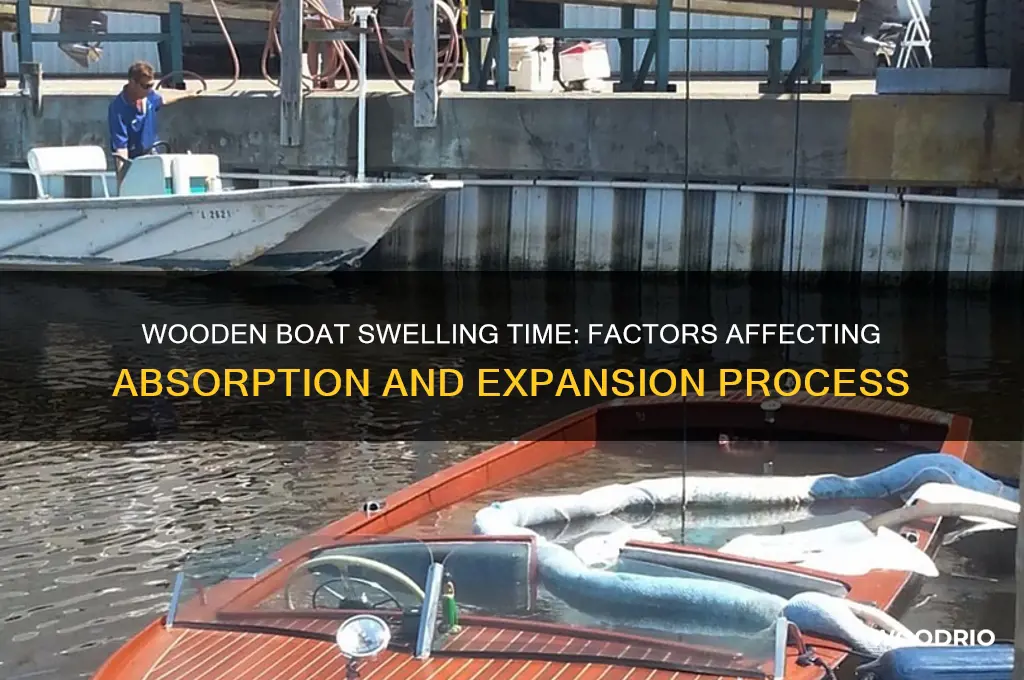

The time it takes for a wooden boat to swell depends on several factors, including the type of wood, the boat's construction, the moisture content of the wood, and the environmental conditions it is exposed to. Typically, wooden boats begin to swell when they absorb water, a process that can take anywhere from a few hours to several days, depending on how dry the wood was initially. Hardwoods like oak or teak may take longer to swell compared to softer woods like pine. Prolonged exposure to water, such as being submerged or left in humid conditions, accelerates swelling, while occasional or brief contact with water may result in minimal or slower absorption. Proper maintenance, such as regular sealing and waterproofing, can significantly reduce the rate at which a wooden boat swells, preserving its structural integrity and longevity.

| Characteristics | Values |

|---|---|

| Time to Swell | 24-48 hours (varies based on wood type, moisture content, and conditions) |

| Wood Types | Hardwoods (e.g., oak, teak) swell slower than softwoods (e.g., pine) |

| Moisture Absorption Rate | 5-10% increase in weight (depends on wood density and exposure time) |

| Environmental Factors | Higher humidity and prolonged water exposure accelerate swelling |

| Temperature Influence | Warmer temperatures increase swelling rate |

| Sealing Effect | Properly sealed wooden boats swell less due to reduced moisture intake |

| Structural Impact | Swelling can cause joints to tighten or planks to expand |

| Drying Time After Swelling | 3-7 days in dry conditions to return to original dimensions |

| Maintenance Requirement | Regular sealing and inspection prevent excessive swelling |

| Long-Term Effects | Repeated swelling/drying cycles can weaken wood fibers over time |

Explore related products

$11.99

What You'll Learn

Factors affecting swelling time

Wooden boats absorb moisture from their environment, causing the fibers to expand—a process known as swelling. The time this takes varies widely, influenced by factors like wood type, environmental conditions, and maintenance practices. Understanding these variables allows boat owners to predict swelling behavior and mitigate potential issues.

