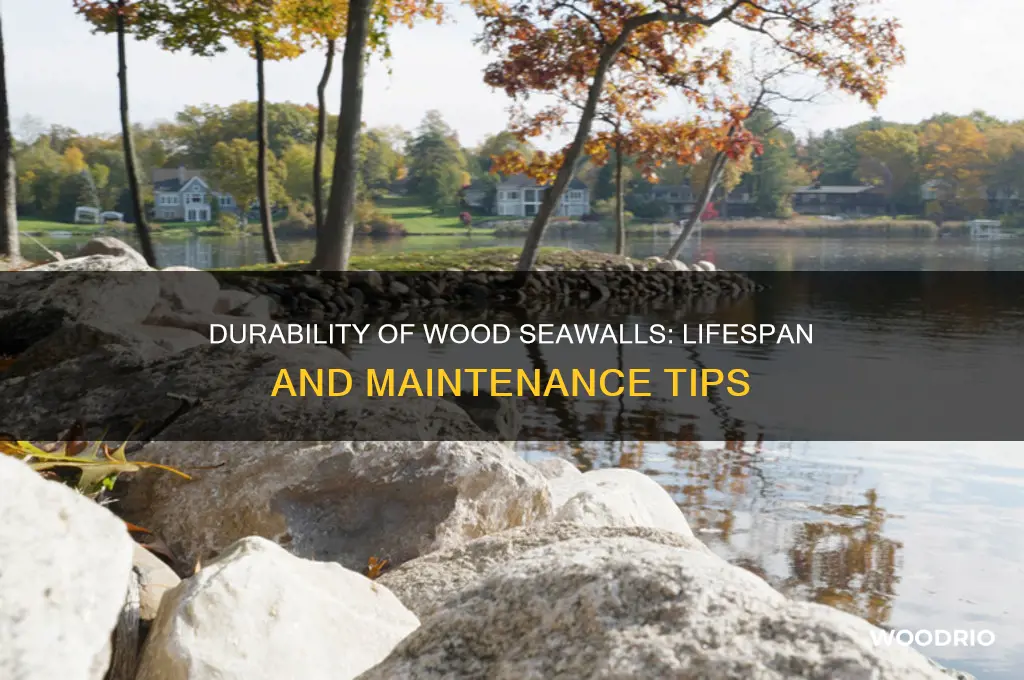

Wooden seawalls, while a popular and cost-effective option for shoreline protection, have a limited lifespan due to their exposure to harsh marine environments. The durability of a wood seawall depends on several factors, including the type of wood used, the quality of construction, and the level of maintenance. Typically, a well-built and maintained wood seawall can last anywhere from 15 to 30 years, with some lasting even longer under optimal conditions. However, constant exposure to saltwater, wave action, marine borers, and UV radiation accelerates deterioration, making regular inspections and repairs essential to maximize its lifespan. Compared to more durable materials like concrete or vinyl, wood seawalls generally require more frequent replacement, making them a more temporary solution for coastal erosion control.

Explore related products

What You'll Learn

Material Quality Impact

The lifespan of a wood seawall hinges on the quality of the materials used. Pressure-treated lumber, for instance, is a popular choice due to its resistance to rot and insect damage. However, not all pressure-treated wood is created equal. Wood treated with chromated copper arsenate (CCA) can last 20–40 years, while newer treatments like alkaline copper quaternary (ACQ) may offer similar durability but require proper installation to avoid warping. Opting for higher-grade, denser wood species like cedar or redwood can further extend lifespan, though at a higher initial cost.

Consider the environmental conditions when selecting materials. Seawalls in saltwater environments face harsher conditions than those in freshwater. For saltwater exposure, choose wood with a higher retention level of preservatives—typically 0.60 pounds per cubic foot (pcf) for CCA or equivalent in ACQ. Additionally, stainless steel fasteners should be used to prevent corrosion, which can weaken the structure over time. In freshwater settings, a lower retention level (0.40 pcf) may suffice, but always prioritize materials rated for marine or wet environments.

Maintenance plays a critical role in maximizing material longevity. Even high-quality wood requires regular inspections and treatments. Apply a marine-grade sealant every 2–3 years to protect against moisture intrusion and UV damage. For added durability, consider installing a geotextile filter fabric behind the seawall to reduce soil erosion and pressure on the wood. Neglecting maintenance can halve the expected lifespan, regardless of initial material quality.

