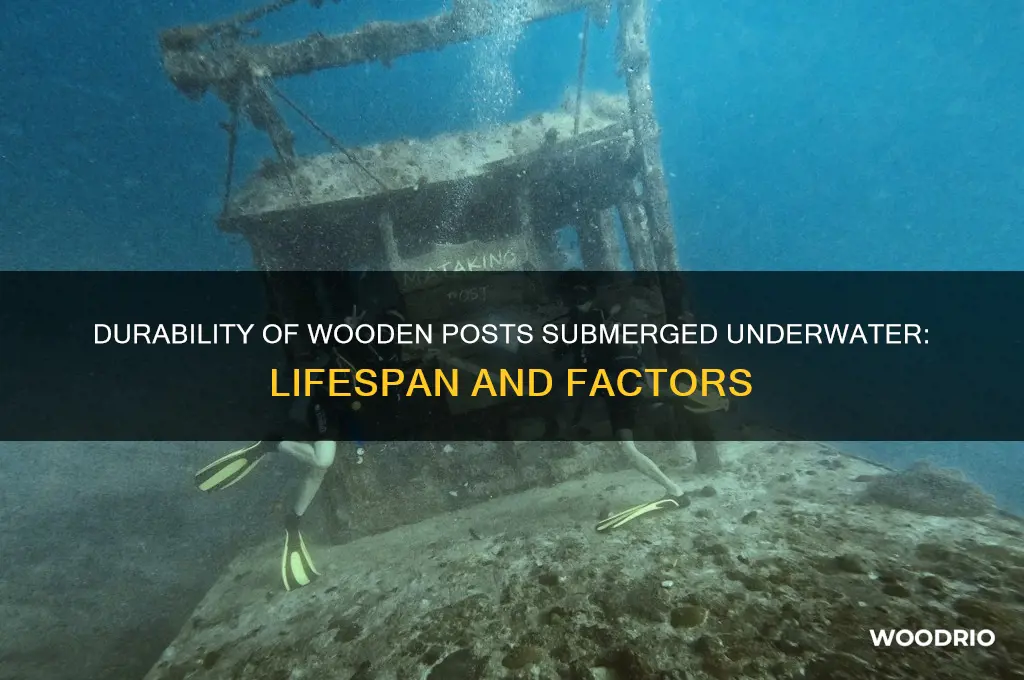

Wooden posts submerged underwater face unique challenges that significantly impact their longevity. While wood is a durable material, prolonged exposure to water, especially in marine environments, can accelerate decay due to factors like moisture absorption, fungal growth, and marine borer activity. The lifespan of wooden posts underwater varies widely, typically ranging from 5 to 40 years, depending on the type of wood, treatment methods, and environmental conditions. Hardwoods like oak or cedar, along with pressure-treated or creosote-coated posts, tend to last longer due to their natural resistance or added preservatives. However, factors such as water salinity, temperature, and movement can expedite deterioration, making proper selection and maintenance crucial for maximizing their underwater lifespan.

| Characteristics | Values |

|---|---|

| Type of Wood | Hardwoods (e.g., oak, cedar) last longer than softwoods (e.g., pine). |

| Treatment | Pressure-treated wood can last 20–40+ years underwater. |

| Water Conditions | Still, freshwater environments extend lifespan compared to saltwater. |

| Oxygen Levels | Low-oxygen environments (e.g., deep water) reduce decay. |

| Temperature | Colder water slows decay; warmer water accelerates it. |

| Biological Activity | Presence of wood-boring organisms (e.g., shipworms) reduces lifespan. |

| pH Levels | Neutral to slightly acidic water is less damaging. |

| Average Lifespan (Untreated) | 5–10 years in freshwater; 1–5 years in saltwater. |

| Average Lifespan (Treated) | 20–40+ years in freshwater; 10–20 years in saltwater. |

| Maintenance | Regular inspection and re-treatment can extend lifespan. |

| Environmental Impact | Treated wood may leach chemicals, affecting aquatic life. |

| Alternative Materials | Concrete, steel, or composite materials last longer underwater. |

Explore related products

What You'll Learn

- Treatment Methods: How preservatives like CCA or creosote extend underwater wooden post lifespan

