Seasoning wood is a crucial process that involves drying it to reduce its moisture content, making it suitable for burning efficiently and safely. The time required for wood to be fully seasoned depends on various factors, including the type of wood, its initial moisture level, the climate, and the method of drying. Hardwoods like oak or maple typically take longer to season, often requiring 6 to 12 months, while softer woods like pine may be ready in 3 to 6 months. Properly stacking wood in a dry, well-ventilated area and protecting it from rain can significantly speed up the seasoning process. Understanding these factors ensures that the wood is adequately dried, maximizing its heat output and minimizing creosote buildup in chimneys.

| Characteristics | Values |

|---|---|

| Time to Season (General) | 6 months to 2 years, depending on wood type, climate, and storage. |

| Softwood (e.g., Pine, Fir) | 6–12 months |

| Hardwood (e.g., Oak, Maple) | 1–2 years |

| Moisture Content Goal | 20% or less |

| Ideal Stacking Method | Split logs, stack off the ground, cover top, and allow airflow. |

| Climate Influence | Warmer, drier climates speed up seasoning; colder, humid climates slow it. |

| Wood Density Impact | Denser woods take longer to season than less dense woods. |

| Kiln Drying Alternative | 2–7 days (accelerated method, not traditional seasoning). |

| Signs of Seasoned Wood | Darker ends, cracks in bark, lighter weight, and hollow sound when tapped. |

| Storage Requirement | Covered, elevated, and well-ventilated area. |

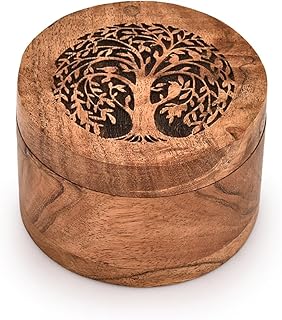

Explore related products

What You'll Learn

Ideal seasoning time for hardwoods

Hardwoods, such as oak, maple, and hickory, require a longer seasoning period compared to softwoods due to their denser cellular structure. This density slows moisture release, making the seasoning process more time-consuming. On average, hardwoods need 6 to 12 months of seasoning for every inch of wood thickness. For example, a 4-inch thick hardwood log would ideally season for 24 to 48 months. This extended timeframe ensures the wood reaches a moisture content of 20% or less, optimal for burning efficiency and structural stability.

The seasoning process for hardwoods is not just about time but also about technique. Proper stacking is critical—wood should be piled in a single row, allowing air to circulate freely on all sides. A raised platform or pallets can prevent ground moisture absorption, while a covered top protects from rain without blocking airflow. Regularly rotating the stack every few months ensures even drying. For those in humid climates, seasoning hardwoods indoors or in a kiln can expedite the process, reducing the risk of mold or decay.

Comparing hardwoods to softwoods highlights the trade-off between durability and seasoning time. While softwoods like pine season in 3 to 6 months, their lower density makes them less suitable for long-term structural use or high-heat applications. Hardwoods, despite their longer seasoning requirement, offer superior strength, heat output, and longevity, making the wait worthwhile. For instance, seasoned oak burns hotter and longer than pine, justifying its use in fireplaces or wood-fired ovens.

A practical tip for determining if hardwood is adequately seasoned is to check its weight and appearance. Seasoned wood feels lighter than green wood of the same size and often has cracks or checks at the ends. A moisture meter can provide precise readings, with ideal levels between 15% and 20% for most applications. If you’re unsure, split a piece—seasoned wood will show a lighter, drier interior compared to the darker, wetter core of unseasoned wood. Patience and attention to detail are key to achieving perfectly seasoned hardwood.

Exploring Muir Woods: Time Needed for a Complete Tour

You may want to see also

Explore related products

Softwood seasoning duration comparison

Softwood, derived from coniferous trees like pine, spruce, and fir, seasons faster than hardwood due to its lower density and higher resin content. Typically, softwood requires 6 to 12 months to season adequately, depending on factors like moisture content, climate, and storage conditions. For instance, a freshly cut pine log with 50% moisture content can reach 20%—the ideal level for burning—in about 9 months if stacked in a dry, well-ventilated area. This rapid seasoning makes softwood a practical choice for those needing firewood quickly, though it burns faster and produces less heat than hardwood.

