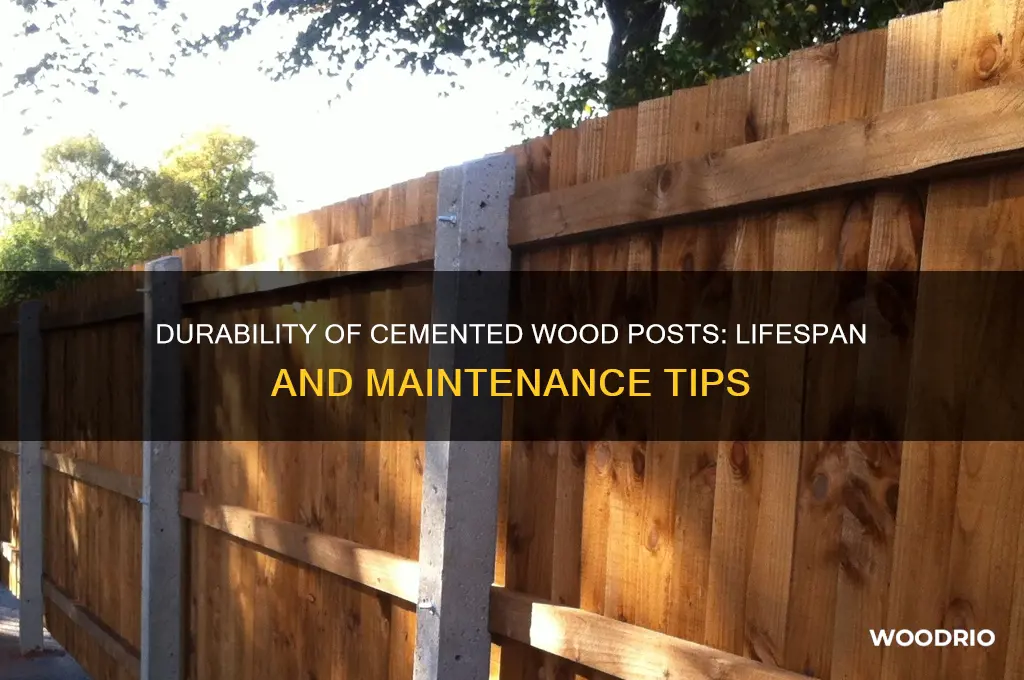

Cemented-in wood posts are a popular choice for various outdoor structures like fences, decks, and mailboxes due to their durability and stability. However, their lifespan can vary significantly depending on several factors, including the type of wood used, the quality of the cement mixture, the depth of the hole, and the environmental conditions they are exposed to. Proper installation techniques, such as using pressure-treated wood and ensuring adequate drainage, can significantly extend their longevity. On average, well-installed cemented-in wood posts can last anywhere from 10 to 20 years or more, though exposure to moisture, soil acidity, and pests can accelerate deterioration. Understanding these factors is crucial for maximizing the lifespan of cemented-in wood posts and ensuring they remain sturdy and functional over time.

| Characteristics | Values |

|---|---|

| Expected Lifespan | 10-20 years (with proper installation and maintenance) |

| Primary Factors Affecting Lifespan | Moisture exposure, soil conditions, wood type, quality of concrete, and installation depth |

| Wood Type Impact | Pressure-treated wood (e.g., pine, cedar) lasts longer than untreated wood |

| Concrete Quality | High-quality, well-mixed concrete improves durability |

| Installation Depth | Deeper burial in concrete (at least 1/3 of post height) increases lifespan |

| Moisture Protection | Proper drainage and sealing wood ends reduce rot |

| Soil Conditions | Well-draining soil prevents water accumulation and prolongs life |

| Maintenance Requirements | Regular inspections, resealing, and addressing cracks in concrete |

| Common Failure Points | Rot at the soil-concrete interface, concrete cracking, and insect damage |

| Alternative Materials | Metal or composite posts may outlast wood in cemented applications |

Explore related products

$103.99 $112.99

What You'll Learn

- Cement Setting Time: How long does cement take to set around wood posts

- Curing Duration: What is the curing time for cemented wood posts

- Load-Bearing Strength: When can cemented wood posts support weight safely

- Weather Impact: How does weather affect cement curing for wood posts

- Longevity Factors: What factors influence the lifespan of cemented wood posts

Cement Setting Time: How long does cement take to set around wood posts?

