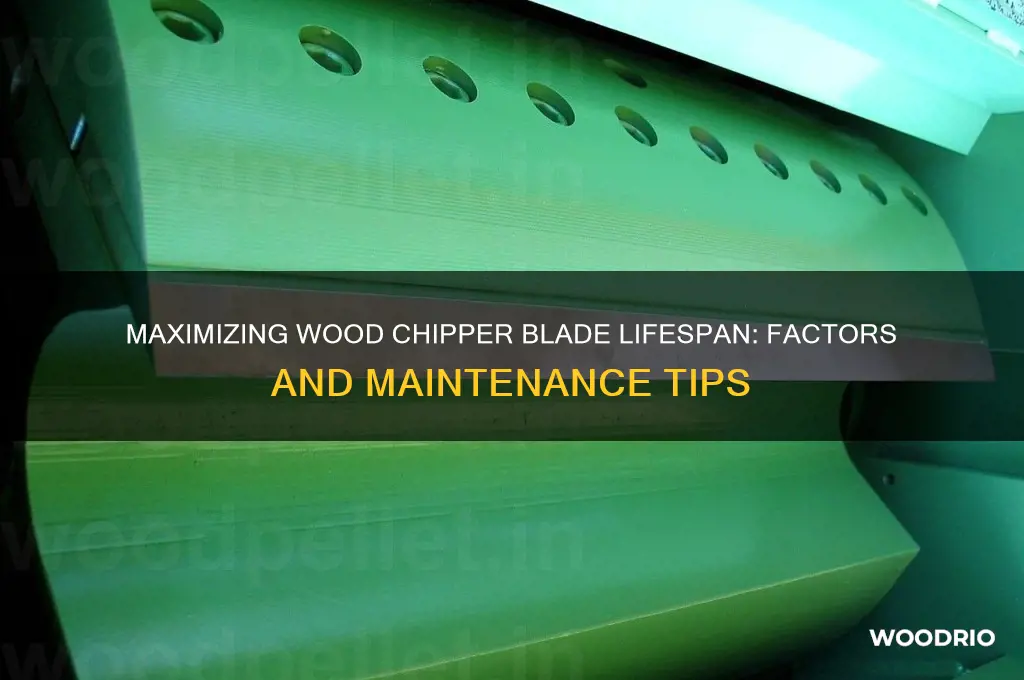

Wood chipper blades are critical components in the efficiency and performance of wood chippers, but their lifespan can vary significantly depending on several factors. Typically, high-quality blades made from durable materials like hardened steel can last anywhere from 50 to 100 hours of continuous use, though this range can be influenced by the type of wood being processed, the frequency of use, and maintenance practices. Hardwoods and materials with high moisture content or contaminants like rocks or metal can accelerate wear, while regular sharpening, proper cleaning, and timely replacement of worn blades can extend their longevity. Understanding these factors is essential for maximizing the lifespan of wood chipper blades and ensuring optimal machine performance.

| Characteristics | Values |

|---|---|

| Average Lifespan | 50-100 hours of operation (varies based on usage and material) |

| Factors Affecting Lifespan | Material type, frequency of use, maintenance, and wood hardness |

| Blade Material | High-carbon steel or carbide-tipped blades for longer durability |

| Maintenance Impact | Regular sharpening and cleaning can extend lifespan by 20-30% |

| Hardwood vs. Softwood | Blades last 20-30% longer when chipping softwood compared to hardwood |

| Professional vs. Residential Use | Professional use reduces lifespan to 50-70 hours; residential use lasts 80-100+ hours |

| Signs of Wear | Dull cutting edges, increased vibration, or uneven wood chips |

| Replacement Cost | $50-$200 per blade, depending on brand and material |

| Sharpening Frequency | Every 10-20 hours of use for optimal performance |

| Environmental Factors | Dusty or dirty conditions can reduce lifespan by 15-25% |

Explore related products

What You'll Learn

Blade material impact on longevity

The material composition of wood chipper blades is a critical factor in determining their lifespan, with variations in durability, resistance to wear, and maintenance requirements. High-carbon steel blades, for instance, are known for their hardness and ability to retain a sharp edge, making them suitable for heavy-duty chipping tasks. However, they are more prone to corrosion and may require frequent sharpening or coating to maintain performance. In contrast, carbide-tipped blades offer superior wear resistance and can last up to 10 times longer than standard steel blades, though they come at a higher initial cost. Understanding these material properties allows users to balance performance needs with budget constraints.

