Boat wood sealer is a crucial protective coating applied to wooden boats to shield them from water damage, UV rays, and other environmental factors that can cause deterioration. The longevity of boat wood sealer varies depending on several factors, including the type of sealer used, the quality of application, the boat’s exposure to harsh conditions, and the frequency of maintenance. Typically, high-quality marine-grade sealers can last anywhere from 1 to 5 years, with some premium products offering even longer protection. Regular inspection and reapplication are essential to ensure the wood remains protected, as prolonged exposure to water and sunlight can degrade the sealer over time. Understanding these factors helps boat owners make informed decisions to maintain their vessel’s structural integrity and appearance.

| Characteristics | Values |

|---|---|

| Typical Lifespan | 1-3 years, depending on sealer type, wood type, and environmental exposure |

| Factors Affecting Durability | UV exposure, moisture, temperature fluctuations, wood porosity, sealer quality |

| Reapplication Frequency | Annually for high-traffic areas or harsh conditions, every 2-3 years for moderate use |

| Common Sealer Types | Marine varnish, epoxy resin, penetrating oil, polyurethane |

| Drying/Curing Time | 24-48 hours for initial drying, 7-14 days for full curing (varies by product) |

| Maintenance Tips | Regular cleaning, prompt repair of damage, reapplication before sealer failure |

| Environmental Impact | Some sealers contain VOCs; choose eco-friendly options when possible |

| Cost Range | $20-$100 per gallon, depending on brand and quality |

| Application Methods | Brush, roller, spray (follow manufacturer instructions) |

| Wood Compatibility | Teak, mahogany, oak, pine (ensure sealer is suitable for specific wood type) |

Explore related products

What You'll Learn

Application time for boat wood sealer

The application time for boat wood sealer is a critical factor in ensuring the longevity and effectiveness of the protective coating. Typically, the process involves preparing the wood surface by sanding and cleaning, followed by applying the sealer in thin, even coats. Most marine-grade wood sealers require 2 to 4 hours of drying time between coats, depending on humidity and temperature. For optimal results, apply at least two coats, allowing the final coat to cure for 24 to 48 hours before exposing the wood to water or heavy use. This ensures maximum penetration and adhesion, safeguarding the wood against moisture, UV rays, and saltwater damage.

Analyzing the variables, temperature and humidity play a significant role in application time. In ideal conditions—70°F (21°C) with 50% humidity—drying times are minimized. However, colder or more humid environments can double the drying time, requiring careful planning. For instance, applying sealer in direct sunlight can cause uneven drying, leading to a blotchy finish. Conversely, high humidity can trap moisture in the wood, preventing proper curing. Professionals often use dehumidifiers or heaters to control conditions, ensuring consistent results. Understanding these factors allows for better scheduling and avoids premature exposure to harsh marine environments.

From a practical standpoint, the application process itself demands precision. Use a natural-bristle brush or roller to apply the sealer, working in the direction of the wood grain. Avoid overloading the brush, as excess sealer can pool and extend drying time. For intricate areas, a foam brush or cloth can provide better control. After each coat, inspect the surface for missed spots or drips, addressing them immediately. A common mistake is rushing the process, which compromises the sealer’s effectiveness. Patience and attention to detail are key to achieving a durable, professional finish.

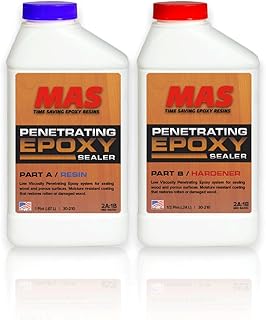

Comparing different types of wood sealers, oil-based products generally require longer drying times—up to 6 hours per coat—but offer deeper penetration and flexibility. Water-based sealers, on the other hand, dry faster (1–2 hours) and are easier to clean up but may require more coats for equivalent protection. Epoxy-based sealers provide the highest level of protection but demand meticulous application and extended curing times (up to 72 hours). Choosing the right sealer depends on the wood type, boat usage, and environmental exposure. For example, teak benefits from oil-based sealers, while plywood may perform better with epoxy coatings.

In conclusion, mastering the application time for boat wood sealer involves balancing product properties, environmental conditions, and technique. By adhering to recommended drying times, controlling application conditions, and selecting the appropriate sealer, boat owners can ensure their wood remains protected and aesthetically pleasing. Regular maintenance, including reapplication every 1–3 years, further extends the wood’s lifespan. With proper care, boat wood sealer not only preserves the vessel’s beauty but also enhances its resilience against the unforgiving marine environment.

Durability of Manufactured Wood Desks: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Drying duration of marine wood sealants

The drying time of marine wood sealants is a critical factor in boat maintenance, directly impacting the effectiveness of the sealant and the overall protection of the wood. Typically, marine wood sealants require 24 to 48 hours to dry to the touch under optimal conditions—temperatures between 70°F and 85°F (21°C to 29°C) with low humidity. However, achieving a full cure, where the sealant reaches maximum hardness and adhesion, can take 7 to 14 days, depending on the product and environmental conditions. For example, oil-based sealants like epoxy or polyurethane often cure slower than water-based alternatives but offer superior durability in marine environments. Always refer to the manufacturer’s guidelines, as drying times vary significantly between brands and formulations.

