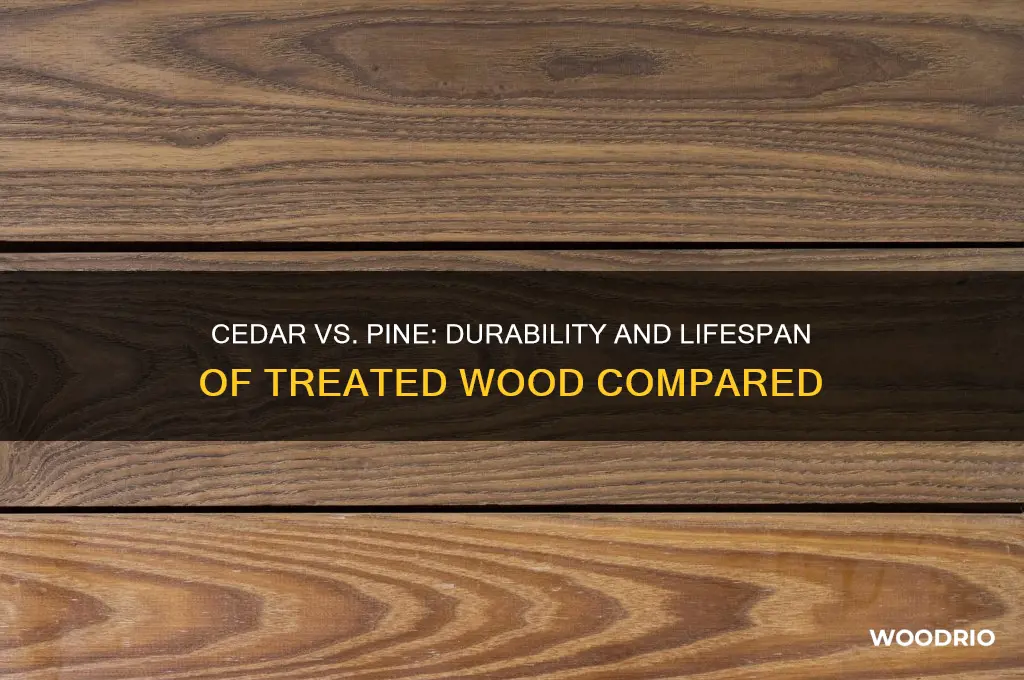

When comparing the durability of cedar versus pine treated wood, it's essential to consider factors such as natural resistance, treatment methods, and environmental conditions. Cedar, known for its inherent resistance to rot, decay, and insects, typically lasts 15-30 years without treatment, while pressure-treated pine, infused with preservatives, can endure 20-40 years or more. The longevity of both woods depends on their specific use, exposure to moisture, and maintenance. Cedar’s natural oils provide an advantage in outdoor applications, whereas treated pine’s chemical protection makes it a cost-effective choice for structural projects. Ultimately, the lifespan of each wood type hinges on its treatment quality and the demands of its environment.

| Characteristics | Values |

|---|---|

| Cedar Wood Lifespan (Untreated) | 15-30 years (naturally resistant to rot, decay, and insects) |

| Cedar Wood Lifespan (Treated) | 30-40+ years (enhanced resistance with treatment) |

| Pine Wood Lifespan (Untreated) | 5-10 years (susceptible to rot, decay, and insects) |

| Pine Wood Lifespan (Treated) | 20-40+ years (depends on treatment quality and maintenance) |

| Natural Resistance | Cedar: High (contains natural oils); Pine: Low |

| Cost | Cedar: Higher; Pine: Lower |

| Maintenance | Cedar: Minimal; Pine: Requires regular maintenance (sealing, staining) |

| Appearance | Cedar: Rich, natural color; Pine: Lighter, may require staining |

| Environmental Impact | Cedar: Sustainable (naturally rot-resistant); Pine: May require chemical treatments |

| Common Uses | Cedar: Decks, fences, outdoor furniture; Pine: Framing, indoor projects, treated for outdoor use |

| Durability (Treated) | Cedar: Excellent; Pine: Good (with proper treatment) |

| Weight | Cedar: Lighter than pine; Pine: Heavier |

| Workability | Cedar: Easy to work with; Pine: Also easy, but may require more care due to softness |

| Availability | Pine: Widely available; Cedar: Less common, may be more expensive |

