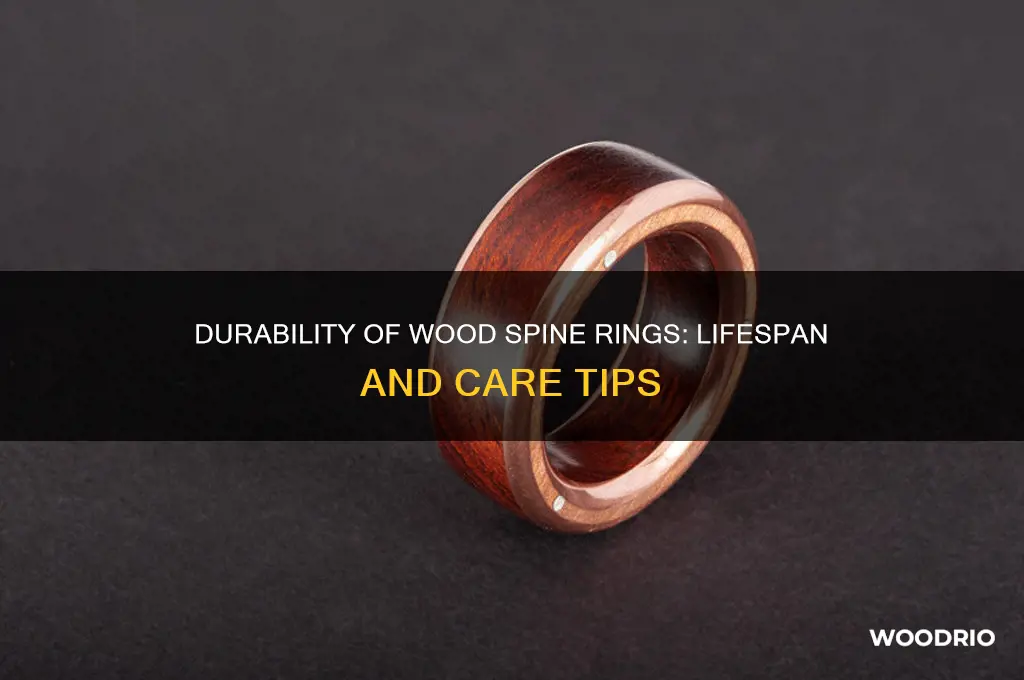

Wood spine rings, also known as wooden spinal implants or wood dowel spinal fusion devices, are innovative medical solutions used in spinal surgeries to promote bone fusion and stabilize the spine. When considering their longevity, several factors come into play, including the type of wood used, the patient’s lifestyle, and the body’s natural response to the implant. Typically, wood spine rings are designed to be bioabsorbable, meaning they gradually break down and are absorbed by the body over time, allowing new bone to grow and replace the implant. While the exact duration varies, these rings generally last between 1 to 3 years before being fully integrated or replaced by natural bone tissue. However, their effectiveness and durability depend on proper surgical placement and the patient’s overall health, making them a promising yet specialized option in spinal care.

Explore related products

What You'll Learn

Factors affecting durability of wood spine rings

Wood spine rings, crafted from natural materials, are subject to various factors that influence their longevity. One critical aspect is the type of wood used. Hardwoods like oak, maple, or walnut inherently offer greater durability compared to softer woods such as pine or cedar. Harder woods resist wear, moisture, and physical stress more effectively, ensuring the ring remains intact over time. For instance, a ring made from African blackwood can last decades with proper care, while a pine ring may show signs of deterioration within a few years.

Environmental conditions play a pivotal role in the lifespan of wood spine rings. Prolonged exposure to moisture or humidity can cause warping, cracking, or mold growth. Rings worn in dry climates fare better, but even then, sudden temperature fluctuations can stress the wood fibers. To mitigate this, apply a thin coat of natural oil (e.g., linseed or tung oil) every 3–6 months to seal the wood and maintain its integrity. Avoid wearing wood rings while swimming, showering, or during activities involving water.

The design and craftsmanship of the ring also significantly impact its durability. Thicker bands and reinforced joints reduce the risk of breakage, while intricate carvings or thin sections are more prone to damage. Handcrafted rings often outlast mass-produced ones due to attention to detail and quality control. For example, a ring with a smooth, polished finish is less likely to splinter compared to one with rough edges. Always inspect the ring for weak points and handle it with care to prevent accidental damage.

Wear and tear from daily use is another factor to consider. Wood spine rings worn frequently, especially during physical activities, will degrade faster than those reserved for occasional use. To extend their life, rotate between multiple rings or remove them during tasks that involve heavy lifting, gardening, or sports. Additionally, storing the ring in a protective case when not in use can shield it from scratches and impacts.

