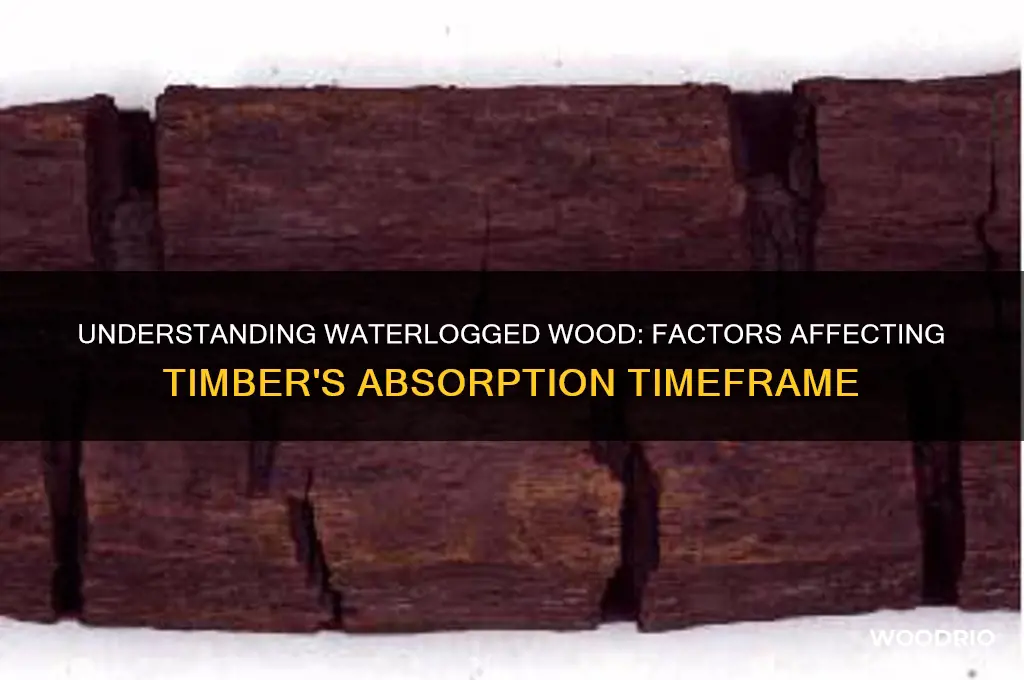

Wood becomes waterlogged when it absorbs a significant amount of water, compromising its structural integrity and buoyancy. The time it takes for wood to become waterlogged depends on several factors, including the type of wood, its density, the presence of protective coatings, and the conditions of water exposure. Softwoods, like pine, typically absorb water more quickly than hardwoods, such as oak, due to their less dense cellular structure. Unprotected wood submerged in water can start to show signs of waterlogging within hours to days, while wood exposed to moisture over time, such as in humid environments or frequent rain, may take weeks or months to become fully waterlogged. Understanding these factors is crucial for applications like shipbuilding, construction, and outdoor furniture, where water resistance and durability are essential.

| Characteristics | Values |

|---|---|

| Time to Waterlog (Freshwater) | 2-4 weeks (varies based on wood type, density, and submersion depth) |

| Time to Waterlog (Saltwater) | 1-2 weeks (salt accelerates water absorption) |

| Wood Type Influence | Softwoods (e.g., pine) waterlog faster than hardwoods (e.g., oak) |

| Density Impact | Lower-density woods absorb water quicker than higher-density woods |

| Temperature Effect | Warmer water speeds up waterlogging; colder water slows it down |

| Submersion Depth | Deeper submersion increases water pressure, accelerating waterlogging |

| Initial Moisture Content | Dry wood waterlogs faster than already moist wood |

| Presence of Air Pockets | Woods with fewer air pockets (e.g., denser woods) waterlog slower |

| Chemical Treatment | Treated wood (e.g., pressure-treated) resists waterlogging longer |

| Signs of Waterlogging | Increased weight, discoloration, softness, and warping |

Explore related products

What You'll Learn

Factors affecting waterlogging time

Wood's journey to waterlogging is a complex process influenced by several key factors, each playing a unique role in determining how quickly it absorbs and retains water. The density of the wood is a primary consideration; denser woods, like teak or oak, naturally resist water absorption due to their tight grain structure, which acts as a barrier against moisture. In contrast, softer woods such as pine or cedar, with their more open pores, can become waterlogged in a matter of hours to days, depending on the conditions. This inherent characteristic of wood density is a fundamental aspect that dictates its susceptibility to waterlogging.

