Aging wood is a process that enhances its durability, appearance, and stability, making it ideal for various applications such as furniture, flooring, and construction. The length of time required to age wood depends on factors like the wood species, desired outcome, and environmental conditions. Hardwoods like oak or maple may need several years to decades to fully mature, while softer woods like pine can be aged more quickly. Natural aging involves air-drying or kiln-drying, with air-drying typically taking 1 to 5 years, depending on thickness and humidity. Accelerated methods, such as heat treatment or chemical processes, can reduce aging time to weeks or months. Ultimately, the goal is to achieve a moisture content of 6-8% for optimal strength and resistance to warping or cracking.

| Characteristics | Values |

|---|---|

| Minimum Aging Time for Most Woods | 6 months to 1 year |

| Ideal Aging Time for Hardwoods (e.g., oak, maple) | 1 to 2 years |

| Ideal Aging Time for Softwoods (e.g., pine, cedar) | 6 months to 1 year |

| Aging Time for Outdoor Use (e.g., decking, fencing) | 1 to 2 years |

| Aging Time for Fine Furniture | 2 to 5 years |

| Moisture Content Reduction Goal | Below 12-15% (depending on climate) |

| Optimal Aging Conditions | Covered, well-ventilated area with consistent humidity and temperature |

| Effect of Aging on Wood | Reduces warping, cracking, and improves stability |

| Aging Time for Reclaimed Wood | Varies (often already aged for decades) |

| Accelerated Aging Methods | Kiln drying (reduces time to weeks or months) |

| Environmental Factors Affecting Aging | Humidity, temperature, airflow, and wood species |

| Signs of Properly Aged Wood | Stable moisture content, minimal movement, and uniform color |

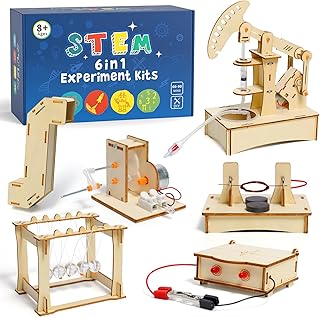

Explore related products

$24.95 $24.95

What You'll Learn

Ideal Aging Time for Different Wood Types

Wood aging is not a one-size-fits-all process; different species require distinct timelines to reach their optimal working and aesthetic qualities. For instance, oak, a hardwood prized for its strength and durability, typically needs 3 to 5 years of air drying to reduce moisture content to 12-15%. This period allows the wood to stabilize, minimizing warping and cracking in furniture or flooring applications. However, if oak is kiln-dried, this time can be reduced to 2-3 weeks, though some artisans argue that air-dried oak retains superior character.

In contrast, pine, a softwood commonly used in construction and cabinetry, ages more rapidly due to its lower density. Freshly cut pine can be air-dried in 6 months to a year, achieving a moisture content of 10-12%. Yet, for projects requiring maximum stability, such as musical instruments, pine may benefit from 2-3 years of aging to allow natural resins to settle and harden. This extended period enhances its tonal qualities and resistance to dents.

Exotic woods, like teak or mahogany, often demand longer aging times due to their high natural oils and density. Teak, for example, requires 3-5 years of air drying to prevent internal stresses that could lead to splitting. Mahogany, while less dense, benefits from 2-4 years of aging to develop its rich, deep color and workability. These woods are often kiln-dried as well, but the process is slower—up to 6 weeks—to avoid damaging their natural properties.

For reclaimed wood, aging is less about moisture reduction and more about preserving historical character. Reclaimed oak or chestnut from old barns, for instance, has already aged for decades, if not centuries. Here, the focus shifts to careful cleaning, de-nailing, and surface treatment to retain its patina while ensuring structural integrity. No additional aging is needed, but proper acclimatization to indoor conditions (2-4 weeks) is essential to prevent further movement.

Finally, green wood—freshly cut and untreated—requires the longest aging time, particularly for carving or turning projects. Species like cherry or walnut should be air-dried for 1-2 years to reduce moisture content to 8-10%, making them easier to shape without distortion. For woodturning, smaller pieces can be dried in 6-12 months, but larger blanks may need up to 3 years. Always stack wood with stickers to promote airflow and cover the pile to protect from rain while allowing ventilation.

Understanding these timelines ensures that wood is used at its peak performance, whether for structural stability, aesthetic appeal, or craftsmanship. Each species has its own rhythm, and respecting it yields results that stand the test of time.

Durability of Wood Pilings: Lifespan, Factors, and Maintenance Tips

You may want to see also

Explore related products

Effects of Moisture Content on Aging

Wood aging is a delicate balance, and moisture content plays a pivotal role in determining the outcome. Freshly cut wood, often referred to as green wood, can have a moisture content exceeding 100% of its dry weight. This high moisture level makes the wood susceptible to warping, cracking, and decay as it dries. To mitigate these issues, wood is typically air-dried or kiln-dried to reduce moisture content to around 12-15% for indoor use or 19-20% for outdoor applications. Understanding this initial moisture reduction is crucial, as it sets the stage for the aging process.