Comparing wood to alternative materials highlights the trade-offs in material quality. While wood is cost-effective and aesthetically pleasing, concrete or vinyl seawalls can last 50+ years with minimal maintenance. However, wood’s natural flexibility allows it to better absorb wave impacts without cracking, making it suitable for dynamic shorelines. If budget is a concern but longevity is a priority, invest in premium wood treatments and pair them with strategic design features like batter (angled walls) to reduce water pressure.

Ultimately, the material quality of a wood seawall dictates its resilience and lifespan. By selecting the right wood grade, treatment, and fasteners, and committing to regular maintenance, you can achieve 20–40 years of service. For those seeking a balance between cost and durability, wood remains a viable option—provided it’s treated with care and foresight.

Do Daddy Long Legs Burrow in Wood? Unveiling the Truth

You may want to see also

Explore related products

Maintenance Frequency Needs

Wooden seawalls, while aesthetically pleasing and cost-effective, are inherently vulnerable to the relentless forces of nature. Their lifespan hinges critically on maintenance frequency, which must be tailored to the specific environmental conditions they face. In calm, freshwater environments, a well-maintained wood seawall can endure for 20–30 years. However, in saltwater or high-wave areas, this lifespan shrinks dramatically to 10–15 years without diligent care. The key to maximizing longevity lies in understanding and implementing a proactive maintenance schedule.

Inspect Annually, Act Seasonally

Begin with a thorough annual inspection, ideally in spring, to assess structural integrity, identify rot, and detect marine borer damage. Look for cracks, warping, or loose fasteners, as these are early indicators of deterioration. Seasonal maintenance is equally vital. After winter storms, check for debris buildup and erosion at the base, which can undermine stability. Summer inspections should focus on UV damage and drying, as prolonged sun exposure can cause wood to splinter and weaken. Addressing these issues promptly prevents minor problems from escalating into costly repairs.

Bi-Annual Treatments for Longevity

To combat the twin threats of moisture and marine organisms, bi-annual treatments are essential. Apply a high-quality, marine-grade wood preservative every six months, focusing on areas below the waterline and those exposed to constant moisture. For added protection, consider installing a geotextile fabric behind the seawall to reduce waterlogging and soil pressure. If marine borers are prevalent, treat the wood with borate-based solutions, which penetrate deeply to deter infestation. Regular cleaning to remove algae, barnacles, and other growths also prevents surface degradation and maintains structural integrity.

Proactive Measures for High-Risk Zones

In harsh environments, such as coastal areas with strong tides or frequent storms, maintenance must be more aggressive. Install sacrificial boards at the waterline, which can be replaced as they degrade, sparing the main structure. Reinforce the seawall with steel or vinyl sheeting to reduce direct water contact and abrasion. Monitor water levels closely, as fluctuating tides can accelerate wear. In such cases, quarterly inspections and treatments are advisable to stay ahead of potential damage.

Balancing Effort and Investment

While frequent maintenance demands time and resources, it is a far more economical approach than premature replacement. Neglecting a wood seawall can lead to catastrophic failure, endangering property and incurring emergency repair costs. By adhering to a structured maintenance plan, you not only extend the seawall’s lifespan but also preserve its functionality and appearance. Think of it as preventive care for a valuable asset—consistent effort yields lasting protection.

In essence, the frequency of maintenance is directly proportional to the lifespan of a wood seawall. Tailor your approach to the environment, stay vigilant, and act decisively to ensure your seawall stands the test of time.

Elle Woods' Class Skipping Habits: Uncovering Her Academic Absences

You may want to see also

Explore related products

Environmental Wear Factors

Wooden seawalls, while effective in shoreline protection, face relentless environmental wear that significantly shortens their lifespan. Water exposure, the primary culprit, accelerates decay through constant moisture absorption, which softens the wood and fosters fungal growth. Unlike treated lumber used in decks, seawall timber is submerged or repeatedly wetted and dried, breaking down protective chemical barriers faster. Studies show untreated pine seawalls may last 5–10 years, while pressure-treated options extend to 15–20 years under moderate conditions. However, these estimates plummet in brackish or saltwater environments, where chloride ions penetrate wood fibers, corroding internal structures and reducing lifespan by up to 40%.

