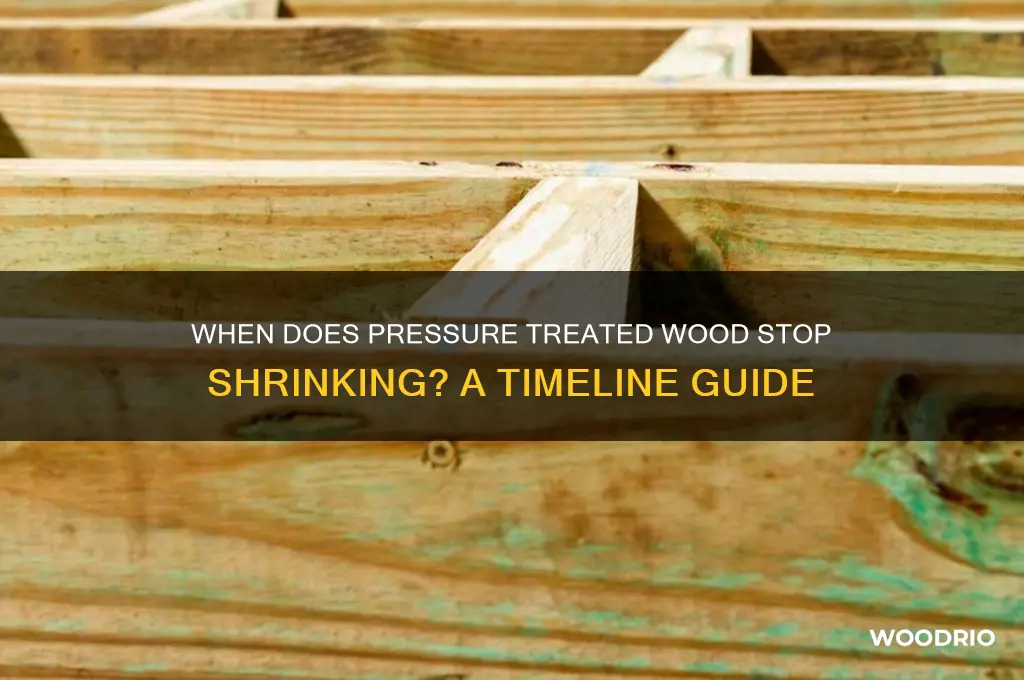

Pressure-treated wood is a popular choice for outdoor construction projects due to its durability and resistance to rot, decay, and insect damage. However, one common concern among builders and homeowners is the natural tendency of this material to shrink over time. The shrinking process occurs as the wood dries out and releases moisture, which is a normal part of its acclimatization to the surrounding environment. Understanding how long it takes for pressure-treated wood to stop shrinking is essential for ensuring the stability and longevity of structures like decks, fences, and outdoor furniture. Several factors influence this timeline, including the wood's initial moisture content, local climate conditions, and the specific treatment process used. Generally, pressure-treated wood can continue to shrink for several months to a year or more, depending on these variables, making proper installation and maintenance practices crucial during this period.

| Characteristics | Values |

|---|---|

| Time for Initial Shrinkage | Most shrinkage occurs within the first 6 months after treatment. |

| Complete Shrinkage Stabilization | Pressure-treated wood typically stabilizes after 1-2 years. |

| Moisture Content Factor | Shrinkage continues until the wood reaches equilibrium moisture content (EMC), usually around 12-15%. |

| Environmental Influence | Humidity, temperature, and exposure to weather affect shrinkage rate. |

| Wood Type Impact | Different wood species (e.g., pine, cedar) may shrink at varying rates. |

| Treatment Chemical Effect | Chemicals used in pressure treatment (e.g., ACQ, CA-B) do not significantly alter shrinkage behavior. |

| Prevention Methods | Proper sealing, painting, or staining can minimize shrinkage. |

| Structural Impact | Shrinkage may cause warping, cracking, or gaps in construction projects. |

| Maintenance Requirement | Regular inspection and maintenance are needed during the first 2 years. |

| Long-Term Stability | After stabilization, pressure-treated wood remains dimensionally stable for decades. |