The relationship between moisture content and wood aging is not linear but rather a dynamic interplay of absorption and release. Wood is hygroscopic, meaning it naturally absorbs and releases moisture in response to its environment. In humid conditions, wood swells as it absorbs moisture, while in dry conditions, it shrinks. This constant fluctuation can lead to internal stresses, causing the wood to crack or split over time. For instance, oak, a popular choice for aging, can experience significant dimensional changes if its moisture content fluctuates by more than 4-6%. To minimize these effects, wood intended for aging should be stored in a controlled environment with relative humidity levels between 50-60%.

One practical strategy to manage moisture content during aging is the use of moisture meters. These devices measure the wood’s moisture level, allowing artisans to monitor and adjust conditions as needed. For example, if a moisture meter reads above 20% in wood intended for indoor furniture, steps such as increasing airflow or using dehumidifiers can be taken to prevent mold growth and structural damage. Conversely, if the moisture content drops below 8%, the wood may become brittle, necessitating the introduction of humidity. Regular monitoring ensures the wood ages gracefully, retaining its structural integrity and aesthetic appeal.

Comparing air-dried and kiln-dried wood highlights the impact of moisture control on aging. Air-drying, a slower process, allows wood to gradually acclimate to its environment, reducing the risk of severe cracking. However, it can take 6 months to 2 years, depending on the wood species and climate. Kiln-drying, on the other hand, accelerates the process to a matter of days or weeks but requires precise control to avoid case hardening, where the outer layers dry too quickly, trapping moisture inside. For aging projects, air-dried wood is often preferred for its stability, though kiln-dried wood can be used if properly conditioned post-drying.

In conclusion, mastering moisture content is essential for successful wood aging. By understanding the hygroscopic nature of wood, employing tools like moisture meters, and choosing appropriate drying methods, artisans can ensure the wood ages beautifully. Whether crafting furniture, musical instruments, or architectural elements, controlling moisture content is the cornerstone of preserving wood’s strength, durability, and timeless charm.

Natalie Wood's Tragic Drowning: Unraveling the Timeline of Her Death

You may want to see also

Explore related products

Accelerated Wood Aging Techniques

Natural wood aging can take decades, but accelerated techniques offer a shortcut to achieving that coveted weathered look. These methods mimic the effects of time, sunlight, moisture, and environmental stress, compressing years of aging into weeks or months. Whether for furniture, flooring, or decorative pieces, understanding these techniques allows you to control the process, ensuring consistency and desired results.

One effective method involves chemical treatments, such as applying a mixture of vinegar and steel wool. The acetic acid in vinegar reacts with the tannins in wood, creating a grayish patina. For optimal results, dissolve 1 cup of vinegar in 1 gallon of water, soak a pad of 0000 steel wool in the solution for 24 hours, then apply the mixture to the wood using a brush or cloth. Allow it to dry and reapply as needed to deepen the effect. This technique works best on woods high in tannins, like oak or cedar.

Physical distressing paired with heat is another powerful approach. Use tools like wire brushes, sandpaper, or chains to create scratches, dents, and texture. Follow this by applying heat with a torch or heat gun to raise the wood grain and darken the surface. Caution is essential here—overheating can scorch the wood, so maintain a consistent distance and monitor the process closely. This method is ideal for achieving a rustic, reclaimed look in a matter of hours.

For a more hands-off approach, consider outdoor exposure combined with controlled moisture. Place the wood in a shaded area where it’s exposed to humidity but not direct sunlight, which can cause uneven fading. Periodically mist the wood with water or apply a damp cloth to encourage fungal growth and surface checking. This technique takes longer—typically 3 to 6 months—but yields a natural, authentic aged appearance.

Each accelerated aging technique has its strengths and limitations, so choose based on the desired outcome and wood type. Chemical treatments offer quick results but may lack depth, while physical distressing and heat provide texture and character. Outdoor exposure is time-consuming but unparalleled in its natural finish. By experimenting with these methods, you can master the art of aging wood, blending science and craftsmanship to achieve timeless beauty in a fraction of the time.

Exploring Muir Woods: Ideal Time for a Serene Nature Experience

You may want to see also

Explore related products

$11.33 $26.99

Signs Wood is Properly Aged

Wood aging is a delicate balance of time, environment, and purpose. Properly aged wood exhibits distinct characteristics that signal its readiness for use in fine craftsmanship or construction. One of the most immediate signs is its color transformation. Freshly cut wood often has a bright, almost raw appearance, but as it ages, it develops a richer, deeper hue. For instance, oak transitions from a pale yellow to a warm, golden brown, while walnut darkens to a luxurious chocolate tone. This natural patina is not just aesthetic; it indicates the wood’s exposure to air and light, which breaks down surface tannins and oils, enhancing both appearance and stability.