Cement setting time around wood posts is a critical factor in ensuring structural integrity and longevity. Typically, standard Portland cement begins to set within 30 minutes to an hour after mixing, but this is just the initial phase. Full curing, where the cement reaches its maximum strength, can take anywhere from 24 to 48 hours under ideal conditions. However, this timeline is influenced by factors such as temperature, humidity, and the water-to-cement ratio. For wood posts, it’s essential to avoid disturbing the cement during this initial setting period to prevent shifting or misalignment.

To optimize setting time, consider the environmental conditions. In colder climates, cement sets more slowly, sometimes requiring up to 72 hours to reach adequate strength. Using additives like accelerators can reduce setting time, but they must be applied carefully to avoid compromising the cement’s durability. Conversely, in hot, dry conditions, the cement may set too quickly, leading to cracking. To mitigate this, keep the area shaded and mist the cement lightly with water during the first few hours after pouring.

The wood post itself plays a role in the setting process. Pressure-treated wood is often recommended for cement applications because it resists rot and decay. However, the moisture content of the wood can affect how the cement adheres. If the wood is too wet, it may delay setting or create a weaker bond. Ensure the post is pre-drilled and properly positioned before pouring the cement to avoid last-minute adjustments that could disrupt the setting process.

Practical tips for success include using a consistent water-to-cement ratio, typically around 0.4 to 0.5 by weight, to achieve optimal strength. Mix the cement thoroughly to eliminate lumps, which can weaken the structure. After pouring, use a trowel to smooth the surface and create a slight slope away from the post to encourage water runoff. Finally, avoid heavy loads or movement near the post for at least 48 hours to ensure the cement cures properly. By following these guidelines, you can ensure a strong, durable bond between the cement and wood post.

Cedar Wood Durability: How Long Does It Last Outdoors?

You may want to see also

Explore related products

Curing Duration: What is the curing time for cemented wood posts?

The curing time for cemented wood posts is a critical factor in ensuring their longevity and structural integrity. Typically, concrete takes about 24 to 48 hours to set initially, but full curing—where it reaches its maximum strength—can take up to 28 days. This extended period allows the concrete to harden completely, creating a robust bond between the post and the ground. During this time, it’s essential to avoid placing heavy loads or stress on the post, as the concrete is still gaining strength. For wood posts, this curing phase is particularly vital because it minimizes the risk of shifting or settling, which can compromise the post’s stability over time.

Several factors influence the curing duration of cemented wood posts, including environmental conditions and the type of concrete mix used. In warmer climates, concrete cures faster due to increased evaporation, while colder temperatures can significantly slow the process. For instance, at temperatures below 50°F (10°C), curing can take twice as long. To accelerate curing in cooler conditions, consider using a concrete mix with accelerators or insulating the area around the post. Conversely, in hot weather, covering the concrete with damp burlap or spraying it with water can prevent premature drying and cracking.

Practical tips for managing curing time include planning the installation during mild weather and using a high-quality concrete mix designed for structural applications. For DIY projects, a standard 50-pound bag of concrete mix is often sufficient for setting a single wood post, but always follow the manufacturer’s instructions for water-to-mix ratios. After pouring the concrete, ensure the post is plumb and braced securely until the initial set occurs. Once the concrete has hardened enough to hold the post in place (usually after 24 hours), remove the braces but avoid heavy use for at least a week to allow further curing.

Comparing curing times for cemented wood posts to other methods, such as using gravel or soil, highlights the advantages of concrete. While gravel provides immediate stability, it lacks the long-term strength of concrete. Soil, on the other hand, can shift over time, leading to post instability. Concrete’s 28-day curing period ensures a permanent, weather-resistant foundation that outperforms these alternatives. For projects requiring maximum durability, such as fence posts or deck supports, the extra curing time is a worthwhile investment.

