The length of pieces of wood can vary significantly depending on their intended use, type, and manufacturing standards. Commonly, lumber is sold in standard lengths such as 8 feet, 10 feet, and 12 feet, though custom lengths are also available for specific projects. In construction, longer pieces like 16 feet or 20 feet are often used for framing, while shorter lengths are typical for furniture making or crafting. Additionally, specialty woods or exotic species may come in non-standard sizes. Understanding the appropriate length of wood for a project is crucial for efficiency, cost-effectiveness, and structural integrity.

Explore related products

What You'll Learn

- Standard lumber lengths: Common sizes for construction and woodworking projects

- Custom wood cutting: Tailoring wood pieces to specific project requirements

- Measuring techniques: Tools and methods for accurate wood length measurement

- Wood shrinkage factors: How moisture content affects wood dimensions over time

- Length variations by type: Differences in length across hardwood and softwood species

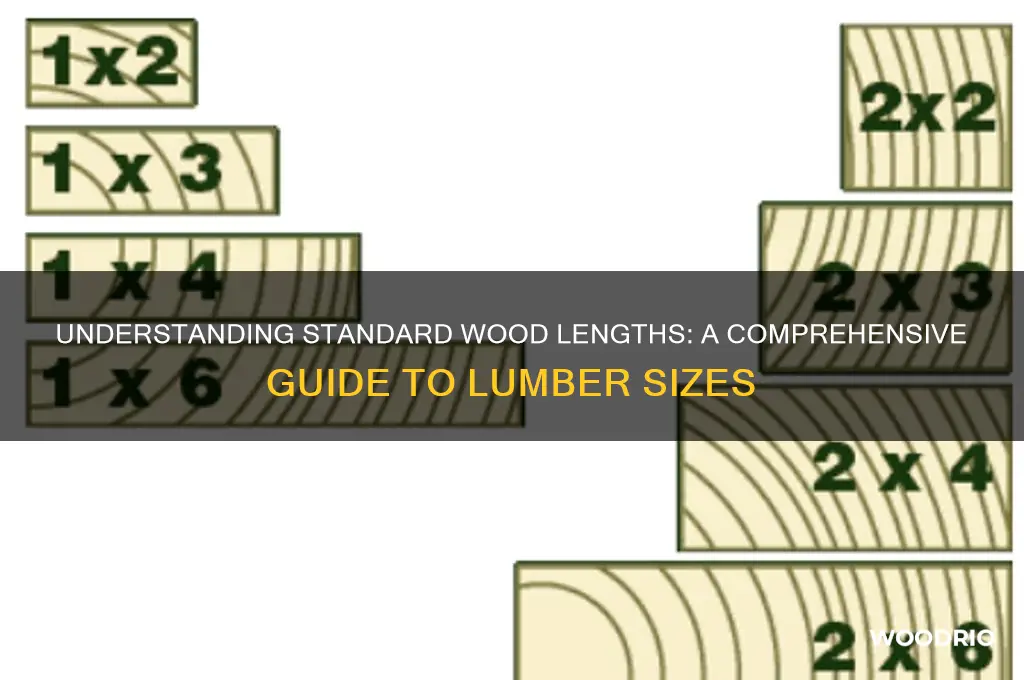

Standard lumber lengths: Common sizes for construction and woodworking projects

Wood lengths are not arbitrary; they are standardized to streamline construction and woodworking projects. In North America, the most common lumber lengths are 8, 10, 12, 14, 16, and 20 feet. These lengths are rooted in historical practices and optimized for efficiency in milling, transportation, and usage. For instance, an 8-foot piece of wood is ideal for framing interior walls, while 16-foot lengths are often used for longer spans like exterior walls or subflooring. Understanding these standards ensures you purchase the right materials for your project, minimizing waste and maximizing cost-effectiveness.

When planning a project, consider the structural requirements and the scale of your work. For small-scale woodworking, such as building shelves or furniture, 6-foot or 8-foot lengths are often sufficient and easier to handle. In contrast, larger construction projects like decking or framing may require 16- or 20-foot boards to reduce the number of seams and joints. Always measure twice and account for cuts to avoid running short. Pro tip: Many lumberyards offer custom cutting services, allowing you to purchase longer boards and have them cut to size on-site.