Explore related products

What You'll Learn

Initial Drying Phase

Pressure-treated wood begins its journey toward stability immediately after treatment, but the initial drying phase is where the most noticeable shrinkage occurs. This stage, typically lasting 6 to 12 months, is characterized by rapid moisture loss as the wood adjusts to its environment. During this period, the wood can shrink by as much as 5% to 10% of its original dimensions, depending on factors like humidity, temperature, and wood species. For instance, pine, a commonly treated wood, tends to shrink more than denser hardwoods like oak. Understanding this phase is crucial for anyone working with pressure-treated wood, as improper handling during this time can lead to warping, cracking, or uneven settling.

To mitigate shrinkage during the initial drying phase, strategic placement and storage are key. Stack treated wood in a well-ventilated area, ensuring air can circulate around all sides to promote even drying. Avoid direct sunlight, as it can cause uneven moisture loss, leading to warping. If using the wood for construction, pre-drilling holes for screws or nails is essential, as the material will continue to shift slightly. For larger projects, consider using temporary braces or supports until the wood stabilizes. A practical tip: monitor the wood’s moisture content using a moisture meter, aiming for a reading below 19% before permanent installation.

Comparing the initial drying phase to other stages of wood stabilization highlights its unique challenges. Unlike the slower, more gradual shrinkage that occurs in later phases, this period demands proactive measures. For example, while later shrinkage might be managed with periodic sealing or refinishing, the initial phase requires physical adjustments to the wood’s environment. This distinction underscores why builders and DIY enthusiasts must prioritize this stage, as it sets the foundation for the wood’s long-term performance.

Persuasively, ignoring the initial drying phase can lead to costly mistakes. Imagine installing a deck or fence only to find gaps between boards or uneven surfaces months later. By respecting this phase and allowing the wood to acclimate naturally, you ensure a more durable and aesthetically pleasing result. Patience here isn’t just a virtue—it’s a necessity. For those in a hurry, kiln-dried pressure-treated wood offers a faster alternative, though it comes at a higher cost and may still require some acclimation time.

In conclusion, the initial drying phase is a critical period in the life of pressure-treated wood, demanding attention to detail and proactive management. By understanding its dynamics and implementing practical strategies, you can minimize shrinkage and set the stage for a successful project. Whether you’re a professional builder or a weekend warrior, mastering this phase ensures your work stands the test of time.

Yellowjackets' Survival Timeline: How Long Do They Thrive in the Woods?

You may want to see also

Explore related products

$26.99 $29.99

Moisture Content Stabilization

Pressure-treated wood, a staple in outdoor construction, undergoes a natural process of moisture content stabilization, which is crucial to its dimensional stability. This process is not instantaneous but rather a gradual journey toward equilibrium. The wood's initial moisture content, often elevated due to the treatment process, gradually decreases as it acclimates to its environment. Understanding this stabilization period is essential for anyone working with pressure-treated lumber, as it directly impacts the wood's susceptibility to shrinkage and warping.

The Science Behind Stabilization

Accelerating Stabilization: Practical Tips

To expedite moisture content stabilization, consider the following strategies. Firstly, store the wood in a well-ventilated area, protected from direct rainfall but exposed to airflow. This setup facilitates evaporation without causing rapid drying, which can lead to checking or splitting. Secondly, stacking wood with spacers between layers promotes air circulation, aiding in uniform drying. For more control, especially in humid climates, consider using a moisture meter to monitor the wood's progress. Aim for a moisture content within 2-3% of the EMC before using the wood in critical applications, such as decking or framing, to minimize post-installation movement.

Environmental Factors and Their Impact

The time it takes for pressure-treated wood to stop shrinking varies significantly based on environmental conditions. In arid regions, with humidity levels below 30%, the wood may stabilize within 8-10 weeks, whereas in humid tropical climates, this process can extend beyond 6 months. Seasonal changes also play a role; wood tends to dry faster in summer due to higher temperatures and lower humidity. It's essential to plan projects with these factors in mind, allowing sufficient time for the wood to stabilize, especially in regions with extreme weather variations.

