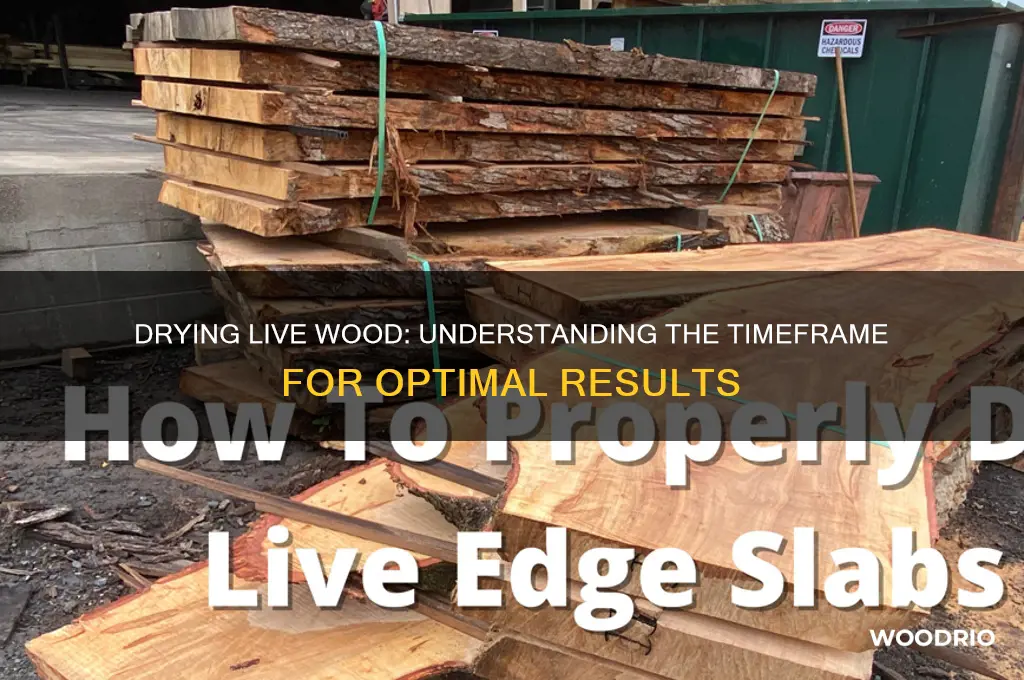

Drying live wood is a crucial process for woodworking and crafting, as it ensures the wood is stable, durable, and less prone to warping or cracking. The time it takes for live wood to dry depends on several factors, including the wood species, its initial moisture content, the drying method used, and environmental conditions such as humidity and temperature. Generally, air-drying can take anywhere from several months to a few years, while kiln-drying, a faster method, can reduce this time to weeks or even days. Understanding these variables is essential for achieving the desired results and preserving the wood's quality.

| Characteristics | Values |

|---|---|

| Drying Time (Air Drying) | 1-3 years (varies based on wood type, thickness, and climate) |

| Drying Time (Kiln Drying) | 2-6 weeks (accelerated process, depends on wood species and moisture content) |

| Moisture Content Reduction | From 30-60% (green wood) to 6-12% (air-dried) or 6-8% (kiln-dried) |

| Wood Type Influence | Hardwoods take longer (e.g., oak, maple) than softwoods (e.g., pine) |

| Thickness Impact | Thicker pieces take significantly longer to dry than thinner ones |

| Climate Effect | Warmer, drier climates speed up drying; humid climates slow it down |

| Cracking/Warping Risk | Higher in air drying; kiln drying reduces risk but requires expertise |

| Cost Considerations | Air drying is cheaper; kiln drying is more expensive but faster |

| Environmental Impact | Air drying is more eco-friendly; kiln drying uses energy |

| End Use Suitability | Air-dried wood is ideal for outdoor use; kiln-dried for indoor projects |

Explore related products

What You'll Learn

Factors Affecting Drying Time

The drying time of live wood is a complex process influenced by several key factors, each playing a unique role in determining how quickly moisture is removed. Understanding these factors can help you optimize the drying process, ensuring the wood is ready for use without compromising its structural integrity. Here, we delve into the critical elements that affect drying time, offering insights and practical tips to navigate this essential step in woodworking.

