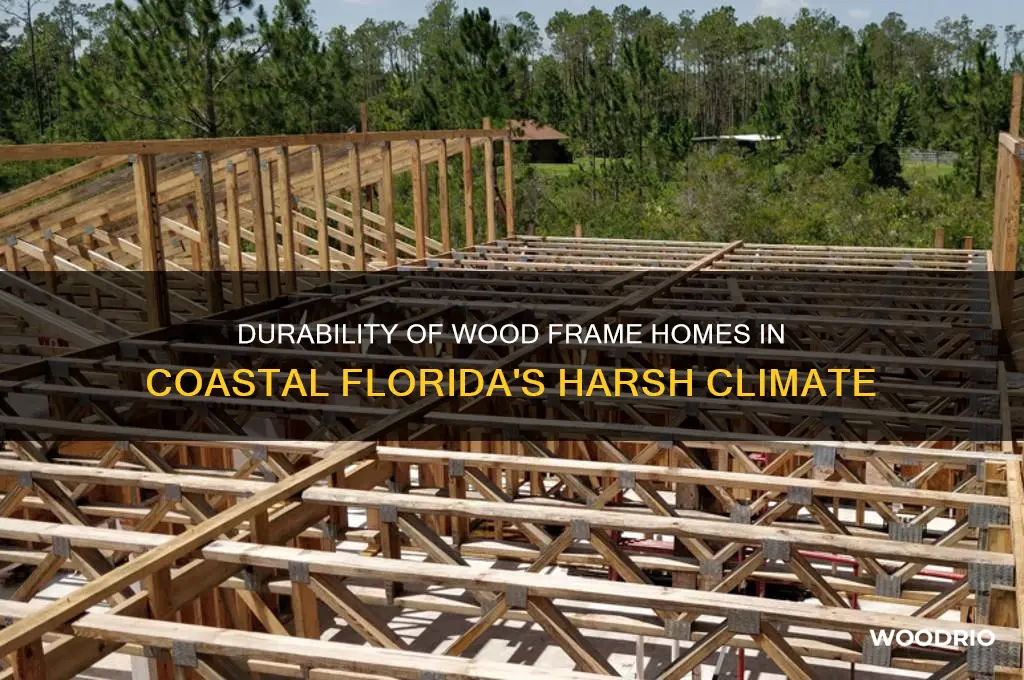

Wood frame houses in coastal Florida face unique challenges due to the region's harsh environmental conditions, including high humidity, saltwater exposure, strong winds, and frequent storms. Despite these factors, a well-constructed and properly maintained wood frame house can last 50 to 100 years or more. Key factors influencing longevity include the use of pressure-treated or naturally rot-resistant wood, effective moisture management through proper ventilation and waterproofing, regular maintenance to address issues like termite infestations and mold, and adherence to building codes designed for hurricane-prone areas. With careful planning and upkeep, wood frame homes in coastal Florida can remain durable and resilient against the demanding climate.

| Characteristics | Values |

|---|---|

| Average Lifespan | 50-70 years (with proper maintenance) |

| Primary Factors Affecting Durability | Humidity, salt air, hurricanes, termites, and moisture-related issues |

| Maintenance Requirements | Regular inspections, termite treatments, waterproofing, and repainting |

| Common Issues | Wood rot, mold, mildew, termite damage, and corrosion of metal fittings |

| Construction Best Practices | Elevated foundations, pressure-treated wood, and moisture barriers |

| Comparative Lifespan (Concrete) | 70-100 years (concrete homes tend to last longer in coastal Florida) |

| Environmental Impact | Susceptible to storm damage and flooding |

| Cost of Maintenance | Higher due to frequent repairs and protective treatments |

| Regional Variability | Lifespan can vary based on proximity to the coast and exposure levels |

| Insurance Considerations | Higher premiums due to increased risk of damage |

Explore related products

What You'll Learn

Material durability in humid climates

In coastal Florida, where humidity levels often exceed 70%, wood frame houses face relentless moisture-related challenges. Wood, a hygroscopic material, naturally absorbs and releases moisture, making it susceptible to warping, cracking, and rot in such environments. Without proper treatment and maintenance, untreated wood can degrade within 5–10 years, while pressure-treated lumber, infused with preservatives like chromated copper arsenate (CCA), can last 20–40 years. However, even treated wood requires vigilant care, including regular inspections for mold, mildew, and termite damage, which thrive in humid conditions.

