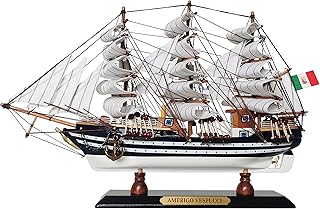

Wooden ships, with their rich maritime history and timeless craftsmanship, have long fascinated both historians and enthusiasts alike. The durability of these vessels is a testament to the skill of their builders and the resilience of the materials used. While the lifespan of a wooden ship can vary significantly depending on factors such as the type of wood, construction techniques, maintenance, and environmental conditions, many have endured for centuries. Properly maintained wooden ships, such as those preserved in museums or still in use for recreational purposes, can last hundreds of years, with some historic examples remaining seaworthy after more than two centuries. However, exposure to harsh elements like saltwater, humidity, and marine organisms can accelerate deterioration, making regular care and preservation efforts essential to extending their longevity. Understanding how long wooden ships last not only highlights their historical significance but also underscores the importance of conservation in safeguarding these maritime treasures for future generations.

Explore related products

What You'll Learn

Maintenance Impact on Durability

Wooden ships, when properly maintained, can endure for centuries, as evidenced by historic vessels like the *Mary Rose* and *USS Constitution*. However, their longevity hinges critically on the rigor and frequency of maintenance. Without consistent care, wood is susceptible to rot, insect damage, and structural degradation, drastically shortening a ship’s lifespan. The key lies in understanding that maintenance is not merely reactive but a proactive strategy to preserve integrity and functionality.

Consider the process of regular inspections, a cornerstone of effective maintenance. At least twice annually, examine the hull for signs of wear, such as cracks, splintering, or discoloration, which often indicate moisture intrusion or fungal growth. Use a moisture meter to detect levels above 20%, as this threshold accelerates decay. Pair inspections with immediate repairs, replacing compromised planks or applying epoxy resins to seal gaps. Neglecting these steps can lead to irreversible damage, reducing a ship’s lifespan from centuries to mere decades.

Coatings play a pivotal role in durability, acting as a barrier against water, UV radiation, and marine organisms. Apply a high-quality marine varnish or epoxy every 12–18 months, ensuring full coverage, especially in high-stress areas like the waterline. For added protection, incorporate antifouling paint on submerged surfaces to prevent barnacle and algae buildup, which can increase drag and foster wood-boring organisms. Skipping these treatments leaves the wood vulnerable, halving its expected lifespan.

Environmental factors also dictate maintenance frequency. Ships in tropical climates require more vigilant care due to higher humidity and temperature, which accelerate rot and insect activity. In such conditions, increase inspections to quarterly and reapply coatings annually. Conversely, ships in drier, cooler regions may need less frequent interventions but should still adhere to a strict schedule. Tailoring maintenance to the environment ensures the ship’s wood remains resilient against localized threats.

Finally, storage and usage patterns significantly impact durability. When not in use, store wooden ships in covered, well-ventilated areas to minimize moisture accumulation. For operational vessels, flush saltwater from the hull after each voyage and allow thorough drying before storage. Incorporate a maintenance log to track repairs, coatings, and inspections, ensuring no critical task is overlooked. By treating maintenance as a disciplined, data-driven practice, wooden ships can defy the odds of time, remaining seaworthy for generations.

Seasoning Wood: Optimal Time for Perfectly Dried Firewood Explained

You may want to see also

Explore related products

$68.95

Type of Wood Used

The longevity of wooden ships hinges significantly on the type of wood used in their construction. Different woods offer varying degrees of durability, resistance to rot, and structural integrity, all of which directly impact a vessel's lifespan. For instance, teak, a dense and oily hardwood, is renowned for its exceptional resistance to water, insects, and fungi, making it a prime choice for shipbuilding. Ships built with teak can last for centuries, as evidenced by the numerous historic vessels still afloat today.

Selecting the right wood is not just about durability; it’s also about the intended use of the ship. For heavy-duty vessels like cargo ships or warships, hardwoods such as oak or mahogany are preferred due to their strength and resilience. Oak, in particular, has been a staple in shipbuilding for millennia, prized for its ability to withstand the stresses of open water. However, for smaller, lighter vessels like sailboats or dinghies, softer woods like cedar or pine may be more suitable, offering ease of construction and lighter weight, though at the cost of reduced longevity.