The choice of lumber length also impacts material cost and labor. Longer boards are generally more expensive per linear foot due to higher demand and milling costs. However, they can save time and reduce waste in projects with fewer joints. For example, using 20-foot boards for a deck can eliminate the need for splicing, creating a cleaner finish. Conversely, shorter lengths are more manageable for DIYers and can be more affordable for smaller projects. Balance your budget and project needs by calculating the total linear feet required and comparing costs across different lengths.

In specialized applications, non-standard lengths may be necessary. For instance, timber framing often uses lengths of 24 feet or more to achieve traditional joinery techniques. Similarly, custom furniture or artistic projects might require unique sizes, which can be sourced from specialty suppliers or milled to order. If your project falls outside standard dimensions, consult with a lumber expert to explore options like custom milling or alternative materials. Flexibility in sourcing can open up creative possibilities while ensuring structural integrity.

Finally, storage and transportation are practical considerations when selecting lumber lengths. Longer boards require adequate space for storage and a vehicle capable of handling their size. If you’re working in a small shop or transporting materials yourself, opt for shorter lengths or plan for multiple trips. For large-scale projects, consider delivery options from the supplier. By factoring in logistics, you can avoid delays and damage to your materials, keeping your project on track from start to finish.

Exploring Muir Woods: Time Needed for the Perfect Hiking Experience

You may want to see also

Explore related products

$6.97

Custom wood cutting: Tailoring wood pieces to specific project requirements

Wood comes in standard lengths, typically 8, 10, or 12 feet for dimensional lumber, but these off-the-shelf sizes rarely align perfectly with project needs. Custom wood cutting bridges this gap, allowing you to tailor pieces to exact specifications. Whether you’re framing a 9-foot ceiling or crafting a bespoke bookshelf, precision in length, width, and thickness ensures structural integrity and aesthetic coherence. Without it, you’re left with inefficient material usage, awkward joints, or the need for complex workarounds.

To begin custom cutting, measure twice and cut once—a timeless rule that minimizes waste and ensures accuracy. Use a tape measure or laser level for straight, consistent markings, and always account for blade kerf (the width of the cut) when calculating dimensions. For intricate projects, create a detailed cut list specifying each piece’s length, quantity, and purpose. Tools like a miter saw or table saw are ideal for straight cuts, while a jigsaw or band saw handles curves or angles. Always prioritize safety: wear eye protection, secure the wood firmly, and keep hands clear of the blade.

Custom cutting isn’t just about length; it’s about optimizing material for function and design. For example, a dining table requiring a 72-inch top might need boards joined edge-to-edge, demanding precise cuts to ensure seamless alignment. Similarly, cabinetmakers often cut wood to within 1/16-inch tolerances for doors and drawers to fit snugly without binding. Advanced techniques like rip cuts (lengthwise) or crosscuts (widthwise) allow for tailored dimensions, while bevels or chamfers add decorative edges. Each cut must align with the project’s structural and visual demands.

The benefits of custom cutting extend beyond fit and finish. It reduces material waste, saving costs and minimizing environmental impact. For instance, a project requiring 45-inch pieces can be optimized by cutting two from a 90-inch board, rather than purchasing multiple shorter lengths. Additionally, custom cuts allow for creative problem-solving, such as nesting smaller pieces within larger offcuts or repurposing scraps for accents. This approach transforms wood from a commodity into a resource tailored to your vision, ensuring every piece serves a purpose.

While DIY custom cutting is feasible with the right tools and skills, complex projects may benefit from professional services. Many lumberyards and woodworking shops offer precision cutting for a fee, often with advanced machinery like CNC routers for intricate designs. When outsourcing, provide clear, detailed plans and verify measurements to avoid errors. Whether you cut it yourself or hire a pro, the goal remains the same: transforming standard wood lengths into components that fit your project like a glove, ensuring both functionality and craftsmanship.