Environmental conditions significantly accelerate or decelerate the waterlogging process. Temperature, for instance, plays a pivotal role; warmer water increases the kinetic energy of molecules, facilitating faster penetration into the wood's cellular structure. A study by the Forest Products Laboratory suggests that wood submerged in water at 70°F (21°C) can show signs of waterlogging within 24-48 hours, whereas colder temperatures may extend this period to several days. Humidity levels also contribute, as high humidity environments can cause wood to absorb moisture from the air, even without direct water contact, though this process is slower compared to full immersion.

The duration of exposure to water is another critical factor, with prolonged contact leading to inevitable waterlogging. For example, wood used in marine environments, constantly exposed to saltwater, may become waterlogged within weeks, while wood in freshwater settings might take months. The salinity of the water also matters; saltwater, with its higher mineral content, can expedite the breakdown of wood fibers, making it more susceptible to water absorption. This is why wooden structures in coastal areas often require more frequent maintenance and treatment to prevent waterlogging.

Treatment and maintenance of wood can significantly mitigate the risk of waterlogging. Applying waterproof sealants or preservatives creates a protective barrier, reducing water absorption rates. For instance, a coat of epoxy resin can extend the time it takes for wood to become waterlogged by several years, depending on the application thickness and environmental conditions. Regular maintenance, such as reapplying sealants every 1-2 years, is crucial for wood exposed to harsh conditions. Additionally, proper ventilation and drainage in wooden structures can prevent standing water, a common cause of rapid waterlogging.

Understanding these factors allows for better management and preservation of wood in various applications. By selecting appropriate wood types, considering environmental impacts, and implementing effective treatment strategies, the lifespan of wooden materials can be significantly extended. Whether it’s for construction, marine use, or outdoor furniture, recognizing the variables that affect waterlogging time is essential for ensuring durability and longevity. This knowledge not only aids in material selection but also guides maintenance practices, ultimately saving time and resources in the long run.

Maximizing Wood Chipper Blade Lifespan: Factors and Maintenance Tips

You may want to see also

Explore related products

Wood type and density impact

Wood species vary dramatically in their susceptibility to waterlogging, and density is the linchpin of this variation. Dense hardwoods like teak or oak, with their tightly packed fibers and natural oils, resist water absorption far longer than softwoods like pine or cedar. This isn't just a theoretical distinction—it's a practical one. A teak dock plank, for instance, can remain structurally sound underwater for decades, while a pine board might begin to warp and weaken within months. Understanding this density-driven disparity is crucial for anyone selecting wood for marine or outdoor applications.

Consider the cellular structure of wood as a sponge, but one with varying pore sizes. Dense woods have smaller, more tightly packed cells, slowing water infiltration. Softwoods, with their larger, more open cells, act like a sieve, allowing water to penetrate rapidly. This isn't merely about initial absorption; it's about long-term stability. A study by the Forest Products Laboratory found that after 12 weeks of water immersion, dense hardwoods retained 80% of their original strength, while softwoods lost up to 50%. For projects requiring durability, this data underscores the importance of choosing density over cost.

However, density isn't the sole factor—grain pattern and natural resins also play roles. Woods with straight, tight grains, like maple, channel water less efficiently than those with irregular grains. Similarly, resin-rich woods like cedar contain natural preservatives that slow decay, even as they absorb water. This interplay of density, grain, and chemistry means that while density is a reliable predictor, it's not the only variable. For instance, a moderately dense wood like cypress, with its natural tannins, outperforms denser but less chemically resistant woods in waterlogged conditions.

