Carbon steel wood lathe tools are a popular choice among woodturners due to their affordability, ease of sharpening, and ability to hold a keen edge. However, their longevity depends on several factors, including the quality of the steel, frequency of use, maintenance practices, and the type of wood being turned. High-quality carbon steel tools, when properly cared for, can last for many years, with some users reporting decades of service. Regular sharpening, proper storage to prevent rust, and avoiding excessive heat during grinding are essential to maximize their lifespan. While they may require more maintenance compared to high-speed steel (HSS) tools, their cost-effectiveness and performance make them a durable and reliable option for both hobbyists and professionals.

| Characteristics | Values |

|---|---|

| Material | Carbon Steel |

| Tool Type | Wood Lathe Tools |

| Lifespan (General) | 20-50 hours of active cutting time (varies based on usage and care) |

| Factors Affecting Lifespan | - Frequency of use - Type of wood (hardwoods reduce lifespan) - Cutting techniques - Maintenance and sharpening practices |

| Sharpening Intervals | Every 10-15 minutes of active use (depending on wear) |

| Re-sharpening Limit | Until the tool becomes too short or unsafe to use |

| Rust Resistance | Low (requires regular oiling or protective coatings) |

| Hardness | Typically 58-62 HRC (Rockwell Hardness Scale) |

| Cost-Effectiveness | High initial cost but longer lifespan with proper care |

| Comparative Lifespan (vs. HSS) | Shorter than High-Speed Steel (HSS) tools |

| Recommended Maintenance | Regular sharpening, cleaning, and oiling to prevent rust |

| Typical Applications | Turning bowls, spindles, and other wooden projects |

| Environmental Impact | Durable and recyclable, but requires energy for frequent sharpening |

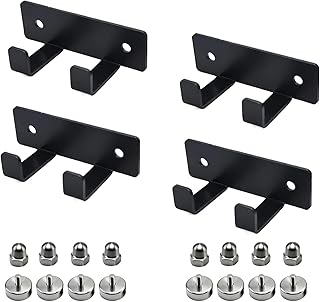

Explore related products

What You'll Learn

Proper Tool Maintenance Techniques

Carbon steel wood lathe tools, when properly maintained, can last for decades, even under frequent use. However, their longevity hinges on consistent and meticulous care. Neglecting maintenance accelerates wear, dulls edges, and invites rust, drastically shortening their lifespan.

Sharpening: The Lifeline of Lathe Tools

Regular sharpening is non-negotiable. Carbon steel tools dull faster than high-speed steel (HSS) counterparts, but their ease of sharpening is a trade-off. Use a coarse grinding wheel (60–80 grit) to reshape the bevel, followed by a finer stone (220–400 grit) for honing. Maintain a consistent angle—typically 35–40 degrees for bowl gouges and 25–30 degrees for skew chisels. Aim for a burr-free edge, testing sharpness on softwood before use. Sharpen after every 1–2 hours of turning, or when the tool struggles to cut cleanly.

Rust Prevention: A Daily Ritual

Carbon steel’s Achilles’ heel is rust. After each use, clean tools with a wire brush to remove wood residue, then wipe down with a rag soaked in mineral spirits. Apply a thin coat of oil—camellia, WD-40, or machine oil—to all surfaces. Store tools in a dry environment, ideally in a tool roll or cabinet with silica gel packets to absorb moisture. For long-term storage, coat tools in a rust-inhibiting paste like T9 or JP’s Paste.

Handling and Storage: Small Habits, Big Impact

Improper handling accelerates wear. Never let tools rest on concrete floors, as moisture wicking can cause rust. When not in use, store tools in a designated rack or tray, ensuring edges don’t knock against each other. Avoid over-tightening handles, as this can warp the tool’s alignment. Periodically check for loose ferrules or cracks in wooden handles, replacing them as needed.

Advanced Care: Heat Treatment and Micro-Maintenance

For enthusiasts, occasional heat treatment can rejuvenate carbon steel tools. Heat the cutting edge to a non-magnetic state (approximately 1,500°F), then quench in oil for hardness. Follow with a tempering cycle at 400°F to reduce brittleness. This process restores edge retention but requires precision—overheating ruins the tool. Additionally, micro-maintenance like stropping on leather with compound or using a diamond paddle sharpener extends sharpness between grindings.

By integrating these techniques into your workflow, carbon steel lathe tools remain reliable partners in craftsmanship. The effort invested in maintenance pays dividends in performance and longevity, ensuring each tool serves faithfully for years to come.

Durability of Wood Siding: Lifespan, Maintenance, and Longevity Tips

You may want to see also

Explore related products

Frequency of Tool Sharpening Needs

Sharpening frequency for carbon steel wood lathe tools hinges on a delicate balance between material removal rate and edge degradation. Aggressive cuts on hard woods like maple or oak will dull a tool faster than gentle shaping of softer woods like pine. As a rule of thumb, expect to sharpen after every 15-30 minutes of active turning when tackling dense species. Softer woods may allow double that duration. Always prioritize edge inspection over arbitrary time limits – a tool that feels sluggish or leaves torn fibers demands attention regardless of elapsed time.