In conclusion, understanding the curing duration for cemented wood posts is essential for achieving a strong and lasting installation. By accounting for environmental factors, using the right materials, and following best practices, you can ensure the concrete cures properly, providing a stable base for years to come. Patience during the curing process pays off in the form of a structurally sound post that withstands the test of time and weather.

Resanding Wet Wood: Optimal Timing for Smooth, Flawless Results

You may want to see also

Explore related products

Load-Bearing Strength: When can cemented wood posts support weight safely?

Cemented wood posts, when properly installed, can bear significant weight, but their load-bearing capacity depends on several critical factors. The strength of the concrete, the depth and diameter of the hole, and the type of wood used all play pivotal roles. For instance, a 6x6 pressure-treated wood post set in a 12-inch diameter hole with a minimum depth of 30 inches can support upwards of 2,000 pounds, provided the concrete is mixed to a compressive strength of at least 3,000 psi. This setup is ideal for structures like decks, fences, or light pergolas.

To ensure safety, follow a systematic approach when installing cemented wood posts. First, excavate a hole three times the diameter of the post and one-third its height below ground level. For a 6x6 post, this translates to a 12-inch diameter hole and a 30-inch depth. Mix the concrete according to manufacturer instructions, ensuring a consistent, pourable consistency. Place the post in the center of the hole, using braces to keep it plumb, and pour the concrete around it. Allow the concrete to cure for at least 48 hours before applying any load. This method maximizes stability and load distribution.

While cemented wood posts are durable, they are not invincible. Overloading or improper installation can lead to failure. For example, using a post with a smaller cross-sectional area or insufficient concrete coverage reduces its load-bearing capacity. Additionally, environmental factors like soil type and moisture levels can affect long-term stability. Sandy soils provide less lateral support compared to clay, while waterlogged conditions can accelerate wood rot. Regular inspections and maintenance, such as sealing the wood and ensuring proper drainage, can extend the post’s lifespan and safety.

Comparing cemented wood posts to alternatives like metal or composite posts highlights their unique advantages. Wood is cost-effective, readily available, and easier to work with for DIY projects. However, it requires more maintenance than metal or composite materials, which are inherently resistant to rot and pests. For applications requiring minimal upkeep, such as commercial structures, metal or composite posts may be preferable. Yet, for residential projects where budget and aesthetics are priorities, cemented wood posts remain a reliable choice when installed correctly.

In conclusion, cemented wood posts can safely support weight when installed with precision and consideration for material properties and environmental conditions. By adhering to specific guidelines—such as using pressure-treated wood, ensuring proper hole dimensions, and allowing adequate curing time—you can maximize their load-bearing strength. Regular maintenance further ensures longevity, making them a practical solution for various structural needs. Always assess the specific demands of your project to determine if cemented wood posts are the right fit.

Women's Golf Club Choice: Woods vs. Long Irons – Which Reigns Supreme?

You may want to see also

Explore related products

Weather Impact: How does weather affect cement curing for wood posts?

Cement curing is a chemical process, and like any chemical reaction, it’s sensitive to temperature and moisture. For wood posts set in concrete, ideal curing conditions are temperatures between 50°F and 75°F (10°C and 24°C) with consistent moisture. At these levels, the cement hydrates properly, forming strong bonds around the post. However, weather extremes—whether scorching heat or freezing cold—can disrupt this process, weakening the final structure. Understanding these vulnerabilities is crucial for anyone installing wood posts in concrete.

In hot weather, cement cures faster but risks losing moisture too quickly, leading to cracking. Temperatures above 90°F (32°C) can cause the water in the mix to evaporate before the cement fully hydrates. To mitigate this, shade the curing area, use windbreaks, and mist the surface periodically. Avoid pouring concrete during the hottest parts of the day; early morning or late afternoon is better. If high temperatures are unavoidable, consider using a set-retarding admixture (dosage: 2-4 ounces per 94-pound bag of cement) to slow the curing process and ensure proper hydration.

