Wooden telephone poles, a common sight in many regions, are essential for supporting power lines and communication cables, but their lifespan is a subject of considerable interest due to environmental and maintenance concerns. Typically, these poles are treated with preservatives to resist decay, insects, and weather, which significantly extends their durability. On average, a well-maintained wooden telephone pole can last between 25 to 50 years, though this can vary based on factors such as climate, soil conditions, and exposure to moisture. In harsher environments, such as areas with high humidity or frequent flooding, their lifespan may be shorter, while in drier climates, they can endure for several decades. Regular inspections and timely replacements are crucial to ensure safety and reliability, as aging poles can pose risks of failure, particularly during severe weather events. Understanding the longevity of wooden telephone poles helps utilities plan for sustainable infrastructure and minimize disruptions to essential services.

| Characteristics | Values |

|---|---|

| Average Lifespan | 25–50 years (varies based on treatment, climate, and maintenance) |

| Preservative Treatment | Extends lifespan by 10–20 years (e.g., creosote, pentachlorophenol) |

| Climate Impact | Shorter lifespan in wet, humid, or termite-prone areas |

| Maintenance Frequency | Regular inspections every 5–10 years; repairs as needed |

| Material Type | Typically Southern Yellow Pine or Douglas Fir |

| Replacement Reasons | Decay, insect damage, storm damage, or safety concerns |

| Environmental Factors | Soil conditions, pollution, and exposure to moisture affect durability |

| Utility Company Standards | Lifespan aligned with National Electrical Safety Code (NESC) guidelines |

| Sustainability Practices | Reuse, recycling, and use of alternative materials becoming common |

| Cost of Replacement | $300–$1,000 per pole (including labor and materials) |

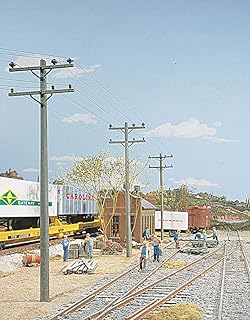

Explore related products

What You'll Learn

Factors affecting pole lifespan

Wooden telephone poles, typically made from durable softwoods like pine or cedar, are designed to withstand decades of exposure to the elements. However, their lifespan varies widely, influenced by a combination of environmental, maintenance, and material-specific factors. Understanding these factors is crucial for utilities aiming to optimize pole longevity and reduce replacement costs.

Environmental Conditions: The Unseen Adversaries

Moisture is the primary enemy of wooden poles. Prolonged exposure to water accelerates rot, particularly in the base where soil contact is highest. Poles in humid climates or flood-prone areas degrade faster, often lasting only 20–30 years. In contrast, arid regions can see poles endure 40–50 years. Temperature extremes also play a role: freeze-thaw cycles cause wood to crack, while intense heat can dry it out, making it brittle. For example, poles in the Pacific Northwest face constant dampness, while those in Arizona battle sun-induced wear. Strategic placement and regular inspections are essential to mitigate these risks.

Maintenance Practices: Proactive Care Extends Life

Regular maintenance can double a pole’s lifespan. Applying preservatives like creosote or pentachlorophenol during manufacturing penetrates the wood, inhibiting decay and insect damage. However, this protection isn’t permanent. Reapplication every 10–15 years is recommended, especially for poles in high-risk areas. Physical inspections for cracks, leaning, or splintering should occur annually. Utilities can also install steel caps on pole tops to prevent water infiltration, a simple measure that adds years to their life. Neglecting these steps can lead to premature failure, as seen in rural areas with limited maintenance budgets.

Material Quality and Treatment: The Foundation of Durability

Not all wooden poles are created equal. The species of wood and its treatment process significantly impact longevity. Southern yellow pine, treated with CCA (chromated copper arsenate), is a gold standard, often lasting 50+ years. Untreated or poorly treated poles, however, may fail in under a decade. Manufacturers must adhere to standards like ANSI O5.1 for treatment levels—a minimum of 0.60 pounds of preservative per cubic foot of wood is required for ground-contact use. Utilities should verify supplier compliance to ensure they’re investing in poles built to last.

External Stressors: Beyond Weather and Wear

Human activity and wildlife can shorten pole lifespan unexpectedly. Vehicle collisions, a common urban issue, can fracture poles instantly or weaken them over time. In rural areas, woodpeckers and termites pose threats, particularly to untreated or aging poles. Even vegetation growth can be problematic—vines and ivy trap moisture against the wood, accelerating decay. Utilities should enforce clearances around poles, trim vegetation annually, and install deterrents like metal wraps to protect against animal damage.

By addressing these factors systematically, utilities can maximize the lifespan of wooden telephone poles, balancing cost-effectiveness with reliability. While no pole lasts forever, informed decisions about placement, treatment, and maintenance can ensure they stand tall for decades.

Wood Glue Drying Time: When Can You Start Sanding?