Wood Species and Grain Orientation: Different woods swell at different rates. Dense hardwoods like teak or oak absorb moisture more slowly than softer woods like pine or cedar. Additionally, the direction of the grain matters—wood swells more across the grain than along it. For instance, a boat with planks laid perpendicular to the keel will expand more in width than length when exposed to water. Builders can minimize distortion by aligning grain patterns strategically during construction.

Humidity and Submersion Duration: Swelling accelerates in high-humidity environments or when the boat is fully submerged. A wooden vessel left in water for 24–48 hours can swell noticeably, with expansion peaking after 72 hours. In contrast, gradual moisture absorption from humid air takes longer—up to several weeks—to produce visible effects. Owners storing boats in damp areas should monitor for signs of swelling, such as tightened joints or warped surfaces, and take preventive measures like using dehumidifiers or waterproof coatings.

Temperature and Water Salinity: Warmer temperatures increase the rate of moisture absorption, as wood fibers expand more readily in heat. For example, a boat in tropical waters may swell 2–3 times faster than one in cooler climates. Saltwater also affects swelling; its higher density and mineral content can cause wood to absorb moisture more aggressively than freshwater. Regular rinsing with fresh water after saltwater exposure reduces this risk, as does applying marine-grade sealants to limit water penetration.

Maintenance and Sealant Quality: Proper maintenance significantly delays swelling. Boats treated with epoxy resins or marine varnishes absorb less moisture than untreated ones. However, sealants degrade over time—typically 1–3 years depending on exposure—requiring reapplication. Neglected boats may swell within months, while well-maintained ones can resist noticeable expansion for 5–10 years. Inspecting for cracks, sanding rough areas, and recoating as needed are essential practices to prolong the boat’s structural integrity.

By addressing these factors, boat owners can manage swelling effectively, ensuring their wooden vessels remain seaworthy and aesthetically pleasing. Tailoring care routines to the specific wood type, climate, and usage conditions yields the best results.

Vinyl vs. Wood Fences: Which Material Offers Longer Durability?

You may want to see also

Explore related products

Wood type and moisture absorption

Wood species vary dramatically in their moisture absorption rates, a critical factor in how quickly a wooden boat swells. Dense, tight-grained woods like teak or oak absorb water more slowly due to their natural oils and resins, which act as barriers. In contrast, softwoods like pine or cedar, with their looser grain structure, soak up moisture rapidly, causing quicker expansion. For instance, teak might take weeks to show noticeable swelling, while pine could expand within days under similar conditions. Understanding these differences helps boat owners predict and manage moisture-related issues.

To minimize swelling, choose wood species with low moisture absorption rates for hull construction. Teak, mahogany, and white oak are excellent choices due to their natural resistance to water penetration. If using softer woods, apply marine-grade sealants or epoxy coatings to create a protective barrier. Reapply these treatments annually, especially in tropical climates where humidity levels exceed 70%. Regular maintenance not only slows swelling but also extends the boat’s lifespan by preventing rot and warping.

Comparing wood types reveals that swelling isn’t just about absorption speed—it’s also about dimensional stability. Woods like cedar, though quick to absorb moisture, release it faster, reducing long-term distortion. Hardwoods like ipe, while slower to swell, retain water longer, potentially leading to cracking. For optimal performance, pair high-absorption woods with efficient drainage systems and low-absorption woods with rigorous sealing. This combination balances immediate and long-term swelling risks.

Practical tips for managing moisture absorption include monitoring humidity levels in storage areas and using dehumidifiers when necessary. Keep boats out of water for extended periods only if they’re properly sealed and stored in dry conditions. For emergency repairs, avoid using untreated softwoods, as they’ll swell unpredictably. Instead, opt for pre-treated marine plywood or hardwoods. By selecting the right wood and maintaining it diligently, boat owners can significantly reduce swelling-related damage.

