Bondo Wood Patch is a popular wood filler used for repairing cracks, holes, and imperfections in wood surfaces, known for its durability and ease of use. When properly applied and maintained, Bondo Wood Patch can last for many years, often matching the lifespan of the surrounding wood. Its longevity depends on factors such as the type of wood being repaired, the environmental conditions it’s exposed to, and the quality of the application process. In indoor settings with minimal moisture and temperature fluctuations, it can remain effective for decades, while outdoor applications may require periodic touch-ups due to weathering. Understanding its durability and proper usage ensures that Bondo Wood Patch provides a long-lasting solution for wood repairs.

Explore related products

$14.19 $16.8

What You'll Learn

Bondo Wood Patch Durability Factors

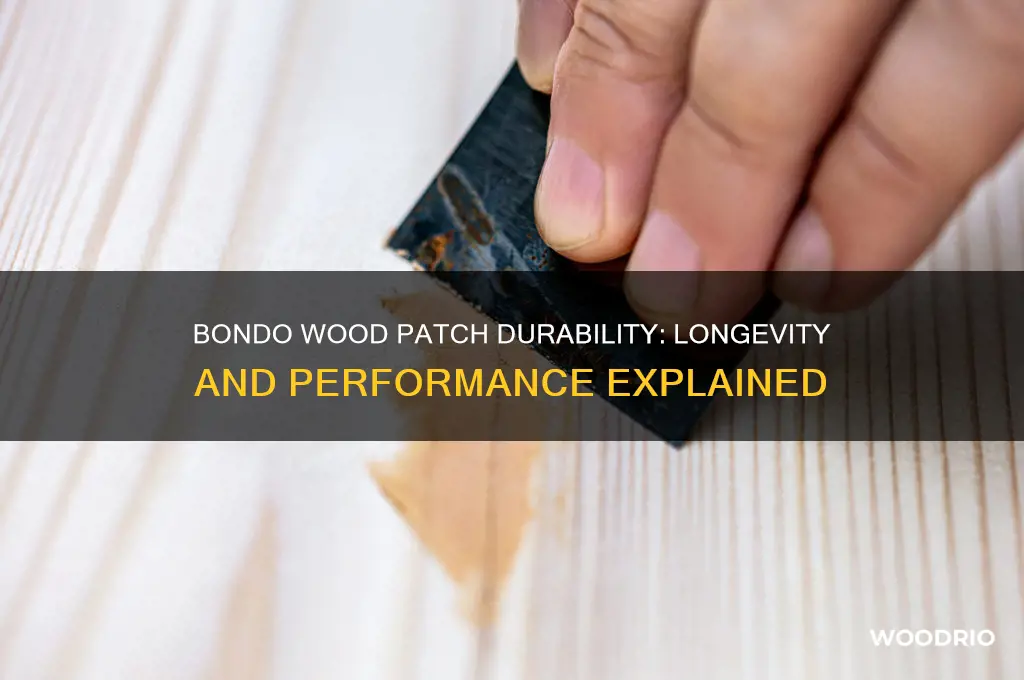

Bondo Wood Patch, a polyester-based filler, is renowned for its ability to repair wood damage, but its longevity hinges on several critical factors. Surface preparation is paramount; the wood must be clean, dry, and free of loose debris. Sanding the area to create a rough texture enhances adhesion, ensuring the patch bonds effectively. Skipping this step can lead to premature failure, as the filler may not grip the wood properly. For optimal results, use 80-grit sandpaper and wipe the surface with a tack cloth before application.

Environmental conditions play a significant role in the durability of Bondo Wood Patch. Exposure to moisture, extreme temperatures, or UV radiation can degrade the material over time. In outdoor applications, consider sealing the repaired area with a waterproof finish or paint to extend its lifespan. Indoor repairs, particularly in humid environments like bathrooms or kitchens, also benefit from sealing. Without proper protection, the patch may crack, shrink, or discolor within 2–3 years, whereas a well-sealed repair can last a decade or more.

