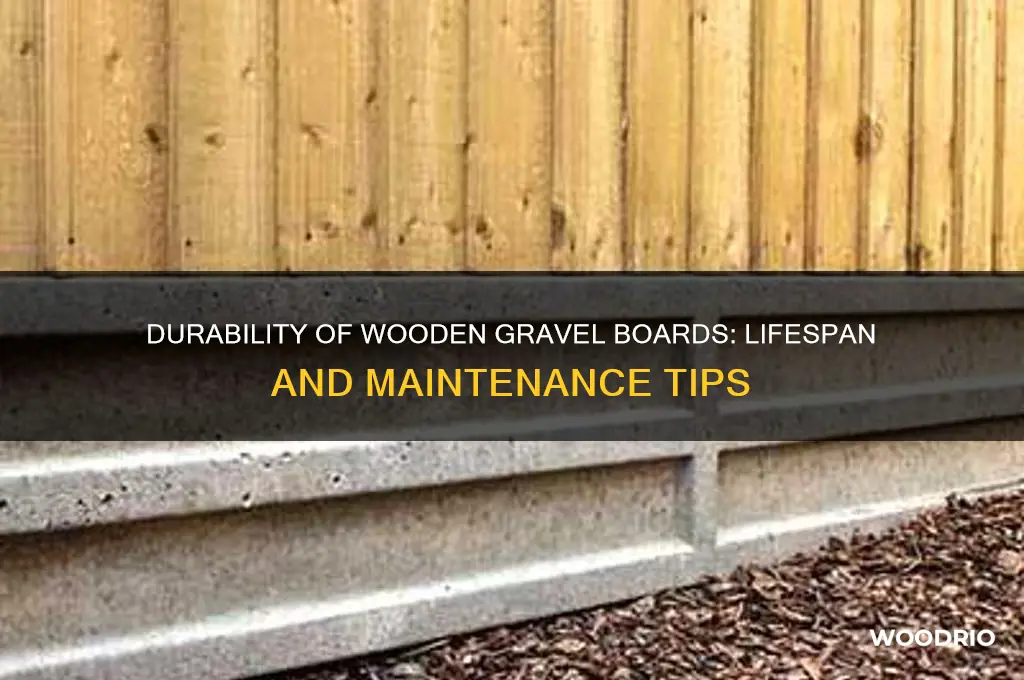

Wooden gravel boards, commonly used as a barrier between gravel and fencing, typically last between 5 to 15 years, depending on factors such as the type of wood, treatment, and environmental conditions. Softwood boards, which are more affordable, generally have a shorter lifespan of around 5 to 10 years, while hardwood or pressure-treated options can endure for up to 15 years or more. Proper installation, regular maintenance, and protection from moisture and pests are crucial in maximizing their durability. Exposure to harsh weather, ground moisture, and insect damage can significantly reduce their longevity, making it essential to choose high-quality materials and apply preservatives to extend their life.

Explore related products

What You'll Learn

Factors affecting durability of wooden gravel boards

Wooden gravel boards, typically used to support fencing and prevent soil erosion, can last anywhere from 5 to 15 years, depending on various factors. Understanding these factors is crucial for maximizing their lifespan and ensuring they remain functional and aesthetically pleasing.

Material Quality and Treatment: The type of wood used significantly impacts durability. Hardwoods like oak or cedar naturally resist decay and insect damage, often lasting over a decade. Softwoods, such as pine, are more affordable but require pressure treatment with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ). These treatments can extend their lifespan to 10–15 years. For optimal results, choose boards treated to a retention level of 0.40 pounds per cubic foot (PCF) for ground contact, as recommended by industry standards.

Environmental Exposure: Climate plays a pivotal role in wooden gravel board longevity. In regions with high humidity or frequent rainfall, boards are more susceptible to rot and fungal growth. Coastal areas expose them to saltwater, which accelerates corrosion of fasteners and wood degradation. Conversely, arid climates may cause wood to dry out and crack. Applying a waterproof sealant every 2–3 years can mitigate these effects, particularly in harsh environments.

Installation and Maintenance: Proper installation is as critical as material choice. Ensure boards are installed with a slight slope away from the fence to prevent water pooling. Use stainless steel or hot-dipped galvanized fasteners to avoid rust, which can weaken connections. Regular maintenance, such as annual inspections for cracks, splinters, or signs of insect infestation, allows for timely repairs. Cleaning debris and applying a fresh coat of preservative every 3–5 years can further enhance durability.

Soil Conditions and Ground Contact: The soil type and moisture levels directly affect wooden gravel boards. Clay soils retain more water, increasing the risk of rot, while sandy soils drain quickly but may shift, causing uneven pressure. Elevating boards slightly above ground level or using a gravel base can reduce direct soil contact. Additionally, installing a geotextile membrane beneath the gravel can prevent soil migration and prolong board life.

