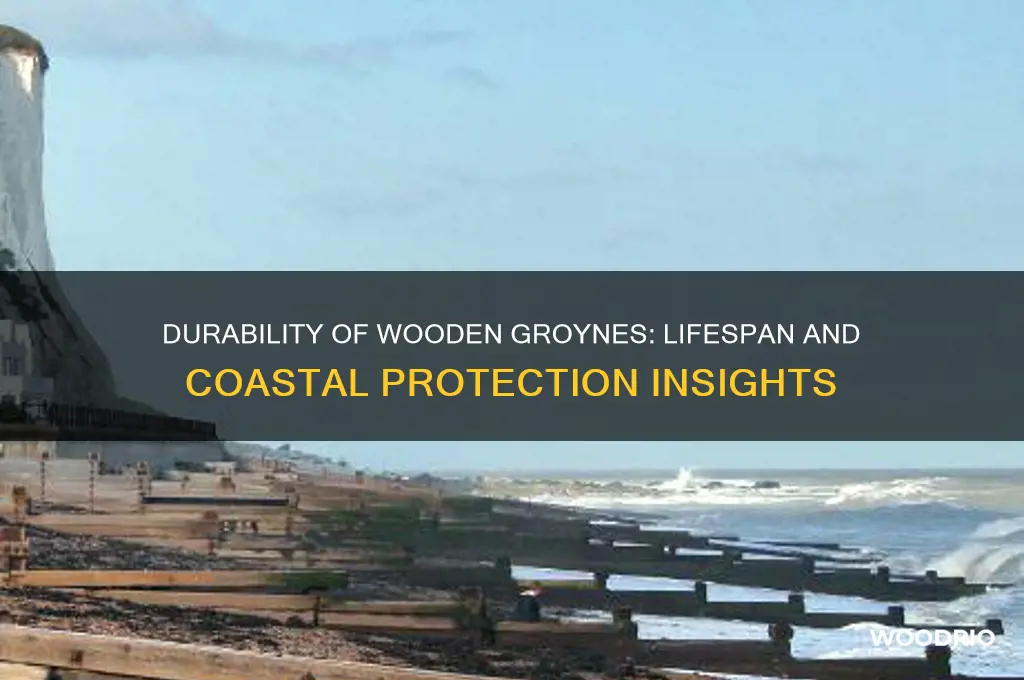

Wooden groynes, commonly used in coastal management to prevent erosion and stabilize shorelines, have a lifespan that varies significantly depending on environmental conditions, maintenance practices, and the type of wood used. Typically, untreated wooden groynes last between 10 to 20 years, while those treated with preservatives can endure for 25 to 40 years or more. Factors such as exposure to saltwater, wave action, tidal fluctuations, and biological degradation from marine organisms play a critical role in their durability. Regular maintenance, including repairs and re-treatment, can extend their life, but eventually, they will require replacement due to structural weakening and deterioration. Understanding their longevity is essential for effective coastal planning and sustainable management strategies.

| Characteristics | Values |

|---|---|

| Average Lifespan | 10-20 years |

| Factors Affecting Lifespan | |

| - Timber Type | Hardwoods (e.g., oak, azobé) last longer than softwoods (e.g., pine) |

| - Treatment | Pressure-treated timber lasts longer than untreated |

| - Environmental Conditions | Exposure to saltwater, waves, and tides accelerates deterioration |

| - Maintenance | Regular inspections and repairs can extend lifespan |

| Common Causes of Failure | |

| - Rot and Decay | Fungal growth due to moisture absorption |

| - Insect Damage | Marine borers and termites |

| - Physical Wear | Abrasion from sand, waves, and debris |

| Comparative Lifespan | |

| - Concrete Groynes | 30-50 years |

| - Rock Armour | 50+ years |

| Cost Considerations | Wooden groynes are generally cheaper to install but may require more frequent replacement |

| Environmental Impact | Biodegradable but may release treatment chemicals into the environment |

| Latest Research (as of 2023) | Ongoing studies explore more durable timber treatments and alternative materials to extend lifespan |

Explore related products

What You'll Learn

Material Quality Impact

The lifespan of wooden groynes is significantly influenced by the quality of the timber used. High-grade, durable hardwoods like oak or greenheart can endure for 20 to 30 years, while lower-quality softwoods, such as pine, may deteriorate within 5 to 10 years. This disparity underscores the critical role material selection plays in groyne longevity. For coastal engineers and planners, investing in premium timber is not merely a cost but a strategic decision to minimize maintenance and replacement frequency.

