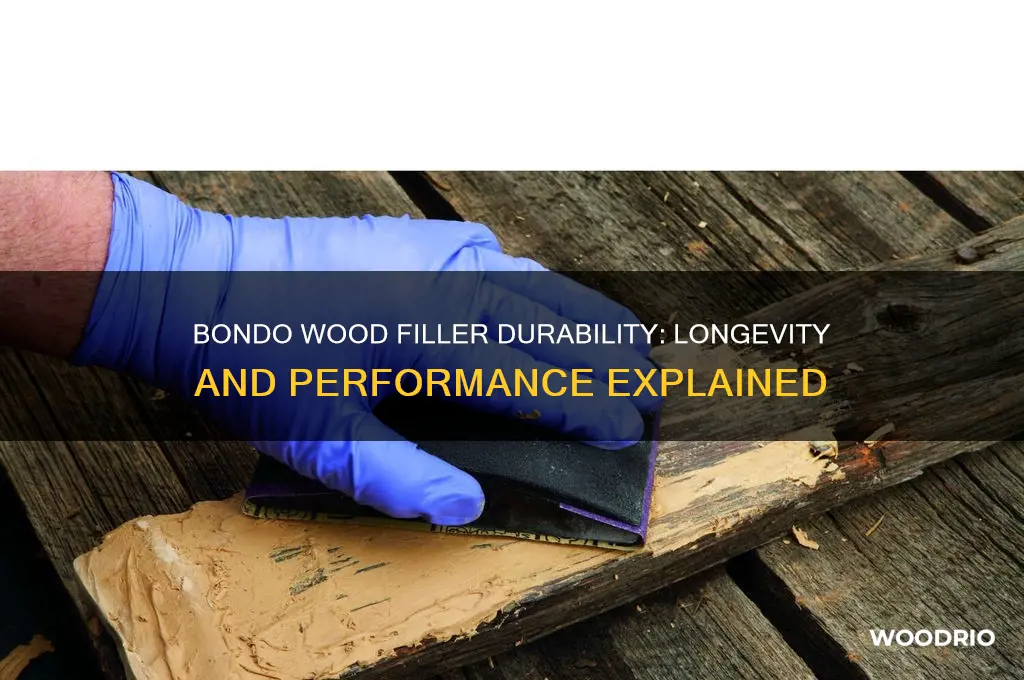

Bondo wood filler is a popular choice for repairing and restoring wood surfaces, known for its durability and ease of use. However, one common question among users is how long it actually lasts. The longevity of Bondo wood filler depends on several factors, including the type of wood, the environmental conditions it’s exposed to, and the quality of the application. When applied correctly and sealed properly, Bondo wood filler can last for many years, often outperforming the original wood in terms of resistance to moisture, temperature fluctuations, and general wear and tear. In ideal conditions, such as indoor applications with minimal exposure to harsh elements, it can remain effective for a decade or more. However, in outdoor settings or areas prone to high humidity, its lifespan may be shorter, typically ranging from 5 to 7 years, unless additional protective measures like paint or varnish are applied. Understanding these variables is key to maximizing the durability of Bondo wood filler in any project.

Explore related products

$14.19 $16.8

What You'll Learn

Bondo Wood Filler Shelf Life

Bondo wood filler, a staple in woodworking and home repair, boasts a shelf life that hinges on proper storage and handling. Unopened containers, when stored in a cool, dry place away from direct sunlight, can last up to 2 years. This longevity is a testament to the product’s formulation, designed to resist drying out or hardening prematurely. However, once opened, the clock starts ticking. Exposure to air accelerates curing, reducing the filler’s usability to a matter of weeks, depending on how much product remains and how well it’s sealed.

To maximize shelf life after opening, follow these steps: first, ensure the lid is tightly secured to minimize air exposure. Second, store the container upside down; this prevents the filler from settling and forming a hardened skin on the surface. Third, consider transferring small amounts to a separate airtight container for immediate use, leaving the bulk of the product undisturbed. These practices can extend the filler’s usability by several weeks, saving both time and money on replacements.

Comparatively, Bondo wood filler’s shelf life outpaces many water-based wood fillers, which often degrade within months due to mold or separation. However, it falls short of epoxy-based fillers, which can remain viable for years, even after opening. This middle-ground durability makes Bondo a practical choice for occasional users who need reliability without the complexity of epoxy systems. For best results, always check the product’s consistency before use; if it’s lumpy or difficult to mix, it’s likely past its prime.

A cautionary note: improper storage can drastically shorten Bondo wood filler’s shelf life. High temperatures, humidity, or exposure to UV light can cause the filler to harden in the container, rendering it unusable. Avoid storing it in garages or sheds where temperature fluctuations are common. Instead, opt for a climate-controlled environment like a basement or indoor workshop. By understanding and respecting these storage requirements, users can ensure the product remains effective for its intended lifespan.