When selecting blade material, consider the type and frequency of wood chipping tasks. For occasional residential use, hardened steel blades may suffice, offering a cost-effective solution with a lifespan of 50 to 100 hours of operation. Commercial operators, however, should prioritize carbide-tipped or alloy steel blades, which can endure 500 to 1,000 hours of use under demanding conditions. Additionally, chromium-plated blades provide enhanced corrosion resistance, ideal for humid environments or outdoor storage. Pairing the right material with usage patterns ensures optimal longevity and minimizes downtime.

A comparative analysis reveals that while carbide-tipped blades dominate in longevity, their brittleness can lead to chipping or cracking under extreme stress. Alloy steel blades, incorporating elements like manganese or vanadium, strike a balance between toughness and hardness, making them versatile for mixed wood types. For those seeking eco-friendly options, recycled steel blades are emerging as a sustainable choice, though their durability may vary based on manufacturing processes. Evaluating these trade-offs helps users make informed decisions tailored to their specific needs.

Practical tips for maximizing blade longevity include regular cleaning to remove sap and debris, which can accelerate wear. Applying a rust-inhibiting oil or spray after each use protects against moisture-induced corrosion, particularly for high-carbon steel blades. Sharpening should be performed when blades show a 10-15% reduction in cutting efficiency, using a file or grinder at the correct angle to preserve the edge. For carbide-tipped blades, professional sharpening services are recommended to avoid damaging the hard tips. By adopting these maintenance practices, users can extend blade life regardless of material choice.

In conclusion, the impact of blade material on longevity is profound, with each option offering distinct advantages and limitations. High-carbon steel provides affordability and sharpness but demands diligent maintenance, while carbide-tipped blades excel in durability at a premium price. Alloy steel and chromium-plated variants cater to specific needs, such as toughness or corrosion resistance. By aligning material selection with usage demands and implementing proper care, wood chipper operators can optimize blade performance and reduce long-term costs.

Best Timing for Splitting Wood: Tips for Optimal Results

You may want to see also

Explore related products

$14.99

$26.97 $28.62

$9.99

Maintenance tips to extend blade life

Wood chipper blades are subjected to immense stress, from fibrous wood to hidden rocks, so their lifespan varies widely—typically 50 to 200 hours of use. Extending blade life hinges on proactive maintenance, not just reactive repairs. Start by inspecting blades before and after each use. Look for chips, dull edges, or uneven wear, which signal improper sharpening or material overload. Addressing these issues early prevents premature failure and ensures consistent performance.

Sharpening is a delicate balance—too little reduces efficiency, while over-sharpening thins the blade, compromising durability. Use a file or grinder at a 30-degree angle, maintaining the original bevel. Sharpen only when necessary, typically after 10–15 hours of use, depending on material hardness. For example, hardwoods like oak dull blades faster than softwoods like pine. Always wear gloves and secure the blade to avoid injury during this process.

Material preparation is equally critical. Remove dirt, stones, and metal debris from wood piles, as these accelerate wear and increase the risk of breakage. A simple magnet pass over the material can save hours of blade life. Additionally, avoid overloading the chipper; exceeding its capacity forces blades to work harder, shortening their lifespan. Refer to the manufacturer’s guidelines for optimal feed rates and material sizes.

Lubrication and storage play a surprising role in blade longevity. Apply a high-temperature lubricant to the blade’s cutting edge and pivot points monthly, or after 10 hours of use. This reduces friction and prevents rust, especially in humid environments. Store the chipper in a dry, covered area to shield blades from moisture and temperature extremes. Blades left exposed degrade faster, even when not in use.