Explore related products

What You'll Learn

Treatment Methods Impact

The longevity of treated wood hinges significantly on the treatment method employed. Pressure-treating, for instance, involves forcing preservatives deep into the wood fibers, creating a barrier against decay and insects. This method is commonly used for both cedar and pine, but the choice of preservative chemicals can vary. Chromated copper arsenate (CCA) was once the standard, offering up to 40 years of protection, but due to health concerns, it has been largely replaced by alternatives like alkaline copper quaternary (ACQ) and copper azole (CA-B). These newer treatments are less toxic but may require additional measures, such as stainless steel fasteners, to prevent corrosion.

For cedar, which naturally contains oils that resist decay, treatment methods often focus on enhancing its inherent properties rather than replacing them. Light preservative treatments, such as those using borates, can extend cedar’s lifespan to 20–30 years in outdoor applications. Borates penetrate the wood’s cellular structure, inhibiting fungal growth and insect damage without compromising cedar’s natural aesthetic. In contrast, pine, which lacks these natural defenses, relies more heavily on chemical treatments. A pine post treated with ACQ, for example, can last 25–30 years in ground contact, but this requires precise application to ensure the preservative reaches the core of the wood.

The application process itself is critical. Pressure-treating involves placing the wood in a sealed cylinder, applying vacuum to remove air, and then forcing the preservative into the wood under high pressure. This ensures even distribution, which is essential for pine but less critical for cedar due to its natural resistance. For DIY projects, brush-on or spray treatments are available, but these are less effective for pine, as they cannot penetrate deeply enough to provide long-term protection. Cedar, however, can benefit from periodic surface treatments with wood sealers or oils, which can add 5–10 years to its lifespan with minimal effort.

Environmental factors also influence how treatment methods impact durability. In humid or wet conditions, treated pine may still require additional protection, such as a waterproof sealant, to prevent surface moisture absorption. Cedar, with its natural oils, fares better in such environments but can still benefit from a protective coating to maintain its appearance. For both woods, proper installation practices, such as ensuring good drainage and avoiding direct soil contact, can maximize the effectiveness of any treatment method.

Ultimately, the choice of treatment method should align with the wood’s intended use and environmental exposure. While cedar’s natural properties make it a strong candidate for lighter treatments, pine’s reliance on heavy-duty preservatives necessitates careful selection and application. By understanding these nuances, homeowners and builders can make informed decisions to ensure their treated wood structures last as long as possible.

Durability of California Wood Homes: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Climate and Weather Effects

Moisture is the arch-nemesis of wood, and its presence or absence dramatically influences the longevity of both cedar and pine. In humid climates, where moisture lingers in the air and rain is frequent, untreated pine succumbs quickly to rot and decay. Cedar, with its natural oils, fares better, but even it requires vigilant maintenance. The key lies in understanding the wood's cellular structure: cedar's dense grain repels water more effectively than pine's looser composition. For regions with high humidity, consider using pressure-treated pine, which has been infused with preservatives to combat moisture-induced deterioration.

Temperature extremes act as silent accelerants of wood degradation. In arid, sun-drenched environments, both cedar and pine are susceptible to warping, cracking, and fading. The intense UV radiation breaks down the wood's lignin, a natural polymer that binds cells together. Cedar, with its inherent resistance to insects and decay, may retain its structural integrity longer, but its surface will still show signs of weathering. Pine, especially untreated varieties, will deteriorate faster under these conditions. To mitigate this, apply a UV-protective sealant annually, ensuring it penetrates the wood's surface to form a barrier against solar damage.

Freeze-thaw cycles in temperate climates pose a unique challenge, particularly for pine. As water seeps into the wood's pores and freezes, it expands, causing microfractures that weaken the material over time. Cedar, with its lower moisture absorption rate, is less prone to this issue, but it’s not immune. To combat this, ensure proper drainage around wooden structures and apply a water-repellent treatment before winter sets in. For pine, pressure-treated options are a must in such climates, as the preservatives help resist the damaging effects of freezing temperatures.