Consider the treatment processes applied to the wood, as these directly impact its resilience. Pressure-treated timber, infused with preservatives like creosote or copper azole, can resist rot, insect damage, and fungal decay far longer than untreated alternatives. For instance, creosote-treated groynes have been documented to last up to 25 years, whereas untreated wooden structures often fail within a decade. When specifying materials, opt for treatments compliant with environmental regulations, such as those meeting the AWPA (American Wood Protection Association) standards, to balance durability with ecological responsibility.

Environmental exposure further amplifies the importance of material quality. Wooden groynes in high-energy coastal zones, where wave action and tidal currents are intense, require denser, more resilient timber to withstand mechanical stress. In contrast, groynes in sheltered areas may perform adequately with less robust materials. A comparative analysis of sites in the UK revealed that groynes constructed with tropical hardwoods in exposed locations outlasted those made from softwoods by over 15 years. This highlights the need to match material quality to site-specific conditions for optimal performance.

Finally, the economic and environmental implications of material choices cannot be overlooked. While high-quality timber carries a higher upfront cost, its extended lifespan reduces long-term expenses associated with repairs and replacements. For example, replacing a groyne every 10 years with softwood costs approximately £50,000 per cycle, whereas a single installation of hardwood groynes, at £80,000, can serve for 30 years. Additionally, frequent replacements contribute to deforestation and carbon emissions, making durable materials a more sustainable choice. By prioritizing material quality, stakeholders can achieve both fiscal efficiency and environmental stewardship.

Metal vs. Wood Porch Gliders: Which Lasts Longer Outdoors?

You may want to see also

Explore related products

Maintenance Frequency Effects

Wooden groynes, those essential coastal defense structures, face a relentless battle against the elements. Their lifespan, typically ranging from 15 to 25 years, is significantly influenced by maintenance frequency. Neglecting regular upkeep can lead to premature deterioration, while proactive care can extend their functionality by several years. This section delves into how maintenance intervals directly impact the longevity of wooden groynes, offering actionable insights for coastal managers.

The Science of Decay: Why Frequency Matters

Wooden groynes are susceptible to rot, insect damage, and erosion, primarily caused by constant exposure to saltwater, wave action, and UV radiation. Maintenance frequency determines how effectively these threats are mitigated. For instance, annual inspections coupled with bi-annual treatments (such as creosote or eco-friendly preservatives) can slow decay rates by up to 40%. In contrast, groynes inspected only every 5 years often exhibit advanced rot within a decade, reducing their lifespan by 30–50%. The key lies in early detection—minor cracks or splintering, when addressed promptly, prevent water infiltration and fungal growth, the primary culprits of structural failure.

Practical Maintenance Schedules: A Step-by-Step Guide

To maximize groyne lifespan, adopt a tiered maintenance approach. Monthly Visual Checks: Inspect for visible damage like cracks, loose bolts, or shifting. Quarterly Cleaning: Remove debris and sediment buildup, which accelerates rot by trapping moisture. Annual Treatments: Apply preservatives or repair minor damage. Biennial Structural Assessments: Hire professionals to evaluate load-bearing capacity and recommend reinforcements. For groynes in high-energy wave zones, increase treatment frequency to every 6–9 months. Pro tip: Document each inspection with photos and notes to track deterioration trends.

Cost vs. Longevity: The Economic Argument

While frequent maintenance incurs upfront costs, it’s a cost-effective strategy in the long run. Replacing a groyne costs approximately $10,000–$20,000, whereas annual maintenance averages $1,500–$3,000. Studies show that groynes maintained every 1–2 years last 20–25 years, whereas those maintained every 3–5 years rarely exceed 15 years. Coastal managers should view maintenance as an investment, not an expense. For example, the UK’s Norfolk coast saw a 30% reduction in replacement costs after implementing a rigorous bi-annual maintenance program.