The geometry of the cutting edge plays a pivotal role in determining sharpening intervals. A steeply ground bevel (25-30 degrees) sacrifices durability for chip clearance, necessitating more frequent touch-ups. Shallower angles (20-25 degrees) provide longer edge life but are more prone to chipping. For most woodturning tasks, a 25-degree primary bevel with a micro-bevel of 30 degrees strikes an optimal balance. This compound grind extends time between sharpenings while maintaining chip evacuation efficiency.

Environmental factors introduce variability into sharpening schedules. Humidity levels above 60% accelerate rust formation on carbon steel tools, potentially compromising edge integrity between uses. Woodturners in damp climates should apply a light coat of paste wax or oil to tools after each session and inspect edges for oxidation before resuming work. Temperature fluctuations can also affect tool performance – cold shops may require slightly more frequent honing as steel contracts and micro-fractures become more apparent.

Developing a systematic sharpening routine is essential for maximizing tool life. Start with a coarse grit (120-220) to remove nicks and reshape the bevel, then progress through medium (400-600) and fine (1000-1500) grits to refine the edge. Finish with a strop charged with chromium oxide or diamond paste to achieve a mirror polish. Aim for a consistent 2-3 degree micro-bevel to enhance edge retention. Proper technique – maintaining the established angle and applying even pressure – is as critical as grit selection in achieving durable cutting edges.

Ultimately, the frequency of sharpening carbon steel wood lathe tools is a dynamic parameter influenced by wood species, cutting style, tool geometry, and environmental conditions. Rather than adhering to rigid schedules, cultivate a habit of regular edge assessment. A well-maintained tool not only extends the lifespan of the steel but also elevates the quality of your turning. Remember: a sharp tool is safer, more efficient, and more pleasurable to use than one allowed to degrade through neglect.

Ground Contact Wood Durability: Lifespan and Preservation Tips Explained

You may want to see also

Explore related products

Impact of Wood Hardness Levels

Wood hardness directly influences the wear rate of carbon steel lathe tools, with harder woods acting as an abrasive that accelerates edge degradation. The Janka hardness scale, a standard measure of wood density, provides a clear correlation: turning hardwoods like hickory (1820 lbf) or maple (1450 lbf) will dull a carbon steel tool 2-3 times faster than softwoods like pine (540 lbf) or cedar (350 lbf). This disparity stems from the increased silica and lignin content in harder woods, which act like sandpaper on the tool’s cutting edge. For context, a carbon steel bowl gouge used exclusively on walnut (1010 lbf) may retain sharpness for 3-4 hours of continuous turning, while the same tool on balsa (100 lbf) could last upwards of 10 hours.

To mitigate premature wear, adjust feed rates and bevel angles based on wood hardness. When turning dense exotics like ebony (3220 lbf) or teak (1155 lbf), reduce feed pressure by 30-40% and use a micro-bevel of 40-45 degrees to distribute force across a wider edge. Conversely, softer woods like basswood (410 lbf) allow for more aggressive feeds and a sharper 30-degree bevel. A practical tip: coat the tool’s flank with a thin layer of paste wax when working with abrasive woods like oak (1360 lbf) to minimize friction and prolong edge life.

Comparatively, carbide-tipped tools outlast carbon steel by 5-10x in hard woods due to their superior hardness (90+ HRC vs. 60-62 HRC for carbon steel). However, for those committed to carbon steel, strategic wood selection can extend tool life. Prioritize softer woods for roughing stages, reserving harder species for final passes. For example, turn a bowl’s exterior from butternut (490 lbf) before refining the interior with cherry (950 lbf). This staged approach reduces cumulative wear on the tool’s cutting edge.

A cautionary note: avoid alternating between extremely hard and soft woods without intermediate sharpening. The compressive forces of hard woods can deform the tool’s edge, making it less effective on softer materials. Carry a diamond paddle sharpener (600-grit) to restore the edge after 15-20 minutes of turning dense woods. For prolonged projects, plan sharpening intervals every 30-45 minutes to maintain precision.

In conclusion, wood hardness is a controllable variable in the lifespan of carbon steel lathe tools. By aligning wood selection, technique, and maintenance with the material’s Janka rating, woodturners can maximize tool longevity without sacrificing performance. For instance, a hobbyist turning primarily softwoods like aspen (350 lbf) could expect a carbon steel skew chisel to last 6-8 months with weekly use, while a professional working predominantly with hard woods like purpleheart (2580 lbf) might need to replace the same tool every 4-6 weeks. Understanding this dynamic transforms wood hardness from a challenge into a strategic advantage.

Wood Chips vs. Mulch: Which Lasts Longer in Your Garden?

You may want to see also

Explore related products

Effects of Usage Intensity Rates

The lifespan of carbon steel wood lathe tools is significantly influenced by how intensely they are used. High usage rates, such as those seen in professional workshops where tools are engaged for 6–8 hours daily, can reduce their effective life by up to 50% compared to hobbyist use (1–2 hours weekly). This is primarily due to increased wear from friction, heat buildup, and repeated impact, which accelerate the dulling and degradation of the cutting edge.