In practical terms, the shelf life of Bondo wood filler translates to cost-effectiveness and convenience. For DIY enthusiasts or professionals tackling sporadic projects, knowing how to preserve the product means less waste and fewer trips to the hardware store. Pairing this knowledge with proper application techniques—such as using the correct ratio of filler to hardener—ensures optimal results every time. Ultimately, Bondo’s shelf life is a feature that, when leveraged wisely, enhances its value as a versatile and dependable wood repair solution.

Wood Ticks' Survival Duration Without a Host: A Comprehensive Guide

You may want to see also

Explore related products

Application Longevity Factors

Bondo wood filler, a staple in woodworking and home repair, boasts impressive durability, but its longevity hinges on several application factors. One critical element is surface preparation. Wood must be clean, dry, and free of loose debris. Sanding the area to create a rough texture enhances adhesion, ensuring the filler bonds securely. Skipping this step can lead to premature cracking or peeling, drastically reducing the filler’s lifespan.

Environmental conditions play a pivotal role in determining how well Bondo wood filler holds up over time. Exposure to moisture, extreme temperatures, or UV radiation accelerates degradation. For outdoor applications, consider using a marine-grade wood filler or applying a protective sealant. Indoor projects benefit from stable, controlled environments, where temperature and humidity fluctuations are minimal. Properly managed conditions can extend the filler’s life by years.

The thickness of the applied filler also impacts longevity. Thin layers cure more evenly and are less prone to shrinkage or cracking. For larger gaps or holes, apply multiple thin coats rather than one thick layer. Each coat should be allowed to cure fully before sanding and adding the next. This method ensures a stronger, more durable repair that resists wear and tear over time.

Finally, the choice of finishing product can significantly affect the filler’s lifespan. Paint, stain, or varnish not only enhances appearance but also provides a protective barrier against environmental stressors. Select finishes compatible with both the wood and the filler. For instance, oil-based stains may require specific primers to prevent discoloration. A well-chosen finish can double or even triple the longevity of the repaired area.

By meticulously addressing these application factors—surface preparation, environmental conditions, layer thickness, and finishing—you can maximize the durability of Bondo wood filler. Each step, though seemingly minor, contributes to a repair that stands the test of time.

Cedar Wood Fence Lifespan: Durability, Maintenance, and Longevity Explained

You may want to see also

Explore related products

Curing Time Impact

Bondo wood filler, a staple in woodworking and home repair, owes much of its longevity to its curing process. The curing time directly influences the filler’s durability, adhesion, and overall performance. Typically, Bondo wood filler takes 20 to 30 minutes to cure enough for sanding, but full curing can extend up to 24 hours depending on factors like temperature, humidity, and application thickness. This variability underscores the importance of understanding how curing time impacts the material’s effectiveness.

Analyzing the curing process reveals why rushing it can compromise results. During curing, the filler’s chemical components harden and bond to the wood surface. Insufficient curing time weakens this bond, leading to cracks, shrinkage, or detachment over time. For instance, applying a second coat or paint too soon can trap moisture, causing the filler to degrade prematurely. Conversely, allowing the filler to cure fully ensures maximum strength and resistance to environmental stressors like moisture and temperature fluctuations.

Practical tips can optimize curing time for better outcomes. Maintaining a room temperature of 70°F (21°C) accelerates curing without sacrificing quality. Thinner applications cure faster than thicker ones, so consider applying multiple thin layers instead of one thick coat. Using a hairdryer on a low setting can gently speed up curing in small areas, but avoid excessive heat, which can cause bubbling or warping. Always follow the manufacturer’s instructions for specific curing times and conditions.

Comparing Bondo wood filler to alternatives highlights its curing time advantages. Unlike epoxy-based fillers, which can take hours or even days to cure fully, Bondo’s polyester resin formula hardens relatively quickly. This makes it ideal for time-sensitive projects or repairs. However, its faster curing also demands precision—once mixed, the filler begins to set within 3 to 5 minutes, leaving a narrow window for application. This contrasts with slower-curing fillers, which offer more flexibility but less immediate usability.

In conclusion, mastering the curing time of Bondo wood filler is key to maximizing its lifespan and effectiveness. By understanding the chemistry behind curing, applying practical techniques, and comparing it to alternatives, users can ensure their repairs stand the test of time. Patience and attention to detail during this critical phase pay dividends in the form of durable, long-lasting results.

Wood County Ohio Probate Records Retention: How Long Are They Kept?