- Wood Type: Durability differences between hardwoods (e.g., oak) and softwoods (e.g., pine) underwater

- Water Conditions: Impact of saltwater vs. freshwater on wooden post deterioration rates

- Environmental Factors: Effects of temperature, oxygen levels, and marine life on post longevity

- Maintenance Tips: Strategies like regular inspections and protective coatings to prolong underwater life

Treatment Methods: How preservatives like CCA or creosote extend underwater wooden post lifespan

Wooden posts submerged in water face relentless decay from microorganisms, insects, and moisture. Without intervention, untreated wood can deteriorate within 5 to 10 years. However, preservatives like Chromated Copper Arsenate (CCA) and creosote dramatically extend this lifespan, often to 40 years or more. These treatments work by creating a toxic barrier that repels wood-destroying organisms, slowing degradation to a near halt.

CCA, a water-soluble preservative, is applied through pressure treatment, forcing the chemicals deep into the wood’s cellular structure. The typical retention level for CCA in marine environments is 0.60 pounds per cubic foot (PCF), ensuring maximum protection. While effective, CCA has faced environmental concerns due to arsenic leaching, leading to its restriction in residential applications since 2003. For underwater posts, however, it remains a top choice in industrial and commercial settings due to its proven longevity.

Creosote, a tar-based preservative, offers a different approach. Applied through brushing, spraying, or pressure treatment, it forms a hydrophobic coating that repels water and inhibits fungal growth. Creosote-treated posts can last 30 to 50 years underwater, making it a cost-effective option for marine structures like piers and bridges. Its strong odor and potential health risks during application require proper protective gear, including gloves, goggles, and respirators.

Comparing the two, CCA provides deeper penetration and longer-lasting protection, while creosote excels in surface durability and ease of application. The choice depends on the project’s specific needs, environmental regulations, and budget. For instance, creosote is often preferred for larger, exposed structures where surface treatment suffices, while CCA is ideal for smaller, deeply embedded posts requiring full-body protection.

To maximize the lifespan of treated wooden posts, follow these practical tips: ensure proper installation to minimize water pooling, use stainless steel or hot-dipped galvanized fasteners to prevent corrosion, and inspect posts periodically for signs of wear. While preservatives significantly extend durability, no treatment is permanent. Regular maintenance remains key to achieving the full 40+ year potential of underwater wooden posts.

Measuring History: Understanding Cordwood Lengths in Traditional Times

You may want to see also

Explore related products

$94.47 $99.99

$142.49

$144.99

Wood Type: Durability differences between hardwoods (e.g., oak) and softwoods (e.g., pine) underwater

The lifespan of wooden posts submerged in water hinges largely on the wood type, with hardwoods and softwoods exhibiting stark durability differences. Hardwoods like oak, known for their dense cellular structure, inherently resist decay better than softwoods such as pine. This density reduces water absorption, slowing the growth of fungi and bacteria that accelerate rot. For instance, oak posts can last 15–20 years underwater, while untreated pine posts may degrade within 5–10 years. However, these estimates vary based on water conditions, treatment, and maintenance.

To maximize durability, consider treating softwoods with preservatives like creosote or copper azole, which can extend their underwater lifespan to 15–20 years. Hardwoods, though naturally resilient, benefit from similar treatments, particularly in harsh environments. For example, applying a 2–3% solution of copper naphthenate to oak posts can add 5–10 years to their lifespan. Always follow manufacturer guidelines for application rates and safety precautions, as improper treatment can lead to uneven protection or environmental harm.

When choosing between hardwoods and softwoods, weigh cost against longevity. Softwoods are generally more affordable and readily available, making them suitable for short-term projects. Hardwoods, while pricier, offer superior durability and are ideal for long-term applications like bridge pilings or marine structures. For instance, using oak instead of pine for a dock piling can reduce replacement frequency, saving labor and material costs over time. Assess your project’s needs and budget to determine the best wood type.

Environmental factors also play a critical role in wood durability underwater. Saltwater accelerates decay faster than freshwater due to its corrosive properties, shortening the lifespan of both hardwoods and softwoods. In such conditions, hardwoods still outperform softwoods, but both require vigilant maintenance. Regularly inspect posts for cracks, splintering, or signs of marine borer infestation, and replace or treat them promptly. Combining the right wood type with proactive care ensures optimal performance in aquatic environments.