Resanding Wet Wood: Optimal Timing for Smooth, Flawless Results

You may want to see also

Explore related products

$16.99 $20.99

Measuring techniques: Tools and methods for accurate wood length measurement

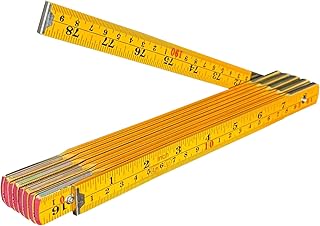

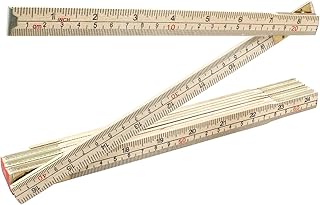

Wood length measurement is a fundamental skill in carpentry, construction, and DIY projects, yet accuracy often hinges on the tools and techniques employed. The most basic tool, a tape measure, offers versatility for both short and long pieces, but its accuracy depends on proper tension and alignment. For precision, especially in fine woodworking, a steel rule or folding ruler provides rigid, consistent measurements, though they’re limited to shorter lengths. Digital calipers, while typically used for smaller dimensions, can also measure wood thickness and length with remarkable precision, often to the nearest millimeter or thousandth of an inch. Each tool has its niche, but the key to accuracy lies in selecting the right one for the task at hand.

Instructive precision begins with understanding the wood itself. Always measure along the longest edge for consistency, and account for irregularities like warping or tapering. For long pieces, a straightedge or chalk line can guide your tape measure to ensure a true measurement. When using a tape measure, hook the end securely onto one edge and pull the tape taut without stretching it, as excessive tension can distort the reading. For repetitive measurements, mark the desired length on the tape with a piece of tape or a notch to streamline the process. These small adjustments can significantly improve efficiency and accuracy in both small-scale and large-scale projects.

Persuasive arguments for investing in quality tools are clear when considering the long-term benefits. A laser distance measurer, for instance, offers unparalleled speed and accuracy for long pieces, eliminating the need for a second pair of hands. While the initial cost may be higher, the time saved and errors avoided make it a worthwhile investment for professionals. Similarly, a track saw guide system not only ensures straight cuts but also doubles as a measuring aid, combining two essential functions into one tool. By prioritizing tools that enhance both precision and workflow, craftsmen can elevate the quality of their work while reducing frustration.

Comparatively, traditional methods like marking with a pencil and ruler hold value for their simplicity and accessibility. However, they lack the repeatability and speed of modern tools. For example, a sliding bevel can transfer angles and lengths with ease, but it requires careful handling to avoid errors. In contrast, a digital angle finder provides instant, accurate readings, though it may be overkill for basic tasks. The choice between traditional and modern tools often comes down to the project’s complexity and the user’s preference for tactile versus technological solutions.

Descriptively, the process of measuring wood is as much an art as it is a science. The feel of a well-calibrated tool in hand, the sound of a tape measure retracting, and the sight of a perfectly aligned mark all contribute to the satisfaction of precise work. Yet, it’s the attention to detail—checking twice, accounting for blade kerf in cuts, and ensuring the wood is securely positioned—that transforms a good measurement into a great one. By mastering these techniques and tools, craftsmen can approach each project with confidence, knowing their measurements will stand the test of time.

Manufactured Wood Durability: Long-Lasting or Short-Lived? Uncovering the Truth

You may want to see also

Explore related products

Wood shrinkage factors: How moisture content affects wood dimensions over time

Wood dimensions aren’t static—they fluctuate with changes in moisture content, a phenomenon known as shrinkage. This occurs as wood fibers release or absorb moisture from their surroundings, causing them to expand or contract. For instance, freshly cut lumber can have a moisture content of 30% to 200%, depending on the species, while kiln-dried wood typically stabilizes around 6% to 8%. Understanding this relationship is critical for anyone working with wood, as improper moisture management can lead to warping, cracking, or dimensional inaccuracies in finished projects.

The degree of shrinkage varies by wood species and grain orientation. For example, oak shrinks approximately 12% tangentially and 6% radially as it dries from green to 6% moisture content, while pine shrinks about 9% tangentially and 4% radially under the same conditions. These differences are due to variations in cell structure and density. To mitigate shrinkage issues, woodworkers often acclimate lumber to its intended environment, allowing it to reach equilibrium moisture content (EMC) before use. For indoor projects, this typically means storing wood in a controlled space with 30% to 50% relative humidity for several weeks.

Practical steps can minimize shrinkage-related problems. First, measure wood moisture content using a pin-type or pinless moisture meter, aiming for a reading within 2% to 4% of the EMC for the project’s environment. Second, seal end grain with paint or wax to slow moisture absorption or release, as this area dries or wets 5 to 10 times faster than other surfaces. Third, design joints and assemblies with expansion gaps, such as 1/8-inch spacing between floorboards, to accommodate dimensional changes. Ignoring these precautions can result in costly repairs or replacements.

