When considering the durability of a wood section path, several factors come into play, including the type of wood used, the climate, maintenance practices, and the level of foot traffic. Typically, a well-constructed wood path made from naturally rot-resistant species like cedar, redwood, or black locust can last anywhere from 10 to 20 years or more. However, softer woods like pine may only endure 5 to 10 years without proper treatment. Regular maintenance, such as sealing or staining to protect against moisture and UV damage, can significantly extend the lifespan. Additionally, paths in drier climates tend to outlast those in wet or humid regions, where rot and insect damage are more prevalent. Proper installation, including adequate drainage and ground preparation, also plays a crucial role in maximizing longevity.

| Characteristics | Values |

|---|---|

| Lifespan of Wood Section Path | 5–15 years (varies based on wood type, maintenance, and environmental factors) |

| Wood Type | Hardwoods (e.g., cedar, redwood) last longer than softwoods (e.g., pine) |

| Maintenance | Regular sealing, staining, and cleaning can extend lifespan by 5–10 years |

| Environmental Factors | High moisture, extreme temperatures, and pest exposure reduce durability |

| Installation Quality | Proper drainage, ground preparation, and spacing impact longevity |

| Usage Level | High foot traffic accelerates wear and tear, shortening lifespan |

| Cost of Replacement | $5–$15 per square foot (depending on wood type and labor costs) |

| Sustainability | Reclaimed or treated wood can improve durability and eco-friendliness |

| Aesthetic Appeal | Natural weathering may be desirable, but structural integrity must be maintained |

Explore related products

What You'll Learn

Material Quality Impact

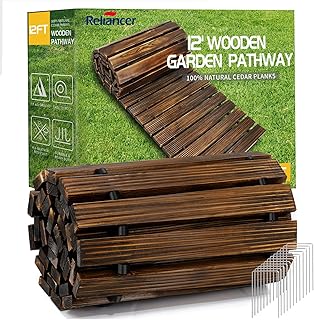

The lifespan of a wood section path hinges significantly on the quality of the material chosen. Opting for premium hardwoods like cedar, redwood, or tropical hardwoods can extend durability to 20–30 years, while lower-grade softwoods like pine may degrade within 5–10 years. This disparity underscores the importance of selecting wood with natural resistance to rot, insects, and moisture—factors that accelerate decay. For instance, cedar contains natural oils that repel pests and fungi, making it a superior choice for longevity.

Analyzing the impact of material quality reveals a direct correlation between density and durability. Denser woods, such as ipe or teak, are less prone to warping, splitting, or cracking under foot traffic and weather exposure. Conversely, less dense woods absorb more moisture, leading to swelling, shrinkage, and eventual structural failure. A practical tip: measure wood density by checking its weight; heavier boards typically indicate higher density and better performance over time.

Instructively, treating wood with preservatives can mitigate quality deficiencies. Pressure-treated lumber, infused with chemicals like chromated copper arsenate (CCA), can last 15–20 years, even if the base material is less durable. However, this approach requires careful handling due to potential health risks from chemical exposure. Alternatively, eco-friendly options like acetylated wood, treated with acetic anhydride to reduce moisture absorption, offer a safer, long-lasting solution without compromising environmental integrity.

Comparatively, the cost of high-quality materials often offsets long-term expenses. While premium hardwoods may cost 2–3 times more than softwoods upfront, their extended lifespan reduces the need for frequent repairs or replacements. For example, a 100-foot cedar path might cost $1,500–$2,000, but it will outlast a $500 pine path by decades, saving money and labor over time. This makes investing in better materials a financially prudent decision for those prioritizing sustainability and low maintenance.

Descriptively, the aesthetic appeal of high-quality wood evolves gracefully over time. Premium woods develop a silver-gray patina when left untreated, blending naturally with outdoor environments. In contrast, lower-quality woods often fade unevenly or become discolored, detracting from the path’s visual appeal. For those seeking a timeless look, choosing materials that age beautifully ensures the path remains an asset rather than an eyesore as years pass.