To optimize softwood seasoning, follow these steps: stack logs in a single row to maximize airflow, elevate the pile off the ground using pallets to prevent rot, and cover the stack with a tarp while leaving the sides open for ventilation. Monitor moisture levels using a wood moisture meter; readings should consistently fall below 20% before use. In humid climates, seasoning may take closer to 12 months, while drier regions can achieve results in 6 to 8 months. Proper stacking and storage are critical, as softwood’s resin can attract pests if left exposed or damp.

Comparatively, hardwoods like oak or maple take 1 to 2 years to season, making softwood a more time-efficient option. However, softwood’s lower density means it degrades faster when exposed to moisture, so it must be used promptly once seasoned. For example, seasoned pine stored outdoors without protection can reabsorb moisture within 3 to 6 months, rendering it unsuitable for burning. This vulnerability underscores the need for timely use or indoor storage.

A persuasive argument for softwood seasoning lies in its accessibility and cost-effectiveness. Homeowners with access to pine or spruce trees can sustainably harvest and season their own firewood within a single year, reducing reliance on purchased hardwood. While softwood may not match hardwood’s longevity or heat output, its quick turnaround makes it ideal for supplemental heating or outdoor fires. Pairing softwood with denser logs in a fire can balance burn time and intensity, maximizing efficiency.

In summary, softwood’s 6 to 12-month seasoning duration offers a practical solution for those prioritizing speed over longevity. By adhering to proper stacking techniques, monitoring moisture levels, and using the wood promptly, individuals can harness softwood’s benefits effectively. While it may not replace hardwood for all applications, its rapid seasoning time and availability make it a valuable resource for short-term heating needs.

Safe Wood Priming After Rain: Timing Tips for Outdoor Projects

You may want to see also

Explore related products

Factors affecting wood drying speed

Wood drying is a complex process influenced by several key factors that determine how quickly it reaches the seasoned state. One of the most critical elements is moisture content, which varies by wood species and initial conditions. Hardwoods like oak or maple typically start with 40-60% moisture content, while softwoods like pine begin at 80-100%. The goal is to reduce this to 15-20% for optimal seasoning, a process that can take 6 months to 2 years depending on these factors.

Environmental conditions play a pivotal role in drying speed. Humidity levels directly impact moisture evaporation; wood dries faster in arid climates (below 30% humidity) compared to humid regions (above 60%). Temperature is equally important, with warmer conditions (70-90°F) accelerating drying. For instance, stacking wood in a sunny, well-ventilated area can reduce drying time by 30-50% compared to a damp, shaded spot. However, extreme heat can cause cracking, so gradual drying is preferable.

The wood’s thickness and density are structural factors that dictate drying time. Thicker logs (over 6 inches) retain moisture longer due to reduced surface area-to-volume ratio, often requiring 1-2 years to season. Conversely, split firewood (2-4 inches) dries in 6-12 months. Dense woods like teak dry slower than less dense options like cedar, as moisture migrates more slowly through compact fibers. Splitting wood exposes more surface area, expediting the process.

Airflow and stacking techniques are actionable factors within your control. Properly stacked wood with 2-4 inches of space between logs allows air to circulate, reducing drying time by up to 40%. Using a raised platform prevents ground moisture absorption, while covering the stack with a tarp (leaving sides open) protects from rain without trapping humidity. For example, a well-stacked cord of maple can season in 8 months, while a poorly stacked pile may take 18 months.

Finally, wood species and initial treatment significantly influence drying speed. Resinous woods like pine dry faster due to natural oils that repel moisture, while tropical hardwoods like mahogany require longer due to high density. Kiln-dried wood, treated at 140°F for 48-72 hours, achieves seasoning in days, but this method is costly and less accessible for home use. For natural seasoning, selecting faster-drying species and splitting wood early are practical steps to expedite the process.

Transporting Oversized Wood: Practical Tips for Moving Long Lumber Safely

You may want to see also

Explore related products

Seasoning methods: air vs. kiln drying

Wood seasoning is a critical process that transforms freshly cut timber into a stable, durable material suitable for construction, furniture, and firewood. The two primary methods—air drying and kiln drying—offer distinct advantages and trade-offs, each suited to specific needs and timelines. Understanding these methods ensures you choose the right approach for your wood, balancing time, cost, and quality.

