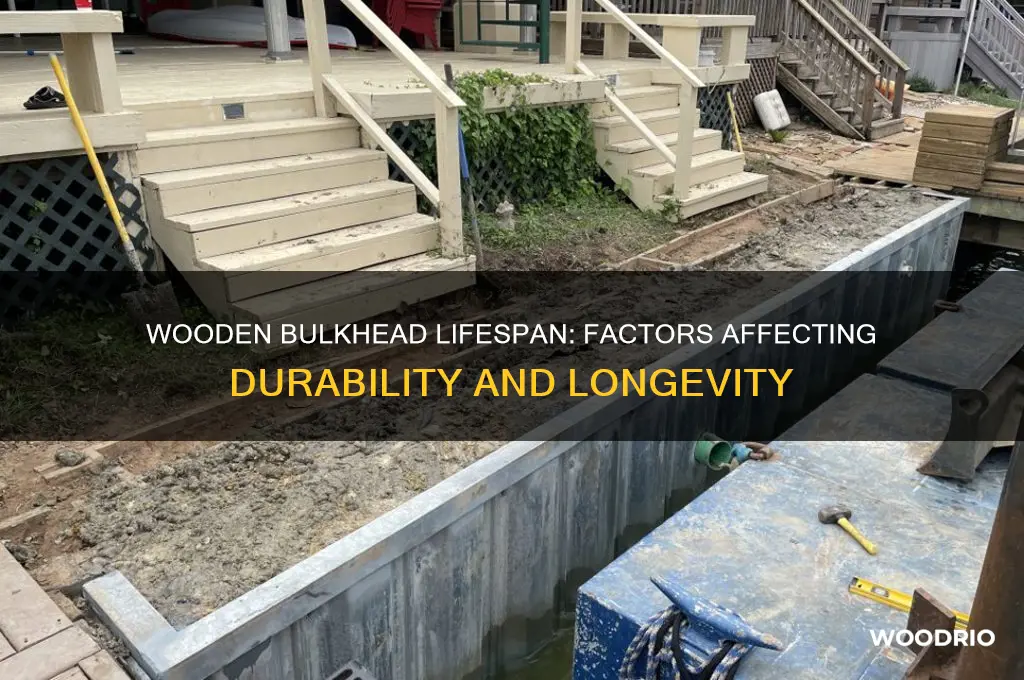

Wooden bulkheads, commonly used in coastal and waterfront structures to prevent erosion and provide stability, have a lifespan that varies significantly based on environmental conditions, maintenance, and the type of wood used. Typically, untreated wooden bulkheads last between 10 to 20 years, while pressure-treated or naturally rot-resistant woods, such as cedar or cypress, can endure for 20 to 40 years or more. Factors like exposure to saltwater, tidal fluctuations, marine borers, and regular maintenance play crucial roles in determining longevity. Proper installation, routine inspections, and timely repairs can extend their lifespan, making wooden bulkheads a viable but temporary solution for shoreline protection.

Explore related products

What You'll Learn

Factors affecting bulkhead lifespan

Wooden bulkheads, essential for shoreline protection and erosion control, face a myriad of environmental and structural challenges that dictate their longevity. One critical factor is the type of wood used. Pressure-treated southern yellow pine, a common choice, can last 20 to 40 years, while more durable options like cedar or redwood may extend lifespan to 40 to 50 years. However, these estimates are not set in stone; they hinge on several variables that can either accelerate deterioration or preserve integrity.

Exposure to Water and Moisture: Prolonged contact with water is a wooden bulkhead’s greatest adversary. Tidal fluctuations, wave action, and submersion in saltwater create conditions ripe for rot, decay, and marine borer infestation. Bulkheads in brackish or saltwater environments typically degrade faster than those in freshwater settings. To mitigate this, ensure proper drainage systems are in place and consider installing a protective barrier, such as a geotextile fabric, between the soil and wood. Regular inspections for signs of moisture damage are crucial, especially after storms or high-water events.