In conclusion, material quality is not just a factor but the cornerstone of a wood section path’s longevity. By prioritizing density, natural resistance, and appropriate treatments, one can create a path that withstands time, weather, and use. Whether driven by practicality, aesthetics, or sustainability, the choice of wood dictates not only how long the path lasts but also how well it serves its purpose throughout its lifespan.

Wood Pilings Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

Weathering Effects Over Time

Wooden pathways, while aesthetically pleasing, are subject to relentless weathering that accelerates their degradation. Sunlight, a primary culprit, breaks down lignin—a key component in wood—through a process called photodegradation. This UV-induced damage manifests as surface graying, cracking, and warping, reducing structural integrity over time. In regions with intense sunlight, untreated wood can show significant wear within 2–3 years, while treated or naturally resistant species like cedar or redwood may endure up to 5–7 years before requiring intervention.

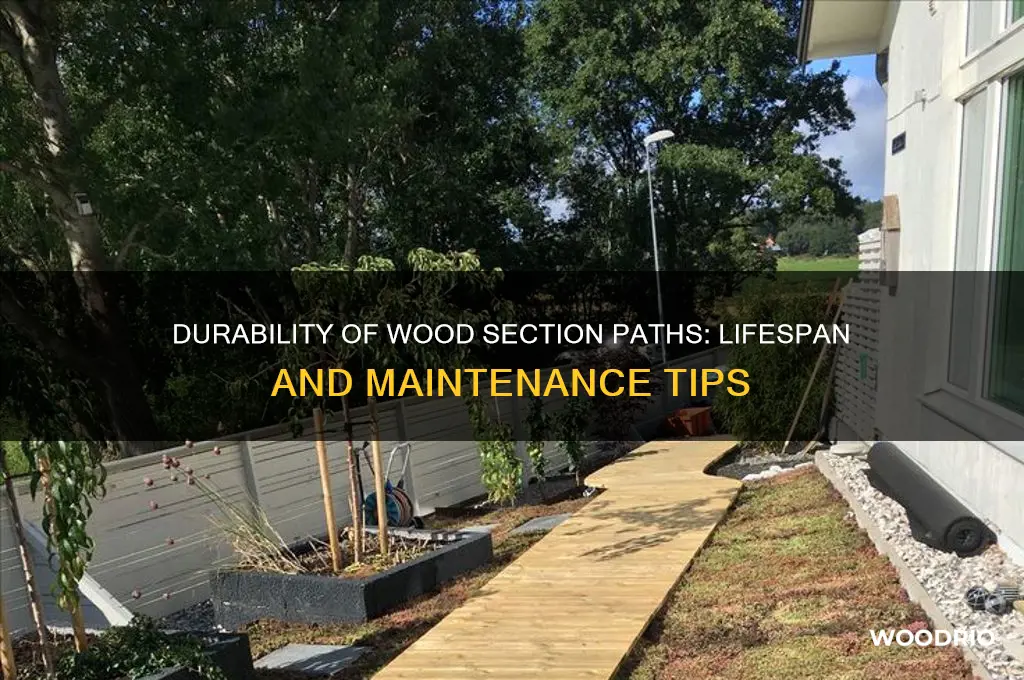

Moisture, another formidable adversary, infiltrates wood fibers, causing swelling, shrinking, and eventual rot. Rain, humidity, and ground moisture create ideal conditions for fungi and insects, which further compromise the material. For instance, a wood section path in a damp, shaded area can deteriorate within 3–5 years, whereas elevated or well-drained installations may last 8–10 years. Applying water-repellent sealants or using pressure-treated wood can mitigate this, but reapplication every 1–2 years is essential for prolonged protection.

Temperature fluctuations exacerbate weathering by causing wood to expand and contract, leading to splits and splinters. In climates with extreme seasonal shifts, such as freezing winters and hot summers, wood pathways experience accelerated stress. For example, a path in a temperate climate might last 6–8 years, while one in a continental climate could degrade in half that time. Strategic design choices, like incorporating expansion gaps or using thermally stable composites, can alleviate these effects.