Finally, consider blade rotation and replacement as part of routine maintenance. Rotating blades every 20–30 hours ensures even wear across all edges, extending their collective lifespan. Keep a spare set on hand to minimize downtime during replacements. While high-quality blades cost more upfront, their durability often outweighs the expense of frequent replacements. By integrating these practices, you can maximize blade life and maintain peak chipper performance.

How Long Does Buried Wood Last Before Rotting Away?

You may want to see also

Explore related products

Frequency of blade replacement

Wood chipper blades endure immense stress, facing abrasive wood fibers, hidden nails, and the constant impact of feeding materials. Their lifespan varies dramatically based on usage intensity, material type, and maintenance practices. While some blades may last 50–100 hours under light residential use with clean, dry wood, commercial operators processing wet, dirty, or knotty wood might need replacements every 20–30 hours. Understanding these variables is crucial for optimizing performance and minimizing downtime.

Consider the following factors when assessing replacement frequency: material hardness (hardwoods like oak wear blades faster than softwoods like pine), moisture content (wet wood is more abrasive), and foreign object contamination (nails, rocks, or metal can cause immediate damage). Regular inspections for dulling, chipping, or uneven wear patterns are essential. A blade that’s lost more than 10% of its original thickness or shows significant damage should be replaced immediately to prevent inefficiency or safety hazards.

For those seeking a structured approach, implement a tiered maintenance schedule. Light users (1–2 hours weekly) should inspect blades monthly and replace annually or after 50 hours. Moderate users (3–5 hours weekly) should inspect bi-weekly and replace every 6 months or after 100 hours. Heavy users (daily commercial operation) should inspect weekly and replace blades every 1–3 months or after 200 hours. Always keep a spare set on hand to avoid project delays.

Persuasive arguments for timely replacement center on cost-effectiveness and safety. Dull blades increase fuel consumption by up to 20% and slow processing speeds, negating potential savings from delaying replacement. Worse, worn blades can shatter under stress, posing severe injury risks. Investing in high-quality, hardened steel blades and adhering to a proactive replacement schedule ensures both operational efficiency and operator protection.

Finally, compare blade longevity across chipper types. Drum-style chippers typically wear blades more evenly but may require full set replacements due to synchronized wear. Disc-style chippers often allow individual blade swaps, extending overall lifespan. Regardless of design, pairing sharp blades with proper feeding techniques—such as avoiding overloading and using a steady, controlled feed rate—maximizes durability. Treat blades as a critical investment, not an expendable part, and they’ll reward you with consistent performance.

Railroad Ties vs. Treated Wood: Which Lasts Longer in Landscaping?

You may want to see also

Explore related products

$52.99

Effects of wood type on wear

Wood density directly impacts blade wear in chippers. Hardwoods like oak and hickory, with densities exceeding 40 pounds per cubic foot, act like sandpaper against cutting edges. Each pass abrades the steel, accelerating dulling and necessitating frequent sharpening or replacement. Conversely, softwoods like pine (15-25 lbs/cu ft) are gentler, allowing blades to retain their edge longer. For reference, a 4-inch hardwood log can wear blades 2-3 times faster than an equivalent softwood piece.

Consider the silica content of the wood, a hidden blade assassin. Woods like cedar and redwood contain higher silica levels, which act like microscopic razor blades, scoring and pitting the blade surface. This not only dulls the edge but also weakens the metal, leading to premature cracking or chipping. If processing silica-rich wood, expect blade life to plummet by 50% or more compared to silica-poor species.

Moisture content plays a dual role in blade wear. Green wood, with moisture levels above 20%, is softer and easier to cut, reducing initial wear. However, the constant exposure to moisture accelerates corrosion, particularly in carbon steel blades. Seasoned wood (below 15% moisture) is harder but drier, minimizing corrosion while increasing friction and heat buildup, both of which contribute to wear. Aim for a moisture content of 15-20% for optimal blade longevity.

