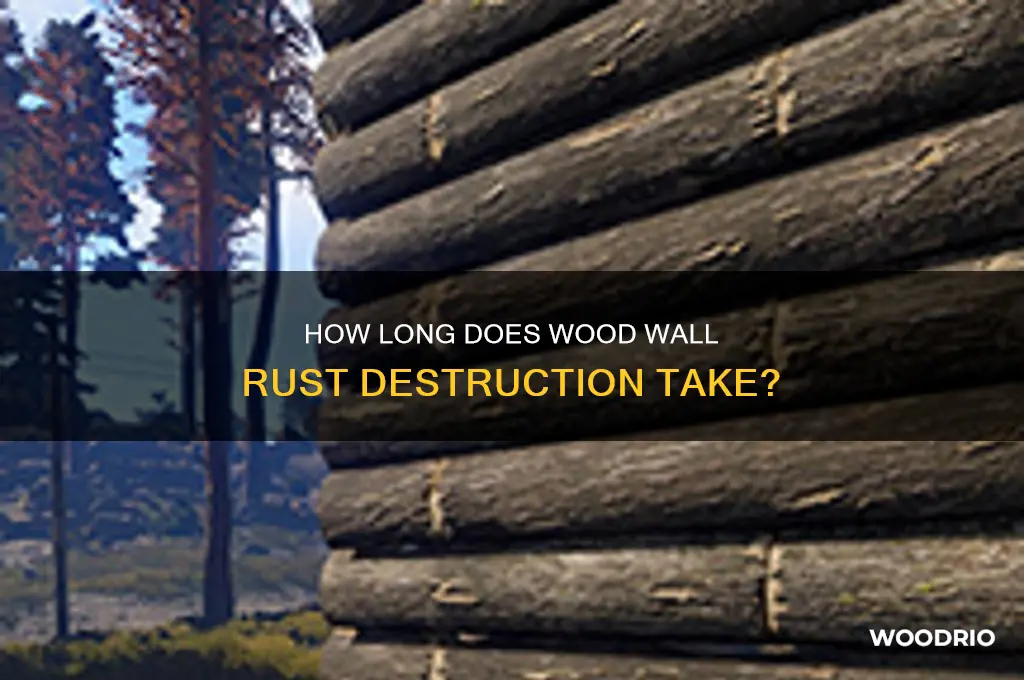

The rate at which a wooden wall succumbs to rust is a complex interplay of factors, primarily hinging on the presence of metal components within or adjacent to the wood. Rust, a form of iron oxide, forms when iron or its alloys are exposed to moisture and oxygen. If a wooden wall contains nails, screws, or other metal elements, these can corrode over time, potentially compromising the structural integrity of the wood. The speed of this process depends on environmental conditions such as humidity, temperature, and exposure to saltwater or chemicals. In ideal conditions for corrosion—high moisture and oxygen levels—rust can begin to form within days, though significant damage to the wooden structure may take months or even years. Understanding these dynamics is crucial for maintaining the longevity and safety of wooden structures.

Explore related products

What You'll Learn

Factors Affecting Wood Wall Rust

Wood wall rust, a term often used to describe the degradation of wood due to moisture, fungi, and metal fasteners, progresses at varying rates depending on several key factors. Moisture content, for instance, is a primary accelerant. Wood with a moisture level above 20% becomes a breeding ground for fungi and bacteria, which break down cellulose and lignin, the structural components of wood. In humid climates or areas with poor ventilation, wood walls can deteriorate within 2–5 years if left untreated. Conversely, wood maintained below 15% moisture can last decades without significant damage.

The type of wood species plays a critical role in its susceptibility to rust-like degradation. Softwoods, such as pine and spruce, are more prone to decay due to their lower density and higher resin content, which attracts moisture. Hardwoods like oak and teak, with their natural oils and denser structure, resist decay more effectively. For example, untreated pine walls in a damp basement may show signs of rot within 1–2 years, while teak walls in the same environment could remain intact for over a decade.

Environmental conditions, particularly temperature and humidity, directly influence the speed of wood wall deterioration. In tropical regions with high humidity and temperatures above 75°F (24°C), fungal growth accelerates, leading to rapid decay. In contrast, colder, drier climates slow down biological activity, prolonging the lifespan of wood walls. Installing dehumidifiers or ensuring proper insulation can mitigate these effects, reducing decay rates by up to 50%.

The presence of metal fasteners, such as nails or screws, introduces another factor: galvanic corrosion. When metal reacts with moisture, it releases ions that stain and weaken the surrounding wood. Stainless steel or galvanized fasteners are less reactive and can extend the life of wood walls by 3–5 years compared to standard steel. Regular inspection and replacement of corroded fasteners are essential to prevent localized decay.

Finally, maintenance practices significantly impact the longevity of wood walls. Applying water-repellent sealants or fungicides every 2–3 years can reduce moisture absorption and inhibit fungal growth. Sanding and refinishing surfaces every 5 years removes early signs of decay and restores protective barriers. Neglecting these steps can halve the expected lifespan of wood walls, while proactive care can double it, making maintenance a decisive factor in the battle against rust-like degradation.

