Wooden playgrounds are a popular choice for outdoor recreational spaces due to their natural aesthetic and eco-friendly appeal, but their longevity can vary significantly based on several factors. Typically, well-maintained wood playgrounds can last anywhere from 10 to 20 years, though some may endure longer with proper care and regular inspections. The durability of these structures depends on the type of wood used, with treated or naturally rot-resistant woods like cedar or redwood offering greater resilience against weathering, pests, and decay. Additionally, factors such as climate, exposure to moisture, frequency of use, and adherence to maintenance routines, including sealing and staining, play crucial roles in extending their lifespan. Understanding these variables is essential for maximizing the investment in wooden playgrounds and ensuring they remain safe and functional for children over time.

| Characteristics | Values |

|---|---|

| Average Lifespan | 10-15 years (with proper maintenance) |

| Primary Material Degradation Factor | Weather exposure (sun, rain, snow) |

| Maintenance Frequency | Annual inspections and repairs recommended |

| Rot Resistance | Depends on wood type (e.g., cedar or redwood last longer) |

| Insect Damage | Common without proper treatment (e.g., termites, carpenter ants) |

| Safety Standards Compliance | Requires regular updates to meet ASTM and CPSC guidelines |

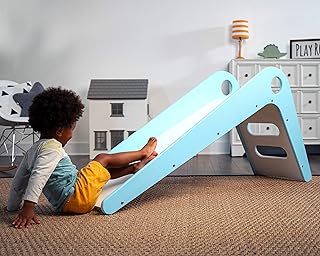

| Surface Wear | High-traffic areas may degrade faster (e.g., slides, climbing areas) |

| Cost of Maintenance | $500-$2,000 annually (varies by size and condition) |

| Replacement Cost | $10,000-$50,000+ (depending on size and features) |

| Environmental Impact | Biodegradable but requires sustainable sourcing |

| Alternative Materials | Plastic or metal playgrounds last 20-30 years but are less eco-friendly |

Explore related products

What You'll Learn

Material Quality Impact

The lifespan of a wooden playground hinges significantly on the quality of the materials used. Opting for premium, naturally rot-resistant hardwoods like cedar, redwood, or black locust can extend durability by decades compared to cheaper, less resilient softwoods. These dense woods contain natural oils and tannins that repel moisture, insects, and fungal decay, reducing the need for frequent treatments. For instance, a cedar playground can last 15–20 years with minimal maintenance, while untreated pine may deteriorate in as little as 5–7 years.

Selecting pressure-treated wood is another critical decision. Look for lumber treated with ACQ (alkaline copper quaternary) or CA-B (copper azole), which are safer alternatives to the now-banned CCA (chromated copper arsenate). While pressure-treated wood can last 12–18 years, the treatment’s effectiveness depends on proper installation—ensure cut ends are sealed with compatible preservatives to prevent premature rot. Avoid using untreated wood in ground-contact areas, as it will degrade rapidly without protection.

The finish applied to wooden playground structures plays a pivotal role in longevity. A high-quality, UV-resistant sealant or stain should be reapplied every 1–2 years to shield the wood from sun damage, which causes cracking and warping. For high-traffic areas, consider marine-grade varnish or epoxy coatings, which provide superior moisture resistance. Conversely, skipping this step or using low-grade finishes can halve the playground’s lifespan, as unprotected wood becomes brittle and splinter-prone within 3–5 years.

Hardware quality is often overlooked but equally vital. Stainless steel or galvanized fasteners resist corrosion, ensuring joints remain secure over time. Using inferior materials like standard steel screws can lead to rusted, weakened structures within 2–3 years, particularly in humid climates. Regularly inspect and replace hardware as part of a maintenance routine to avoid safety hazards and extend the playground’s functional life.

Finally, the sourcing of wood matters. Certified sustainable hardwoods from responsibly managed forests not only support environmental conservation but also tend to be of higher quality, free from defects that accelerate wear. While these materials may have a higher upfront cost, they offer long-term savings by reducing replacement and repair needs. For example, a sustainably sourced black locust playground can outlast cheaper alternatives by 10+ years, making it a wiser investment for public spaces or high-use areas.

Understanding Wood Degradation: Factors Affecting Quality and Longevity Over Time

You may want to see also

Explore related products

Maintenance Frequency Needs

Wooden playgrounds, when properly maintained, can last 15 to 20 years or more. However, the frequency and quality of maintenance are critical determinants of their lifespan. Neglecting regular upkeep can lead to premature deterioration, while consistent care can significantly extend their usability. The key lies in understanding the specific maintenance needs of wood and implementing a structured schedule to address them.