Innovative Solutions: Extending Lifespan Beyond Tradition

Modern techniques can further enhance groyne durability. Consider hybrid designs incorporating steel or composite materials for high-stress sections, reducing wooden component wear. Alternatively, eco-friendly preservatives like copper naphthenate offer longer protection intervals (up to 5 years) compared to traditional creosote (2–3 years). Pilot programs using drone inspections have also proven effective, reducing labor costs and improving accuracy in identifying early-stage damage. By integrating these innovations into maintenance schedules, coastal managers can push groyne lifespans closer to 30 years.

Takeaway: Frequency as a Lifeline

Maintenance frequency is not just a task—it’s a lifeline for wooden groynes. A proactive, structured approach, backed by data and modern tools, can significantly extend their service life. Coastal managers must prioritize regular, tiered upkeep to balance costs, durability, and environmental impact. After all, in the battle against coastal erosion, consistency is key.

Understanding the Standard Length of Wooden Dummy Arms for Training

You may want to see also

Explore related products

Environmental Wear Factors

Wooden groynes, designed to combat coastal erosion, face relentless environmental wear that significantly shortens their lifespan. Exposure to saltwater is a primary culprit, as its corrosive nature accelerates the decay of timber. Salt crystals infiltrate the wood’s cellular structure, weakening fibers and fostering rot. Studies show that untreated wooden groynes in high-salinity environments degrade within 5–10 years, while those in freshwater or low-salinity areas may last up to 15 years. To mitigate this, regular maintenance, such as applying preservative coatings, can extend durability, though it adds to long-term costs.

Wave action is another relentless force, subjecting groynes to constant physical stress. Each wave impact erodes the wood’s surface, while the abrasive effect of sand and sediment carried by the water wears down structural integrity. Groynes in areas with high wave energy, like exposed coastlines, often require replacement within 8–12 years. In contrast, those in sheltered bays may endure for 15–20 years. Strategic placement and the use of reinforced timber or composite materials can reduce wear, but these solutions come with higher initial investment.

UV radiation from sunlight silently degrades wooden groynes by breaking down lignin, a key component of wood’s structure. Over time, this exposure causes the timber to become brittle and prone to cracking. In tropical regions, where UV levels are intense, groynes may show significant deterioration within 7–10 years. Applying UV-resistant coatings or using naturally durable hardwoods, like teak or greenheart, can slow this process, though such materials are often more expensive and less sustainable.

Biological factors, such as marine borers and fungi, further compound environmental wear. Teredo worms, for instance, bore into wood, creating tunnels that compromise its strength. Similarly, fungi thrive in damp coastal conditions, leading to rot and structural failure. In humid climates, untreated groynes may fail within 5 years due to biological infestation. Treating timber with preservatives like creosote or copper azole can deter these organisms, but such treatments must be reapplied periodically, adding to maintenance demands.

Finally, temperature fluctuations and moisture levels play a critical role in groyne longevity. Freeze-thaw cycles cause wood to expand and contract, leading to cracks and splits, while prolonged moisture exposure encourages decay. In temperate climates with seasonal variations, groynes may last 10–15 years, whereas in more stable tropical environments, moisture-related decay can reduce lifespan to 7–12 years. Incorporating ventilation gaps in groyne design and using moisture-resistant materials can help, but these measures require careful planning and execution. Understanding these environmental wear factors is essential for optimizing groyne performance and balancing cost with durability.

Durability of Wood Planters: Lifespan and Maintenance Tips Revealed

You may want to see also

Design Lifespan Estimates

Wooden groynes, those slanted structures along coastlines, face a relentless assault from waves, tides, and weather. Their lifespan is a critical factor in coastal management, balancing erosion control with maintenance costs. Design lifespan estimates for wooden groynes typically range from 15 to 30 years, but this is far from a fixed number.