Soil Conditions and Backfill Material: The soil surrounding a bulkhead plays a pivotal role in its stability and lifespan. Sandy or loose soils offer less support, increasing the risk of shifting or leaning. Clay-rich soils, while more stable, can retain moisture, promoting rot at the base. Backfilling with clean, compacted gravel or sand can improve drainage and reduce hydrostatic pressure. Additionally, incorporating a filter fabric can prevent soil migration and maintain structural integrity.

Maintenance and Protective Treatments: Regular maintenance is non-negotiable for maximizing a wooden bulkhead’s lifespan. Annual inspections should include checking for cracks, splinters, and signs of pest activity. Reapplying water-repellent sealants or preservatives every 2 to 3 years can significantly slow decay. For bulkheads in high-risk areas, consider professional treatments like creosote or copper-based preservatives, which offer enhanced protection against fungi, insects, and moisture. Neglecting maintenance can halve a bulkhead’s expected lifespan, turning a 30-year structure into a 15-year liability.

Environmental Stressors and Human Activity: External forces, such as boat wakes, ice movement, and storm surges, exert constant pressure on bulkheads. In high-traffic areas, installing protective measures like fenders or buffer zones can absorb impacts. Climate change, with its rising sea levels and increased storm frequency, poses an emerging threat. Proactive measures, such as elevating bulkheads or incorporating flexible materials, can future-proof structures against these challenges.

Understanding these factors empowers property owners to make informed decisions, balancing initial investment with long-term durability. While wooden bulkheads offer a cost-effective solution, their lifespan is a delicate interplay of material choice, environmental conditions, and diligent care. By addressing these variables head-on, one can ensure these structures remain effective for decades, safeguarding both land and investment.

Wooden Ships: Unraveling the Mystery of Their Longevity and Decay

You may want to see also

Explore related products

Maintenance tips for longevity

Wooden bulkheads, when properly maintained, can last 20 to 30 years or more, but their lifespan hinges on consistent care. Exposure to water, soil erosion, and pests are the primary culprits of deterioration. Regular inspections are your first line of defense. At least twice a year, examine the bulkhead for signs of rot, cracks, or shifting. Pay close attention to areas where wood meets water or soil, as these are most vulnerable. Early detection of issues can prevent costly repairs or premature replacement.

One of the most effective ways to extend the life of a wooden bulkhead is through proper sealing and treatment. Apply a marine-grade sealant or wood preservative every 2–3 years, depending on exposure levels. For bulkheads in saltwater environments, use a copper-based preservative to combat marine borers. Freshwater bulkheads benefit from creosote or eco-friendly alternatives like borate-based treatments. Always follow manufacturer guidelines for application rates—typically 1 gallon of sealant covers 150–200 square feet. Reapplication should occur when water no longer beads on the surface.

Erosion control is another critical aspect of bulkhead maintenance. Install riprap (large stones) or geotextile fabric at the base to stabilize the soil and absorb wave energy. For added protection, consider planting native vegetation along the shoreline. Plants like grasses or shrubs help anchor soil and reduce runoff. Avoid heavy landscaping near the bulkhead, as excessive weight can cause settling or leaning. If erosion is severe, consult a marine engineer to assess the need for structural reinforcements.

Pest management is often overlooked but essential for longevity. Termites and marine borers can silently weaken wooden structures. To deter termites, maintain a 6-inch gap between soil and wood, and treat the area with termiticide annually. For marine borers, ensure the wood is fully submerged or consistently treated with preservatives. Regularly remove barnacles and algae, as they can trap moisture and accelerate decay. Pressure washing once a year can help keep the surface clean and inspectable.

Finally, monitor environmental factors that accelerate wear. Fluctuating water levels can stress joints and fasteners, so ensure bolts and brackets are tightened annually. After storms, inspect for damage and repair immediately. If the bulkhead is in a high-traffic area, install protective barriers to prevent impact damage. By combining proactive inspections, targeted treatments, and environmental management, you can maximize the lifespan of your wooden bulkhead and avoid premature failure.