Wind, often overlooked, plays a significant role in wood erosion. In coastal or windy areas, sand and debris carried by gusts act like sandpaper, wearing down the wood's surface. Cedar’s natural resins provide some protection, but pine, especially softer varieties, will show wear more rapidly. Regularly inspect and refinish exposed surfaces, using a coarse-grit sandpaper to remove rough patches before applying a protective coat. For high-wind zones, consider installing windbreaks or choosing denser wood grades to minimize abrasion.

Ultimately, the interplay of climate and weather demands a tailored approach to wood selection and maintenance. Cedar’s natural advantages make it a superior choice in most conditions, but treated pine can hold its own with proper care. Assess your local climate’s dominant factors—moisture, temperature, freeze-thaw, or wind—and choose treatments and maintenance routines accordingly. By understanding these effects, you can maximize the lifespan of either wood, ensuring durability and aesthetic appeal for years to come.

Understanding the Standard Lengths of Wood Slabs for Your Projects

You may want to see also

Explore related products

Maintenance Requirements Comparison

Cedar and pine treated wood each demand distinct maintenance routines to maximize their lifespan. Cedar, naturally resistant to rot and insects, requires minimal intervention—typically a yearly inspection and occasional cleaning with mild soap and water. Pine, while durable when pressure-treated, needs more proactive care. Every 3–5 years, pine should be inspected for cracks, splinters, or signs of mold, and re-stained or sealed to maintain its protective barrier. Neglecting this schedule accelerates pine’s deterioration, especially in humid or wet climates.

For cedar, the focus is preservation rather than repair. Applying a clear sealant or UV-protective finish every 2–3 years enhances its natural color and shields it from sun damage. Pine, however, often requires more frequent treatments—annual staining or sealing is recommended for high-exposure areas like decks or fences. Additionally, pine benefits from regular cleaning with a mildew-resistant solution, particularly in shaded or damp environments where mold thrives. These steps are not optional for pine; they are essential to prevent premature warping or decay.

A critical difference lies in how each wood responds to environmental stressors. Cedar’s inherent oils repel moisture, reducing the risk of swelling or splitting, even without treatment. Pine, despite its treatment, remains more susceptible to moisture absorption, necessitating vigilant drainage management around structures. For instance, ensuring proper ground slope away from pine fences or decks minimizes water pooling, a common culprit in wood rot. This proactive approach significantly extends pine’s functional life.

Lastly, consider the tools and products used for maintenance. Cedar’s soft grain accepts finishes smoothly, requiring only a brush or sprayer for application. Pine’s denser surface may need a power washer for deep cleaning before resealing, but caution is advised to avoid damaging the wood fibers. For both woods, using non-toxic, water-based products aligns with eco-friendly practices while ensuring longevity. Tailoring maintenance to the wood’s unique properties ensures optimal performance and appearance over decades.

Oven Drying Wood: Optimal Time for Perfectly Seasoned Wood Pieces

You may want to see also

Explore related products

Cost vs. Lifespan Analysis

Treated pine typically costs 20-30% less upfront than cedar, making it an attractive option for budget-conscious projects. However, this initial savings comes with a trade-off. Pine’s lifespan averages 15-20 years, while cedar can endure 25-30 years or more, even without treatment. To illustrate, a 100-square-foot deck built with treated pine might cost $800 in materials, whereas cedar could run $1,100. Over 30 years, the cedar deck would require no replacement, while the pine deck might need a $1,200 rebuild after 20 years, totaling $2,000—nearly double the cedar’s cost over the same period.

Analyzing maintenance costs further tilts the scale. Treated pine requires regular staining or sealing every 2-3 years, at $100-$200 per application, adding $500-$1,000 over its lifespan. Cedar, naturally resistant to rot and insects, needs treatment only every 4-5 years, cutting maintenance to $200-$400. Factoring in labor, pine’s upkeep costs can surpass $1,500 over 20 years, while cedar remains under $600 for 30 years. This gap widens when considering the environmental and time costs of repeated maintenance.

For high-moisture areas like docks or ground-contact structures, the lifespan disparity grows. Treated pine in such conditions may last only 10-15 years, necessitating replacement sooner. Cedar, with its natural oils, can persist 30+ years even in harsh environments. A waterfront deck in pine might cost $1,500 initially but require $3,000 in replacements and maintenance over 30 years. Cedar, at $2,200 upfront, would cost only $2,500 total, including minimal upkeep. This makes cedar the more cost-effective choice for long-term, exposed applications.