Another critical indicator is moisture content. Properly aged wood typically has a moisture level between 6% and 8%, aligning with the ambient humidity of its intended environment. You can test this using a moisture meter—a tool essential for woodworkers. Wood that hasn’t aged sufficiently retains higher moisture, leading to warping, cracking, or mold when used. Conversely, overly dry wood becomes brittle. Achieving this balance requires air-drying for 1–3 years, depending on the species and thickness, or kiln-drying for faster, controlled results.

Texture and hardness also reveal a wood’s maturity. Aged wood feels smoother to the touch as its fibers tighten and stabilize. Run your hand along the surface—properly aged wood lacks the rough, splinter-prone quality of fresh lumber. Additionally, it becomes harder and more resistant to dents, a trait particularly valued in flooring or furniture. For example, aged maple or hickory will dent less under heavy use compared to their green counterparts. This change occurs as the wood’s cellular structure consolidates, a process accelerated by slow, controlled drying.

Finally, odor and insect resistance are subtle yet telling signs. Fresh wood often carries a strong, resinous scent, but aged wood’s aroma is milder and more earthy. This reduction in smell indicates the dissipation of volatile compounds, which also makes the wood less attractive to pests like termites or beetles. Properly aged wood is less likely to harbor infestations, ensuring longevity in structural or decorative applications. To verify, inspect the wood for boreholes or frass—signs of insect activity that suggest inadequate aging.

In summary, recognizing properly aged wood involves observing its color, moisture content, texture, hardness, and odor. These signs collectively ensure the material’s durability, workability, and aesthetic appeal. Whether you’re a professional woodworker or a DIY enthusiast, understanding these cues will help you select wood that meets your project’s demands, avoiding costly mistakes and ensuring a timeless finish.

Maximizing Flavor: Apple Wood Chips Lifespan and Storage Tips

You may want to see also

Explore related products

Storage Conditions for Optimal Aging

Wood aging is a delicate balance of time, environment, and care. Proper storage conditions can significantly influence the quality and speed of the aging process, ensuring the wood develops desirable characteristics like stability, color, and workability. The ideal storage environment mimics natural conditions that promote slow, even drying and aging, minimizing defects such as warping, cracking, or insect damage.

Humidity and Temperature Control

Maintain a relative humidity between 50–70% and a temperature range of 60–80°F (15–27°C) for optimal aging. These conditions prevent the wood from drying too quickly, which can cause internal stresses and cracks. A dehumidifier or humidifier may be necessary to regulate moisture levels, especially in extreme climates. For example, hardwoods like oak or maple benefit from slower drying, while softer woods like pine may tolerate slightly faster processes.

Air Circulation and Stacking Techniques

Proper airflow is critical to prevent mold and mildew. Stack wood stickers (small spacers) between layers to allow air to circulate freely. Stickers should be placed every 12–16 inches, depending on the wood’s thickness. Avoid overcrowding and ensure the stack is off the ground using pallets or supports to prevent moisture absorption from the floor. For larger batches, consider a covered outdoor area with shade to protect from direct sunlight, which can cause uneven drying.

Duration and Monitoring

Aging time varies by wood type and intended use. Softwoods typically require 6–12 months, while hardwoods may need 1–3 years or more. Regularly inspect the wood for signs of pests, mold, or uneven drying. Rotate stacks every 3–6 months to ensure even exposure and reduce the risk of warping. For accelerated aging, kiln-drying can reduce time to weeks, but this method lacks the natural patina achieved through air-drying.

Protective Measures

Shield wood from pests like termites or beetles by applying non-toxic, wood-safe insecticides or storing it in a sealed environment. Cover stacks with breathable tarps to protect from rain while allowing moisture to escape. For long-term storage, consider end-sealing cuts with wax or shellac to minimize moisture loss from exposed ends, which can lead to splitting.

By mastering these storage conditions, you can ensure wood ages gracefully, retaining its structural integrity and aesthetic appeal. Whether for furniture, flooring, or craftsmanship, the right environment transforms raw timber into a material of enduring beauty and strength.

Evan Rachel Wood and Justin Long: Did They Date?

You may want to see also

Frequently asked questions

Wood for outdoor projects typically needs to be aged for at least 6 to 12 months to ensure it is properly dried and stabilized, reducing the risk of warping, cracking, or rotting.

For furniture making, wood should ideally be aged for 1 to 2 years to achieve optimal moisture content (around 8-12%) and minimize movement after crafting.

Yes, the aging time varies by wood species. Dense hardwoods like oak or maple may require 2-3 years, while softer woods like pine may only need 6-12 months.

Yes, the aging process can be accelerated using kiln drying, which reduces the time to weeks or months instead of years, though natural air drying is often preferred for better stability.