Drying Split Wood: Timeframe, Factors, and Tips for Optimal Results

You may want to see also

Explore related products

$249.99

Environmental conditions impact

Wooden boats, unlike their fiberglass or metal counterparts, are highly sensitive to environmental conditions, particularly moisture. The swelling of wood is a natural process driven by its hygroscopic nature, meaning it absorbs and releases water in response to humidity levels. This phenomenon is not merely a curiosity but a critical factor in boat maintenance and longevity. Understanding how environmental conditions accelerate or mitigate swelling is essential for any wooden boat owner.

Humidity: The Primary Driver

High humidity is the most direct environmental factor affecting wooden boat swelling. Wood fibers expand as they absorb moisture from the air, a process that can occur within hours in extremely humid conditions (above 70% relative humidity). For instance, a wooden boat left uncovered in a tropical climate can show noticeable swelling in as little as 24–48 hours. Conversely, in arid environments (below 30% humidity), wood may dry out and shrink, but prolonged exposure to moisture—whether from rain, dew, or splashes—can still lead to swelling over days or weeks. Monitoring humidity levels and using dehumidifiers in storage areas can significantly reduce swelling risk.

Temperature Fluctuations: The Hidden Culprit

Temperature changes exacerbate swelling by influencing the rate of moisture absorption and release. Rapid temperature shifts, such as those experienced in coastal regions with cool nights and warm days, create condensation on boat surfaces. This moisture penetrates the wood, accelerating swelling. For example, a wooden boat exposed to a 30°F (16.7°C) temperature swing within 12 hours can absorb enough moisture to swell noticeably within 3–5 days. To mitigate this, store boats in temperature-controlled environments or use breathable covers to minimize condensation buildup.

Water Exposure: Immediate and Long-Term Effects

Direct water exposure, whether from rain, waves, or immersion, is the most aggressive environmental factor. Submerging a wooden boat, even partially, can lead to swelling within hours, as wood absorbs water at a rate of approximately 5–10% of its dry weight per hour in the first few hours. Prolonged exposure, such as leaving a boat in the water for weeks, can cause wood to swell by 2–5% in volume, compromising structural integrity. Regularly inspecting for leaks, applying waterproof sealants, and ensuring proper drainage are critical preventive measures.

Sunlight and UV Radiation: The Silent Degraders

While sunlight and UV radiation do not directly cause swelling, they weaken wood fibers over time, making them more susceptible to moisture absorption. UV rays break down lignin, the natural glue in wood, reducing its ability to resist water penetration. A wooden boat exposed to direct sunlight for 6–8 hours daily can experience accelerated swelling when subsequently exposed to moisture. Applying UV-protective coatings and storing boats in shaded areas can extend their resistance to swelling.

Practical Tips for Minimizing Swelling

To protect wooden boats from environmental swelling, follow these steps:

- Monitor Conditions: Use hygrometers and thermometers to track humidity and temperature in storage areas.

- Ventilation: Ensure proper airflow around the boat to prevent moisture buildup.

- Regular Maintenance: Inspect for cracks, apply sealants, and re-coat surfaces annually.

- Cover Strategically: Use breathable, UV-resistant covers to shield from rain and sunlight while allowing moisture to escape.

By proactively managing environmental conditions, wooden boat owners can significantly reduce swelling, preserving both the vessel’s functionality and aesthetic appeal.

Cedar Wood Durability: How Long Does It Last Outdoors?

You may want to see also

Explore related products

Boat size and construction role

Wooden boats, unlike their fiberglass counterparts, are living entities that interact dynamically with water. This interaction is most evident in the process of swelling, where the wood fibers absorb moisture, expanding and tightening joints. The time it takes for a wooden boat to swell is not a fixed value but a spectrum influenced heavily by its size and construction.

A larger boat, with its greater surface area exposed to water, will naturally take longer to reach equilibrium. Imagine a massive oak-planked schooner compared to a delicate mahogany dinghy; the schooner's hulking frame will require significantly more time for water to penetrate its thick planks and reach the core. Conversely, the dinghy, with its thinner hull, will swell more rapidly, its lighter construction allowing moisture to permeate quicker.

Construction techniques play an equally crucial role. Traditionally built boats with carvel planking, where planks are butted edge-to-edge, tend to swell faster than those with lapstrake construction, where planks overlap. This overlap creates a natural barrier, slowing water absorption. Additionally, the type of wood used is paramount. Dense hardwoods like teak or mahogany are more resistant to swelling than softer woods like pine or cedar.

