Installing a wood fence is a popular choice for homeowners seeking privacy, security, and aesthetic appeal, but the time required for installation can vary significantly based on several factors. On average, a professional crew can complete the project in 1 to 3 days for a standard backyard fence, while a DIY installation may take 2 to 5 days or longer, depending on experience and the complexity of the terrain. Key factors influencing the timeline include the length of the fence, the type of wood used, ground conditions, and whether additional features like gates or post caps are included. Proper planning, having all materials ready, and favorable weather conditions can also streamline the process, ensuring a smoother and quicker installation.

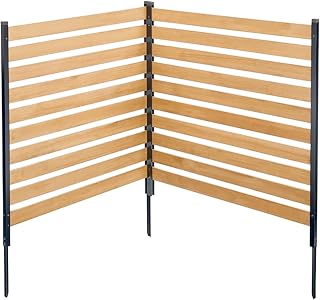

Explore related products

What You'll Learn

- Preparation Time: Clearing area, marking boundaries, and gathering materials can take 1-2 days

- Post Installation: Setting posts in concrete typically requires 2-3 days to complete

- Drying Time: Concrete curing for posts usually takes 24-48 hours before proceeding

- Fence Panel Assembly: Attaching panels to posts can be done in 1-2 days

- Finishing Touches: Adding gates, staining, or sealing extends the project by 1-2 days

Preparation Time: Clearing area, marking boundaries, and gathering materials can take 1-2 days

Before the first post is set, a wood fence installation demands a critical phase often underestimated: preparation. This stage, encompassing clearing the area, marking boundaries, and gathering materials, typically spans 1-2 days but can extend further depending on site-specific challenges. Overlooking this step risks misaligned fences, material shortages, or costly delays.

Clearing the Area: The Foundation of Efficiency

Begin by removing obstructions like vegetation, rocks, or debris. For dense foliage, allocate time for cutting back shrubs or uprooting small trees. Renting a sod cutter or chainsaw can expedite this process, especially in overgrown areas. Pro tip: Check local regulations for tree removal or protected plant species to avoid fines. This step alone can consume half a day to a full day, depending on the terrain and vegetation density.

Marking Boundaries: Precision Prevents Disputes

Accurate boundary marking is non-negotiable. Use a surveyor’s map or hire a professional to confirm property lines, as DIY measurements often lead to encroachment disputes. Stake the corners and run a string line to guide post placement. For uneven terrain, adjust the string to account for slope or grade. This task, though seemingly simple, requires meticulous attention and can take 2-4 hours, depending on property size and complexity.

Gathering Materials: A Logistics Puzzle

Material procurement is both a science and an art. Calculate the exact quantity of posts, rails, pickets, and hardware based on fence length and design. Factor in a 10% buffer for cuts and mistakes. Delivery lead times vary—wood suppliers may take 3-5 days, while hardware stores offer same-day pickup. Pro tip: Order materials after clearing and marking to avoid storage issues or mismatches. Missteps here can halt installation, so dedicate a full day to sourcing and organizing supplies.

Cautions and Takeaways

Rushing preparation invites errors that compound during installation. For instance, unmarked utilities can lead to hazardous strikes, while poorly cleared areas result in uneven post placement. Conversely, thorough preparation streamlines the build phase, reducing overall project time by up to 30%. Treat this stage as the blueprint for success, investing time now to save effort later.

In essence, preparation is the unsung hero of fence installation. By dedicating 1-2 days to clearing, marking, and gathering, homeowners ensure a seamless transition to the build phase, transforming a daunting task into a manageable project.

Understanding the Lifespan of Woods Roses: Care Tips for Longevity

You may want to see also

Explore related products

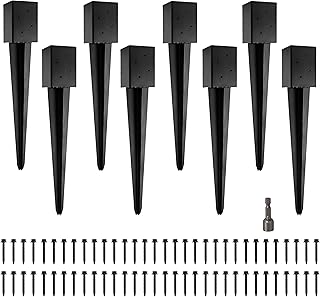

Post Installation: Setting posts in concrete typically requires 2-3 days to complete

Setting fence posts in concrete is a critical step that demands patience, as the process typically spans 2-3 days from start to finish. This timeline isn’t arbitrary—it’s rooted in the chemical curing of concrete, which requires time to harden sufficiently to support the weight and stress of a wood fence. Rushing this phase risks unstable posts, leading to sagging or leaning fences over time. While the initial pour may take only a few hours, the real work lies in waiting for the concrete to cure, a process influenced by factors like temperature, humidity, and concrete mix ratios.

To ensure a successful post installation, begin by preparing the concrete mix according to manufacturer instructions, typically a ratio of 1 part cement to 2 parts sand and 3 parts gravel, with water added gradually to achieve a thick, pourable consistency. Pour the concrete into the post hole, ensuring it covers at least one-third of the post’s height for stability. Use braces or supports to keep the post plumb while the concrete sets, as even minor deviations at this stage can compound into major alignment issues later. Avoid disturbing the post for at least 24 hours, even if the concrete feels firm to the touch, as internal curing continues.