How Long Does Spider Wood Take to Sink in Aquariums?

You may want to see also

Explore related products

Rust Spread Rate on Wood

The rate at which rust spreads on wood is influenced by a combination of environmental factors and the material's condition. Rust, a form of iron oxide, forms when iron or steel is exposed to moisture and oxygen. When wood is in contact with rusty metal, the corrosion process can accelerate due to the wood's ability to retain moisture, creating a conducive environment for rust to thrive. For instance, a wood wall with embedded metal fasteners can show signs of rust spreading within 3 to 6 months in humid climates, while drier regions may delay this process to 1 to 2 years.

To mitigate rust spread, consider the following steps: first, inspect wood walls for metal components like nails, brackets, or hinges. Apply a rust-inhibiting primer or paint to these areas, ensuring complete coverage. Second, treat the wood with a moisture-resistant sealant to reduce water absorption. For existing rust, use a wire brush or sandpaper to remove surface corrosion, followed by application of a rust converter to neutralize the remaining oxide. Regular maintenance, such as reapplying protective coatings every 12 to 18 months, can significantly slow rust progression.

Comparatively, untreated wood walls in coastal areas, where salt air accelerates corrosion, may exhibit rust spread 50-70% faster than inland structures. This highlights the importance of region-specific preventive measures. For example, in coastal regions, using stainless steel fasteners instead of galvanized ones can extend the wood's lifespan by 3 to 5 years. Additionally, installing a vapor barrier behind the wood can reduce moisture infiltration, further slowing rust formation.

A descriptive analysis reveals that rust spread on wood is not uniform; it often begins at points of metal-wood contact and radiates outward in a circular or linear pattern. Over time, the rust can weaken the wood's structural integrity, leading to cracks, warping, or even collapse. In severe cases, rust-induced damage may require replacing entire sections of the wood wall, a process that can cost $50 to $150 per square foot, depending on the material and labor.

Finally, a persuasive argument for proactive management is clear: the cost and effort of preventing rust spread are minimal compared to the expense of repairing or replacing damaged wood walls. By understanding the factors driving rust formation and implementing targeted interventions, property owners can preserve both the aesthetic and functional qualities of their wood structures for decades. Regular inspections, combined with appropriate treatments, are the most effective strategies to combat this insidious form of deterioration.

Cedar Wood Cladding Durability: Lifespan, Maintenance, and Longevity Explained

You may want to see also

Explore related products

Preventing Wood Wall Rust

Wood walls, while aesthetically pleasing, are susceptible to rust when metal components like nails, screws, or brackets are embedded within them. Rust occurs when iron oxidizes in the presence of moisture and oxygen, a process accelerated by humidity, salt, and temperature fluctuations. Preventing wood wall rust requires a proactive approach, focusing on material selection, protective coatings, and environmental control.

Material Selection: The First Line of Defense

Opt for galvanized or stainless steel fasteners instead of standard iron or carbon steel. Galvanized steel is coated with zinc, which acts as a sacrificial layer, corroding before the underlying metal. Stainless steel, with its chromium content, forms a passive oxide layer resistant to rust. For existing structures, consider replacing vulnerable fasteners during routine maintenance. If using iron, ensure it’s embedded deeply enough to minimize exposure to moisture, though this is a temporary solution compared to rust-resistant alternatives.

Protective Coatings: A Barrier Against Moisture

Apply rust-inhibiting primers and paints to metal surfaces before installation. Products containing phosphoric acid or tannic acid convert existing rust into a stable compound, preventing further corrosion. For wood, use sealants or waterproof coatings to reduce moisture absorption. Reapply these coatings annually, especially in high-humidity areas like bathrooms or exteriors. For added protection, use marine-grade varnishes or epoxy resins, which provide a thicker, more durable barrier against environmental factors.

Environmental Control: Managing Moisture and Airflow

Rust thrives in damp, stagnant conditions. Install proper ventilation systems to reduce humidity levels, particularly in enclosed spaces. Dehumidifiers are effective in basements or coastal regions where moisture is pervasive. Regularly inspect wood walls for signs of water damage, such as discoloration or warping, and address leaks promptly. Ensure the area around the wood walls is well-drained to prevent water accumulation. In outdoor settings, position wood walls away from sprinklers or areas prone to pooling water.

Maintenance and Monitoring: Staying Ahead of Rust

Inspect metal components biannually for early signs of rust. Use a wire brush or sandpaper to remove surface rust, then apply a rust converter and protective coating. For severe cases, replace affected fasteners immediately. Keep a maintenance log to track inspections and treatments, ensuring consistency. Educate occupants on the importance of avoiding water contact with wood walls and reporting any damage promptly.

By combining strategic material choices, protective coatings, environmental management, and vigilant maintenance, wood wall rust can be prevented effectively. While the process requires initial investment and ongoing effort, the longevity and aesthetic appeal of wood walls make it a worthwhile endeavor.