Inspect Monthly, Treat Annually

A practical maintenance schedule begins with monthly inspections. Look for signs of wear, such as splintering, loose hardware, or mold growth. Address minor issues immediately to prevent them from escalating. Annually, apply a protective sealant or stain to shield the wood from moisture, UV rays, and pests. For high-traffic areas, consider reapplying sealant every 6 to 8 months. This dual approach ensures that both surface-level and structural integrity are preserved.

Seasonal Adjustments Matter

Maintenance frequency should also align with seasonal changes. In regions with harsh winters, inspect playgrounds before and after the cold season for frost damage or warping. In humid climates, increase mold and mildew checks to quarterly, using a mild bleach solution (1 part bleach to 10 parts water) to clean affected areas. Sanding rough spots and tightening bolts should be part of spring and fall routines to prepare for peak usage periods.

Proactive vs. Reactive Maintenance

Proactive maintenance is always more cost-effective than reactive repairs. For instance, replacing a single rotting board early costs far less than replacing an entire structure later. Establish a maintenance log to track inspections, repairs, and treatments. This documentation helps identify recurring issues and ensures no task is overlooked. For larger playgrounds, consider hiring a professional inspector annually to assess structural safety and provide expert recommendations.

Community Involvement Extends Lifespan

Engaging the community in maintenance efforts can reduce the burden on staff and foster a sense of ownership. Organize volunteer days for tasks like cleaning, sanding, and staining. Provide clear instructions and safety guidelines to ensure work is done correctly. Schools and parks can also implement "adopt-a-playground" programs, where local businesses or groups commit to regular upkeep in exchange for recognition. This collaborative approach not only extends the playground’s lifespan but also strengthens community ties.

By adhering to a tailored maintenance frequency, wooden playgrounds can remain safe, functional, and aesthetically pleasing for decades. The investment in time and resources pays off in longevity, ensuring generations of children can enjoy these natural play spaces.

Pressure Treated Wood Lifespan: Preventing Rot and Ensuring Durability

You may want to see also

Explore related products

Climate Effects on Durability

Wooden playgrounds, while charming and natural, face a formidable adversary in the form of climate. Extreme temperatures, humidity, and precipitation can significantly impact their lifespan. In regions with scorching summers, prolonged exposure to UV rays can cause wood to fade, crack, and become brittle. Conversely, in areas with harsh winters, freezing temperatures and snow can lead to warping, splitting, and decay. For instance, a wooden playground in Arizona might require more frequent sealing and staining to combat sun damage, whereas one in Minnesota would need robust waterproofing to prevent moisture infiltration.

To mitigate these effects, consider the climate-specific maintenance regimen. In humid environments, ensure proper ventilation to discourage mold and mildew growth. Apply mildew-resistant sealants at least twice a year, particularly in tropical regions where relative humidity often exceeds 70%. In arid climates, use UV-protective finishes to minimize sun damage. For playgrounds in areas with significant temperature fluctuations, opt for thermally modified wood, which has been treated to enhance its dimensional stability and resistance to warping.

A comparative analysis reveals that wooden playgrounds in temperate climates, such as those in the Pacific Northwest, can last 15–20 years with regular maintenance. In contrast, those in more extreme climates may degrade in as little as 5–10 years without proper care. For example, a study in Florida showed that untreated pine structures exhibited visible rot within 3 years due to high humidity and rainfall. Meanwhile, a cedar playground in Oregon, treated annually with a water-repellent preservative, remained structurally sound after 18 years.

For practical longevity, tailor your approach to the local climate. In coastal areas, where salt spray accelerates corrosion, use stainless steel hardware and apply marine-grade sealants. In regions prone to heavy rainfall, incorporate sloped surfaces and drainage systems to prevent water pooling. Regular inspections are crucial—check for signs of wear, such as splintering or loose joints, at least quarterly. For playgrounds in extreme climates, consider a hybrid design, combining wood with more resilient materials like recycled plastic or metal, to balance aesthetics and durability.

Ultimately, the key to maximizing a wooden playground’s lifespan lies in proactive, climate-specific care. By understanding the unique challenges posed by your local environment and implementing targeted maintenance strategies, you can ensure these structures remain safe and functional for years to come. Whether through advanced treatments, thoughtful design, or routine upkeep, adapting to climate effects is non-negotiable for preserving the integrity of wood in outdoor play spaces.

Boiling Wood for Aquariums: Optimal Time for Safe Submersion

You may want to see also

Explore related products

Usage Intensity Factors

The lifespan of a wooden playground is not solely determined by the quality of materials but also by how intensely it is used. Usage intensity factors play a critical role in wear and tear, influencing maintenance needs and overall longevity. High-traffic areas, such as climbing structures and slides, experience accelerated degradation compared to quieter zones like sandboxes or balance beams. Understanding these patterns allows for targeted interventions, such as reinforcing high-use components or scheduling more frequent inspections.