Practical application of this knowledge requires a nuanced approach. If you're building a boat, opt for dense, resinous woods like mahogany or teak, which can withstand years of moisture without compromising integrity. For temporary structures, like garden borders, softwoods like pine are cost-effective, despite their shorter lifespan. Always consider the environment: saltwater accelerates degradation faster than freshwater, so even dense woods may require treatment. Applying a marine-grade sealant can extend the life of any wood, but it’s no substitute for choosing the right species from the start.

Finally, while density is a key indicator, it’s not an absolute rule. Pressure-treated softwoods, for example, can rival hardwoods in water resistance due to chemical preservatives. Yet, these treatments add cost and environmental concerns. For purists or eco-conscious builders, understanding the natural properties of wood remains paramount. By balancing density, grain, and chemistry, you can predict—and control—how long any wood will endure before becoming waterlogged, ensuring your project stands the test of time and tide.

Perfect Soaking Time for Cholla Wood: A Complete Guide

You may want to see also

Explore related products

Environmental conditions role

Wood's journey to waterlogging is a complex dance with its surroundings, where environmental conditions play a pivotal role in dictating the pace and extent of this transformation. The primary factor at play is moisture content, with relative humidity (RH) levels above 70% significantly accelerating the process. In regions with high RH, such as tropical climates or areas near large bodies of water, wood can become waterlogged in as little as 2-4 weeks, whereas in arid environments, this process may take several months or even years.

Consider the case of wooden boat hulls, which are constantly exposed to water. The rate of water absorption is directly proportional to the temperature and salinity of the surrounding water. In warmer waters (above 25°C), wood can absorb up to 30% of its dry weight in moisture within the first week, compared to 10-15% in colder waters (below 15°C). Salinity also plays a crucial role, as saltwater can penetrate wood fibers more rapidly than freshwater due to its higher ionic content, reducing the time to waterlogging by 20-30%.

To mitigate the effects of environmental conditions, it's essential to implement preventive measures. For outdoor wooden structures, such as decks or fences, apply a high-quality sealant or stain every 2-3 years to create a barrier against moisture. In areas with high RH, consider using naturally rot-resistant wood species like cedar or redwood, which contain natural oils and tannins that slow down water absorption. Additionally, ensure proper ventilation and drainage to minimize standing water, which can accelerate wood decay by up to 50%.

The interplay between environmental factors and wood's susceptibility to waterlogging highlights the importance of context-specific solutions. For instance, in coastal regions, where wood is exposed to both high RH and saltwater, combining regular maintenance with the use of pressure-treated wood can extend the material's lifespan by 10-15 years. Conversely, in arid climates, focusing on UV protection and periodic moisture checks can prevent wood from becoming brittle and prone to cracking, even in the absence of excessive moisture.

Ultimately, understanding the nuanced relationship between environmental conditions and wood's waterlogging process enables more informed decision-making in material selection, maintenance, and preservation. By tailoring strategies to specific climatic conditions, it's possible to significantly slow down the onset of waterlogging, ensuring the longevity and structural integrity of wooden structures in diverse environments. This may involve investing in higher-quality materials, implementing rigorous maintenance schedules, or adopting innovative preservation techniques, but the payoff is a more resilient and durable built environment.

How Long Does COVID-19 Survive on Wood Furniture Surfaces?

You may want to see also

Explore related products

Water absorption rate variations

Wood species exhibit dramatically different water absorption rates due to variations in cellular structure and density. Dense hardwoods like teak or oak have tightly packed cells with natural oils and resins, slowing moisture penetration to hours or even days in submerged conditions. In contrast, softwoods such as pine or cedar have larger, less dense cells and absorb water more rapidly, often becoming waterlogged within minutes to hours. This disparity underscores the importance of species selection in applications where moisture exposure is inevitable.

Environmental factors further complicate absorption rates, even within the same wood type. Temperature, humidity, and water pressure act as accelerants or inhibitors. Warm water, for instance, expands wood fibers more aggressively than cold water, increasing absorption speed by up to 40%. Similarly, pressurized environments, like underwater installations, force moisture into pores faster than static conditions. Understanding these variables allows for better predictive modeling of waterlogging timelines, especially in outdoor or aquatic applications.