Several factors influence these estimates. Timber species play a pivotal role, with hardwoods like oak and greenheart outlasting softer woods like pine. Treatment methods are equally crucial. Pressure-treating timber with preservatives like creosote or copper azole can significantly extend lifespan, often adding 5–10 years compared to untreated wood. Environmental conditions further complicate predictions. Groynes in high-energy wave zones or areas with frequent storms will degrade faster than those in sheltered locations.

To refine lifespan estimates, engineers employ predictive modeling. These models incorporate data on timber type, treatment, wave energy, and historical performance. For instance, a groyne made of creosote-treated greenheart in a moderate wave environment might be projected to last 25–30 years, while an untreated pine groyne in a storm-prone area could fail within 10–15 years.

Practical tips for maximizing groyne lifespan include regular inspections to identify early signs of rot or damage, proactive repairs to address issues before they worsen, and strategic placement to minimize exposure to the most destructive wave forces. While wooden groynes are not permanent solutions, thoughtful design and maintenance can ensure they serve their purpose effectively within their estimated lifespan.

Sanding Wood Glue: Timing Tips for Smooth, Seamless Joints

You may want to see also

Cost vs. Durability Trade-offs

Wooden groynes, while effective in managing coastal erosion, present a classic dilemma: balancing upfront costs with long-term durability. Initial installation expenses for timber groynes are often lower compared to concrete or steel alternatives, making them an attractive option for budget-conscious projects. However, this cost advantage comes with a trade-off—wooden groynes typically last 10 to 20 years, significantly shorter than the 50+ year lifespan of concrete structures. This disparity forces decision-makers to weigh immediate financial savings against the need for frequent replacements and associated maintenance costs.

Consider the lifecycle costs of wooden groynes. While the initial investment might be modest, the cumulative expenses of repairs, treatments, and eventual replacements can surpass the cost of a more durable material over time. For instance, timber groynes require regular treatments with preservatives to combat rot, insect damage, and marine borers, adding to their maintenance burden. In contrast, concrete groynes, though more expensive upfront, demand minimal upkeep and offer decades of uninterrupted service. This highlights the importance of adopting a long-term financial perspective when evaluating coastal management solutions.

The choice between cost and durability also hinges on the specific environmental conditions of a site. In areas with high wave energy or frequent storms, wooden groynes may degrade faster, shortening their effective lifespan and increasing the frequency of replacements. Here, investing in more durable materials could prove cost-effective despite higher initial outlays. Conversely, in milder coastal environments, wooden groynes might provide sufficient protection without excessive wear, making them a viable option for their lower cost.

For project planners, a strategic approach involves assessing the total cost of ownership (TCO) rather than focusing solely on initial expenses. This includes factoring in maintenance, replacement, and environmental impact costs over the groyne’s lifespan. Tools like lifecycle cost analysis (LCA) can help quantify these trade-offs, providing a clearer picture of the most economically and environmentally sustainable option. By prioritizing TCO, stakeholders can make informed decisions that balance immediate budget constraints with long-term resilience.

Ultimately, the cost vs. durability trade-off in wooden groynes underscores the need for tailored solutions. While timber offers affordability and ease of installation, its limited lifespan and maintenance demands may not align with all project goals. For short-term or low-budget initiatives, wooden groynes remain a practical choice. However, for long-term coastal protection, investing in more durable materials could yield greater value, reducing both financial and environmental costs over time. The key lies in aligning material selection with the specific needs and constraints of each project.

Wood Pigeon Lifespan in the UK: Facts and Insights Revealed

You may want to see also

Frequently asked questions

Wooden groynes generally last between 10 to 25 years, depending on factors like wood type, maintenance, exposure to weather, and seawater conditions.

The lifespan is influenced by wood quality, treatment (e.g., pressure-treating), exposure to saltwater, wave action, and regular maintenance practices.

Yes, treating wooden groynes with preservatives like creosote or pressure-treating them can significantly extend their lifespan by protecting against rot, insects, and weathering.

Wooden groynes are less durable than concrete, which can last 50+ years. However, wood is cost-effective and easier to install, making it a popular choice despite its shorter lifespan.