To maximize value, consider the project’s purpose and location. For temporary structures like garden borders or playground borders, treated pine’s lower cost and 15-year lifespan suffice. For permanent features like pergolas or siding, cedar’s longevity justifies the higher investment. Pro tip: Calculate the total cost of ownership (initial cost + maintenance + replacements) over 20-30 years to make an informed decision. Tools like lifecycle cost calculators can simplify this analysis, ensuring you choose the wood that aligns with both budget and durability needs.

Foraging for Wood in The Long Dark: Essential Survival Tips

You may want to see also

Explore related products

Common Decay Resistance Factors

The durability of wood, whether cedar or pine, hinges on its natural and treated resistance to decay. Cedar, with its innate oils and tannins, inherently repels insects and fungi, often lasting 15–20 years untreated in outdoor settings. Pine, while less naturally resilient, can match or exceed cedar’s lifespan when properly pressure-treated with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ). However, the effectiveness of treated pine depends on factors beyond the chemical itself.

Moisture Exposure: The Silent Destroyer

Moisture is the primary catalyst for wood decay, fostering fungal growth and insect infestation. Cedar’s natural hydrophobic properties reduce water absorption, but even treated pine will fail if constantly saturated. To maximize longevity, ensure wood is installed with proper drainage, at least 6 inches above ground, and sealed annually with a water-repellent finish. For treated pine, avoid cutting or drilling without applying a preservative to exposed areas, as these create entry points for moisture.

Chemical Concentration and Penetration

The efficacy of treated pine relies on the preservative’s concentration and depth of penetration. ACQ-treated wood, for instance, requires a retention level of 0.40 pounds per cubic foot (pcf) for ground contact applications, while above-ground use can use 0.25 pcf. Inadequate penetration leaves the wood’s core vulnerable. When purchasing, verify the treatment level and inspect for uniform coloration, which indicates thorough saturation. Cedar, while naturally resistant, can still benefit from borate treatments to enhance its decay resistance in high-moisture environments.

Environmental Stressors: Sun, Soil, and Salt

UV radiation, soil acidity, and salt exposure accelerate wood degradation. Cedar’s natural pigments provide some UV resistance, but both woods require staining or painting every 2–3 years to prevent surface cracking. In acidic soils (pH < 5.0), pine’s preservatives may leach faster, necessitating more frequent inspections. Coastal areas demand stainless steel fasteners and premium sealants to combat salt corrosion. For extreme conditions, consider using cedar for above-ground structures and treated pine for ground contact, combining their strengths.

Biological Threats: Fungi and Termites

Fungi and termites target wood’s cellulose, with termites causing more rapid damage in untreated pine. Cedar’s thujaplicin oil deters both, but treated pine’s chemical barrier is equally effective if maintained. Regularly inspect for mud tubes (termite signs) and fungal discoloration. For termite-prone regions, use pine treated with termiticide additives like permethrin. Cedar can be supplemented with borate sprays, which penetrate deeply to create a toxic barrier against both pests and fungi.

By understanding these decay resistance factors, you can strategically select and maintain cedar or treated pine to ensure their maximum lifespan. Combine cedar’s natural advantages with treated pine’s chemical fortification, and prioritize proactive measures against moisture, environmental stressors, and biological threats. The result? Wood structures that endure decades, not just years.

Jeremy Sumpter and Rachel Hurd-Wood's Brief Romance: How Long Did It Last?

You may want to see also

Frequently asked questions

Cedar treated wood can last 15–30 years or more, depending on maintenance and environmental conditions, while pine treated wood typically lasts 10–20 years.

Cedar naturally contains oils and tannins that resist rot, decay, and insect damage, whereas pine relies heavily on chemical treatments for durability.

No, treated pine may degrade faster in wet or humid climates, while cedar’s natural resistance makes it more durable in such conditions.

Regular maintenance, such as sealing and staining, can extend pine’s lifespan, but it’s unlikely to match cedar’s natural longevity without additional effort.