Wood Glue Setting Time: How Long Does It Take to Dry?

You may want to see also

Explore related products

Wood type durability comparison

The lifespan of wooden bulkheads hinges largely on the type of wood chosen, with each species offering distinct durability characteristics. Hardwoods like oak and teak are renowned for their resilience, often lasting 30–50 years or more in marine environments due to their natural resistance to rot, insects, and moisture. These dense woods contain high levels of tannins and oils, which act as natural preservatives, making them ideal for bulkheads exposed to harsh conditions. In contrast, softwoods such as pine and cedar, while more affordable, typically last 10–20 years without treatment. Cedar, however, stands out among softwoods due to its inherent resistance to decay, thanks to natural oils that repel insects and fungi.

When selecting wood for bulkheads, consider the treatment and maintenance requirements of each type. Pressure-treated pine, for instance, can extend its lifespan to 20–30 years by infusing preservatives like chromated copper arsenate (CCA) into the wood fibers. This process makes it more durable but requires careful handling due to potential chemical leaching. Alternatively, tropical hardwoods like ipe and mahogany offer exceptional durability with minimal treatment, often lasting 40–60 years, but their high cost and environmental concerns (e.g., deforestation) may limit their use. For those seeking eco-friendly options, thermo-treated wood, which is heat-treated to improve durability, can last 25–30 years and is free from chemical additives.

Environmental factors play a critical role in wood durability, regardless of type. Bulkheads in saltwater environments face accelerated degradation due to corrosion and marine borers, while freshwater settings pose risks of fungal decay. Wood density is a key predictor of longevity; denser woods like oak (0.75 g/cm³) outperform less dense options like cedar (0.45 g/cm³) in challenging conditions. To maximize lifespan, apply marine-grade sealants every 2–3 years and inspect for cracks or damage annually. For bulkheads in high-moisture areas, consider installing a sacrificial layer of treated wood at the base to prolong the structure’s overall life.

Finally, cost-benefit analysis should guide your wood selection. While exotic hardwoods offer superior durability, their price tag (often $5–$10 per board foot) may outweigh the benefits for short-term projects. Softwoods, priced at $1–$3 per board foot, are budget-friendly but require more frequent replacement. For a balance of durability and affordability, redwood (lasting 20–30 years) or pressure-treated fir (15–25 years) are viable options. Pairing mid-range woods with proactive maintenance, such as regular cleaning and resealing, can yield results comparable to premium choices at a fraction of the cost. Ultimately, the right wood type depends on your budget, environmental exposure, and willingness to maintain the bulkhead over time.

Composite Lumber vs. Wood: Which Material Offers Longer Durability?

You may want to see also

Explore related products

Environmental impact on decay

Wooden bulkheads, essential for shoreline protection and erosion control, face relentless environmental forces that dictate their lifespan. Among these, decay stands as a primary adversary, accelerated by factors like moisture, temperature, and biological activity. Understanding these environmental impacts is crucial for predicting longevity and implementing mitigation strategies.

Moisture: The Silent Destroyer

Water is the arch-nemesis of wood, permeating fibers and creating an ideal habitat for decay-causing fungi and bacteria. Prolonged exposure to saltwater, common in coastal bulkheads, exacerbates this due to its corrosive chloride content. Studies show that untreated wooden bulkheads in saltwater environments can deteriorate within 5–10 years, while freshwater counterparts may last 10–15 years. To combat this, consider pressure-treated wood infused with preservatives like chromated copper arsenate (CCA), which can extend lifespan by 20–40 years. Alternatively, apply marine-grade sealants annually to create a moisture barrier, reducing absorption by up to 90%.

Temperature Fluctuations: A Hidden Stress Factor

Extreme temperature swings cause wood to expand and contract, weakening its structure over time. In regions with freezing winters, ice formation can exacerbate cracking, while scorching summers accelerate drying and warping. For instance, bulkheads in temperate climates like the Pacific Northwest may outlast those in the Gulf Coast due to milder temperature variations. To mitigate, install ventilation gaps between planks to reduce thermal stress, and opt for denser hardwoods like cedar or cypress, which naturally resist splitting.