Practical mitigation strategies can offset absorption rate variations, particularly in vulnerable species. Applying sealants or waterproofing agents creates a barrier that reduces moisture ingress, extending the time to waterlogging by weeks or months. For example, a single coat of marine-grade varnish can halve the absorption rate of pine. Additionally, pre-treatment methods like pressure-treating wood with preservatives or kiln-drying to reduce moisture content can further delay saturation, making these techniques essential for structural or decorative wood exposed to water.

Comparative analysis reveals that absorption rates are not linear but follow a logarithmic curve, with the fastest changes occurring in the first hour of exposure. After this initial spike, the rate plateaus as the wood reaches equilibrium moisture content (EMC), typically around 25-30% for most species. This insight is critical for time-sensitive projects, such as boatbuilding or dock construction, where early-stage protection is most effective. By focusing on the first hour of exposure, one can significantly prolong the wood’s functional lifespan in wet environments.

Rubber vs. Wood Mulch: Which Lasts Longer in Your Garden?

You may want to see also

Explore related products

$23.03 $24.79

Preventing wood waterlogging tips

Wood exposed to moisture will inevitably absorb water, leading to waterlogging, a process that can compromise its structural integrity and aesthetic appeal. The time it takes for wood to become waterlogged varies depending on factors such as wood type, moisture content, and environmental conditions. Softwoods like pine may show signs of waterlogging within 24-48 hours of continuous exposure, while denser hardwoods like teak can resist for several days or even weeks. Understanding this timeline is crucial for implementing preventive measures.

Sealants and Finishes: Your First Line of Defense

Applying a high-quality sealant or finish is the most effective way to prevent waterlogging. Polyurethane, epoxy, and marine-grade varnishes create a barrier that repels water. For outdoor furniture or structures, use a sealant with UV protection to prevent degradation. Reapply every 1-2 years, depending on exposure. For example, a wooden deck in a rainy climate may require annual sealing, while an indoor wooden table might only need treatment every 3-5 years. Always sand the surface lightly before reapplication to ensure proper adhesion.

Strategic Design and Placement

Waterlogging often occurs due to poor design or placement. Elevate wooden structures like decks, fences, or planters using pressure-treated posts or concrete footings to minimize ground contact. Incorporate drainage holes in wooden containers or furniture to allow water to escape. For example, a wooden planter box should have at least 2-3 holes per square foot of base area. Avoid placing wood in areas prone to standing water, and ensure proper grading around structures to direct water away.

Regular Maintenance and Inspection

Preventive care extends the life of wood significantly. Inspect wooden items seasonally for cracks, splinters, or signs of moisture penetration. Repair damaged areas promptly with wood filler or epoxy, then reseal. For outdoor wood, clean surfaces with a mild detergent and water solution every 3-6 months to remove dirt and mildew, which can trap moisture. In humid climates, consider using a dehumidifier in enclosed spaces like sheds or basements to reduce ambient moisture levels.

Alternative Materials and Treatments

In high-moisture environments, consider using naturally water-resistant woods like cedar or cypress, or opt for pressure-treated lumber, which is infused with preservatives. For existing wood, apply a wood preservative containing copper azole or borate, which penetrates the fibers to inhibit water absorption. These treatments are particularly useful for wooden foundations, docks, or bridges. However, always follow manufacturer guidelines, as some preservatives require professional application or specific safety precautions.

By combining these strategies, you can significantly delay or even prevent waterlogging, ensuring wood retains its strength and beauty for years to come.

Understanding the Lifespan of Wood Bison in the Wild

You may want to see also

Frequently asked questions

The time it takes for wood to become waterlogged depends on the type of wood, its density, and the conditions it’s exposed to. Softwoods like pine can become waterlogged in as little as a few hours to a day, while denser hardwoods like oak may take several days to weeks.

Yes, wood can become waterlogged when submerged in water. The process is faster in still water, as the wood absorbs water through its cells, causing it to swell and lose structural integrity.

Yes, warmer water accelerates the absorption process, as higher temperatures increase the movement of water molecules into the wood fibers. Cold water slows down the process but does not prevent waterlogging entirely.

While treated or sealed wood is more resistant to water absorption, it can still become waterlogged over time, especially if the protective coating is damaged or worn away. Proper maintenance and reapplication of sealants can significantly delay waterlogging.