Moisture Content and Wood Species: The Foundation of Drying

The initial moisture content of live wood is a primary determinant of drying time. Freshly cut wood can contain up to 100% moisture (relative to its dry weight), while air-dried wood typically stabilizes around 12-15%. Harder woods like oak or maple retain moisture longer than softer woods like pine or cedar due to their denser cellular structure. For instance, oak may take 1-2 years to air-dry, whereas pine can dry in 6-12 months. To expedite the process, measure moisture levels using a wood moisture meter, aiming for a target range of 6-8% for indoor use.

Environmental Conditions: The Role of Climate and Airflow

Climate significantly impacts drying time. In humid regions, wood dries slower due to higher ambient moisture levels, while arid climates accelerate drying but risk cracking. Optimal drying occurs in environments with 50-70% humidity and temperatures between 60°F and 90°F. Enhance airflow by stacking wood with spacers or using stickers between layers, allowing air to circulate evenly. For controlled drying, kiln-drying reduces time to weeks but requires precise temperature and humidity management, typically ranging from 120°F to 180°F.

Thickness and Dimensions: Size Matters

The thickness of wood directly correlates with drying time—thicker pieces take longer to dry. A 1-inch board may air-dry in 6 months, while a 4-inch slab could require 2-3 years. To mitigate this, quarter-saw or slab-cut logs to reduce thickness, and seal end grain with wax or paint to prevent rapid moisture loss, which causes warping. For larger pieces, consider a combination of air-drying and kiln-drying to balance speed and stability.

Drying Method: Choosing the Right Approach

The chosen drying method—air-drying, kiln-drying, or solar-drying—dramatically affects timeframes. Air-drying is cost-effective but slow, while kiln-drying is faster but more expensive. Solar-drying, using greenhouse-like structures, offers a middle ground, reducing drying time by 30-50% compared to air-drying. For hobbyists, a DIY solar kiln can be constructed using clear plastic sheeting and a simple frame, providing controlled drying without the cost of industrial equipment.

Practical Tips for Efficient Drying

To optimize drying, start by cutting wood during the dormant season when moisture content is naturally lower. Store wood in a shaded, well-ventilated area, protecting it from rain and direct sunlight. Regularly inspect for mold or insect infestation, especially in humid climates. For thicker pieces, consider a preliminary kiln-drying phase followed by air-drying to stabilize moisture levels. Finally, always acclimate dried wood to its intended environment for 2-4 weeks before use to prevent shrinkage or expansion.

By addressing these factors—moisture content, wood species, environmental conditions, dimensions, and drying method—you can significantly reduce drying time while preserving wood quality. Whether you’re a professional woodworker or a DIY enthusiast, mastering these variables ensures your live wood is ready for crafting, construction, or artistry.

Corona on Wood: Understanding the Survival Duration of the Virus

You may want to see also

Explore related products

Air Drying vs. Kiln Drying

Drying live wood is a critical step in preparing it for use in furniture, construction, or crafting, and the method chosen—air drying or kiln drying—significantly impacts the timeline and outcome. Air drying, the traditional method, relies on natural conditions, exposing wood to ambient air and allowing moisture to evaporate gradually. This process can take anywhere from 6 months to 2 years, depending on the wood species, thickness, and climate. For instance, a 1-inch thick board of oak might dry in 6 months in a dry, warm climate but could take a year or more in a humid region. Air drying is cost-effective and environmentally friendly but requires patience and space, making it ideal for hobbyists or small-scale projects.

Kiln drying, on the other hand, is a controlled, accelerated process that uses heat and humidity to remove moisture from wood in a matter of days to weeks. A typical kiln cycle for 1-inch thick hardwood lasts 4–8 weeks, while softer woods may dry in as little as 2–3 weeks. Kiln drying offers precision, reducing the risk of warping, cracking, or insect infestation, which are common concerns with air drying. However, it requires specialized equipment and consumes energy, making it more expensive. Professionals often prefer kiln drying for its consistency and efficiency, especially when working with large volumes or time-sensitive projects.