Wind and debris contribute subtly but significantly to wear. Abrasive particles carried by wind gradually erode the wood’s surface, while fallen leaves or dirt trap moisture, fostering decay. Regular maintenance, such as sweeping and clearing debris, can extend a path’s lifespan by 1–2 years. Additionally, installing the path in a sheltered area or using denser wood species reduces susceptibility to wind-driven damage.

Understanding these weathering mechanisms allows for informed decisions to maximize durability. Combining preventative measures—like UV-resistant finishes, moisture barriers, and strategic placement—can significantly extend a wood section path’s life. While no solution is permanent, proactive care ensures these pathways remain functional and attractive for as long as possible.

Wood Ticks' Survival Duration Without a Host: A Comprehensive Guide

You may want to see also

Explore related products

Maintenance Frequency Needs

Wood section paths, when properly maintained, can last anywhere from 10 to 20 years, depending on factors like climate, usage, and material quality. However, the key to maximizing their lifespan lies in understanding and adhering to specific maintenance frequency needs. Neglecting this aspect can lead to premature deterioration, while over-maintenance can be unnecessary and costly.

Analytical Insight:

The frequency of maintenance for wood section paths is directly tied to environmental exposure. In regions with high humidity or frequent rainfall, inspections and treatments should occur every 6 to 12 months. For drier climates, an annual check-up may suffice. The type of wood also matters—hardwoods like cedar or redwood naturally resist decay longer than softer pine, reducing maintenance demands. Monitoring for signs of wear, such as splintering or mold, allows for targeted interventions rather than reactive repairs.

Instructive Steps:

To maintain a wood section path effectively, follow a tiered maintenance schedule. Monthly: Clear debris and inspect for loose boards or protruding nails. Seasonally: Apply a protective sealant or stain to shield against UV rays and moisture. Annually: Pressure wash the surface to remove dirt and mildew, ensuring the wood’s pores remain open for treatment absorption. Every 3–5 Years: Replace individual sections showing significant wear to prevent structural compromise.

Comparative Perspective:

Unlike concrete or gravel paths, wood requires more proactive care but offers aesthetic and ergonomic benefits. While gravel paths may need occasional regrading, and concrete may crack over time, wood paths demand regular sealing and spot repairs. However, with proper maintenance, wood’s natural warmth and adaptability make it a worthwhile investment. For instance, a cedar path in a temperate climate, maintained biannually, can outlast a poorly sealed pine path in the same conditions by 5–7 years.

Practical Tips:

To streamline maintenance, keep a log of inspections and treatments, noting areas of concern. Use a breathable sealant to prevent moisture trapping, and trim overhanging vegetation to minimize leaf litter and mold growth. For high-traffic areas, consider adding gravel or mulch alongside the path to reduce direct wear. Finally, invest in quality materials upfront—pressure-treated or composite wood may cost more initially but reduces long-term maintenance frequency.

Maintenance frequency is not one-size-fits-all for wood section paths. By tailoring care to environmental conditions, wood type, and usage patterns, you can significantly extend the path’s lifespan. Consistent, proactive measures ensure the path remains safe, functional, and visually appealing for years to come.

Boiling Wooden Spoons: The Ultimate Guide to Safe Sterilization

You may want to see also

Explore related products

Foot Traffic Influence

Wooden pathways, while charming and natural, face a silent adversary in foot traffic. Each step exerts pressure, accelerating wear and tear. High-traffic areas, like garden entrances or public parks, can see a wooden path degrade in as little as 5–7 years without proper maintenance. Conversely, low-traffic zones, such as secluded backyard trails, may endure for 10–15 years. The key lies in understanding how frequency and intensity of use directly correlate with longevity.

To mitigate foot traffic’s impact, consider strategic design choices. Wider paths distribute weight more evenly, reducing stress on individual planks. Incorporating gravel or mulch alongside the wood can divert some traffic and provide natural drainage. For high-traffic areas, opt for hardwoods like cedar or redwood, which are more resistant to decay. Applying a protective sealant annually can also double the lifespan by repelling moisture and UV damage.