To combat humidity’s effects, builders often pair wood with moisture-resistant materials like galvanized steel connectors and synthetic sheathing. For instance, using borate-treated wood, which inhibits fungal growth and insect infestation, can extend a structure’s lifespan by 15–20 years. Additionally, incorporating vapor barriers and proper ventilation reduces moisture accumulation within walls. Homeowners should also apply water-repellent sealants every 2–3 years and ensure gutters and downspouts direct water away from the foundation to minimize wood exposure to standing water.

A comparative analysis of wood versus alternative materials reveals both strengths and weaknesses. While wood is cost-effective and readily available, concrete block and steel framing offer superior durability in humid climates, lasting 50–100 years with minimal maintenance. However, these materials come with higher upfront costs and less flexibility in design. For those committed to wood, combining it with advanced protective measures, such as fiber-cement siding or PVC trim, can strike a balance between aesthetics and longevity.

Instructively, homeowners can take proactive steps to preserve their wood frame houses. Start by scheduling annual inspections to identify early signs of moisture damage, such as soft spots or discoloration. Install dehumidifiers in crawl spaces and attics to maintain indoor humidity below 60%. For exterior wood, choose paints and stains with mildewcide additives, reapplying them every 3–5 years. Finally, consider retrofitting vulnerable areas, like window sills and door frames, with composite materials that resist moisture absorption.

Persuasively, investing in material durability is not just about extending a home’s lifespan but also about safeguarding its value and safety. In coastal Florida, where hurricanes and tropical storms exacerbate humidity’s impact, resilient construction practices are non-negotiable. By prioritizing moisture-resistant materials and maintenance, homeowners can ensure their wood frame houses withstand the test of time, even in one of the most challenging climates for construction.

Natalie Wood and Warren Beatty's Brief Romance: Unraveling the Timeline

You may want to see also

Explore related products

$23.42 $24.93

Impact of salt air on wood

Salt air accelerates the deterioration of wood in coastal Florida homes, primarily through corrosion and moisture absorption. The sodium chloride in seawater acts as a catalyst for metal corrosion, causing fasteners like nails and screws to rust and weaken structural integrity. As these metals degrade, they expand, leading to wood splitting and warping. For instance, galvanized steel fasteners, which typically last 10–20 years in inland areas, may fail within 5–7 years in coastal environments due to the corrosive effects of salt air.

Moisture absorption is another critical factor. Salt air increases wood’s hygroscopic nature, allowing it to absorb and retain moisture more readily. This prolonged dampness fosters mold, mildew, and rot, particularly in untreated or poorly sealed wood. In coastal Florida, where humidity levels often exceed 70%, wood in direct contact with salt air can show signs of decay within 3–5 years if not properly maintained. Pressure-treated lumber, while more resistant, still requires regular inspection and resealing to combat these effects.

To mitigate salt air damage, homeowners should prioritize proactive measures. Applying marine-grade sealants or paints every 2–3 years creates a barrier against moisture and salt penetration. Additionally, using non-corrosive fasteners like stainless steel or hot-dipped galvanized hardware can extend the lifespan of wood structures. Regular cleaning with fresh water to remove salt residue is also essential, especially after storms or high-tide events.

Comparatively, alternative materials like aluminum, vinyl, or composite lumber offer greater durability in coastal environments. While wood remains a popular choice for its aesthetic appeal, its longevity in salt air conditions depends heavily on maintenance. For example, a well-maintained wood frame house in coastal Florida can last 30–50 years, whereas untreated structures may deteriorate in half that time. The key takeaway is that salt air demands vigilance—without consistent care, wood’s lifespan in coastal regions is significantly compromised.