Choosing between the two methods depends on your priorities. Air drying is best for those who value sustainability and have the luxury of time, while kiln drying suits those seeking speed and reliability. For example, a furniture maker crafting a single heirloom piece might opt for air drying to preserve the wood’s natural character, whereas a commercial manufacturer producing hundreds of chairs would likely choose kiln drying to meet deadlines. Understanding these trade-offs ensures the wood dries optimally for its intended use.

Practical tips can enhance either method. For air drying, stack wood with stickers (spacers) to promote airflow, and cover the pile to protect it from rain while allowing ventilation. Kiln operators should monitor moisture levels closely, adjusting temperature and humidity to avoid over-drying. Both methods benefit from proper initial preparation, such as cutting wood to rough dimensions before drying to reduce waste and improve efficiency. Ultimately, the choice between air and kiln drying hinges on balancing time, cost, and quality for your specific needs.

Alaskan Wood Frogs: Survival Secrets of Their Frozen Hibernation

You may want to see also

Explore related products

Moisture Content Measurement

Live wood, freshly harvested and still containing its natural moisture, undergoes a transformation as it dries, a process critical for its stability and usability in woodworking. But how do we know when it's truly dry? This is where moisture content measurement becomes essential.

Understanding Moisture Content:

Wood's moisture content is the weight of water it holds as a percentage of its oven-dry weight. Freshly cut wood can have a moisture content of over 100%, meaning it carries more water than its dry weight. The goal is to reduce this to a level suitable for its intended use, typically between 6-12% for indoor furniture and 12-15% for outdoor applications.

Measurement Techniques:

- Oven-Dry Method: The most accurate but time-consuming method involves weighing a wood sample, drying it in an oven at 103°C (217°F) until it reaches a constant weight, and then reweighing. The difference in weight indicates the moisture lost.

- Moisture Meters: Handheld devices offer a quicker solution. Pin-type meters measure electrical resistance, while pinless meters use electromagnetic waves. Calibration is key; ensure the meter is set for the specific wood species.

- Kiln Monitoring: For large-scale drying, kilns use sensors to monitor moisture content, temperature, and humidity, providing real-time data for precise control.

Practical Tips for Woodworkers:

When working with live wood, regular moisture content checks are crucial. For small projects, a moisture meter is a handy tool, allowing you to assess the wood's readiness. For larger batches, consider the oven-dry method for initial testing and then use a meter for ongoing monitoring. Remember, wood dries from the outside in, so check multiple locations on each piece.

The Drying Timeline:

Drying time varies significantly based on wood species, initial moisture content, and drying conditions. Softwoods like pine may take 4-6 weeks to air-dry, while denser hardwoods such as oak can require 6-12 months. Kiln drying accelerates this process, reducing time to days or weeks, but requires careful control to avoid cracking or warping.

In the context of live wood drying, moisture content measurement is not just a technical detail but a critical factor in determining the wood's readiness for its intended purpose. It ensures the wood's longevity and structural integrity, making it a vital skill for woodworkers and craftsmen.

Bailey Hanks' Elle Woods: Her Legally Blonde Broadway Journey

You may want to see also

Explore related products

Species-Specific Drying Rates

The drying time of live wood varies significantly across species, influenced by factors like density, moisture content, and cellular structure. For instance, softwoods like pine dry faster due to their lower density and more open cell structure, often reaching usable moisture levels within 6 to 12 months. Hardwoods, such as oak or maple, take considerably longer—up to 2 years or more—because of their denser composition and higher natural moisture content. Understanding these species-specific rates is crucial for preventing cracks, warping, or fungal growth during the drying process.

Analyzing specific examples highlights these differences further. Cedar, a lightweight softwood, can air-dry to 12% moisture content in as little as 3 to 6 months, making it ideal for quick projects like outdoor furniture. In contrast, teak, a dense hardwood, requires at least 18 months to dry properly, with some logs taking up to 3 years. Kiln-drying can expedite this process but must be species-specific: pine can handle rapid kiln drying, while walnut risks splitting if dried too quickly. Always reference species-specific guidelines to avoid costly mistakes.

For practical application, consider these steps when drying live wood. First, identify the species and its typical drying timeline. Second, monitor moisture levels using a wood moisture meter, aiming for 6–12% for indoor use. Third, stack wood with stickers to allow airflow, and store it in a dry, well-ventilated area. For hardwoods, seal the ends with wax to reduce end-grain drying and cracking. Finally, be patient—rushing the process can ruin the wood. For example, drying ash too quickly can lead to honeycomb defects, while slow, controlled drying preserves its strength.