A comparative analysis reveals that foot traffic isn’t just about quantity—it’s about quality. Children’s play areas, for instance, experience lighter but more erratic footfalls, which can splinter wood faster than steady, adult-paced traffic. Similarly, runners or cyclists increase friction and impact, shortening the path’s life by up to 30%. Tailoring maintenance to the type of traffic—such as sanding rough edges or replacing high-impact sections—can extend durability significantly.

For those seeking a persuasive argument, investing in foot traffic management is cost-effective in the long run. Installing stepping stones or pavers in high-wear zones can redirect traffic and preserve the wood. Alternatively, using modular wooden sections allows for easy replacement of damaged parts without overhauling the entire path. By proactively addressing traffic patterns, you can enjoy a functional, aesthetically pleasing pathway for over a decade, rather than facing premature replacement.

Finally, a descriptive approach highlights the interplay between foot traffic and environmental factors. In humid climates, constant moisture combined with heavy use accelerates rot, while in arid regions, UV exposure and foot-induced cracks become the primary concern. Regular inspections—checking for splinters, warping, or loose boards—are essential. Pairing this with traffic-conscious design ensures the path not only lasts but thrives, blending seamlessly into its surroundings despite the demands placed upon it.

Durability of Wood Doors: Lifespan, Maintenance, and Longevity Factors

You may want to see also

Explore related products

Pest & Rot Damage

Wood section paths, while charming and natural, are susceptible to pest and rot damage, which can significantly shorten their lifespan. Termites, carpenter ants, and powderpost beetles are common culprits that feast on wood, compromising its structural integrity. These pests are particularly drawn to untreated or poorly maintained wood, making regular inspection and preventive measures essential. Rot, often caused by fungi like brown rot or white rot, thrives in damp conditions, breaking down the wood’s cellular structure. Understanding these threats is the first step in preserving your path’s longevity.

To combat pest infestations, consider treating wood sections with borate-based preservatives, which are effective against termites and beetles. Apply a solution of 10–15% borate concentration to bare wood before installation, ensuring thorough penetration. For existing paths, drill small holes into the wood and inject the solution using a garden sprayer. Pair this with physical barriers like metal mesh or gravel around the path to deter pests from accessing the wood. Regularly inspect for frass (wood shavings or pellets) or hollow-sounding sections, which indicate active infestations.

Preventing rot requires managing moisture, the primary catalyst for fungal growth. Elevate wood sections slightly above ground level using gravel or concrete footings to improve drainage. Apply a water-repellent sealant annually, focusing on end grains and cut surfaces where moisture absorption is highest. In humid climates, incorporate ventilation gaps between wood sections to allow air circulation. If rot is detected, remove affected areas promptly and replace them with treated wood. For minor cases, fungicidal treatments containing copper azole or sodium silicate can halt progression.

Comparing preventive strategies, chemical treatments offer robust protection but require careful application to avoid environmental harm. Natural methods, like using cedar or redwood (naturally pest-resistant), are eco-friendly but may still need maintenance. Combining both approaches—using resistant wood and applying preservatives—yields the best results. For instance, a cedar path treated with borates and sealed with a water-repellent can last 15–20 years, compared to 5–10 years for untreated pine.

In practice, maintaining a wood section path involves a proactive mindset. Schedule biannual inspections, especially after wet seasons, to catch issues early. Keep surrounding vegetation trimmed to reduce shade and moisture retention. If replacing damaged sections, ensure new wood is pressure-treated and compatible with existing pieces. By addressing pest and rot risks systematically, you can extend your path’s lifespan while preserving its aesthetic appeal.

Perfect Wooden Kabob Sticks: Soaking Time for Safe Grilling

You may want to see also

Frequently asked questions

A well-maintained wood section path can last between 10 to 20 years, depending on factors like wood type, climate, and maintenance.

Yes, hardwoods like cedar or redwood are more durable and can last longer (15–25 years), while softer woods like pine may only last 5–10 years.

Extreme weather, such as heavy rain, snow, or intense sunlight, can shorten the lifespan of a wood path. Proper sealing and regular maintenance can mitigate these effects.

Absolutely. Regular sealing, staining, and repairing damaged sections can significantly extend the lifespan of a wood path, potentially adding 5–10 years to its durability.