Lastly, maintenance practices are essential for preserving the ring’s durability. Regular cleaning with a soft, dry cloth removes dirt and oils that can degrade the wood over time. Avoid harsh chemicals or abrasive cleaners, as they can strip the wood’s natural oils and cause drying. For rings with inlays or embellishments, ensure these materials are compatible with wood care products to prevent discoloration or damage. With mindful care, a well-crafted wood spine ring can remain a cherished accessory for years, blending natural beauty with lasting functionality.

Drying Time for Pressure Treated Wood: What to Expect

You may want to see also

Explore related products

Average lifespan of untreated wood spine rings

Wood spine rings, crafted from untreated wood, are a unique and natural accessory choice, but their lifespan is inherently limited by the material's organic nature. Unlike metal or synthetic materials, wood is susceptible to environmental factors such as moisture, temperature fluctuations, and physical wear. These elements accelerate degradation, making the average lifespan of untreated wood spine rings relatively short compared to other materials. Typically, without protective treatments, these rings may last anywhere from 6 months to 2 years, depending on usage and care.

To maximize durability, consider the type of wood used. Harder woods like oak or maple tend to outlast softer varieties such as pine or cedar. However, even with harder woods, the absence of treatment leaves the material vulnerable. For instance, exposure to water—whether from rain, sweat, or accidental submersion—can cause swelling, warping, or cracking. Similarly, prolonged sunlight can lead to fading and brittleness. If you wear your wood spine ring daily, especially in harsh conditions, expect it to wear out faster than if it’s reserved for occasional use.

Practical tips can extend the life of untreated wood spine rings. Avoid wearing them during activities that expose them to moisture, such as swimming or washing dishes. Store the ring in a dry, cool place when not in use, and consider applying a natural sealant like beeswax or linseed oil to provide minimal protection without altering the wood’s appearance. However, these measures only delay the inevitable—untreated wood will eventually deteriorate, and the ring will need replacement.

Comparatively, treated wood spine rings or those made from alternative materials offer significantly longer lifespans. For example, rings treated with waterproof coatings or made from metals like titanium can last decades. While untreated wood rings have a shorter lifespan, their appeal lies in their natural aesthetic and biodegradable nature. If sustainability and eco-friendliness are priorities, the temporary nature of untreated wood rings may align with your values, despite their limited durability.

In conclusion, the average lifespan of untreated wood spine rings is a trade-off between natural beauty and material fragility. By understanding the factors that influence their durability and implementing simple care practices, you can enjoy these rings for their intended lifespan. For those seeking longevity, exploring treated or alternative materials may be a more practical choice, but untreated wood remains a charming, if fleeting, option for the environmentally conscious wearer.

Oak Wood Petrification: Fire Risks and Timeframe Explained

You may want to see also

Explore related products

Impact of finishing on wood ring longevity

Wood spine rings, crafted from natural materials, inherently face challenges in durability due to wood’s susceptibility to moisture, UV light, and physical wear. Finishing acts as a protective barrier, significantly influencing how long these rings remain functional and aesthetically pleasing. Without proper finishing, wood rings can warp, crack, or degrade within months, especially in humid or outdoor environments. Conversely, a well-applied finish can extend their lifespan to several years, even decades, depending on the type and maintenance.

Analytical Perspective:

The effectiveness of a finish depends on its ability to seal the wood’s pores while allowing it to breathe. Oil-based finishes, like tung or linseed oil, penetrate deeply, enhancing natural grain but offering moderate protection. They require reapplication every 6–12 months, making them ideal for low-wear rings. Polyurethane finishes, on the other hand, create a hard, waterproof surface, providing superior durability but potentially obscuring the wood’s texture. Water-based finishes strike a balance, drying quickly and offering UV resistance, though they may need touch-ups every 1–2 years.

Instructive Steps:

To maximize longevity, follow these finishing steps:

- Sand the Ring: Start with 120-grit sandpaper, progressing to 220-grit for a smooth surface. Remove all dust with a tack cloth.

- Apply the First Coat: Use a brush or cloth to apply a thin, even layer of your chosen finish. Allow 24 hours to dry.

- Sand Lightly: Between coats, lightly sand with 400-grit paper to ensure adhesion. Wipe clean.

- Repeat Coats: Apply 3–5 coats, depending on the finish. Oil finishes may require more layers for adequate protection.

- Cure Properly: Let the final coat cure for 72 hours before wearing.

Comparative Insight:

While oil finishes are beginner-friendly and enhance wood’s natural beauty, they fall short in high-moisture environments. Epoxy resin finishes, though labor-intensive, provide the highest protection, encapsulating the wood entirely. However, they can yellow over time and require precise application to avoid bubbles. For daily-wear rings, a hybrid approach—such as a base coat of oil followed by a polyurethane topcoat—combines aesthetic appeal with durability.

Practical Tips:

Avoid exposing finished wood rings to prolonged water contact, harsh chemicals, or extreme temperatures. Reapply finishes annually or as needed, especially for oil-based coatings. Store rings in a dry, cool place when not in use. For minor scratches, lightly sand the area and apply a touch-up coat. With proper care, even delicate wood spine rings can withstand years of wear, proving that the right finish is not just a cosmetic choice but a critical factor in their longevity.

