The longevity of wooden ships has been a subject of fascination and inquiry for maritime historians and enthusiasts alike. These vessels, crafted from timber, played a pivotal role in global exploration, trade, and warfare for centuries. While the durability of wooden ships varied depending on factors such as the type of wood used, construction techniques, and maintenance practices, many of these vessels were known to withstand the test of time. On average, a well-built and maintained wooden ship could last anywhere from 20 to 50 years, with some exceptional examples enduring for over a century. The lifespan of these ships was influenced by their exposure to harsh marine environments, including saltwater corrosion, shipworm infestations, and the constant stress of waves and wind. Despite these challenges, the craftsmanship and resilience of wooden ships have left an indelible mark on naval history, sparking curiosity about the secrets behind their enduring legacy.

| Characteristics | Values |

|---|---|

| Average Lifespan | 20-30 years |

| Maximum Lifespan (with regular maintenance) | Up to 100 years |

| Factors Affecting Durability | Quality of wood, construction techniques, maintenance, environmental conditions (e.g., saltwater exposure, climate) |

| Common Woods Used | Oak, pine, teak, cedar |

| Maintenance Requirements | Regular cleaning, painting, caulking, and replacement of damaged parts |

| Decay and Damage | Rot, insect damage, shipworm, and physical damage from collisions or grounding |

| Preservation Techniques | Creosote treatment, copper sheathing (to prevent shipworm), and regular inspection |

| Historical Examples | Some Viking longships lasted for centuries, while others like the USS Constitution (launched in 1797) is still afloat today with ongoing restoration |

| Modern Replicas | Often built with modern preservation techniques, extending their lifespan beyond historical averages |

| Environmental Impact | Wooden ships are biodegradable, but their maintenance and preservation can involve environmentally harmful substances |

Explore related products

What You'll Learn

Factors affecting wooden ship lifespan

Wooden ships, marvels of craftsmanship and engineering, have sailed the seas for centuries, but their lifespans varied dramatically based on a multitude of factors. One of the most critical determinants was the type of wood used. Hardwoods like oak, known for their durability and resistance to rot, were favored for ship construction. For instance, the HMS *Victory*, launched in 1765, remains preserved today due in part to the robust oak framing. In contrast, softer woods like pine, while easier to work with, were more susceptible to decay and insect damage, often limiting a ship's lifespan to a few decades.

Another significant factor was the ship's maintenance and care. Regular inspection, caulking, and treatment with preservatives like tar or pitch were essential to prevent water intrusion and wood-boring organisms. Ships that received consistent upkeep, such as those in naval fleets, often outlasted merchant vessels left to the mercy of profit-driven owners. For example, the *Mary Rose*, which sank in 1545, suffered from poor maintenance, contributing to its demise. Modern wooden boat owners can extend their vessel's life by applying epoxy coatings and storing them in dry environments during off-seasons.

The operating conditions of a wooden ship also played a pivotal role in its longevity. Ships subjected to harsh weather, frequent grounding, or heavy cargo loads experienced accelerated wear and tear. The *Cutty Sark*, a 19th-century clipper, endured decades of rough seas and high-speed sailing, yet its lifespan was extended through careful restoration efforts. Conversely, ships operating in calmer waters, like those in the Mediterranean, often lasted longer due to reduced structural stress. For contemporary wooden boat enthusiasts, avoiding overloading and navigating cautiously in shallow waters can significantly preserve the hull.

Lastly, technological advancements in shipbuilding techniques influenced wooden ship lifespans. The introduction of iron and steel fasteners in the 19th century reduced the reliance on wooden pegs, which were prone to rot. Similarly, improved design methods, such as diagonal bracing, enhanced structural integrity. The *USS Constitution*, launched in 1797, benefited from such innovations, earning its nickname "Old Ironsides" and remaining afloat today. For those building or restoring wooden ships, incorporating modern materials like stainless steel fasteners and fiberglass sheathing can dramatically increase durability.

In summary, the lifespan of a wooden ship was shaped by the interplay of material choice, maintenance practices, operating conditions, and technological progress. By understanding these factors, both historians and modern sailors can appreciate the resilience of these vessels and apply lessons to preserve wooden maritime heritage.

Phil Robertson's Wilderness Life: Years Spent in the Woods

You may want to see also

Explore related products

$68.95

Maintenance practices for longevity

Wooden ships, when meticulously maintained, could endure for centuries. The *Vasa*, a Swedish warship, lay preserved in the Baltic Sea for over 300 years, a testament to the durability of wood when shielded from shipworms and fungi. Yet, such longevity wasn’t accidental—it hinged on rigorous maintenance practices. Regular inspection, timely repairs, and protective treatments were the cornerstones of preserving these maritime marvels. Without such care, even the sturdiest oak hulls would succumb to rot, infestation, and the relentless forces of nature.