Understanding Morning Wood Duration: What's Normal and When to Worry

You may want to see also

Explore related products

Termite and pest resistance measures

In coastal Florida, where humidity and warmth create a paradise for termites and pests, protecting a wood frame house requires proactive, multi-layered strategies. Termites alone cause billions in damage annually, making resistance measures not just advisable but essential. The first line of defense is choosing pressure-treated wood, infused with chemicals like alkaline copper quaternary (ACQ) or chromated copper arsenate (CCA), which repel termites and fungi. However, this is just the beginning; a comprehensive approach includes soil treatment, bait systems, and regular inspections.

Soil treatment, or termiticide barriers, involves applying liquid pesticides like imidacloprid or fipronil around the foundation. These chemicals create a protective zone that termites cannot cross without being eliminated. For new constructions, this is typically done pre-build, but existing homes can benefit from trench and treat methods. Dosage and application must follow label instructions precisely, as overuse can harm the environment and underuse leaves gaps in protection. Pairing this with physical barriers, such as stainless steel mesh or sand particles, adds an extra layer of defense by blocking termite entry points.

Bait systems offer a less invasive alternative, using cellulose-based stations installed around the property. These stations contain slow-acting toxins that termites carry back to their colonies, eventually eradicating them. Brands like Sentricon and Exterra are widely used, with annual monitoring and bait replacement ensuring long-term effectiveness. While bait systems are eco-friendlier, they require patience, as colony elimination can take months. Combining baits with soil treatments provides both immediate and sustained protection.

Regular inspections are the cornerstone of pest resistance, as early detection prevents minor infestations from becoming major structural threats. Homeowners should schedule annual inspections by licensed professionals, who can identify signs like mud tubes, hollowed wood, or discarded wings. Between inspections, homeowners can conduct visual checks for moisture issues, wood-to-ground contact, and cracks in the foundation—all of which attract pests. Addressing these vulnerabilities promptly, such as fixing leaks or sealing gaps, reduces risk significantly.

Finally, integrating pest-resistant landscaping enhances overall protection. Avoid planting dense vegetation near the house, as it retains moisture and provides termite highways. Opt for termite-resistant plants like marigolds or lavender, and maintain a gravel barrier between soil and wood structures. Elevating wood decks or porches at least 6 inches above ground level also minimizes contact with pests. By combining chemical, physical, and environmental strategies, wood frame houses in coastal Florida can withstand the relentless pressure of termites and pests, ensuring longevity in a challenging climate.

Durability of Wood Shake Shingles: Lifespan and Maintenance Tips

You may want to see also

Explore related products

$5.07

Storm and hurricane resilience

In coastal Florida, where hurricanes are a seasonal threat, the resilience of wood-frame houses hinges on proactive design and maintenance. A well-built wood-frame home can withstand decades of storms, but only if it adheres to specific standards. For instance, the Florida Building Code mandates hurricane ties and straps to secure the roof to the walls, reducing the risk of uplift during high winds. Additionally, impact-resistant windows and doors are essential to prevent debris penetration, which is a common cause of structural failure. Regular inspections and upgrades, such as reinforcing garage doors, can further extend a home’s lifespan in this volatile environment.

Consider the role of elevation in storm resilience. In flood-prone areas, raising a wood-frame house above the base flood elevation (BFE) is not just a recommendation—it’s a necessity. The Federal Emergency Management Agency (FEMA) advises homes in coastal zones to be elevated at least 1 to 3 feet above the BFE, depending on local regulations. This simple measure can prevent water damage, which is often more destructive than wind alone. For existing homes, retrofitting with pilings or foundation upgrades is a costly but invaluable investment, potentially adding 20–30 years to a structure’s lifespan.

Material selection also plays a critical role in hurricane resilience. Pressure-treated lumber, resistant to moisture and termites, is ideal for coastal environments. Pairing this with synthetic roofing materials, such as asphalt shingles rated for 130 mph winds, creates a robust defense against storms. However, even the best materials require proper installation. Hiring certified contractors who understand Florida’s unique challenges ensures that every nail, screw, and sealant meets code requirements. A poorly installed roof or siding can fail in a Category 1 hurricane, while a well-executed build can endure Category 3 conditions.