Sunlight and temperature fluctuations further compound wear through photodegradation and thermal stress. UV rays break down lignin, the natural "glue" in wood, causing surface cracking and splintering. In tropical regions, where UV indices exceed 10 for over 200 days annually, untreated seawalls exhibit surface erosion within 2 years. Similarly, freeze-thaw cycles in temperate zones expand and contract wood fibers, creating microfractures that weaken structural integrity. For instance, seawalls in the Great Lakes region, subjected to 50+ freeze-thaw events yearly, show 25% more cracking than those in milder climates.

Biological agents, particularly marine borers and fungi, exploit weakened wood to accelerate deterioration. Teredo worms, common in coastal waters, can burrow 12–18 inches into untreated wood annually, compromising thickness by 30% within 3 years. Even pressure-treated wood, while resistant, isn’t immune; copper-based preservatives leach 5–10% per year in saltwater, leaving the core vulnerable after a decade. Fungal species like *Poria monticola* thrive in damp conditions, digesting cellulose and reducing tensile strength by 50% in 5 years. Regular inspections for frass (worm excrement) or mushroom growth are critical to identify infestations early.

Wave action and sediment abrasion introduce mechanical wear, stripping protective coatings and exposing raw wood. In high-energy wave zones, where swells exceed 3 feet, seawalls lose 0.5–1 inch of surface material annually. Sediment, especially silica-rich sand, acts like sandpaper during tidal shifts, doubling surface degradation rates. Installing sacrificial rock buffers or geotextile wraps can reduce abrasion by 40%, but these require replacement every 3–5 years. Without such measures, a seawall in a dynamic estuary may lose structural integrity within 8–12 years, compared to 15–20 years in calmer bays.

Mitigating environmental wear requires proactive strategies tailored to local conditions. For saltwater environments, choose woods like cedar or cypress, naturally resistant to rot, and apply marine-grade sealants reapplied biannually. In high-UV areas, use UV-inhibiting stains and consider shading structures. For biological threats, install stainless steel mesh barriers to deter borers and ensure proper drainage to minimize fungal habitats. Finally, monitor erosion patterns and reinforce vulnerable sections with composite panels or concrete overlays. While no solution is permanent, combining these measures can extend a wood seawall’s lifespan by 50–70%, balancing cost and durability effectively.

Traeger 575 Wood Pellet Burn Time: How Long Do They Last?

You may want to see also

Explore related products

Treatment Lifespan Boost

Wooden seawalls, while robust, face relentless assault from water, weather, and marine organisms. Their lifespan typically ranges from 15 to 25 years, but this can be significantly extended with strategic treatments. The key lies in understanding the primary threats—moisture penetration, fungal decay, and insect damage—and addressing them proactively. Treatment lifespan boost focuses on enhancing the wood’s resistance through chemical preservatives, physical barriers, and regular maintenance. By investing in these measures, you can double or even triple the longevity of your seawall, ensuring it remains functional and cost-effective for decades.

One of the most effective methods to boost a wood seawall’s lifespan is through pressure treatment with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ). These chemicals penetrate deep into the wood, creating a barrier against fungi, termites, and rot. For optimal results, ensure the wood is treated to a retention level of 0.60 pounds per cubic foot (PCF) for ground contact applications. After installation, apply a water-repellent sealant to minimize moisture absorption, which is the primary catalyst for deterioration. This two-pronged approach can extend the seawall’s life by 10–15 years, depending on environmental conditions.

Another critical aspect of treatment lifespan boost is regular inspection and maintenance. Annually inspect the seawall for signs of wear, such as cracks, splintering, or fungal growth. Address minor issues immediately—for instance, use epoxy fillers for cracks and reapply preservatives to exposed areas. Every 3–5 years, consider re-sealing the wood to maintain its moisture resistance. For seawalls in high-salinity environments, use marine-grade sealants that can withstand corrosive saltwater. Consistent upkeep not only prolongs the structure’s life but also reduces the need for costly repairs or replacements.