Grain orientation is often overlooked but critical. Cutting against the grain, especially in hardwoods, increases friction and heat, accelerating wear. Whenever possible, feed wood with the grain parallel to the blade’s cutting edge. This reduces resistance and minimizes edge deformation, extending blade life by up to 30%.

Finally, wood contaminants like nails, rocks, or dirt act as blade destroyers. A single embedded nail can instantly chip or crack a blade, rendering it useless. Always inspect wood for foreign objects before chipping. Using a metal detector or pre-cutting with a handsaw can prevent catastrophic damage, saving both blades and downtime.

Mastering Smoking: Optimal Wood Chip Soaking Time for Perfect Flavor

You may want to see also

Explore related products

Signs of worn-out chipper blades

Wood chipper blades are subjected to immense stress, from fibrous wood to hidden rocks, so their lifespan varies widely—typically 50 to 200 hours of use. However, wear isn’t always obvious until it affects performance. Recognizing early signs of deterioration can prevent costly downtime and ensure consistent chipping quality.

Visual Inspection: The First Line of Defense

Start with a simple visual check. Worn blades often exhibit uneven edges, chips, or rounded cutting surfaces. Compare the blade’s current state to its original profile; a noticeable difference indicates material loss. For example, a blade designed with a sharp, angular edge should retain that shape. If it appears smoothed or dulled, it’s time for sharpening or replacement. Additionally, look for cracks or warping, which compromise structural integrity and pose safety risks.

Performance Metrics: When Efficiency Drops

A worn blade forces the chipper to work harder, leading to observable inefficiencies. If you notice increased fuel consumption, longer chipping times, or the machine straining under normal loads, the blades may be the culprit. Another red flag is inconsistent chip size—worn blades produce larger, uneven pieces instead of uniform mulch. For commercial operators, tracking chipping time per load can highlight gradual declines in blade effectiveness.

Auditory and Tactile Clues: Listen and Feel

A well-maintained chipper operates with a steady, rhythmic sound. Worn blades often produce a higher-pitched, labored noise as the machine struggles to cut. Vibration is another telltale sign; dull blades cause the chipper to shake excessively due to uneven cutting forces. If you feel increased vibration through the handles or hear a grinding noise, inspect the blades immediately.

Material Output: The Final Verdict

Examine the chipped material for clues. Fresh, sharp blades produce clean cuts with minimal tearing. Worn blades leave jagged edges, splintered wood, or even unprocessed chunks. For instance, if you’re chipping hardwoods and notice fibrous strands instead of uniform chips, the blades are likely dull. Similarly, softwoods may compress rather than cut cleanly, indicating excessive blade wear.

Proactive Maintenance: Extending Blade Life

While blades eventually wear out, proper care can maximize their lifespan. Regularly sharpen blades after every 50–100 hours of use, depending on material hardness. Avoid feeding contaminated wood, as dirt and debris accelerate wear. For heavy-duty users, keep a log of operating hours and schedule inspections every 25 hours to catch issues early. Replacing blades in pairs ensures balanced cutting force and prevents uneven wear.

By staying vigilant for these signs, operators can maintain peak performance, reduce repair costs, and ensure safety. After all, a wood chipper is only as effective as its blades.

Composite vs. Wood Fences: Which Lasts Longer in Your Yard?

You may want to see also

Frequently asked questions

The lifespan of wood chipper blades depends on usage frequency, material type, and maintenance. On average, blades can last between 50 to 200 hours of operation, but this varies widely based on conditions.

Blade longevity is influenced by the type of wood being chipped (hardwoods wear blades faster), the presence of debris or rocks, and regular sharpening and maintenance practices.

To extend blade life, avoid chipping dirty or rocky materials, sharpen blades regularly, and inspect them for damage. Proper maintenance and using the chipper within its recommended capacity also help maximize durability.

![Lifespan [Hardcover], The Telomere Effect, How Not To Die 3 Books Collection Set](https://m.media-amazon.com/images/I/61qCslmrnIL._AC_UY218_.jpg)