The thickness and layering of the patch directly impact its durability. Bondo Wood Patch should be applied in thin layers, no more than 1/4 inch at a time, allowing each layer to cure fully before adding another. Thick applications are prone to cracking as the material shrinks during curing. For deep repairs, build up the patch gradually, sanding between layers to ensure a smooth, even surface. This method not only improves adhesion but also distributes stress evenly, reducing the likelihood of failure under pressure or movement.

Curing time and conditions are often overlooked but crucial for longevity. Bondo Wood Patch typically cures within 2–4 hours at room temperature, but full strength is not achieved until 12–24 hours have passed. Accelerating the process with heat or failing to allow sufficient curing time weakens the bond and reduces durability. For best results, maintain a consistent temperature of 65–80°F during curing and avoid disturbing the repaired area until fully hardened.

Finally, the type of wood and repair purpose influence how long the patch will last. Softwoods like pine may require more frequent touch-ups compared to hardwoods like oak, which provide a more stable base. Structural repairs, such as those on load-bearing beams or furniture joints, demand meticulous application and sealing to withstand stress. Cosmetic repairs, like filling small holes or cracks, are less demanding but still benefit from proper technique. Understanding these factors allows users to maximize the durability of Bondo Wood Patch, ensuring repairs remain intact for years to come.

Durability of Wood Prints: Longevity and Care Tips Revealed

You may want to see also

Explore related products

Indoor vs. Outdoor Longevity

Bondo Wood Patch, a popular wood filler, exhibits significantly different longevity when used indoors versus outdoors due to varying environmental factors. Indoor applications benefit from controlled conditions—stable temperatures, low humidity, and minimal UV exposure—which can extend the material's lifespan to 10 years or more. In contrast, outdoor use subjects the patch to harsh elements, including moisture, temperature fluctuations, and UV radiation, which accelerate degradation. Understanding these differences is crucial for selecting the right materials and maintenance strategies.

For outdoor projects, proper preparation and protective measures are essential to maximize durability. Start by ensuring the wood surface is clean, dry, and free of debris. Apply the Bondo Wood Patch according to the manufacturer’s instructions, typically in layers no thicker than ¼ inch to prevent cracking. Once cured, seal the patch with a high-quality exterior paint or wood sealant to create a barrier against moisture and UV rays. Reapply the sealant every 1–2 years to maintain protection. Without adequate sealing, outdoor patches may begin to fail within 2–3 years, especially in humid or rainy climates.

Indoor applications allow for more flexibility in maintenance but still require attention to detail. While Bondo Wood Patch is inherently more stable indoors, it can still be affected by localized moisture, such as in bathrooms or kitchens. To enhance longevity, consider using a moisture-resistant primer before painting or staining. Additionally, avoid placing patched surfaces in direct contact with water or high-humidity areas. For structural repairs, ensure the patch is fully cured (typically 24–48 hours) before sanding or painting to achieve optimal adhesion and strength.

Comparing the two environments reveals a clear trade-off between convenience and durability. Indoor patches require less maintenance but must still be monitored for signs of wear, such as cracking or discoloration. Outdoor patches demand proactive care but can perform well with consistent upkeep. For example, a window sill repaired with Bondo Wood Patch might last 5–7 years outdoors with proper sealing, while the same repair indoors could endure for over a decade with minimal intervention.

In conclusion, the longevity of Bondo Wood Patch hinges on its environment and the care it receives. Indoor applications thrive under stable conditions, while outdoor use necessitates vigilant protection against the elements. By tailoring your approach to the specific demands of each setting, you can ensure the patch performs reliably for years to come. Whether repairing a kitchen cabinet or a garden bench, understanding these nuances will help you achieve lasting results.