One critical practice was the application of protective coatings. Pitch, tar, and pine resin were commonly used to seal wooden planks, repelling water and deterring shipworms. For instance, the *Mary Rose*, Henry VIII’s flagship, employed thick layers of pitch to safeguard its hull. Modern equivalents, like epoxy resins, offer similar benefits but require precise application—a thin, even coat to avoid trapping moisture beneath the surface. Reapplication every 5–10 years, depending on exposure, ensures the wood remains impervious to decay.

Another vital maintenance task was caulking, the process of sealing gaps between planks with fibrous materials like oakum soaked in tar. This prevented water ingress, which could weaken the structure over time. Sailors would inspect caulking annually, re-stuffing and re-paying seams as needed. A well-caulked ship could withstand decades of rough seas, while neglect led to leaks, rot, and eventual failure. Today, synthetic materials like silicone offer longer-lasting alternatives, but the principle remains unchanged: seal the seams, save the ship.

Proactive measures against marine borers were equally essential. Copper sheathing, introduced in the 18th century, became a game-changer, as seen on ships like HMS *Victory*. The metal repelled shipworms and reduced fouling, extending hull life by decades. For smaller vessels, wrapping the hull in fine mesh or treating the wood with borate solutions provided similar protection. Regular cleaning of the hull, either by careening (tilting the ship) or using divers, prevented the buildup of barnacles and other organisms that accelerated deterioration.

Finally, structural integrity demanded constant vigilance. Wooden ships flexed with the waves, and repeated stress could loosen joints or crack timbers. Periodic overhauls in dry dock allowed carpenters to replace damaged planks, reinforce frames, and tighten fasteners. The *Cutty Sark*, a 19th-century clipper, survived over a century thanks to such meticulous care. Modern wooden boat owners should follow suit, scheduling inspections every 2–3 years and addressing issues before they escalate. With disciplined maintenance, wooden ships can defy time, their lifespans measured not in years, but in generations.

Wood vs. Steel: Which Material Offers Superior Longevity?

You may want to see also

Explore related products

Impact of wood type on durability

The lifespan of wooden ships varied dramatically based on the type of wood used in their construction. Hardwoods like oak, known for their density and natural resistance to decay, were the backbone of naval vessels for centuries. The HMS Victory, Nelson’s flagship at Trafalgar, remains preserved today, a testament to oak’s longevity. In contrast, softer woods like pine, while easier to work with, deteriorated more quickly, especially in harsh marine environments. This disparity highlights the critical role wood selection played in determining a ship’s durability.

Consider the practical implications of wood choice for shipbuilders. Oak, with its high tannin content, naturally repelled shipworms and fungi, making it ideal for hulls and structural components. However, its weight and cost limited its use in smaller vessels or less critical parts. Fir and cedar, lighter and more flexible, were often employed for decking and masts, balancing durability with the need for maneuverability. Shipwrights had to weigh these trade-offs, ensuring the wood’s properties aligned with its intended function.

A comparative analysis reveals further nuances. Teak, prized in tropical shipbuilding, outlasted even oak in warm, humid climates due to its natural oils and resins. Its use in British and Dutch naval vessels during the colonial era underscores its superiority in specific conditions. Conversely, woods like chestnut, though durable, lacked the strength for heavy structural use, relegating them to secondary roles. These examples illustrate how regional availability and environmental factors dictated wood choice, influencing a ship’s overall lifespan.

For modern enthusiasts or restorers, understanding these historical practices is invaluable. When replicating or maintaining wooden ships, prioritize woods with proven track records. For hulls, oak remains unmatched, while teak is ideal for decks exposed to tropical conditions. Always consider the wood’s natural preservatives—tannins in oak, oils in teak—and supplement with modern treatments like epoxy resins where necessary. By aligning wood type with historical precedent and environmental demands, you can ensure longevity akin to the great ships of yore.

Finally, a cautionary note: not all durable woods are sustainable today. Overharvesting has depleted many traditional shipbuilding species, necessitating responsible sourcing or alternatives. Engineered woods and composites offer modern solutions, but they lack the proven centuries-long track record of natural hardwoods. Balancing historical accuracy with ecological responsibility is the challenge for contemporary shipbuilders and preservationists alike.

Eric Rudolph's Elusive Escape: Years Hidden in the Wilderness

You may want to see also

Explore related products

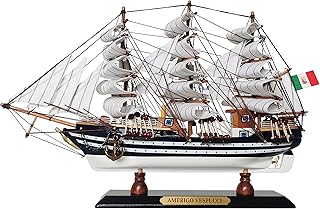

Historical examples of wooden ship lifespans

Wooden ships, when meticulously maintained, could endure for centuries, as evidenced by historical examples that defy the ephemeral nature often associated with organic materials. The USS Constitution, launched in 1797, remains a prime example. Nicknamed "Old Ironsides" for its resilience in battle, this frigate has survived over 225 years through a combination of robust construction, periodic restoration, and limited active service. Its longevity underscores the potential durability of wooden ships when shielded from constant maritime stresses and environmental degradation.