Mastering Chopping Wood in BDO: Time-Saving Tips and Tricks

You may want to see also

Explore related products

Water Conditions: Impact of saltwater vs. freshwater on wooden post deterioration rates

Saltwater and freshwater environments exert distinct pressures on wooden posts, accelerating deterioration through different mechanisms. In saltwater, the high chloride ion concentration promotes galvanic corrosion, particularly in metal fasteners, which can compromise the structural integrity of the wood. These ions also catalyze the breakdown of cellulose and lignin, the primary components of wood, leading to faster degradation. For instance, untreated wooden posts in saltwater may last only 5–10 years, compared to 15–20 years in freshwater. This disparity underscores the corrosive power of saltwater, making it a more hostile environment for submerged wood.

To mitigate saltwater damage, consider using naturally rot-resistant woods like teak or cedar, which contain protective oils and resins. Alternatively, pressure-treated wood infused with copper azole or chromated copper arsenate (CCA) can extend lifespan by up to 40 years in saltwater. For freshwater applications, less toxic treatments like alkaline copper quaternary (ACQ) suffice, offering 25–30 years of durability. Always ensure proper installation, including adequate drainage and ventilation, to minimize moisture retention, a common culprit in both environments.

A comparative analysis reveals that freshwater, while less aggressive, still poses risks through fungal decay and insect infestation. Freshwater’s lower salinity allows microorganisms like fungi and bacteria to thrive, particularly in stagnant conditions. To combat this, apply fungicides or borate treatments, which penetrate the wood to inhibit microbial growth. In contrast, saltwater’s high salinity limits biological activity but accelerates chemical degradation, necessitating a focus on corrosion-resistant materials and coatings.

Practical tips for maximizing post longevity include regular inspections for cracks, warping, or discoloration, which signal early deterioration. In saltwater settings, rinse posts periodically with freshwater to reduce chloride buildup. For freshwater installations, maintain water flow to discourage fungal colonies. Regardless of the environment, embedding posts in gravel or sand rather than silt can improve stability and reduce moisture absorption. By tailoring strategies to the specific water conditions, you can significantly extend the lifespan of submerged wooden posts.

BBQ Wood Pellets Lifespan: How Long Do They Really Last?

You may want to see also

Explore related products

Environmental Factors: Effects of temperature, oxygen levels, and marine life on post longevity

Temperature plays a pivotal role in determining the lifespan of wooden posts submerged in water. In colder environments, such as northern lakes or deep ocean waters where temperatures hover around 4°C (39°F), wooden posts can endure for decades, even centuries. This is because low temperatures slow metabolic rates of wood-degrading organisms and reduce chemical reactions that break down cellulose and lignin. Conversely, in tropical waters where temperatures exceed 25°C (77°F), posts degrade significantly faster due to accelerated microbial activity and increased enzyme efficiency. For optimal preservation, consider submerging posts in waters below 10°C (50°F) or treat them with temperature-resistant preservatives like creosote or copper azole.

Oxygen levels in water directly influence the rate of wood decay, as aerobic microorganisms thrive in oxygen-rich environments. In shallow, well-oxygenated waters, such as rivers or coastal areas, wooden posts typically last 5–10 years due to rapid fungal and bacterial colonization. In contrast, posts submerged in deep, oxygen-depleted environments like stagnant ponds or anoxic lake bottoms can persist for 50 years or more. To mitigate oxygen-driven decay, bury posts in sediment or use anaerobic barriers, such as geotextile wraps, to limit oxygen exposure. For marine applications, choose naturally rot-resistant woods like teak or greenheart, which have inherent resistance to aerobic degradation.

Marine life, from shipworms to barnacles, poses a significant threat to submerged wooden posts. Teredo worms, for instance, can bore through untreated wood at a rate of 1–2 cm per month, reducing structural integrity within 2–3 years in infested waters. Barnacles and mussels, while not directly destructive, increase drag and stress on posts, accelerating mechanical failure. To combat marine borers, treat posts with borate or copper-based preservatives, which are toxic to these organisms. Alternatively, encase posts in protective barriers like fiberglass or concrete jackets. Regular inspections and cleaning can also prevent biofouling, extending post life by 30–50%.