You may want to see also

Explore related products

Average lifespan of treated poles

Treated wooden telephone poles, when properly maintained, can endure for 50 to 75 years, significantly outperforming their untreated counterparts. This extended lifespan is primarily due to the application of preservatives that protect the wood from decay, insects, and environmental stressors. Common treatments include creosote, pentachlorophenol, and copper-based compounds, which penetrate the wood fibers to create a barrier against degradation. The choice of preservative and the treatment process itself are critical factors in determining the pole’s longevity. For instance, pressure treatment ensures deeper penetration of the preservative, enhancing resistance to rot and insect damage.

The effectiveness of these treatments, however, depends on several variables. Soil conditions, moisture levels, and exposure to harsh weather can accelerate wear despite treatment. Poles installed in wet or acidic soil, for example, may degrade faster due to increased microbial activity. Similarly, poles in coastal areas face additional challenges from saltwater exposure, which can corrode metals and weaken the wood over time. Regular inspections and proactive maintenance, such as re-treatment or reinforcement, are essential to maximize the lifespan of treated poles in such environments.

Comparatively, treated poles offer a cost-effective solution for utility companies, balancing initial investment with long-term durability. While the upfront cost of treatment and installation is higher than that of untreated poles, the reduced need for replacement and maintenance translates to savings over decades. This economic advantage is particularly evident when considering the logistical and financial burdens of pole replacement, which includes labor, equipment, and service disruptions. For rural or hard-to-reach areas, the extended lifespan of treated poles minimizes these challenges, making them a preferred choice for infrastructure planning.

To ensure optimal performance, utility companies should adhere to industry standards for pole treatment and installation. The American Wood Protection Association (AWPA) provides guidelines for preservative application, specifying retention levels and treatment methods tailored to different environmental conditions. For instance, poles in high-risk areas may require heavier preservative dosages or additional protective coatings. Pairing treated poles with proper installation techniques, such as adequate backfilling and drainage, further safeguards against premature failure. By combining these practices, utilities can reliably achieve the upper end of the expected lifespan for treated wooden poles.

Italian Wood Aging Secrets: Unveiling the Timeless Craft of Master Luthiers

You may want to see also

Explore related products

Impact of weather on durability

Wooden telephone poles, typically made from durable softwoods like pine or cedar, are designed to withstand decades of exposure to the elements. However, their lifespan is significantly influenced by weather conditions, which can accelerate deterioration through moisture absorption, temperature fluctuations, and physical damage. Understanding these impacts is crucial for utilities aiming to optimize maintenance schedules and extend pole longevity.

Moisture: The Silent Destroyer

Rain, snow, and humidity are primary culprits in reducing wooden pole durability. Prolonged exposure to moisture encourages rot, primarily caused by fungi and bacteria that thrive in damp environments. Poles installed in regions with annual rainfall exceeding 40 inches, such as the Pacific Northwest, are particularly vulnerable. To mitigate this, utilities often apply water-repellent treatments like creosote or pentachlorophenol during manufacturing. Field inspections should focus on ground-level moisture accumulation, as poles buried 6–8 feet underground are especially susceptible to decay where soil meets wood.

Temperature Extremes: A Double-Edged Sword

Cyclical freezing and thawing in temperate climates exacerbate cracking and splitting. When water seeps into wood fibers and freezes, it expands, creating microfractures that weaken the structure over time. Conversely, arid regions with temperature swings exceeding 50°F in a single day (e.g., desert areas) cause wood to dry out, becoming brittle and prone to splintering. Utilities in such zones should prioritize poles treated with oil-based preservatives, which retain flexibility under stress.

Wind and Storms: Immediate Physical Threats

High winds and storms pose acute risks, particularly for poles over 30 years old. Hurricane-force winds exceeding 74 mph can uproot poles or snap them at the base, where decay often begins unnoticed. Coastal areas face additional corrosion from saltwater spray, which accelerates chemical breakdown of wood fibers. Reinforcing older poles with guy wires or replacing them preemptively in storm-prone regions is a cost-effective strategy to prevent widespread outages.

Sunlight and UV Degradation: The Slow Burn

Prolonged UV exposure in sunny climates degrades wood’s lignin, causing surface erosion and color fading. While less dramatic than storm damage, this cumulative effect reduces tensile strength by up to 30% over 20 years. Applying UV-resistant coatings every 5–7 years can preserve structural integrity, especially in regions with over 250 sunny days annually, such as the Southwest U.S.

Practical Tips for Weather-Resilient Poles

To maximize durability, utilities should:

- Inspect annually for cracks, leaning, or ground-level rot, particularly after extreme weather events.

- Treat poles with borate or copper naphthenate preservatives to inhibit fungal growth in humid zones.

- Install poles with proper drainage to minimize water pooling around the base.

- Replace poles older than 40 years in high-risk weather areas, even if they appear sound.

By addressing weather-specific vulnerabilities, utilities can extend the average 30–50-year lifespan of wooden poles, ensuring reliable service while reducing replacement costs.