Biological Threats: Microorganisms and Marine Life

Fungi, termites, and marine borers like shipworms thrive in damp, nutrient-rich wood, digesting cellulose and lignin that bind fibers together. In tropical waters, shipworms can render untreated bulkheads structurally unsound within 3–5 years. To deter these pests, embed wood with boron-based preservatives, which are toxic to wood-boring organisms but environmentally safer than CCA. Additionally, encasing the submerged portion of the bulkhead in a geotextile fabric can block borer access while allowing water flow.

Soil and Water Chemistry: The Unseen Corroders

Acidic or alkaline soil and water can leach preservatives from treated wood, hastening decay. For example, bulkheads in acidic peat soils (pH < 5.0) may lose 30–50% of their preservative efficacy within 5 years. Test soil pH and, if necessary, neutralize acidity with lime applications. In areas with high tannin content, such as near marshes, use vinyl or composite materials, which are impervious to chemical degradation.

Practical Takeaways for Longevity

To maximize the lifespan of wooden bulkheads, adopt a multi-pronged approach: select preservative-treated wood, apply protective coatings, and monitor environmental conditions regularly. For coastal installations, elevate the bulkhead slightly above the waterline to minimize submersion time. Finally, schedule biennial inspections to detect early signs of decay, such as splintering or fungal growth, and address them promptly. By proactively managing environmental impacts, you can ensure bulkheads remain functional for decades rather than years.

Durability of Wood Under Shingles: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Signs of bulkhead deterioration

Wooden bulkheads, while durable, are not immune to the ravages of time and environment. Understanding the signs of deterioration is crucial for timely maintenance and repair. One of the earliest indicators is visible cracking or splitting in the wood. These cracks often start small but can quickly expand due to water infiltration, temperature fluctuations, or structural stress. Inspect bulkheads seasonally, focusing on areas where wood meets soil or water, as these are prime spots for initial damage.

Another telltale sign is rot or decay, which manifests as soft, spongy, or discolored wood. Rot typically occurs in areas with prolonged moisture exposure, such as near waterlines or in poorly drained soil. To test for rot, press a screwdriver into the wood—if it penetrates easily, the wood is compromised. Addressing rot early is essential, as it weakens the bulkhead’s structural integrity and can lead to collapse if left unchecked.

Leaning or shifting bulkheads are a red flag that should never be ignored. This often indicates soil erosion behind the structure or compromised foundation supports. If you notice a bulkhead tilting, measure its deviation from vertical using a level or plumb line. A lean of more than 5 degrees warrants immediate professional inspection, as it poses a risk of failure, especially during heavy rains or flooding.

Finally, pest infestations, particularly from termites or carpenter ants, can accelerate bulkhead deterioration. Look for small holes, sawdust-like frass, or hollow-sounding wood, which are signs of active infestations. Regularly treat wooden bulkheads with EPA-approved pesticides or consider installing physical barriers like metal shields to deter pests. Combining preventive measures with routine inspections can significantly extend the lifespan of wooden bulkheads, often from 20 to 50 years, depending on maintenance and environmental conditions.

Exploring the Lifespan of Wood Elves in Dungeons & Dragons

You may want to see also

Frequently asked questions

Wooden bulkheads typically last 15 to 25 years, depending on factors like wood type, maintenance, exposure to moisture, and environmental conditions.

Factors like prolonged exposure to water, lack of proper sealing or treatment, insect damage, and soil erosion can significantly shorten the lifespan of wooden bulkheads.

Yes, regular maintenance such as sealing, staining, inspecting for damage, and addressing issues promptly can extend the life of wooden bulkheads by several years.

Yes, alternatives like vinyl, composite, or concrete bulkheads can last 30 to 50 years or more, offering greater durability and lower maintenance compared to wood.