Contrastingly, ships subjected to rigorous use and harsh conditions often had shorter lifespans. The Mary Rose, Henry VIII’s flagship, sank in 1545 after just 34 years of service, a victim of both structural weaknesses and the demands of naval warfare. Its demise highlights the fragility of wooden vessels when pushed beyond their design limits or inadequately maintained. Salvaged and preserved in modern times, the Mary Rose serves as a cautionary tale about the balance between operational demands and material endurance.

Viking longships, such as the Oseberg Ship (circa 820 AD), offer another perspective. Built for both warfare and exploration, these vessels were designed for speed and maneuverability rather than longevity. The Oseberg Ship, discovered in a burial mound, survived over 1,100 years due to its ceremonial burial rather than its inherent durability. This example illustrates how context—whether a ship is used, abandoned, or preserved—dramatically influences its lifespan.

Finally, the HMS Victory, Admiral Nelson’s flagship at the Battle of Trafalgar (1805), provides a middle ground. Launched in 1765, it has survived over 250 years, though much of its original timber has been replaced. Its preservation in a dry dock as a museum ship showcases how active conservation efforts can extend a wooden ship’s life far beyond its operational years. This blend of historical significance and ongoing maintenance offers a blueprint for sustaining wooden maritime heritage.

These examples reveal that wooden ships’ lifespans varied widely based on construction quality, usage intensity, and preservation efforts. While some succumbed to the elements or combat within decades, others endured for centuries through careful stewardship. Understanding these historical cases provides valuable insights into the factors that determine a wooden ship’s longevity and how we might preserve such vessels today.

Durability of Wood Fences: Lifespan, Maintenance, and Longevity Tips

You may want to see also

Explore related products

$135

$78.95 $85.95

Comparison with modern materials

Wooden ships, once the backbone of maritime exploration and trade, typically lasted 20 to 30 years with diligent maintenance. This lifespan was contingent on factors like wood type, construction quality, and environmental exposure. Teak, prized for its durability, often outlasted softer woods like pine. Yet, even the sturdiest wooden vessels succumbed to rot, insect damage, and the relentless forces of wind and water. Modern materials, however, have redefined the longevity and performance of ships, raising the question: how do they compare?

Consider the advent of steel, which emerged as a dominant shipbuilding material in the late 19th century. Steel hulls, when properly maintained, can endure 40 to 50 years or more, dwarfing the lifespan of wooden ships. Unlike wood, steel resists biological degradation and offers superior structural integrity. For instance, the *RMS Titanic*, though tragically short-lived, demonstrated steel’s potential for strength and durability. However, steel is prone to corrosion, requiring regular coatings and inspections to prevent rust. Modern advancements like galvanized steel and corrosion-resistant alloys have further extended its lifespan, making it a benchmark for durability.

Composite materials, such as fiber-reinforced polymers (FRP), represent another leap forward. Widely used in recreational and smaller commercial vessels, FRP combines lightweight strength with resistance to rot and corrosion. A well-maintained FRP boat can last 50 years or more, rivaling steel in longevity while offering the added benefit of reduced maintenance. For example, fiberglass boats, a subset of FRP, dominate the modern boating market due to their ease of repair and resistance to environmental wear. However, FRP is not without drawbacks; it can be susceptible to osmotic blistering and UV degradation, requiring protective coatings and periodic inspections.

Aluminum, another modern material, strikes a balance between weight and durability. Its natural oxide layer provides inherent corrosion resistance, making it ideal for high-speed vessels and naval craft. Aluminum ships can last 30 to 40 years, comparable to well-maintained wooden ships but with significantly less maintenance. The *USS Freedom*, a littoral combat ship, exemplifies aluminum’s application in modern naval architecture. Yet, aluminum is more expensive than steel and less impact-resistant, limiting its use in certain applications.

The comparison reveals a clear evolution in shipbuilding materials, each offering unique advantages over wood. Steel provides unmatched strength, FRP minimizes maintenance, and aluminum optimizes weight and speed. While wooden ships remain iconic for their historical significance, modern materials have set new standards for longevity, performance, and efficiency. For shipbuilders and owners, the choice of material hinges on specific needs—whether prioritizing durability, cost, or maintenance—but the trend is unmistakable: modern materials have extended the lifespan of ships far beyond what wood could achieve.

Mastering Smoking: Optimal Wood Chip Soaking Time for Perfect Flavor

You may want to see also

Frequently asked questions

The lifespan of wooden ships varied widely depending on usage, maintenance, and construction quality. On average, well-maintained wooden ships could last 20 to 30 years, though some vessels, like warships or merchant ships, might only last 10 to 15 years due to heavy use and harsh conditions.

Key factors included the type of wood used (e.g., oak was more durable), construction techniques, exposure to saltwater and marine organisms like shipworms, frequency of maintenance, and the intensity of use. Regular care, such as caulking and painting, could significantly extend a ship's life.

Yes, some wooden ships lasted over 100 years, particularly those used for ceremonial or stationary purposes, such as museum ships or harbor vessels. For example, the USS Constitution, launched in 1797, remains in active service (though primarily ceremonial) due to meticulous preservation efforts.