By addressing these factors—material quality, environmental exposure, installation practices, and soil conditions—homeowners and landscapers can significantly extend the durability of wooden gravel boards. While no solution guarantees indefinite lifespan, strategic choices and proactive maintenance can ensure these boards remain effective for over a decade, providing both functionality and visual appeal.

Nina and Chris Wood's Relationship Timeline: How Long Did They Date?

You may want to see also

Explore related products

Average lifespan of treated vs. untreated boards

The lifespan of wooden gravel boards hinges significantly on whether they are treated or untreated. Untreated boards, exposed to the elements, typically last 5 to 10 years. Moisture, insects, and UV radiation accelerate decay, causing warping, splitting, and rot. While untreated boards offer a natural aesthetic, their short lifespan makes them a high-maintenance choice, requiring frequent replacement or additional protective measures.

Treated boards, on the other hand, undergo processes like pressure treatment with preservatives such as chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ). These treatments penetrate the wood, providing resistance to rot, insects, and fungal growth. As a result, treated gravel boards can last 15 to 25 years or more, depending on the quality of treatment and environmental conditions. For instance, boards treated with ACQ, which is less toxic than CCA, often perform well in damp or ground-contact applications, extending their lifespan further.

When comparing the two, the initial cost of treated boards is higher, but their longevity often justifies the investment. Untreated boards may seem economical upfront, but the cumulative cost of replacements and maintenance can surpass the price of treated alternatives over time. For example, replacing untreated boards every 7 years versus a one-time installation of treated boards lasting 20+ years highlights the long-term savings of treated options.

Practical tips for maximizing lifespan include ensuring proper installation to minimize ground contact, applying additional sealants or stains to treated boards for added protection, and regularly inspecting for signs of wear. In regions with harsh climates, treated boards are particularly advantageous, as they withstand extreme weather better than untreated ones. Ultimately, the choice between treated and untreated boards should balance aesthetic preferences, budget, and the desired maintenance commitment.

Cynthia Woods Mitchell Pavilion Concert Length: What to Expect

You may want to see also

Explore related products

Maintenance tips to extend board longevity

Wooden gravel boards, typically lasting 5–15 years, degrade faster without proper care. Exposure to moisture, pests, and sunlight accelerates rot and warping. Strategic maintenance can double their lifespan, making them a cost-effective fencing solution.

Inspect and repair early. Annually examine boards for cracks, splinters, or signs of insect infestation. Use a screwdriver to probe for softness, indicating rot. Replace damaged sections promptly—a small repair now prevents larger replacements later. For minor cracks, apply wood filler and sand smooth before resealing.

Seal and treat consistently. Apply a high-quality wood preservative every 1–2 years, depending on climate. In wet regions, opt for water-repellent sealants with UV protection. For drier areas, oil-based treatments penetrate deeper, enhancing durability. Always clean boards with a stiff brush and mild detergent before application to ensure adhesion.

Manage moisture and drainage. Ensure soil slopes away from the boards to prevent water pooling. Install gravel or small stones at the base to improve drainage. Trim vegetation near the fence to reduce moisture retention and discourage pests. For added protection, attach a plastic membrane behind the boards to block soil contact.

Elevate and ventilate. When installing new boards, leave a 2-inch gap between the ground and the wood. This reduces direct moisture exposure and allows airflow, slowing decay. If retrofitting, consider adding supports to lift existing boards slightly. Pair this with regular debris clearing to maintain ventilation.

By combining proactive inspections, protective treatments, and environmental adjustments, wooden gravel boards can endure closer to their maximum lifespan. The effort pays off in reduced replacement costs and sustained aesthetic appeal.

Durability of Wood Storage Boxes: Lifespan Without TC Rust Protection

You may want to see also

Explore related products

Impact of weather conditions on board lifespan

Wooden gravel boards, typically made from softwoods like pine or spruce, are designed to be durable but are inherently susceptible to environmental factors. Weather conditions play a pivotal role in determining their lifespan, which generally ranges from 5 to 15 years. However, this range can fluctuate dramatically based on exposure to specific climatic elements. For instance, prolonged exposure to moisture, whether from rain, snow, or high humidity, accelerates rot and decay, particularly in untreated or poorly treated wood. Conversely, dry climates can cause wood to shrink, crack, and warp, compromising structural integrity. Understanding these weather-related vulnerabilities is essential for maximizing the longevity of wooden gravel boards.

In regions with high rainfall or frequent wet conditions, water absorption becomes the primary enemy of wooden boards. Moisture seeps into the wood fibers, creating an ideal environment for fungi and insects that break down cellulose and lignin, the primary components of wood. To mitigate this, boards should be treated with preservatives like creosote or copper-based solutions, which can extend lifespan by up to 50%. Additionally, installing gravel boards at least 2 inches above ground level and ensuring proper drainage can reduce direct contact with water. For areas with annual rainfall exceeding 40 inches, consider using pressure-treated wood, which has a proven track record of lasting 10–15 years in such conditions.