Comparing softwoods and hardwoods reveals why their drying rates differ. Softwoods, like spruce or fir, have larger resin canals and lower density, allowing moisture to escape more easily. Hardwoods, such as mahogany or cherry, have smaller vessels and higher tannin content, which slows moisture movement. This biological difference necessitates tailored drying methods. For instance, hardwoods benefit from a slower initial drying phase to prevent surface checking, while softwoods can tolerate faster drying without significant risk.

Persuasively, investing time in species-specific drying pays off in wood quality and longevity. Properly dried wood is less prone to shrinkage, splitting, or insect infestation, ensuring durability in projects like flooring, cabinetry, or musical instruments. For example, properly dried ebony retains its deep black color and stability, while rushed drying can cause it to crack or fade. By respecting each species’ unique needs, woodworkers can maximize material value and minimize waste, making the extra time a worthwhile investment.

John Wood Water Heater Lifespan: What to Expect and How to Extend It

You may want to see also

Explore related products

Preventing Cracks and Warping

Live wood, still containing moisture from its living state, is inherently unstable. As it dries, the uneven shrinkage of its cellular structure creates internal stresses that manifest as cracks and warping. This is particularly true for wood with high moisture content or dense, uneven grain patterns. Understanding the drying process and implementing preventive measures are crucial for preserving the wood's integrity.

Air-drying, the most common method, relies on natural conditions and can take months to years depending on wood species, thickness, and climate. Kiln-drying accelerates the process but requires careful monitoring to avoid excessive heat, which can exacerbate cracking. Regardless of method, controlling the drying environment is key.

The Art of Slow Drying:

Imagine a seasoned luthier crafting a violin. They wouldn't rush the drying of the tonewood, knowing that slow, controlled drying is essential for optimal sound quality and structural stability. Similarly, preventing cracks and warping in live wood demands patience. Aim for a gradual moisture loss of 1-2% per week, allowing the wood to adjust internally without stress. This might mean stacking wood with stickers to promote airflow, covering it to control humidity, and regularly monitoring moisture levels with a reliable meter.

Think of it as a delicate dance, balancing the need for drying with the wood's natural tendency to resist change.

Strategic Stacking and Support:

Picture a stack of freshly cut lumber, each board separated by stickers – thin strips of wood allowing air circulation. This simple technique prevents warping by promoting even drying on all surfaces. For larger pieces, consider using supports at regular intervals to prevent sagging and twisting. Imagine a sculptor shaping clay; the supports act as a framework, guiding the wood's transformation without forcing it into unnatural shapes.

Remember, the goal is to mimic the wood's natural drying process in a controlled environment, minimizing stress and maximizing stability.

Moisture Control: The Silent Guardian:

Humidity plays a pivotal role in drying live wood. In dry climates, covering the wood with breathable materials like burlap can slow moisture loss and prevent surface checking. Conversely, in humid environments, ensuring adequate ventilation is crucial to prevent mold and mildew. Think of moisture control as a delicate balancing act, constantly adjusting to the wood's needs and the surrounding conditions.

Accepting Imperfection, Embracing Character:

Despite our best efforts, some cracking and warping are inevitable, especially with certain wood species. Instead of viewing these as flaws, consider them as unique characteristics that tell the story of the wood's journey from living tree to crafted object. A skilled woodworker can incorporate these natural imperfections into their designs, creating pieces with depth and individuality. Ultimately, preventing cracks and warping is about respecting the wood's inherent nature, guiding its transformation with patience, knowledge, and a touch of artistic vision.

Durability Unveiled: Composite Wood Siding's Lifespan Explained

You may want to see also

Frequently asked questions

Natural air drying of live wood can take anywhere from 6 months to 2 years, depending on the wood species, thickness, humidity, and temperature.

Yes, kiln drying can significantly speed up the process, typically taking 2 to 8 weeks, depending on the wood type and kiln settings.

Yes, higher moisture content in live wood will increase drying time. Freshly cut wood with 50-100% moisture content will take longer to dry compared to wood with lower moisture levels.