To mitigate the effects of intense usage, implement a systematic tool rotation strategy. For example, maintain a set of 3–4 identical tools for each primary function (e.g., roughing gouges, parting tools). Rotate them daily or after 2–3 hours of continuous use to allow cooling and reduce localized wear. Additionally, keep a dedicated sharpening schedule: tools used heavily should be honed every 1–2 hours, while lighter-use tools may only require sharpening every 4–6 hours.

Material hardness also plays a critical role in how tools withstand high-intensity use. Carbon steel with a Rockwell hardness of 60–62 HRC offers a balance between edge retention and toughness but will wear faster under prolonged stress. For extreme usage scenarios, consider tools with tungsten or chromium alloys, which can extend lifespan by 30–40% but at a higher cost. Alternatively, apply a micro-ceramic coating to standard carbon steel tools to enhance durability without sacrificing sharpness.

Finally, monitor usage patterns to predict tool replacement needs. Track hours of operation and note performance declines, such as increased vibration or tear-out. As a rule of thumb, professional users should budget for tool replacement every 6–12 months, while hobbyists can expect 2–3 years of service. Regularly inspect tools for micro-fractures or chipping, as these are early indicators of failure under high-stress conditions. By aligning usage intensity with maintenance and material choices, woodturners can optimize both tool performance and longevity.

Women's Golf Club Choice: Woods vs. Long Irons – Which Reigns Supreme?

You may want to see also

Explore related products

Tool Quality and Brand Differences

Carbon steel wood lathe tools, when properly maintained, can last for decades, but their lifespan varies significantly based on quality and brand. High-end brands like Sorby and Ashley Iles use superior carbon steel alloys, often with added chromium or vanadium, which enhance hardness and wear resistance. These tools retain their edge longer, reducing the frequency of sharpening and extending their usable life. In contrast, budget brands may use lower-grade carbon steel, which dulls more quickly and is prone to chipping or deformation under heavy use. For hobbyists, mid-range brands like Crown or Henry Taylor offer a balance of quality and affordability, typically lasting 5–10 years with moderate use.

The manufacturing process also plays a critical role in tool longevity. Premium brands employ precision grinding and heat treatment techniques to ensure consistent hardness and edge geometry. For instance, Sorby’s tools are hardened to 62–64 HRC, making them durable yet easy to sharpen. Cheaper tools often lack this precision, leading to uneven wear and premature failure. Additionally, brand-specific designs, such as ergonomic handles or ground bevels, can improve usability and reduce user fatigue, indirectly extending tool life by minimizing misuse or over-sharpening.

Sharpening practices are another factor where brand differences become apparent. High-quality carbon steel tools respond well to traditional sharpening methods, such as water stones or diamond plates, and can be restored to a factory edge repeatedly. Lower-quality tools may require more frequent sharpening and are more susceptible to overheating or warping during the process. Some brands, like Two Cherries, even offer pre-ground bevels optimized for specific tasks, simplifying maintenance for beginners. Investing in a quality sharpening system, such as a Wolverine jig, can further maximize the lifespan of premium tools.

Storage and care routines amplify the impact of brand and quality differences. Premium tools often come with protective coatings or storage solutions, such as Sorby’s micro-film rust protection or Ashley Iles’s oiled finishes. Budget tools may require more proactive rust prevention, such as regular oiling or storage in a dry environment. Proper handling, like avoiding drops or excessive force, is equally important, as even the best tools can be damaged by misuse. For example, a $100 Sorby bowl gouge, if cared for meticulously, can outlast three generations of $20 alternatives.

Ultimately, the choice of brand and quality level should align with the user’s needs and budget. Professional turners or frequent users will benefit from the durability and performance of top-tier brands, while occasional hobbyists may find mid-range options sufficient. Regardless of brand, consistent maintenance—sharpening every 1–2 hours of use, cleaning after each session, and storing tools properly—is essential to maximize lifespan. By understanding these brand and quality differences, woodturners can make informed decisions that balance cost and longevity, ensuring their tools remain reliable for years to come.

Stardew Valley Wood Chipper Efficiency: Time to Process Wood Explained

You may want to see also

Frequently asked questions

Carbon steel wood lathe tools can last anywhere from a few months to several years, depending on usage frequency, maintenance, and the type of wood being turned.

Yes, harder carbon steel tools tend to hold their edge longer but are more brittle, while softer carbon steel tools are easier to sharpen but wear out faster.

Regular and proper sharpening significantly extends the lifespan of carbon steel lathe tools by maintaining a keen edge and reducing wear from dullness.

Yes, harder or abrasive woods (like oak or exotic species) wear down carbon steel tools faster compared to softer woods (like pine or cedar).

Regular cleaning, drying after use to prevent rust, and storing in a protective case or with rust inhibitors can help carbon steel tools last longer.