Durability of Wooden Dishes: Lifespan and Care Tips Revealed

You may want to see also

Explore related products

Proper Application Techniques

Bondo Wood Patch, a polyester-based filler, can last for decades when applied correctly, but its longevity hinges on proper application techniques. Surface preparation is paramount. Begin by cleaning the wood thoroughly to remove dirt, grease, and loose debris. Sand the area to create a rough texture, ensuring the patch adheres firmly. For deeper repairs, undercut the damaged area slightly to provide mechanical bonding. This step, often overlooked, significantly enhances durability.

Mixing the Bondo Wood Patch requires precision. Follow the manufacturer’s ratio of filler to hardener, typically 7 parts filler to 1 part hardener by volume. Overmixing or undermixing compromises curing and strength. Stir until the mixture is uniform in color, avoiding air pockets. Apply the patch in layers, pressing firmly into the repair area. For larger voids, add wood reinforcement, such as a wooden dowel or mesh, to prevent shrinkage and cracking. Each layer should be no thicker than 1/4 inch to ensure proper curing.

Curing time is critical for longevity. Bondo Wood Patch typically hardens within 20 minutes, but full curing takes 24 hours. Avoid disturbing the patched area during this period. Sanding should only begin after the patch is fully cured. Use progressively finer grits (80 to 220) to achieve a smooth finish. Proper sanding not only improves appearance but also ensures subsequent coatings adhere effectively.

Environmental factors play a role in durability. Bondo Wood Patch performs best in temperatures between 65°F and 85°F. Avoid applying it in humid or damp conditions, as moisture can weaken the bond. Once cured, seal the patched area with a primer and paint or stain to protect against UV rays and moisture. Regular maintenance, such as repainting every 3–5 years, further extends its lifespan.

Mastering these techniques ensures Bondo Wood Patch lasts as long as the surrounding wood. While the product itself is durable, improper application can lead to premature failure. By focusing on preparation, mixing, curing, and environmental considerations, you can achieve repairs that stand the test of time.

Transporting Oversized Wood: Practical Tips for Moving Long Lumber Safely

You may want to see also

Explore related products

Environmental Impact on Lifespan

The durability of Bondo wood patch is significantly influenced by its exposure to environmental factors, which can either extend or shorten its lifespan. Moisture, temperature fluctuations, and UV radiation are the primary culprits that degrade its structural integrity over time. For instance, in humid climates, Bondo wood patch may absorb moisture, leading to swelling, cracking, or delamination. Conversely, in arid environments, repeated exposure to dry conditions can cause the material to become brittle and prone to chipping. Understanding these interactions is crucial for maximizing the product’s effectiveness in various settings.

To mitigate environmental damage, consider the application environment and take preventive measures. For outdoor repairs, apply a waterproof sealant over the cured Bondo wood patch to create a moisture barrier. This step is particularly vital in regions with high rainfall or humidity, where water infiltration can accelerate deterioration. Additionally, in areas with extreme temperature variations, ensure the patched surface is shielded from direct sunlight or freezing conditions by using protective coatings or shade structures. These precautions can significantly prolong the lifespan of the repair, often adding years to its durability.

A comparative analysis reveals that Bondo wood patch performs best in controlled indoor environments, where temperature and humidity levels remain stable. In such conditions, the product can last upwards of 10–15 years with minimal maintenance. However, in harsh outdoor settings, its lifespan may reduce to 3–5 years without proper protection. For example, a wooden door repaired with Bondo in a temperate, low-humidity climate will outlast the same repair on a deck exposed to constant rain and sunlight. This disparity underscores the importance of tailoring application methods to the specific environmental demands of the project.

For optimal results, follow these practical steps: First, assess the environmental conditions of the repair area. If the surface is outdoors, clean and dry it thoroughly before application, ensuring no residual moisture is present. Second, mix the Bondo wood patch according to the manufacturer’s instructions, using precise ratios to achieve the correct consistency. Third, apply the product in thin layers, allowing each to cure fully before adding the next. Finally, seal the repaired area with a high-quality exterior-grade varnish or paint to protect against environmental stressors. By adhering to these guidelines, you can enhance the longevity of the repair and minimize the need for frequent touch-ups.