Long-Term Stability and Maintenance

Once pressure-treated wood reaches moisture content stabilization, it enters a phase of relative dimensional stability. However, this doesn't render it immune to environmental influences. Fluctuations in humidity can still cause minor expansions and contractions, particularly in the radial and tangential directions. To maintain stability, consider applying a water-repellent sealant, which reduces moisture absorption during wet periods. Regular inspections and maintenance, such as cleaning and resealing every 2-3 years, can significantly extend the wood's service life, ensuring it remains structurally sound and aesthetically pleasing.

Discovering the Lifespan of Wood Ducks: How Long Do They Live?

You may want to see also

Explore related products

Environmental Factors Impact

Pressure-treated wood's shrinkage timeline is significantly influenced by environmental factors, which can either accelerate or prolong the stabilization process. Humidity, temperature, and exposure to sunlight are the primary culprits. In regions with high humidity, wood tends to absorb moisture, delaying shrinkage as it reaches equilibrium with the surrounding environment. Conversely, arid climates can expedite moisture loss, causing the wood to shrink more rapidly. For instance, pressure-treated wood in a coastal area with 70-80% humidity may take up to 2 years to stabilize, while in a desert climate with 20-30% humidity, this process could shorten to 6-12 months. Understanding these regional variations is crucial for planning projects that require dimensionally stable wood.

Temperature fluctuations play a dual role in the shrinkage process, acting as both a catalyst and a hindrance. During warmer months, increased temperatures enhance evaporation, speeding up moisture loss from the wood fibers. However, extreme heat can also cause the wood to expand temporarily, leading to warping or cracking if not properly acclimated. In colder seasons, the shrinkage process slows as moisture freezes within the wood, delaying stabilization. For optimal results, store pressure-treated wood in a controlled environment with temperatures between 50-70°F (10-21°C) for the first 3-6 months post-treatment. This minimizes the risk of uneven shrinkage and ensures a more uniform drying process.

Sunlight exposure introduces another layer of complexity, as UV rays degrade the wood's surface and accelerate moisture loss. While this can hasten shrinkage, it often results in uneven drying, leading to surface checks or splits. To mitigate this, apply a UV-protective sealant or stain after the initial 3-6 months of drying. This not only preserves the wood's appearance but also reduces the risk of structural damage caused by rapid, uneven shrinkage. For outdoor applications, consider orienting the wood to minimize direct sunlight exposure during peak hours, typically between 10 AM and 4 PM.

The interplay of these environmental factors necessitates a tailored approach to managing pressure-treated wood shrinkage. For example, in a temperate climate with moderate humidity (40-60%) and seasonal temperature variations, allow the wood to acclimate outdoors for at least 1 year, ensuring it experiences a full cycle of weather conditions. Regularly inspect the wood for signs of uneven shrinkage, such as gaps or warping, and adjust its placement or apply protective coatings as needed. By proactively addressing these environmental impacts, you can significantly reduce the time it takes for pressure-treated wood to stop shrinking and achieve long-term stability.

Understanding Morning Wood: Duration and Factors Affecting Its Disappearance

You may want to see also

Explore related products

Wood Type Variations

Pressure-treated wood's shrinkage timeline isn't a one-size-fits-all scenario. Different wood species react uniquely to the treatment process and subsequent environmental conditions. Pine, a common choice for pressure treatment, tends to shrink more rapidly than denser hardwoods like oak or cedar. This is due to pine's higher resin content and looser grain structure, which allows for more moisture absorption during treatment and quicker release afterward.

Cedar, known for its natural rot resistance, shrinks less overall due to its inherent density and lower moisture content.

Understanding these variations is crucial for project planning. For instance, if you're building a deck with pressure-treated pine, expect noticeable shrinkage within the first 6-12 months, with minor adjustments continuing for up to 2 years. In contrast, a cedar fence might experience minimal shrinkage, primarily within the first year.

Pro Tip: To minimize shrinkage-related issues, allow pressure-treated wood to acclimate to its environment for at least 2 weeks before construction. This allows for some initial moisture release and reduces the risk of warping or splitting.