You may want to see also

Explore related products

$17.18

Environmental Conditions Effect

Moisture is the arch-nemesis of Bondo wood filler's longevity. In environments with high humidity, such as coastal regions or poorly ventilated bathrooms, the filler's curing process slows dramatically. This extended curing time not only delays usability but also weakens the bond, making it susceptible to cracking or peeling. For optimal results, apply Bondo in areas with humidity levels below 60%. If working in humid conditions, consider using a dehumidifier or scheduling repairs during drier seasons.

Temperature extremes can also sabotage Bondo's durability. Cold temperatures below 50°F (10°C) hinder the chemical reaction necessary for curing, leaving the filler soft and pliable. Conversely, excessive heat above 90°F (32°C) can cause the filler to dry too quickly, leading to shrinkage and surface imperfections. To mitigate these risks, store Bondo at room temperature (65°–75°F or 18°–24°C) and apply it in a climate-controlled environment. If outdoor application is unavoidable, choose mild days and avoid direct sunlight.

UV exposure is another environmental factor that accelerates Bondo's degradation. While primarily used indoors, Bondo wood filler applied to exterior surfaces will deteriorate rapidly without proper protection. UV rays break down the filler's resin, causing it to become brittle and discolored over time. To combat this, always seal outdoor applications with a UV-resistant primer and topcoat. For added durability, consider mixing a UV stabilizer into the filler before application, though this may alter its curing properties.

Finally, the presence of chemicals or pollutants in the environment can compromise Bondo's integrity. In industrial settings or areas with high levels of airborne chemicals, the filler may absorb contaminants, leading to discoloration or structural failure. Similarly, exposure to solvents, acids, or alkalis can dissolve or weaken the cured filler. To protect Bondo in such environments, apply a chemical-resistant sealant and ensure proper ventilation during both application and curing. Regularly inspect and maintain the sealed surface to extend its lifespan.

Wood Chip Decomposition Timeline: Factors Affecting Breakdown in Nature

You may want to see also

Explore related products

Maintenance for Durability

Bondo wood filler, when applied correctly, can last for decades, but its longevity hinges on proper maintenance. Exposure to moisture, temperature fluctuations, and physical stress are the primary culprits of deterioration. Regular inspections are crucial; look for cracks, peeling, or discoloration, as these are early signs of wear. Addressing these issues promptly can prevent more extensive damage and extend the filler’s lifespan significantly.

To maintain durability, start by sealing the filled area with a high-quality wood sealer or paint. This creates a barrier against moisture and UV rays, which can degrade the filler over time. Reapply the sealant every 2–3 years, especially in outdoor applications or high-humidity environments. For indoor use, a single coat of paint or varnish often suffices, but monitor for wear and reapply as needed. Avoid using harsh chemicals or abrasive cleaners, as these can strip the protective layer and expose the filler to damage.

Another key maintenance practice is to minimize physical stress on the repaired area. For furniture or structural elements, avoid placing heavy objects directly on the filled spot. Use coasters or pads to distribute weight evenly and reduce pressure. In high-traffic areas, consider reinforcing the repair with a thin layer of epoxy or additional filler to add strength. Regularly sanding and smoothing the surface can also prevent splintering and maintain a seamless finish.

Comparatively, Bondo wood filler outperforms many traditional wood fillers in durability, but it still requires proactive care. Unlike water-based fillers, Bondo’s two-part resin system hardens into a robust, long-lasting patch. However, its strength can be compromised if not maintained properly. For instance, while it resists shrinking and cracking better than most, it’s not immune to these issues without proper sealing and protection. By investing time in maintenance, you ensure the filler remains as durable as the material it repairs.

Finally, consider the environment in which the filler is used. Outdoor applications demand more frequent maintenance due to exposure to the elements. For example, a wooden deck repaired with Bondo should be inspected seasonally and resealed annually. Indoor repairs, such as on cabinets or trim, may only require attention every few years. Tailoring your maintenance routine to the specific conditions of the repaired item will maximize the filler’s durability and ensure it lasts as long as possible.

Hardwood Cooking Pellets: Shelf Life and Storage Tips for Longevity

You may want to see also

Frequently asked questions

Bondo wood filler, when properly applied and cured, can last for many years, often decades, depending on the environmental conditions and the type of wood it is used on.

Yes, unopened Bondo wood filler typically has a shelf life of 1 to 2 years if stored in a cool, dry place. Always check the expiration date on the packaging.

Bondo wood filler usually cures within 2 to 6 hours, but full hardness and strength may take up to 24 hours, depending on humidity and temperature.

Yes, prolonged exposure to moisture can cause Bondo wood filler to weaken or degrade. It is recommended to seal or paint the repaired area to protect it from moisture.