Environmental factors play a pivotal role in drying duration. High humidity or cool temperatures can double or even triple drying times, as moisture in the air slows evaporation and curing processes. Conversely, excessive heat can cause the sealant to dry too quickly, leading to uneven application or surface imperfections. To optimize drying, apply sealants during dry, mild weather and avoid direct sunlight, which can cause rapid surface drying while trapping moisture underneath. If working indoors, use fans or dehumidifiers to control air circulation and moisture levels. Proper preparation of the wood surface—sanding, cleaning, and ensuring it’s dry—also ensures the sealant adheres correctly and dries uniformly.

For boat owners, understanding the drying process is essential for scheduling maintenance tasks. Applying multiple coats of sealant? Allow 4 to 6 hours between coats to prevent trapping solvents or creating a tacky surface. If time is a constraint, consider using quick-drying marine sealants designed for rapid curing, though these may sacrifice some durability. For long-term protection, prioritize products with extended curing times, as they form a more robust barrier against water, UV rays, and saltwater corrosion. Always test the sealant on a small, inconspicuous area to confirm drying times and appearance before full application.

Practical tips can further streamline the drying process. Lightly sanding between coats improves adhesion and reduces drying time by promoting better penetration. Avoid walking on or handling sealed surfaces until fully cured to prevent damage or imprints. In urgent situations, using a heat gun or infrared lamp can accelerate drying, but this requires careful monitoring to avoid overheating or scorching the wood. Finally, store sealants properly—unopened containers can last up to 5 years, but exposure to extreme temperatures or air can alter their drying properties. By mastering these nuances, boat owners can ensure their wood remains protected and aesthetically pleasing for years to come.

Treated Wood Fence Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

Cure time for boat wood protection

Boat wood sealers typically require 24 to 72 hours to cure superficially, but full curing—where the sealer reaches maximum hardness and durability—can take 7 to 14 days. This timeline varies based on factors like humidity, temperature, and the specific product used. For instance, oil-based sealers often cure slower than water-based options, which can dry to the touch within 2 to 4 hours. Always check the manufacturer’s instructions, as some high-performance marine sealers may require extended curing periods to ensure optimal protection against water, UV rays, and saltwater exposure.

Analyzing the curing process reveals why patience is critical. During the initial 24 hours, the sealer penetrates the wood fibers, forming a protective barrier. Over the next week, chemical reactions harden the sealer, enhancing its resistance to abrasion and environmental stressors. Skipping this full cure time can lead to premature wear, peeling, or inadequate protection. For example, applying a second coat too soon can trap solvents, preventing proper bonding and reducing longevity.

To maximize cure time efficiency, apply sealers in dry, well-ventilated conditions with temperatures between 50°F and 90°F. Avoid high humidity, as it slows evaporation and curing. For multi-coat applications, wait at least 4 hours between coats, lightly sanding with 220-grit sandpaper to ensure adhesion. If using a two-part epoxy sealer, mix components precisely and apply within the pot life (usually 30–60 minutes) to avoid curing issues.

Comparing cure times across products highlights the importance of selecting the right sealer for your needs. Traditional tung oil sealers may take up to 30 days to fully cure but offer a natural, breathable finish. Polyurethane sealers cure faster (3–5 days) and provide superior hardness, ideal for high-traffic areas like decks. Epoxy sealers, while curing in 5–7 days, offer unmatched moisture resistance, making them suitable for below-deck applications.

In practice, plan your sealing project around weather forecasts and boat usage. Avoid launching the boat or exposing treated surfaces to water until the sealer is fully cured. For maintenance, reapply sealer annually or biennially, depending on exposure. Regularly inspect for cracks or wear, as even the best sealer degrades over time. By respecting cure times and following best practices, you’ll ensure your boat’s wood remains protected, functional, and aesthetically pleasing for years to come.

Termites and Exterior Wood: Do They Create Long Holes?

You may want to see also

Explore related products

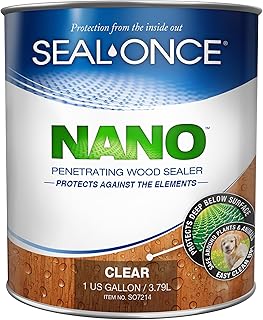

Reapplication frequency for wood sealers

Wood sealers are not a one-and-done solution for boat maintenance. The frequency of reapplication depends heavily on the type of sealer used, the wood species, and the environmental conditions the boat is exposed to. For instance, oil-based sealers like teak oil or linseed oil typically require reapplication every 3 to 6 months due to their tendency to break down under UV exposure and moisture. In contrast, synthetic sealers, such as polyurethane or epoxy-based products, can last 1 to 2 years before needing a refresh. Understanding these differences is crucial for maintaining optimal protection.