Comparatively, untreated wood seawalls often fail within a decade, while those with proper treatments can last 30–40 years or more. The difference lies in the cumulative effect of small, consistent interventions. For example, installing a geotextile fabric behind the seawall can reduce soil erosion and water pressure, further protecting the wood. Additionally, incorporating sacrificial anodes can mitigate corrosion in metal fasteners, a common weak point. These layered strategies demonstrate that treatment lifespan boost is not a single action but a holistic approach to preserving the seawall’s integrity.

Finally, consider the environmental impact of your treatment choices. While CCA is highly effective, it contains arsenic, which can leach into the soil over time. ACQ and copper azole are safer alternatives, though slightly less durable. Pairing these treatments with eco-friendly sealants and erosion control measures ensures both longevity and sustainability. By balancing efficacy with environmental responsibility, you can achieve a treatment lifespan boost that benefits both your property and the surrounding ecosystem.

Wood Deck Wet Sanding: Optimal Timing for Smooth, Refinished Surfaces

You may want to see also

Explore related products

Replacement Cost Estimates

Wood seawalls, while effective in protecting shorelines, are not permanent solutions. Their lifespan varies significantly, typically ranging from 15 to 25 years, depending on factors like wood type, environmental conditions, and maintenance. When the time comes for replacement, understanding the cost estimates is crucial for planning and budgeting.

Factors Influencing Replacement Costs:

The expense of replacing a wood seawall hinges on several variables. Material choice is primary—pressure-treated pine is more affordable but shorter-lived, while hardwoods like oak or cypress cost more upfront but may extend the lifespan. Labor accounts for a substantial portion, with complex installations or difficult access increasing prices. Permitting fees, site preparation, and disposal of the old structure also contribute. For instance, a 100-foot seawall might range from $20,000 to $50,000, with premium materials and labor pushing costs higher.

Cost-Saving Strategies:

To mitigate expenses, consider phased replacement, where sections are addressed as they deteriorate, rather than the entire structure at once. Regular maintenance, such as reapplying preservatives or repairing minor damage, can delay replacement. Opting for recycled or sustainably sourced materials may reduce costs while aligning with environmental goals. Additionally, obtaining multiple contractor bids ensures competitive pricing and highlights potential cost-saving alternatives.

Long-Term Investment Perspective:

While initial replacement costs may seem daunting, viewing the expense as a long-term investment can shift perspective. A well-constructed seawall protects property value by preventing erosion and flooding. Comparing the cost of replacement to the potential damage from a failed seawall underscores its value. For example, shoreline erosion can devalue a property by tens of thousands of dollars, making a $30,000 replacement a prudent safeguard.

Practical Tips for Accurate Estimates:

To obtain precise replacement cost estimates, start by consulting marine contractors with experience in seawall projects. Provide detailed site information, including length, height, and soil conditions. Request itemized quotes to understand material, labor, and permit costs. Factor in a contingency budget of 10–15% for unforeseen issues, such as hidden damage or regulatory changes. Finally, explore financing options or grants for shoreline protection projects, which can offset costs and make replacement more manageable.

By carefully considering these factors and strategies, property owners can navigate the financial aspects of wood seawall replacement with confidence and clarity.

Understanding Wood Mites: Lifespan and Survival in Wooden Environments

You may want to see also

Frequently asked questions

A wood seawall typically lasts between 20 to 30 years, depending on factors like wood type, maintenance, and environmental conditions.

Factors like exposure to saltwater, marine borers, lack of maintenance, and frequent storms can significantly shorten the lifespan of a wood seawall.

Yes, pressure-treated wood can extend the life of a seawall by 5 to 10 years, as it is more resistant to rot, insects, and decay.

Regular maintenance, such as inspections, repairs, and protective coatings, can extend the life of a wood seawall by up to 50%, potentially adding 10–15 years to its lifespan.

Yes, alternatives like vinyl, concrete, or steel seawalls can last 30–50+ years, offering greater durability and lower maintenance compared to wood.

![Preservation [Import]](https://m.media-amazon.com/images/I/81+IBpvrysL._AC_UL320_.jpg)

![Preservation Society [DVD]](https://m.media-amazon.com/images/I/31AJS2ZS1YL._AC_UL320_.jpg)