While pressure treatment enhances wood's durability, it doesn't eliminate the natural drying process. Softwoods, like pine and spruce, are more susceptible to shrinkage due to their cellular structure. Hardwoods, with their tighter grain, shrink less but at a slower, more gradual pace. This means a pressure-treated oak beam might take 2-3 years to reach its final dimensions, while a pine beam could stabilize within 18 months.

Consideration: For projects requiring precise dimensional stability, consider using naturally rot-resistant hardwoods like cedar or redwood, even if they come at a higher cost.

The environment plays a significant role in shrinkage rates. Humidity accelerates moisture loss, leading to faster shrinkage, while dry climates slow the process. Temperature fluctuations can also cause wood to expand and contract, exacerbating shrinkage effects. Practical Tip: In humid climates, allow for slightly larger gaps between boards during installation to accommodate for potential shrinkage. In dry climates, tighter spacing may be acceptable.

Final Thought: Understanding the unique shrinkage characteristics of different wood types, combined with environmental factors, allows for informed material selection and construction techniques, ensuring the longevity and structural integrity of your project.

Does Aging Wood Reduce BTU Output? Exploring Long-Term Storage Effects

You may want to see also

Explore related products

Shrinkage Prevention Tips

Pressure-treated wood, while durable, undergoes a natural drying process that leads to shrinkage, typically stabilizing within 6 to 12 months after installation. However, proactive measures can minimize this movement, ensuring structural integrity and aesthetic appeal. One effective strategy is to seal the wood immediately after cutting and before installation. Apply a high-quality wood sealer or stain to all surfaces, including cut ends, to slow moisture loss and reduce uneven drying. Reapply the sealant annually to maintain protection, especially in climates with extreme temperature fluctuations.

Another critical factor is proper wood selection and storage. Choose pressure-treated lumber with a lower moisture content, ideally below 19%, as this reduces the potential for shrinkage. If storing wood before use, stack it on stickers (small supports) in a dry, well-ventilated area to prevent warping and promote even drying. Cover the stack with a breathable tarp to shield it from rain while allowing air circulation. For larger projects, consider kiln-dried pressure-treated wood, which has been pre-dried to minimize shrinkage.

During installation, incorporate expansion gaps to accommodate inevitable movement. Leave a 1/8-inch gap between boards for decking or siding, and use corrosion-resistant fasteners to allow for slight shifts without compromising the structure. Pre-drilling holes reduces splitting, which can exacerbate shrinkage-related issues. Additionally, avoid over-tightening screws or nails, as this can restrict natural movement and lead to cracking.

For existing structures, monitor moisture levels and address issues promptly. Install gutters and downspouts to divert water away from wooden elements, and ensure proper grading slopes the ground away from the foundation. Periodically inspect for signs of uneven shrinkage, such as gaps or warping, and make adjustments as needed. In high-humidity areas, consider using a dehumidifier in enclosed spaces like sheds or porches to maintain consistent moisture levels.

Finally, embrace the natural characteristics of wood while mitigating shrinkage. Opt for construction techniques that work with the material’s tendencies rather than against them. For example, use diagonal bracing in large panels to distribute stress evenly, or incorporate flexible materials like rubber padding in joints to absorb movement. By combining these strategies, you can significantly reduce shrinkage in pressure-treated wood, extending its lifespan and enhancing its performance.

Understanding 3 Wood Shaft Length: A Comprehensive Guide for Golfers

You may want to see also

Frequently asked questions

Pressure treated wood can continue to shrink for 6 months to 2 years, depending on factors like moisture content, climate, and wood species.

Shrinking slows significantly after the initial drying period, but pressure treated wood may experience minor dimensional changes over its lifetime due to environmental conditions.

Sealing or painting can reduce moisture absorption and slow shrinking, but it won’t completely prevent the wood from drying and shrinking as it acclimates.

Allow the wood to air-dry for a few weeks before use, store it in a covered area to control moisture exposure, and pre-drill holes to reduce cracking as it shrinks.

The type of treatment (e.g., ACQ, CA-B) doesn’t significantly impact shrinking time, as it primarily depends on the wood’s moisture content and species.