The interplay of temperature, oxygen, and marine life creates unique challenges for wooden post longevity in different aquatic ecosystems. For example, posts in warm, oxygenated coral reefs face triple threats: high microbial activity, abundant borers, and mechanical stress from wave action. In such environments, combine multiple strategies—use heat-treated wood, apply antifouling coatings, and install sacrificial anodes to deter marine life. Conversely, posts in cold, low-oxygen fjords may require minimal treatment but benefit from sediment burial to further restrict oxygen and borer access. Tailor solutions to the specific environmental conditions for maximum durability.

Sunken Wooden Ships: Uncovering Their Remarkable Underwater Lifespan

You may want to see also

Explore related products

Maintenance Tips: Strategies like regular inspections and protective coatings to prolong underwater life

Wooden posts submerged in water face relentless threats: microbial decay, marine borers, and constant moisture absorption. Without intervention, their lifespan rarely exceeds 5–10 years. However, strategic maintenance can double or even triple this expectancy. The key lies in proactive measures that address both biological and environmental stressors.

Inspections: The First Line of Defense

Regular inspections are non-negotiable. Schedule quarterly dives or visual checks using underwater cameras to assess post integrity. Look for telltale signs of deterioration: hairline cracks, splintering, or borehole patterns indicative of teredo worms. Early detection allows for localized repairs, such as epoxy injections or spot replacements, before structural failure occurs. For posts in high-traffic areas, consider biannual inspections to account for increased wear.

Protective Coatings: A Barrier Against Decay

Applying specialized coatings is the most effective way to shield wood from waterlogging and organisms. Creosote, a traditional choice, penetrates deep into the grain, offering 15–20 years of protection. However, its toxicity restricts use in ecologically sensitive areas. For greener alternatives, consider copper naphthenate (applied at 2–4 gallons per 100 square feet) or polymeric sealers, which create a hydrophobic barrier without leaching chemicals. Reapply coatings every 5–7 years, sanding surfaces lightly to ensure adhesion.

Strategic Material Pairing: When Wood Isn’t Enough

In high-risk environments, combine wood with sacrificial anodes or composite sleeves. Galvanized steel anodes, attached 6–12 inches below the post, divert corrosive activity away from the wood. Alternatively, encase the submerged portion in HDPE sleeves, which block borer access while allowing water flow. This hybrid approach extends lifespan to 25+ years, though it increases upfront costs by 30–40%.

Environmental Mitigation: Controlling the Uncontrollable

Water flow and sediment buildup accelerate decay by trapping debris and reducing oxygenation. Install deflectors around posts to redirect currents, minimizing silt accumulation. For static waters, embed posts in gravel beds to promote drainage. In brackish environments, where chloride ions accelerate rot, consider freshwater flushing systems to periodically rinse the post surfaces.

Documentation and Adaptation: The Long Game

Maintain a logbook tracking inspection dates, damage patterns, and maintenance actions. Over time, this data reveals site-specific vulnerabilities—e.g., seasonal borer activity or temperature-driven expansion cracks. Use these insights to refine strategies, such as scheduling coatings before peak infestation periods or adjusting material choices based on observed wear rates. With disciplined care, wooden posts can defy their ephemeral reputation, standing firm for decades beneath the waves.

Composite Decking vs. Wood: Which Lasts Longer and Why?

You may want to see also

Frequently asked questions

Wooden posts underwater can last anywhere from 15 to 40 years, depending on factors like the type of wood, water conditions, and treatment methods.

Yes, treating wood with preservatives like creosote or CCA (chromated copper arsenate) can significantly extend its lifespan underwater, often doubling or tripling its durability.

Naturally rot-resistant woods like cedar, redwood, or black locust last the longest underwater, with treated southern yellow pine also being a popular and durable choice.

Yes, water conditions such as salinity, oxygen levels, and the presence of marine borers can impact durability. Freshwater environments generally allow wood to last longer than saltwater.