Formaldehyde in Wood: Durability and Longevity Explained

You may want to see also

Explore related products

Repairing Rust-Damaged Wood Walls

Rust on wood walls, often caused by embedded metal fasteners or prolonged exposure to moisture, can compromise both aesthetics and structural integrity. The timeline for rust to destroy wood varies—from months in humid, coastal environments to years in drier climates. However, once rust appears, immediate action is crucial to prevent irreversible damage. Repairing rust-damaged wood walls involves a systematic approach: assessment, removal, treatment, and restoration. Ignoring the issue allows rust to expand, weakening the wood fibers and potentially leading to costly replacements.

Assessment and Preparation

Begin by inspecting the extent of the damage. Surface-level rust may only require spot treatment, while deep corrosion often necessitates replacing affected wood sections. Gather tools like wire brushes, sandpaper, rust converters, and protective gear. For embedded metal, consider removing or replacing fasteners if they’re severely corroded. Clean the area thoroughly to remove debris and loose rust particles. A solution of mild detergent and water works well for this step, followed by a rinse and complete drying to prevent further moisture penetration.

Rust Removal and Treatment

For minor rust, a wire brush or sandpaper can manually remove the corrosion. For stubborn cases, apply a rust converter (e.g., phosphoric acid-based products) to neutralize the rust and create a protective barrier. Follow the manufacturer’s instructions—typically, apply a thin coat, let it dry for 24–48 hours, then scrape off any residue. If metal fasteners remain, coat them with a rust-inhibiting primer to prevent recurrence. Ensure proper ventilation during chemical treatments to avoid inhalation risks.

Wood Restoration and Protection

After addressing the rust, repair the wood. Fill small holes or cracks with wood filler, sanding smooth once dry. For larger damage, replace the affected wood panels entirely. Apply a moisture-resistant sealant or paint to protect the repaired area. In high-humidity zones, consider using marine-grade varnish or epoxy coatings for added durability. Regularly inspect the wall for signs of recurring rust or moisture issues, especially in areas prone to water exposure.

Preventive Measures

To avoid future rust damage, use stainless steel or galvanized fasteners instead of standard metal ones. Ensure proper ventilation and drainage around wood walls to minimize moisture accumulation. Periodically inspect and maintain the wall, reapplying protective coatings every 2–3 years. By proactively addressing rust and its underlying causes, you can extend the lifespan of wood walls and maintain their structural and visual appeal.

Mastering Brisket: Ideal Wood Smoking Times for Perfect Results

You may want to see also

Explore related products

$29.99 $34.98

Environmental Impact on Rust Formation

Rust formation on wood walls is a complex process influenced significantly by environmental factors. Moisture, for instance, is a primary catalyst. When wood walls are exposed to consistent dampness, whether from rain, humidity, or condensation, the iron in nails or fasteners oxidizes more rapidly. This reaction is exacerbated in coastal areas where saltwater accelerates corrosion due to its higher electrolyte content. For example, wood walls near the ocean may show signs of rust within 6 months, compared to 2–3 years in drier climates.

Temperature fluctuations also play a critical role. In regions with extreme weather, such as hot summers and cold winters, the expansion and contraction of wood can create micro-cracks. These cracks allow moisture to penetrate deeper, increasing the surface area for rust to form. Studies show that wood walls in temperate zones with moderate humidity and stable temperatures experience slower rust progression, often taking 5–7 years to become visibly damaged.

Air quality is another overlooked factor. Pollutants like sulfur dioxide and nitrogen oxides, common in urban areas, react with moisture to form acidic compounds that corrode metal faster. Wood walls in cities with high pollution levels may exhibit rust within 1–2 years, whereas rural areas with cleaner air can delay this process by up to 4 years.

Preventing rust on wood walls requires proactive environmental management. Applying waterproof sealants or rust-inhibiting paints can create a barrier against moisture and pollutants. For coastal or high-humidity areas, using stainless steel or galvanized fasteners instead of iron nails can extend the lifespan of wood walls by 10–15 years. Regular inspections, especially after extreme weather events, can identify early signs of rust and allow for timely intervention.

In conclusion, the environmental impact on rust formation is multifaceted, driven by moisture, temperature, and air quality. By understanding these factors and implementing targeted strategies, the degradation of wood walls can be significantly slowed, preserving both aesthetics and structural integrity.

Wood Filler Drying Time: How Long Does It Take to Harden?

You may want to see also

Frequently asked questions

Wood does not rust; rust is a process that occurs in iron and steel. However, wood can decay due to moisture, insects, or fungi, which can take anywhere from 5 to 50 years depending on environmental factors.

The rate of wood deterioration is influenced by moisture levels, temperature, exposure to sunlight, insect activity, and the presence of fungi. Proper treatment and maintenance can significantly slow this process.

Yes, wood walls can be treated with preservatives, sealants, or paints to prevent decay. The effectiveness of treatment typically lasts 5 to 15 years, depending on the product and environmental conditions.

In a humid environment, wood walls can begin to show signs of decay, such as mold, warping, or rot, within 1 to 5 years if not properly treated or maintained. Regular inspections and preventive measures are crucial.