In conclusion, the environmental impact on the lifespan of Bondo wood patch is a critical factor that demands proactive management. By understanding how moisture, temperature, and UV exposure affect the material, users can implement targeted strategies to preserve its integrity. Whether through protective sealants, strategic placement, or proper application techniques, these measures ensure the repair remains functional and aesthetically pleasing for as long as possible. With careful consideration of environmental conditions, Bondo wood patch can be a reliable solution for both indoor and outdoor wood restoration projects.

Wood Protector Durability: How Long Does It Really Last?

You may want to see also

Explore related products

Repair vs. Replacement Considerations

Bondo Wood Patch, a popular wood filler, is often touted for its durability and ease of use. However, its longevity depends heavily on the context of its application. When deciding between repairing a damaged wood surface with Bondo or opting for a full replacement, several factors come into play. The first consideration is the extent of the damage. Minor cracks, holes, or rot can often be effectively repaired with Bondo Wood Patch, which, when applied correctly, can last for years, even decades, especially in indoor environments. For instance, a small hole in a door frame or a cracked window sill can be restored to near-original strength and appearance with proper preparation and application.

The environment in which the wood is located plays a critical role in this decision-making process. Bondo Wood Patch is not impervious to moisture, and while it can withstand occasional exposure, prolonged contact with water or high humidity can degrade its integrity over time. In outdoor applications, such as repairing a wooden deck or fence, the lifespan of the patch may be significantly shorter—often 5 to 10 years—compared to indoor repairs, which can last 20 years or more. If the wood is constantly exposed to harsh weather conditions, replacement might be the more cost-effective and long-lasting solution, despite the higher upfront cost.

Another key factor is the structural importance of the wood in question. For load-bearing structures like beams or joists, the risk of failure must be carefully weighed. While Bondo Wood Patch can restore the appearance and some strength to damaged wood, it may not fully restore the structural integrity required for critical components. In such cases, replacement is often the safer and more reliable option, even if it involves greater expense and labor. For non-structural elements, like decorative trim or furniture, repair is usually the more practical choice, provided the damage is not extensive.

Cost and time are also significant considerations. Repairing with Bondo Wood Patch is generally faster and less expensive than replacing an entire piece of wood or structure. The process involves cleaning the damaged area, applying the patch according to the manufacturer’s instructions (typically mixing the resin and hardener in a 7:1 ratio by volume), and sanding it smooth once cured. This can often be completed in a single day, whereas replacement may require multiple days of work and specialized tools. However, if the wood is severely compromised or the damage is widespread, the cumulative cost of repeated repairs may eventually outweigh the initial investment in replacement.

Ultimately, the decision to repair or replace should be guided by a balance of practicality, safety, and long-term value. For minor damage in low-risk areas, Bondo Wood Patch offers a durable and cost-effective solution. In contrast, for high-moisture environments, structural components, or extensive damage, replacement is often the more prudent choice. By carefully assessing the specific circumstances, homeowners and professionals can make informed decisions that maximize both the lifespan of the wood and the efficiency of their efforts.

Hen of the Woods Storage Tips: Maximizing Freshness and Shelf Life

You may want to see also

Frequently asked questions

Bondo Wood Patch can last for many years, often decades, when properly applied and maintained, as it is designed to be a durable and long-lasting solution for wood repairs.

While Bondo Wood Patch is resistant to weather, prolonged exposure to harsh outdoor elements like UV rays and moisture may cause it to degrade faster. Proper sealing and painting can extend its lifespan.

Yes, when applied correctly and protected with a suitable finish, Bondo Wood Patch can last as long as, or even longer than, the surrounding wood, depending on environmental conditions.

Bondo Wood Patch typically cures within 15-30 minutes, but full hardening occurs over 24 hours. Proper curing is essential for maximum durability, as incomplete curing can reduce its lifespan.