Think of it like a sponge: a dense, tightly woven sponge takes longer to absorb water than a loose, open-celled one.

Understanding these factors is essential for proper boat maintenance. A boat that swells unevenly due to variations in plank thickness or wood type can develop structural weaknesses. Regular inspection, particularly after periods of prolonged immersion, is vital. Applying a suitable sealant or varnish can help slow down the swelling process, but it's important to remember that some degree of swelling is natural and even desirable, as it ensures watertight integrity.

Durability of Wooden Picket Fences: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Maintenance and sealing effects

Wooden boats absorb moisture over time, causing the wood to swell and potentially compromising structural integrity. Proper maintenance and sealing are critical to mitigating this process, but their effectiveness depends on the materials, techniques, and environmental conditions involved. For instance, epoxy-based sealants can reduce moisture absorption by up to 90%, significantly extending the time it takes for a boat to swell. However, even the best sealants degrade over time, requiring periodic reapplication to maintain their protective properties.

Analytical Perspective:

The rate at which a wooden boat swells is inversely proportional to the quality and frequency of its maintenance. Regular inspections for cracks, leaks, or worn sealant can identify vulnerabilities before they allow water penetration. For example, a boat stored in humid climates or frequently exposed to saltwater will require more frequent sealing—typically every 1–2 years—compared to one kept in dry, freshwater environments. Using marine-grade varnishes or epoxy resins with UV inhibitors can further slow swelling by protecting the wood from both moisture and sunlight, which accelerates degradation.

Instructive Steps:

To maximize the sealing effect, follow these steps:

- Clean the Surface: Remove old sealant, dirt, and debris using a mild detergent and a stiff brush. Sand the wood lightly to create a smooth base.

- Apply Epoxy Resin: Use a marine-grade epoxy, applying it in thin, even coats. Allow each layer to cure fully (typically 24–48 hours) before adding the next. Aim for 3–4 coats for optimal protection.

- Seal with Varnish: Finish with a high-quality marine varnish, applying 2–3 coats. Reapply varnish annually or as needed, depending on exposure.

- Monitor for Wear: Inspect the sealant every 6 months, touching up any areas where the coating has cracked or peeled.

Comparative Insight:

Traditional oil-based sealants, like linseed oil, offer a natural, breathable finish but provide minimal protection against swelling, often requiring monthly applications. In contrast, modern synthetic sealants, such as polyurethane or epoxy, form a durable barrier that can last years. While synthetic options are more expensive upfront, their longevity and effectiveness make them a cost-effective choice for long-term boat preservation. For example, a boat treated with epoxy may take 5–10 years to show signs of swelling, whereas an oil-treated boat might begin swelling within 6–12 months.

Practical Tips:

- Storage Matters: Keep the boat under a covered structure or use a breathable cover to minimize exposure to rain and humidity.

- Temperature Control: Avoid storing wooden boats in areas with extreme temperature fluctuations, as this can cause the sealant to crack.

- Emergency Repairs: Carry a small tube of marine sealant for quick fixes to minor leaks or cracks while on the water.

By understanding the interplay between maintenance and sealing, boat owners can significantly delay the swelling process, ensuring their wooden vessels remain seaworthy for decades. The key lies in consistent care and the strategic use of advanced sealing materials.

Measuring History: Understanding Cordwood Lengths in Traditional Times

You may want to see also

Frequently asked questions

The time it takes for a wooden boat to swell depends on the type of wood, its dryness, and environmental conditions. Generally, it can take anywhere from a few hours to several days for the wood to absorb enough moisture to swell noticeably.

Yes, the swelling process is significantly influenced by climate. In humid or wet conditions, swelling occurs faster, often within hours, while in dry climates, it may take days or even weeks for the wood to absorb enough moisture to swell.

Swelling can be minimized by properly sealing the wood with marine-grade finishes, storing the boat in a dry environment, and ensuring it is not left in water for extended periods. Regular maintenance and proper care can help control and reduce swelling.