Finally, landscaping can either protect or endanger a wood-frame house during a storm. Strategic planting of native trees and shrubs acts as a natural windbreak, reducing wind speed and debris impact. However, trees must be pruned regularly to prevent branches from becoming projectiles. Similarly, securing outdoor furniture and decor is a small but crucial step often overlooked. By integrating these measures, homeowners can transform a vulnerable wood-frame house into a resilient fortress, capable of withstanding Florida’s harshest storms for generations.

Mastering Wood Carving: Optimal Drying Time for Perfect Results

You may want to see also

Explore related products

Maintenance tips for longevity

In coastal Florida, wood frame houses face relentless challenges from humidity, salt air, and intense UV radiation. Without proactive maintenance, these elements can accelerate decay, leading to structural issues within 20–30 years. However, with diligent care, a wood frame house can endure for 50 years or more. The key lies in understanding the specific vulnerabilities of the coastal environment and addressing them systematically.

Inspect and Seal Regularly

Begin with biannual inspections, focusing on areas prone to moisture accumulation, such as crawl spaces, eaves, and window sills. Use a moisture meter (aim for readings below 20%) to detect hidden dampness. Seal gaps with silicone caulk and apply a high-quality exterior sealant every 3–5 years. For wood siding, opt for a marine-grade sealant to combat salt corrosion. Pressure-washing once a year removes salt buildup but avoid high pressure to prevent wood fiber damage.

Protect Against Pests and Rot

Termites and fungi thrive in Florida’s damp climate, posing significant threats to wood structures. Treat exposed wood with borate-based preservatives, which penetrate deeply to deter pests and inhibit rot. Reapply every 2–3 years, especially after heavy rains. Install termite bait stations around the perimeter and schedule annual pest inspections. For added protection, use pressure-treated lumber in ground-contact areas like piers and joists.

Manage Moisture and Ventilation

Poor ventilation accelerates wood decay by trapping humidity. Ensure soffit and ridge vents are clear of debris, and install dehumidifiers in crawl spaces if necessary. Maintain gutters and downspouts to direct water away from the foundation, and slope the ground to prevent pooling. Consider vapor barriers in crawl spaces to minimize ground moisture infiltration.

Maintain Roof and Exterior Finishes

The roof is your first line of defense against coastal elements. Inspect shingles annually for curling, cracking, or missing pieces, and replace them promptly. Use reflective roof coatings to reduce UV damage and heat absorption. Repaint exterior wood surfaces every 5–7 years with UV-resistant, mildew-inhibiting paint. For decks and railings, apply a semi-transparent stain to allow wood to breathe while providing protection.

By implementing these targeted maintenance strategies, you can significantly extend the lifespan of a wood frame house in coastal Florida. The investment in regular care not only preserves structural integrity but also enhances the home’s resilience against the region’s harsh conditions.

Durability of Wood Basements: Lifespan and Maintenance Tips Revealed

You may want to see also

Frequently asked questions

A well-maintained wood frame house in coastal Florida can last 50 to 100 years, depending on factors like construction quality, maintenance, and exposure to harsh coastal conditions.

The main factors include exposure to saltwater, humidity, hurricanes, termites, and UV radiation, as well as the quality of materials and construction practices.

Saltwater exposure can accelerate corrosion of metal components, degrade wood, and increase the risk of rot and mold, significantly reducing the lifespan of the structure if not properly mitigated.

Regular maintenance includes inspecting and repairing the roof, sealing gaps to prevent moisture intrusion, treating wood for termites, repainting or resealing exterior surfaces, and ensuring proper drainage to avoid water damage.

Yes, using pressure-treated or naturally rot-resistant wood, elevating the structure above flood levels, installing hurricane straps and impact-resistant windows, and applying waterproof barriers can significantly enhance durability in coastal environments.