Petrifying Wood: Understanding the Timeframe for Fossilization Process

You may want to see also

Explore related products

Maintenance tips to extend wood ring life

Wood spine rings, crafted from natural materials, are susceptible to environmental factors that can shorten their lifespan. Moisture, in particular, is a silent adversary, causing warping, cracking, or mold growth. To combat this, store your ring in a dry environment, ideally with a humidity level below 50%. Consider using silica gel packets in your jewelry box to absorb excess moisture, replacing them every 3-4 weeks for optimal effectiveness.

The finish applied to your wood ring acts as a protective barrier against wear and tear. Over time, this finish can degrade, leaving the wood vulnerable. Reapply a thin coat of natural oil, such as tung or linseed oil, every 6-12 months to replenish the protective layer. Avoid using chemical-based polishes, as they can damage the wood’s natural fibers. For best results, apply the oil with a soft cloth, let it penetrate for 15-20 minutes, and buff gently to remove excess.

Daily wear exposes wood rings to dirt, oils, and chemicals that accumulate on the surface. Clean your ring weekly with a mild soap and lukewarm water solution, using a soft-bristled brush to gently scrub away debris. Avoid submerging the ring for prolonged periods, as this can cause the wood to swell or crack. After cleaning, pat the ring dry with a microfiber cloth and allow it to air-dry completely before wearing.

Despite careful maintenance, wood rings may sustain minor damage over time. Small scratches can be buffed out with fine-grit sandpaper (220-grit or higher), followed by a reapplication of oil to restore the finish. For deeper cracks or structural issues, consult a professional woodworker who specializes in jewelry repair. Attempting complex repairs without expertise can exacerbate the damage, so prioritize professional intervention when necessary.

Finally, proactive measures can significantly extend the life of your wood spine ring. Remove it before engaging in activities that expose it to harsh chemicals, extreme temperatures, or physical impact, such as swimming, gardening, or weightlifting. When not in use, store the ring in a fabric-lined box or pouch to prevent scratches and dust accumulation. By integrating these maintenance practices into your routine, you can preserve the beauty and integrity of your wood ring for years to come.

Oven Drying Wood: Optimal Time for Perfectly Seasoned Wood Pieces

You may want to see also

Explore related products

Comparison with other materials' durability

Wood spine rings, while unique and aesthetically striking, face durability challenges when compared to other materials. Their lifespan hinges on factors like wood type, finish, and wear conditions. Hardwoods like ebony or teak, when properly sealed, can last 5–10 years with moderate use. Softer woods like pine or cedar, however, may show signs of wear within 1–3 years, especially with exposure to moisture or friction. This variability underscores the importance of material selection and maintenance.

In contrast, metal rings—whether stainless steel, titanium, or gold—offer superior durability, often lasting decades with minimal degradation. Stainless steel, for instance, resists corrosion and scratches, making it ideal for daily wear. Titanium, while lighter, boasts comparable strength and longevity. Even softer metals like gold, when alloyed, can endure years of use, though they may require occasional refinishing. The key advantage here is consistency: metals provide a predictable lifespan that wood cannot match.

Ceramic and silicone rings present another comparison point. Ceramic rings are lightweight and scratch-resistant but brittle, prone to shattering under impact. Their lifespan typically ranges from 3–7 years, depending on activity level. Silicone, on the other hand, is flexible and durable, often lasting 5–10 years, though it may show surface wear over time. Both materials excel in specific use cases—ceramic for its sleek look, silicone for its comfort—but neither rivals metal’s all-around durability.

For those prioritizing sustainability, wood spine rings offer an eco-friendly alternative, but their shorter lifespan may require more frequent replacements. Metals, while durable, often involve resource-intensive mining processes. Ceramic and silicone, though longer-lasting than wood, are less biodegradable. Thus, the choice between materials becomes a balance of durability, environmental impact, and personal preference.

Practical tips for extending the life of wood spine rings include avoiding water exposure, removing the ring during physical activities, and reapplying sealant annually. For those seeking longevity above all, metal remains the clear winner. However, for those drawn to wood’s natural beauty, understanding its limitations and embracing its transient nature can make the choice equally rewarding.

Wood Sealer Drying Time: Factors Affecting Cure and Dry Time

You may want to see also

Frequently asked questions

Wood spine rings can last several years with proper care, but their lifespan varies depending on factors like wood type, wear frequency, and exposure to moisture or chemicals.

While wood spine rings are durable, they are not indestructible. With minimal wear and careful maintenance, they can last decades, but they may eventually show signs of wear or require refinishing.

Prolonged exposure to moisture can cause wood spine rings to warp, crack, or degrade. Avoid wearing them in water or humid conditions to extend their lifespan.

To prolong the life of your wood spine ring, avoid exposing it to water, chemicals, or harsh environments. Regularly apply a protective finish and store it in a dry place when not in use.