Environmental factors play a crucial role in determining the lifespan of wooden ships, and the choice of wood must account for these conditions. In tropical climates, where humidity and marine borers are prevalent, woods with natural oils and resins, such as teak or iroko, are ideal. In contrast, ships operating in colder, drier climates may fare well with less naturally resistant woods, provided they are properly treated with preservatives. Regular maintenance, including sealing and painting, can significantly extend the life of any wooden ship, regardless of the wood type.

Modern advancements in wood treatment and preservation techniques have expanded the possibilities for wooden shipbuilding. Pressure-treating wood with chemicals like creosote or copper azole can enhance its resistance to rot and pests, making even less durable woods viable options. Additionally, laminating or layering different types of wood can combine their strengths, creating hybrid materials that offer both structural integrity and longevity. For enthusiasts and builders, understanding these treatments and their applications is key to maximizing the lifespan of a wooden ship.

Ultimately, the type of wood used in a ship’s construction is a critical determinant of its longevity, but it is not the sole factor. Proper design, construction techniques, and ongoing maintenance are equally important. By carefully selecting the right wood for the intended purpose and environment, and by employing modern preservation methods, builders can create wooden ships that endure for generations. Whether crafting a historic replica or a modern vessel, the choice of wood remains a cornerstone of successful shipbuilding.

Transporting Oversized Wood: Practical Tips for Moving Long Lumber Safely

You may want to see also

Explore related products

$37.85 $39.85

Environmental Factors Affecting Lifespan

Wooden ships, marvels of craftsmanship and history, face relentless environmental challenges that dictate their longevity. Among these, moisture stands as the arch-nemesis. Prolonged exposure to water, whether from seawater or freshwater environments, accelerates rot and invites marine borers—tiny organisms that feast on submerged wood. For instance, untreated oak hulls in tropical waters can degrade within 10–15 years, while those in colder, less biologically active regions may endure for decades. To mitigate this, shipbuilders often apply creosote or copper sheathing, but even these measures require regular maintenance. Without vigilant care, moisture transforms a sturdy vessel into a fragile relic.

Beyond water, temperature fluctuations play a silent but destructive role. Extreme heat causes wood to warp and crack, while freezing temperatures can split planks as water trapped within expands. Ships in temperate climates, where seasons shift dramatically, often suffer more structural stress than those in equatorial regions. For example, wooden ships in the Mediterranean, with its mild winters and warm summers, typically outlast those in the Baltic Sea, where ice and frost are common. Shipowners can counteract this by storing vessels in controlled environments during off-seasons or using flexible sealants to minimize wood movement.

The salinity of water is another critical factor, with saltwater being far more corrosive than freshwater. Salt crystals infiltrate wood fibers, weakening their structure and creating pathways for moisture intrusion. Ships operating in brackish or freshwater environments, such as the Great Lakes, often retain their integrity longer than those navigating the open ocean. To combat salinity damage, regular freshwater rinses and anti-corrosive treatments are essential. However, even with these precautions, saltwater ships rarely surpass a century without extensive restoration.

Lastly, biological activity in the water column poses a significant threat. Marine organisms like barnacles, algae, and fungi not only add weight to the hull but also secrete acids that degrade wood. In tropical waters, where biodiversity is highest, wooden ships require biocide coatings and frequent cleaning to prevent colonization. Interestingly, some traditional shipbuilders used naturally resistant woods like teak or incorporated sacrificial layers of less valuable wood to protect the core structure. Modern solutions include ultrasonic antifouling systems, which deter organisms without chemicals, though these are costly and not widely adopted.

In summary, the lifespan of wooden ships is a delicate balance between environmental exposure and human intervention. By understanding and addressing these factors—moisture, temperature, salinity, and biological activity—owners can significantly extend their vessel’s life. Whether through traditional methods or cutting-edge technology, the key lies in proactive, informed maintenance. After all, a wooden ship is not just a mode of transport but a testament to the interplay between nature and human ingenuity.