Comparing shrinkage across species highlights the importance of material selection. Tropical hardwoods like teak exhibit lower shrinkage rates (3% to 5%) due to their dense structure, making them ideal for outdoor applications. In contrast, softwoods like cedar shrink more (8% to 10%) but are valued for their workability and resistance to decay. For structural projects, engineers often specify engineered wood products, which are designed to minimize moisture-related movement. By aligning species choice with project demands, craftsmen can ensure longevity and stability.

Finally, long-term maintenance is key to preserving wood dimensions. Regularly monitor indoor humidity levels, keeping them between 30% and 50% to prevent wood from absorbing or releasing moisture. Apply finishes like polyurethane or oil-based sealants to create a barrier against environmental fluctuations. For outdoor projects, use pressure-treated lumber or naturally rot-resistant species, and reapply finishes every 2 to 3 years. By proactively managing moisture content, woodworkers can maintain the integrity of their creations for decades, ensuring both functionality and aesthetic appeal.

Vinyl vs. Wood Windows: Which Material Offers Longer Durability?

You may want to see also

Explore related products

$29.59 $31.19

Length variations by type: Differences in length across hardwood and softwood species

Wood length varies significantly across species, and understanding these differences is crucial for anyone working with timber. Hardwoods, derived from deciduous trees, typically grow more slowly, resulting in denser, heavier wood. This slower growth often limits their natural length, with most hardwood logs averaging between 8 to 16 feet. For example, oak and maple logs rarely exceed 12 feet in length, making them ideal for furniture and flooring but less suitable for long structural beams. In contrast, softwoods like pine and spruce grow faster and taller, yielding logs that can easily reach 20 to 24 feet or more. This length advantage makes softwoods the go-to choice for construction projects requiring extended spans, such as roofing and framing.

Selecting the right wood length for a project requires more than just knowing species averages. Hardwoods, despite their shorter lengths, offer superior strength and durability, making them indispensable for high-stress applications like cabinetry or boatbuilding. Softwoods, while longer, are generally lighter and easier to work with, but may lack the hardness needed for heavy-duty tasks. For instance, a 10-foot hardwood board might be more expensive than a 20-foot softwood plank, but its density and stability could justify the cost in projects demanding precision and longevity. Always consider the specific demands of your project before prioritizing length over other wood properties.

When sourcing wood, be aware of industry standards and practices that affect available lengths. Hardwoods are often sold in shorter, more standardized lengths due to their limited natural size and higher demand for precision cuts. Softwoods, on the other hand, are frequently available in longer, more variable lengths, reflecting their use in large-scale construction. Custom milling can extend hardwood lengths, but this adds cost and complexity. For softwoods, longer lengths are usually more cost-effective, but transportation and handling can become challenging beyond 24 feet. Always measure your workspace and equipment capabilities before committing to unusually long pieces.

Practical tips can help maximize the utility of wood lengths across species. For hardwood projects, plan for shorter boards by designing joints that minimize waste, such as finger or dovetail joints. When using softwoods, take advantage of their length by incorporating fewer seams in structural elements, reducing both material and labor costs. If combining both types, ensure compatibility by matching thickness and width, as length alone won’t guarantee a seamless fit. Finally, always account for shrinkage and expansion due to moisture changes, especially with hardwoods, which can warp or crack if not properly acclimated to their environment.

In conclusion, the length of wood pieces is inherently tied to the species and its growth characteristics. Hardwoods offer shorter but denser options, ideal for precision work, while softwoods provide longer, more versatile lengths suited for large-scale construction. By understanding these differences and planning accordingly, you can select the right wood for your project, balancing cost, durability, and practicality. Whether crafting a delicate piece of furniture or framing a house, the length of your wood is more than a measurement—it’s a critical factor in your project’s success.

Optimal Oxalic Acid Application Time for Wood Restoration Explained

You may want to see also

Frequently asked questions

Standard pieces of wood, such as lumber, are typically available in lengths of 8 feet, 10 feet, 12 feet, and 16 feet, though custom lengths can also be ordered.

Pieces of wood for furniture making vary widely depending on the project, but common lengths range from 2 feet to 8 feet, with custom cuts often tailored to specific design needs.

For crafting or DIY projects, wood pieces can range from a few inches to several feet, depending on the project. Common lengths include 1 foot, 2 feet, and 4 feet, often sold in pre-cut boards or dowels.