Environmental factors play a significant role in determining reapplication schedules. Boats in tropical climates with intense sunlight and high humidity will see sealers degrade faster than those in temperate regions. Saltwater exposure accelerates wear, as salt can penetrate and weaken the sealer’s bond with the wood. For example, a boat in the Caribbean may need its sealer reapplied twice as often as one in the Pacific Northwest. Regular inspections—at least every 6 months—are essential to catch early signs of wear, such as whitening, cracking, or water absorption.

Reapplication isn’t just about timing; it’s also about technique. Before reapplying, thoroughly clean the wood surface to remove dirt, mildew, and old sealer residue. Sanding lightly with 120-grit sandpaper can help create a smooth, receptive surface. When applying the sealer, follow the manufacturer’s instructions for dosage—typically 1 to 2 coats, allowing proper drying time between layers. Overapplication won’t enhance protection and can lead to a sticky, uneven finish. For best results, apply sealers in dry, mild weather to ensure proper curing.

Comparing reapplication frequencies across different sealers highlights the importance of choosing the right product for your needs. For instance, while traditional tung oil may require reapplication every 3 months, it’s ideal for those seeking a natural, matte finish. Conversely, marine-grade varnishes, though more labor-intensive to apply, can last up to 3 years with proper maintenance. Consider the balance between durability and aesthetic appeal when selecting a sealer, and factor in the time and effort required for reapplication.

Finally, proactive maintenance can extend the life of your wood sealer. Regularly rinsing the boat with fresh water after saltwater exposure helps prevent salt buildup. Using UV-protective covers when the boat is not in use can minimize sun damage. For older boats or wood with existing damage, consider a restorative treatment before resealing. By combining the right sealer with diligent care, you can ensure your boat’s wood remains protected, beautiful, and functional for years to come.

Perfectly Cooking Chicken of the Woods: Timing Tips for Delicious Results

You may want to see also

Explore related products

Factors affecting boat wood sealer longevity

Boat wood sealer longevity hinges on several critical factors, each playing a unique role in determining how well the sealant performs over time. The type of sealer used is a primary consideration; for instance, epoxy-based sealers typically last 5–10 years, while polyurethane options may degrade after 2–5 years. Environmental exposure is another key factor—constant UV radiation, saltwater, and temperature fluctuations can accelerate wear. Proper application techniques, such as ensuring the wood is clean, dry, and sanded before sealing, significantly impact durability. Neglecting surface preparation or applying thin coats can reduce effectiveness by up to 40%.

Consider the wood species itself, as density and porosity affect absorption and adhesion. Teak, known for its natural oils, may require less frequent sealing compared to pine, which is more absorbent. Climate plays a decisive role too; boats in tropical regions face harsher conditions than those in temperate zones. For example, a boat in Florida might need resealing every 2–3 years, while one in the Pacific Northwest could last 4–6 years. Regular maintenance, like annual inspections and touch-ups, can extend sealer life by 20–30%.

Application timing is often overlooked but crucial. Applying sealer in humid conditions (above 70% humidity) or extreme temperatures (below 50°F or above 90°F) can hinder curing and reduce longevity. Thickness of application matters as well—most sealers require 2–3 coats, with each coat needing 24–48 hours to dry. Skipping coats or rushing the process compromises protection. For optimal results, follow manufacturer guidelines, such as using a brush or roller to ensure even coverage and avoiding over-application, which can lead to cracking.

Comparing sealers reveals trade-offs between durability and maintenance. Marine-grade varnishes offer a glossy finish but require annual reapplication, while penetrating epoxy sealers provide longer-lasting protection but lack aesthetic appeal. Hybrid sealers, combining UV blockers and water repellents, are emerging as a middle ground, offering 5–7 years of protection with minimal upkeep. Cost-effectiveness varies; while premium sealers are pricier upfront, their extended lifespan often justifies the investment.

Practical tips can maximize sealer longevity. Store boats under cover when not in use to minimize UV exposure. Wash the hull regularly with fresh water to remove salt residue, which can degrade sealers. For older boats, consider a light sanding before resealing to remove old layers and ensure proper adhesion. Finally, monitor wear patterns—areas like gunwales and decks often degrade faster and may need spot treatments. By addressing these factors proactively, boat owners can significantly extend the life of their wood sealer and maintain their vessel’s integrity.

Wooden Ships' Lifespan: Durability and Maintenance Secrets Revealed

You may want to see also

Frequently asked questions

Boat wood sealer typically lasts between 1 to 3 years, depending on the product quality, environmental conditions, and maintenance.

Factors include exposure to sunlight, moisture, temperature fluctuations, the type of sealer used, and how well the wood was prepared before application.

Reapplication is generally recommended every 1 to 2 years, or when signs of wear, such as fading or water absorption, become noticeable.

Yes, regular cleaning, avoiding harsh chemicals, and addressing minor damage promptly can extend the life of boat wood sealer.