The Lifespan of Wooden Battleships: A Historical Overview

You may want to see also

Explore related products

Historical Preservation Techniques

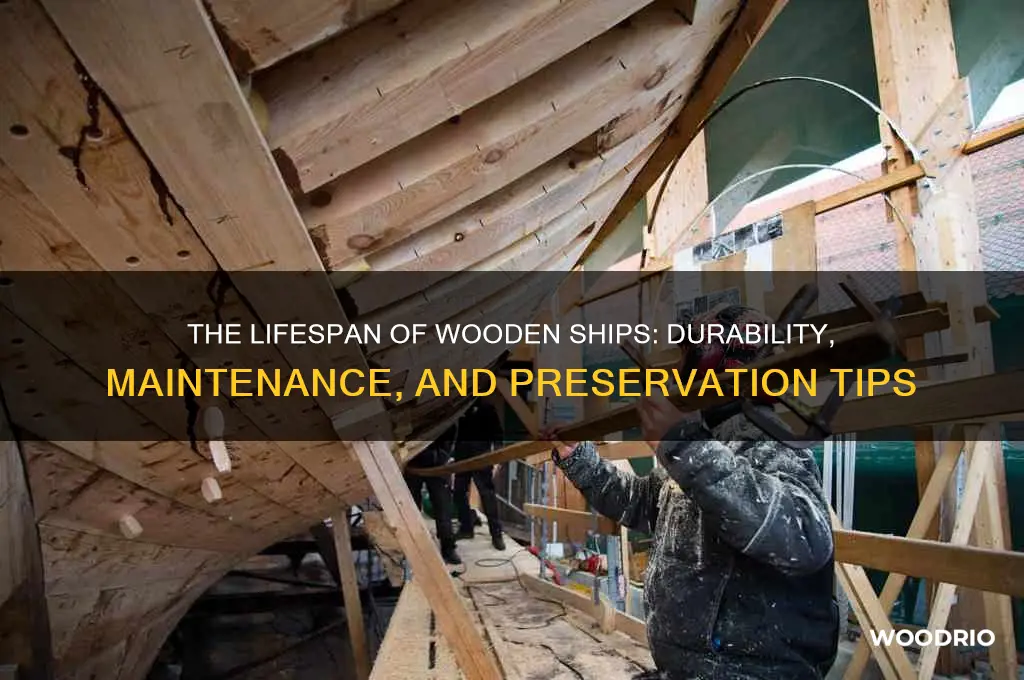

Wooden ships, when exposed to the elements, typically last 50 to 100 years before succumbing to rot, insect damage, and structural degradation. However, historical preservation techniques have allowed some vessels to endure for centuries, becoming invaluable artifacts of maritime history. The Vasa, a Swedish warship that sank in 1628 and was recovered in 1961, is a prime example. Its preservation was achieved through a combination of immediate environmental control and long-term conservation strategies, demonstrating the effectiveness of these methods.

One critical technique in preserving wooden ships is controlled environmental storage. After recovery, vessels must be placed in a climate-controlled environment to prevent further deterioration. For instance, the Vasa was initially sprayed with polyethylene glycol (PEG) to replace the water in its wood cells, a process that took 17 years. This treatment, combined with a humidity-regulated storage facility, halted the degradation process. Modern preservationists often use similar methods, adjusting PEG concentrations (typically 50-80% solutions) based on the wood's condition and the artifact's size.

Another essential practice is regular monitoring and maintenance. Wooden ships require ongoing inspections to detect early signs of decay, insect infestation, or structural weaknesses. For example, the Mary Rose, Henry VIII's flagship raised in 1982, undergoes continuous monitoring for changes in humidity and temperature. Preservation teams use non-invasive techniques like infrared thermography and ultrasonic testing to assess the ship's condition without causing damage. These methods allow for timely interventions, such as localized treatments with fungicides or consolidants, ensuring the ship's longevity.

Traditional craftsmanship also plays a vital role in historical preservation. Skilled shipwrights use age-old techniques to repair and reconstruct damaged sections of wooden ships. For instance, the restoration of the USS Constitution involved replacing deteriorated oak planks with wood sourced from the same type of trees used in its original construction. This approach maintains the ship's authenticity while ensuring structural integrity. Apprenticeship programs and documentation of traditional methods are crucial for passing this knowledge to future generations.