Cold weather poses a different challenge: freezing temperatures halt the curing process entirely. When the temperature drops below 40°F (4°C), the water in the cement mix can freeze, preventing proper hydration and weakening the concrete. To protect against this, use heated enclosures or insulated blankets to maintain the concrete’s temperature above 50°F (10°C) for at least the first 24 hours. Accelerating admixtures (dosage: 2-5% of cement weight) can also be added to speed up initial curing before temperatures drop. Never pour concrete on frozen ground or when snow is forecast.

Rain and humidity introduce excess moisture, which can weaken the concrete’s surface and reduce its bond with the wood post. If rain is expected within 24 hours of pouring, cover the area with plastic sheeting. High humidity, while less critical than rain, can slow evaporation and prolong curing. In such conditions, ensure proper drainage around the post to prevent water pooling. For coastal or humid climates, consider using a waterproof admixture (dosage: 2-3% of cement weight) to enhance durability.

Wind exacerbates moisture loss, particularly in hot and dry conditions. Strong winds can cause the surface to dry too quickly, leading to shrinkage cracks. Erect temporary windbreaks or use damp burlap to cover the curing concrete. In arid climates, curing compounds (applied after the initial set) can form a moisture-retaining film, ensuring the concrete cures evenly. Always monitor weather forecasts and plan installations accordingly to minimize weather-related risks.

By understanding and adapting to weather conditions, you can ensure that cemented wood posts cure properly, providing a stable and long-lasting foundation. Whether battling heat, cold, rain, or wind, proactive measures will safeguard your project against the elements.

Mastering Wood Bending: Optimal Steaming Times for Perfect Curves

You may want to see also

Explore related products

$22.59

Longevity Factors: What factors influence the lifespan of cemented wood posts?

The lifespan of cemented wood posts hinges on a delicate interplay of environmental, material, and installation factors. Moisture is the arch-nemesis, with posts in direct contact with soil or exposed to frequent wetting succumbing to rot within 5-10 years. Conversely, posts set above grade with proper drainage can endure for 20+ years. Pressure-treated wood, infused with preservatives like ACQ or CCA, significantly extends longevity, especially when paired with a gravel base for moisture mitigation.

Consider the installation process a critical determinant of post longevity. A common mistake is insufficient concrete depth, leaving the wood vulnerable to moisture wicking. Aim for a minimum of 6 inches of concrete below grade, with a tapered base to direct water away from the post. Additionally, ensure proper compaction of the surrounding soil to prevent settling and potential water pooling.

Utilizing a post bracket or anchor can further enhance stability and reduce stress on the wood-concrete interface.

The choice of wood species plays a pivotal role in determining post lifespan. Naturally rot-resistant species like cedar or redwood offer inherent durability, often lasting 15-20 years without treatment. However, even these species benefit from pressure treatment, particularly in humid climates or soil with high moisture content. For maximum longevity, opt for posts rated for ground contact, indicating a higher concentration of preservatives.

Regular inspection and maintenance are crucial. Check for cracks, splinters, or signs of insect infestation, addressing issues promptly to prevent further deterioration.

While cemented wood posts offer a robust solution for fencing, decking, and other applications, their longevity is not guaranteed. By carefully considering factors like moisture management, installation techniques, wood selection, and ongoing maintenance, you can significantly extend their lifespan, ensuring years of reliable service. Remember, investing in quality materials and proper installation upfront pays dividends in the long run, minimizing the need for costly replacements and ensuring the structural integrity of your project.

Yellowjackets' Survival Timeline: How Long Were the Girls Lost in the Woods?

You may want to see also

Frequently asked questions

Cemented-in wood posts can last 10–20 years or more, depending on factors like wood type, moisture exposure, soil conditions, and proper installation.

While cement provides stability, it does not fully prevent rot. Moisture can still seep into the wood, so using pressure-treated wood and proper drainage is essential.

Yes, but replacing them is labor-intensive. The concrete must be broken and removed, and the new post must be re-cemented or installed using alternative methods.