Analyzing usage intensity begins with categorizing activities by age group and frequency. Preschool-aged children (3–5 years) typically engage in low-impact play, focusing on sensory and imaginative activities, while school-aged children (6–12 years) tend toward more vigorous, repetitive actions like climbing and swinging. For instance, a wooden climbing tower may show signs of splintering or structural strain after just 3–5 years of daily use by older children, whereas a sandbox might remain intact for 8–10 years with minimal wear. Tracking these patterns helps in designing playgrounds that balance durability with user needs.

To mitigate the effects of usage intensity, implement a tiered maintenance strategy. High-use areas require annual inspections and bi-annual treatments, such as sealing wooden surfaces with non-toxic preservatives to prevent moisture absorption and UV damage. Medium-use zones, like bridges or stepping stones, benefit from semi-annual checks and spot repairs. Low-use areas can be maintained on a biennial schedule, focusing on cleaning and minor touch-ups. Additionally, rotating play equipment seasonally redistributes wear, extending the life of individual components.

Comparing wooden playgrounds in urban versus rural settings highlights the impact of usage intensity. Urban playgrounds, often serving larger, more diverse age groups, may experience 2–3 times the wear of rural counterparts. For example, a wooden play structure in a city park might require replacement after 7–10 years, while a similar structure in a rural schoolyard could last 12–15 years. This disparity underscores the importance of tailoring design and maintenance plans to local usage patterns, ensuring resources are allocated efficiently.

Finally, proactive measures can significantly extend a wooden playground’s lifespan despite heavy use. Installing impact-absorbing surfaces, such as rubber mulch or poured-in-place rubber, reduces stress on wooden structures by minimizing ground-level damage. Encouraging supervised play and posting clear age guidelines prevents misuse, such as overloading platforms or using equipment inappropriately. By addressing usage intensity factors head-on, communities can maximize their investment, creating safe, durable play spaces that withstand the test of time.

Family Dollar Long Wood Narrow Sticks: Uses, Benefits, and Creative Ideas

You may want to see also

Explore related products

$612.24 $674.99

Rot & Pest Resistance

Wooden playgrounds, when properly treated and maintained, can withstand the test of time, often lasting 15 to 20 years or more. However, their longevity hinges significantly on their resistance to rot and pests, two relentless adversaries of wood in outdoor environments. Rot, caused by fungi that thrive in moist conditions, and pests like termites and carpenter ants, can compromise the structural integrity of playground equipment, posing safety risks and increasing maintenance costs. Understanding and implementing strategies to combat these threats is crucial for maximizing the lifespan of wooden playgrounds.

One of the most effective methods to enhance rot resistance is through the use of pressure-treated wood. This process involves impregnating the wood with preservatives, such as chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ), which deter fungal growth and decay. For instance, ACQ-treated wood is a popular choice for playgrounds due to its low toxicity and high efficacy against rot. When selecting materials, ensure the wood is rated for ground contact, as this provides the highest level of protection. Additionally, applying a water-repellent sealant every 1-2 years can further reduce moisture absorption, a key factor in rot prevention.

Pest resistance is equally critical, particularly in regions prone to termite infestations. Incorporating naturally resistant wood species, such as cedar or redwood, can provide a strong first line of defense. These woods contain natural oils and tannins that repel insects. For added protection, consider integrating physical barriers like metal termite shields around the base of playground structures. Chemical treatments, such as borate-based solutions, can also be applied during construction to deter pests. Regular inspections for signs of infestation, such as hollow-sounding wood or frass (termite droppings), are essential for early detection and mitigation.

Maintenance plays a pivotal role in sustaining both rot and pest resistance. Ensure proper drainage around the playground to minimize standing water, which accelerates rot. Trim vegetation and remove debris to reduce habitats for pests. For existing structures, monitor vulnerable areas like joints and crevices, where moisture and pests are likely to accumulate. If damage is detected, promptly replace affected components to prevent further deterioration. By combining proactive material selection, strategic treatments, and diligent upkeep, wooden playgrounds can remain safe, functional, and aesthetically pleasing for decades.

Exploring Muir Woods: Time Needed for the Perfect Hiking Experience

You may want to see also

Frequently asked questions

Wood playgrounds can last between 15 to 25 years with proper maintenance and care, depending on the quality of materials and environmental conditions.

Factors include weather exposure, type of wood used, frequency of maintenance, and the level of usage. Treated wood and regular upkeep can significantly extend its life.

Yes, wood playgrounds can outlast plastic or metal ones if made from durable, treated wood and maintained properly. However, plastic and metal may require less maintenance.

A wood playground should be inspected at least twice a year for signs of wear, rot, or damage. Monthly visual checks are also recommended for high-traffic areas.

Regular maintenance includes cleaning, re-staining or sealing the wood every 1-2 years, tightening hardware, and replacing damaged parts promptly to prevent further deterioration.