Air drying is the traditional, time-honored method of seasoning wood. It relies on natural conditions—ambient temperature, humidity, and airflow—to gradually reduce the wood’s moisture content. Typically, air drying takes 6 months to 2 years, depending on the wood species, thickness, and climate. For instance, a 1-inch thick hardwood plank may season in 6–12 months in a dry, temperate climate, while a 4-inch thick log could require up to 2 years. To optimize air drying, stack wood stickers (small spacers) between layers to promote airflow, and cover the pile to protect it from rain while allowing ventilation. This method is cost-effective and eco-friendly but demands patience and space.

In contrast, kiln drying accelerates the seasoning process using controlled heat and humidity in a specialized chamber. Kiln drying reduces seasoning time to 1–4 weeks, making it ideal for commercial operations or projects with tight deadlines. For example, a 1-inch thick hardwood plank can be kiln-dried in 7–10 days at temperatures between 120°F and 180°F (49°C–82°C). Kiln drying also allows for precise moisture control, typically targeting 8–12% moisture content, which is ideal for woodworking and cabinetry. However, this method requires significant energy input and specialized equipment, increasing costs. Improper kiln settings can also cause defects like warping or checking, so professional oversight is essential.

Comparing the two, air drying excels in affordability and sustainability but lacks the speed and precision of kiln drying. Kiln drying, while faster and more reliable, is resource-intensive and best suited for large-scale operations. For hobbyists or small-scale projects, air drying is often the practical choice, provided you plan for the extended timeline. For professionals or time-sensitive projects, kiln drying offers unmatched efficiency, though at a higher price point.

Ultimately, the choice between air and kiln drying hinges on your priorities: time, cost, or environmental impact. Both methods, when executed correctly, yield well-seasoned wood ready for its intended use. By weighing the pros and cons of each, you can select the method that aligns best with your goals and resources.

Durability of Wood: Factors Affecting Longevity and Preservation Techniques

You may want to see also

Explore related products

$27.99 $29.99

Testing wood moisture content readiness

Wood seasoning is a waiting game, but you don’t have to rely on guesswork to know when it’s ready. Testing moisture content is the most accurate way to determine if your wood is seasoned. A moisture meter, an affordable tool available at hardware stores, is your best ally here. Simply insert the meter’s probes into the wood, ensuring they penetrate at least a quarter-inch. For firewood, aim for a moisture content reading between 15% and 20%. Anything above 25% indicates the wood still needs time to dry.

While moisture meters provide precise data, there are visual and tactile cues to complement your testing. Seasoned wood often has cracks or checks at the ends, and its color may lighten slightly. When you knock two pieces together, they should sound hollow rather than dull. However, these methods are subjective and less reliable than a moisture meter. Always prioritize the meter’s reading, especially if you’re using the wood for critical applications like heating or woodworking.

For those without a moisture meter, the weight test offers a practical alternative. Weigh a sample piece of wood, then dry it in an oven at 200°F (93°C) for 24 hours. Weigh it again after cooling. The difference in weight indicates moisture loss. Seasoned wood should lose minimal weight at this point, as most moisture has already evaporated. This method is time-consuming but effective for small batches.

Professionals often use kiln-drying to expedite seasoning, reducing moisture content to 12% or less within days. However, this method is costly and impractical for most homeowners. Air-drying, the traditional approach, takes 6 months to 2 years, depending on wood type and climate. Hardwoods like oak or maple take longer to season than softwoods like pine. Patience is key, but testing moisture content ensures you’re not burning or using wood prematurely.

Finally, consider environmental factors when testing. Wood absorbs moisture from humid air, so test on dry days for accurate readings. Store seasoned wood off the ground and under cover to maintain its readiness. Testing moisture content isn’t just a step—it’s the definitive answer to the question of when your wood is truly seasoned.

Vinyl vs. Wood Fences: Which Material Offers Longer Durability?

You may want to see also

Frequently asked questions

It typically takes 6 to 12 months for wood to be properly seasoned, depending on factors like wood type, moisture content, and environmental conditions.

Yes, wood can be seasoned faster by splitting it into smaller pieces, storing it in a dry, well-ventilated area, and protecting it from rain and snow. Using a kiln can reduce seasoning time to days or weeks.

Seasoned wood feels lighter, has cracks or checks in the ends, and makes a hollow sound when two pieces are knocked together. A moisture meter can confirm it’s below 20% moisture content.