Black Walnut Wood Oxidation: Understanding the Aging Process and Timeline

You may want to see also

Explore related products

Maintenance to extend pole life

Wooden telephone poles, typically made from durable species like pine or cedar, are designed to withstand decades of exposure to the elements. However, their lifespan, often ranging from 25 to 50 years, can be significantly extended with proper maintenance. The key lies in proactive measures that address common threats such as rot, insect damage, and structural wear. By implementing a structured maintenance plan, utility companies can maximize the longevity of these poles, reducing replacement costs and minimizing service disruptions.

One critical maintenance practice is regular inspection. Poles should be examined at least annually for signs of decay, cracks, or leaning. Ground-line inspections are particularly important, as this area is most susceptible to moisture and insect infestation. For poles showing early signs of rot, treatment with wood preservatives can be highly effective. Copper naphthenate, for instance, is a widely used preservative that can penetrate deep into the wood, providing protection against fungi and termites. Applying 1 to 2 gallons of a 2% solution per pole, as recommended by industry standards, can add years to its life.

Another essential maintenance strategy is managing the surrounding environment. Vegetation control is vital, as overgrown plants can trap moisture against the pole, accelerating decay. Clearing a 3-foot radius around the base and trimming climbing vines or shrubs can prevent this issue. Additionally, ensuring proper drainage by grading the soil away from the pole reduces water accumulation, a primary cause of rot. In areas prone to flooding, installing gravel or rock beds around the base can further mitigate moisture-related damage.

For poles in high-risk areas, such as those near bodies of water or in termite-prone regions, additional protective measures are warranted. Physical barriers like termite shields can be installed at the base to deter insect intrusion. Similarly, applying water-repellent coatings or wraps can provide an extra layer of defense against moisture. While these measures require an initial investment, they are cost-effective in the long run, as they significantly reduce the need for premature replacement.

Finally, structural reinforcement should not be overlooked. Poles bearing heavy loads or located in windy areas may experience increased stress, leading to cracks or splits. Installing guy wires or braces can alleviate this strain, ensuring the pole remains stable and functional. Regularly tightening hardware and replacing corroded components are also simple yet effective ways to maintain structural integrity. By combining these maintenance practices, utility companies can ensure wooden telephone poles serve their intended purpose for as long as possible, balancing operational efficiency with cost savings.

How Long Does a Rick of Wood Last? A Comprehensive Guide

You may want to see also

Explore related products

Signs of pole deterioration

Wooden telephone poles, while sturdy, are not immune to the ravages of time and environment. Understanding the signs of deterioration is crucial for ensuring safety and maintaining infrastructure integrity. One of the earliest indicators of a failing pole is cracking. These fissures often start small, barely noticeable, but can quickly expand due to weather exposure, insect activity, or mechanical stress. Regular inspections should focus on the base of the pole, where moisture accumulation and soil contact accelerate decay.

Another telltale sign is leaning or shifting. A pole that has begun to tilt is a red flag, suggesting compromised structural integrity. This can result from soil erosion, root damage, or even vehicle collisions. Immediate action is necessary, as a leaning pole poses a significant risk of collapse, especially during high winds or storms. Utility companies often use specialized tools to measure deviations from vertical alignment, ensuring timely replacements.

Rot and decay are perhaps the most insidious forms of deterioration. Caused by fungi and bacteria, these issues often go unnoticed until the damage is extensive. Wood that feels soft or spongy to the touch, or that crumbles easily, indicates advanced decay. Treated poles are designed to resist such degradation, but treatments can wear off over time, particularly in humid or wet climates. Periodic probing with a sharp tool can help detect early stages of rot before it becomes a major problem.

Finally, insect infestations can significantly weaken wooden poles. Termites, carpenter ants, and beetles bore into the wood, creating tunnels that reduce its load-bearing capacity. Signs of infestation include small exit holes, sawdust-like frass at the base, or the presence of live insects. Preventive measures, such as regular pesticide treatments and monitoring, can mitigate this risk. However, once an infestation is detected, the pole’s lifespan is often drastically reduced, necessitating swift replacement.

By recognizing these signs—cracking, leaning, rot, and insect damage—maintenance teams can proactively address issues before they escalate. Regular inspections, coupled with timely interventions, ensure that wooden telephone poles remain safe and functional for their intended lifespan, typically ranging from 20 to 40 years depending on environmental conditions and maintenance practices.

Composite Lumber vs. Wood: Which Material Offers Longer Durability?

You may want to see also

Frequently asked questions

Wooden telephone poles generally last between 25 to 50 years, depending on factors like climate, soil conditions, and maintenance.

Exposure to moisture, insect damage, soil acidity, and extreme weather conditions can significantly reduce the lifespan of wooden telephone poles.

Yes, wooden poles are often pressure-treated with preservatives like creosote or pentachlorophenol to resist rot, insects, and decay, which can extend their lifespan.

Utility companies typically inspect wooden telephone poles every 5 to 10 years to assess their condition and ensure they meet safety standards.

Yes, wooden poles are increasingly being replaced by steel, concrete, or composite materials due to their longer lifespan, lower maintenance needs, and environmental concerns related to wood treatment chemicals.