’t steamed long enough. Practice and observation are key—each wood species and thickness will respond slightly differently, so take notes and adjust your technique accordingly.

How Long Do Essential Oils Scent Wood Surfaces?

You may want to see also

Explore related products

Safety precautions during the steaming process

Steaming wood for bending is a precise art, but it’s also a process fraught with potential hazards if not approached with caution. One critical safety measure is protective gear. Always wear heat-resistant gloves to handle the steamed wood, as temperatures can exceed 200°F (93°C), causing severe burns. Pair these with safety goggles to shield your eyes from escaping steam or wood splinters. A long-sleeved shirt and apron made of flame-resistant material further minimize skin exposure to heat and moisture. Neglecting these precautions can turn a routine task into a dangerous one.

Another often-overlooked aspect is ventilation. Steaming wood releases moisture and potentially harmful chemicals, especially if the wood has been treated. Ensure your workspace is well-ventilated by using exhaust fans or opening windows. If working indoors, consider a respirator rated for organic vapors to avoid inhaling wood dust or fumes. Poor ventilation can lead to respiratory issues or even mold growth in damp environments, compounding the risks beyond the immediate steaming process.

Equipment safety is equally vital. Always inspect your steam box for cracks or leaks before use, as pressurized steam escaping unexpectedly can cause burns or damage. Use a reliable thermometer to monitor the internal temperature, aiming for 180°F to 212°F (82°C to 100°C) for most hardwoods. Never leave the steaming process unattended, as overheating can warp the wood or, worse, cause the steam box to fail. Regularly maintain your equipment, replacing worn seals or faulty gauges to prevent accidents.

Finally, handling the wood post-steaming requires care. Steamed wood is pliable but also fragile, prone to cracking if bent too quickly or forcefully. Allow it to cool slightly before bending, but not so much that it hardens. Work efficiently yet deliberately, using clamps or molds to shape the wood while it’s still malleable. Avoid rushing, as this increases the risk of breakage or injury. By respecting the material’s limits and your own safety, you can achieve precise bends without compromising well-being.

Wood Filler Drying Time: When to Sand for Smooth Results

You may want to see also

Frequently asked questions

The steaming time typically ranges from 30 minutes to 2 hours, depending on the wood species and thickness. Harder woods like oak or maple may require closer to 2 hours, while softer woods like pine may only need 30–60 minutes.

Yes, thicker wood requires longer steaming times to ensure the heat penetrates fully. As a rule of thumb, add 15–30 minutes of steaming for every additional ¼ inch of thickness.

Yes, over-steaming can weaken the wood or cause it to become brittle. It’s best to follow recommended times for your specific wood type and monitor the process closely.

The wood is ready when it feels pliable but not mushy. Test a small piece first by gently bending it. If it bends without cracking or breaking, it’s ready for shaping.