Extreme temperatures and UV exposure in arid or sunny climates pose a different set of challenges. High heat causes wood to expand and contract, leading to cracks and splits, while UV rays degrade surface fibers, making the wood brittle. Applying a UV-resistant sealant or paint every 2–3 years can significantly slow this process. In desert climates, where temperature fluctuations between day and night can exceed 30°F, using hardwoods like cedar or redwood, which are naturally more resistant to warping, can be a worthwhile investment. These hardwoods, though pricier, often last 15–20 years even in harsh conditions.

Frost and freeze-thaw cycles in colder climates introduce mechanical stress that weakens wooden boards over time. Water trapped in wood expands when frozen, causing internal damage that accumulates with each cycle. To combat this, ensure boards are installed with adequate ventilation to prevent water accumulation. Applying a water-repellent treatment before winter can also minimize moisture infiltration. In areas with more than 50 frost days annually, consider pairing wooden boards with a concrete or composite base for added stability, which can extend their functional lifespan by 3–5 years.

Finally, wind-driven rain and debris in stormy regions exacerbate wear and tear on gravel boards. Horizontal rain penetrates deeper into the wood, while airborne particles act like sandpaper, eroding surfaces. Installing a protective barrier, such as a fence topper or additional layer of gravel, can shield boards from these elements. Regular inspections after severe weather events are crucial to identify and repair damage early. By tailoring maintenance practices to specific weather conditions, homeowners can ensure wooden gravel boards remain functional and aesthetically pleasing for as long as possible.

Transporting Oversized Wood: Practical Tips for Moving Long Lumber Safely

You may want to see also

Explore related products

Comparing wooden boards to alternative materials' durability

Wooden gravel boards, while traditional and aesthetically pleasing, typically last 10 to 15 years with proper maintenance. However, their lifespan is heavily influenced by factors like moisture exposure, insect damage, and rot. This raises the question: how do alternative materials stack up in terms of durability? Let’s explore concrete, composite, and metal options to understand their longevity and maintenance requirements.

Concrete gravel boards are a robust alternative, boasting a lifespan of 25 to 50 years. Their resistance to rot, insects, and warping makes them a low-maintenance choice. However, they are significantly heavier than wood, requiring more labor for installation. For homeowners seeking a long-term solution without frequent replacements, concrete is a reliable option, though its weight may limit its use in certain applications.

Composite boards, made from a blend of wood fibers and plastic, offer a middle ground with a lifespan of 20 to 30 years. They resist moisture and decay better than wood while being lighter than concrete. However, they can be more expensive upfront. For those willing to invest in reduced maintenance and increased durability, composite boards are a practical compromise, especially in humid climates where wood deteriorates faster.

Metal gravel boards, often made from steel or aluminum, can last 30 to 50 years, depending on corrosion resistance. Powder-coated or galvanized options enhance durability, but they may still scratch or dent over time. Metal is ideal for modern landscapes but can conduct heat, potentially affecting nearby plants. If you prioritize longevity and have a contemporary design aesthetic, metal is a strong contender, though it requires occasional touch-ups to maintain its appearance.

In summary, while wooden gravel boards offer a classic look, their 10- to 15-year lifespan pales in comparison to alternatives. Concrete and metal provide decades of durability, while composite boards balance longevity with ease of installation. The choice depends on your budget, aesthetic preferences, and willingness to trade upfront costs for long-term savings. Assess your priorities to select the material that best aligns with your needs.

Masterbuilt Smoker Wood Chips Lifespan: How Long Do They Last?

You may want to see also

Frequently asked questions

Wooden gravel boards usually last between 5 to 15 years, depending on the type of wood, treatment, and environmental conditions.

Yes, treating wooden gravel boards with preservatives, stains, or sealants can significantly extend their lifespan by protecting them from rot, insects, and moisture.

Factors such as exposure to moisture, soil conditions, quality of wood, and maintenance practices (e.g., regular treatment) can greatly impact how long wooden gravel boards last.

![CFKJ [18 Pounds] Natural Slate Stone Rocks, Mix of Rocks About 2 to 5 inches and 4 Piece 8 inches Slate Stone Rocks for Aquascaping, Aquariums, Terrariums, Amphibian Enclosures](https://m.media-amazon.com/images/I/61VPiACh9rL._AC_UL320_.jpg)

![CFKJ [18 Pounds] Natural Slate Stone Rocks, 5 to 7 inch Slate Stone Rocks for Aquascaping, Aquariums, Terrariums, Amphibian Enclosures](https://m.media-amazon.com/images/I/71JVh1P0T7L._AC_UL320_.jpg)

![CFKJ [18 Pounds] Natural Slate Stone Rocks, 3 to 5 inch Slate Stone Rocks for Aquascaping, Aquariums, Terrariums, Amphibian Enclosures](https://m.media-amazon.com/images/I/81JqkXg4IgL._AC_UL320_.jpg)