Finally, public engagement and education are integral to the preservation of wooden ships. Museums and heritage sites often involve the public in conservation efforts, fostering a sense of stewardship. The Batavia Shipwreck in Australia, for example, features interactive exhibits and live conservation labs where visitors can observe preservation techniques in action. By raising awareness and securing funding through public interest, these initiatives ensure that historical vessels continue to inspire and educate for years to come.

Through a combination of scientific methods, traditional skills, and community involvement, historical preservation techniques transform fragile wooden ships into enduring testaments to human ingenuity and history.

John Wooden's Legendary Coaching Tenure at UC: A Timeline

You may want to see also

Explore related products

Modern Construction vs. Traditional Methods

Wooden ships have historically been marvels of durability, with some ancient vessels surviving centuries. The *Mary Rose*, Henry VIII’s flagship, lay underwater for 437 years before its recovery, its hull remarkably intact due to anaerobic conditions. This raises the question: how do modern construction methods compare to traditional techniques in ensuring longevity? While traditional shipbuilding relied on hand-selected old-growth timber and craftsmanship, modern methods incorporate treated wood, composites, and advanced sealants. Yet, the lifespan of a wooden ship hinges not just on materials but on maintenance, environment, and purpose.

Consider the construction process. Traditional methods prioritized natural durability, using dense hardwoods like oak or teak, which resist rot and pests. Shipwrights employed techniques like caulking with natural fibers and pitch, which, while effective, required frequent upkeep. Modern construction, however, often uses pressure-treated wood infused with preservatives like copper azole or creosote, extending lifespan by decades. For instance, treated pine can last 40+ years in marine environments, compared to untreated wood’s 5–10 years. Yet, over-reliance on chemicals can lead to environmental concerns, a caution for builders.

Maintenance is another critical factor. Traditional ships demanded annual inspections, re-caulking, and scraping to remove biofouling. Modern vessels, equipped with anti-fouling paints and sacrificial anodes, reduce corrosion and marine growth, cutting maintenance frequency by half. However, these innovations come with trade-offs. Anti-fouling paints, while effective, contain biocides like copper oxide, which can leach into ecosystems. Balancing longevity with sustainability requires careful material selection and adherence to regulations like the International Maritime Organization’s guidelines.

Purpose and environment also dictate lifespan. Traditional fishing boats, exposed to harsh conditions, rarely exceed 20–30 years without extensive repairs. In contrast, modern yachts, built with lightweight composites and epoxy resins, can last 50+ years with proper care. For example, epoxy-coated wooden hulls are 3–5 times more resistant to moisture than traditional tar-based coatings. Yet, even modern ships face challenges: UV exposure degrades fiberglass, and delamination can occur if resins are improperly applied. Regular inspections and proactive repairs remain essential, regardless of method.

In conclusion, while modern construction offers advantages in durability and maintenance, traditional methods hold value in their simplicity and sustainability. Builders must weigh factors like material cost, environmental impact, and intended use. For instance, a recreational sailboat might benefit from modern composites, while a heritage vessel could prioritize traditional techniques for authenticity. Ultimately, the lifespan of a wooden ship is a testament to both the method of its making and the care it receives over time.

The Fate of the Largest Wooden Ship: A Brief History

You may want to see also

Frequently asked questions

With proper maintenance, a wooden ship can last for several centuries. Examples like the *Vasa* (1628) and *Mary Rose* (1511) have survived for hundreds of years, though they were preserved after sinking.

Factors include the type of wood used, exposure to water and weather, maintenance frequency, marine borer activity, and the ship's usage (e.g., frequent sailing vs. stationary display).

Wooden ships can last as long or longer than steel ships if properly maintained and protected from rot, pests, and environmental damage. Steel ships, however, are generally more durable in harsh marine conditions.

Hardwoods like oak, teak, and cedar are more durable and resistant to rot, extending a ship's lifespan. Softer woods may deteriorate faster without proper treatment or protection.

Regular maintenance includes caulking, painting, treating wood with preservatives, monitoring for rot or pests, and storing the ship in a dry, covered area when not in use.