Environmental conditions play a significant role in curing time. In warm, dry climates, concrete may cure faster, potentially reducing the wait to 2 days, while colder or humid conditions can extend the process to 3 days or more. For expedited curing, consider using rapid-set concrete mixes, which can reduce waiting time to as little as 4 hours, though these mixes are often more expensive and may require precise handling. Regardless of the mix, always follow the manufacturer’s guidelines for optimal results.

Practical tips can streamline this phase of installation. Pre-digging holes and having all materials ready before mixing concrete minimizes downtime. If installing multiple posts, work in batches to manage the process efficiently without overwhelming yourself. Use a level to check alignment periodically during the initial set, making minor adjustments before the concrete hardens completely. Finally, plan the installation during favorable weather conditions to avoid delays caused by rain or extreme temperatures, which can compromise the concrete’s integrity.

In conclusion, while setting posts in concrete is a time-consuming step, it’s a non-negotiable investment in your fence’s longevity. By understanding the curing process, preparing adequately, and accounting for environmental factors, you can ensure a sturdy foundation that withstands the test of time. Patience here isn’t just a virtue—it’s a necessity for a fence that stands tall and straight for years to come.

Hickory Wood Petrification: Understanding the Timeframe for Fossilization

You may want to see also

Explore related products

$26.99 $30.99

Drying Time: Concrete curing for posts usually takes 24-48 hours before proceeding

Concrete curing is a critical step in the fence installation process, often overlooked by those eager to see the final product. After setting the posts in concrete, the material needs time to harden and reach its full strength, typically taking 24 to 48 hours under ideal conditions. This waiting period ensures the posts are stable enough to support the weight and tension of the fence panels. Rushing this step can lead to wobbly or misaligned posts, compromising the entire structure.

The curing time can vary based on environmental factors. In hot, dry climates, concrete may cure faster, but it also risks drying too quickly, leading to cracks. To mitigate this, cover the concrete with a plastic sheet or damp burlap to retain moisture. Conversely, cold temperatures slow curing, and freezing conditions can halt it entirely. If installing in winter, use quick-setting concrete mixes or add accelerators, but follow manufacturer guidelines carefully to avoid weakening the concrete.

For optimal results, plan your installation timeline around the curing period. Avoid scheduling fence panel attachment or gate installation immediately after setting the posts. Instead, use this downtime to prepare other components, such as staining or cutting rails. If time is a constraint, consider pre-built fence sections or alternative post-setting methods, but remember that concrete curing remains the most reliable option for long-term stability.

Practical tips can further streamline the process. Mix concrete thoroughly, ensuring a consistent, pourable consistency—too dry, and it won’t bond properly; too wet, and it weakens. Pour concrete to a depth of 4–6 inches below ground level, leaving space for gravel drainage. Finally, brace posts with 2x4s during curing to prevent shifting from wind or accidental bumps. Patience during this phase pays off, ensuring a fence that stands strong for years.

Durability of Wooden Playgrounds: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Fence Panel Assembly: Attaching panels to posts can be done in 1-2 days

Attaching fence panels to posts is a pivotal phase in wood fence installation, often completed within 1 to 2 days for a standard residential project. This timeframe assumes pre-assembled panels, favorable weather, and a prepared worksite. The process begins with aligning the first panel against the posts, ensuring it’s level and plumb before securing it with screws or brackets. Repeat this step for each panel, maintaining consistent spacing and alignment. Efficiency hinges on pre-measuring and marking post positions, as well as having all hardware organized and within reach.

The speed of panel assembly depends heavily on the fence’s length and complexity. A 50-foot fence with 5 panels might take half a day, while a 200-foot fence with 20 panels could span the full 2-day estimate. Pre-drilling holes for screws saves time and prevents wood splitting, especially in hardwoods like cedar or redwood. For DIYers, working in pairs accelerates the process—one person holds the panel while the other secures it. Professionals often use pneumatic tools to further streamline fastening.

Weather plays a critical role in this stage. High winds or rain can disrupt alignment and slow progress, while extreme heat may cause wood to expand, complicating fitting. Scheduling this step during mild, dry conditions ensures panels are installed securely and accurately. Additionally, using galvanized or stainless steel hardware prevents rust and extends the fence’s lifespan, even if it adds a few minutes per panel.

A common mistake is rushing alignment, leading to uneven gaps or wobbly panels. Take the time to double-check each panel’s position before fastening. For fences on uneven terrain, step the panels or trim them to follow the slope, adding time but improving aesthetics. Finally, leave a small gap (about 1/8 inch) between panels to allow for wood expansion in humid conditions. This attention to detail ensures a professional finish within the 1-2 day window.

By breaking the task into manageable sections—such as completing one side of the yard per day—both DIYers and professionals can maintain momentum. The key is preparation: pre-assembled panels, pre-measured posts, and a clear plan minimize delays. With focus and the right approach, attaching panels becomes a straightforward, rewarding step in the larger fence installation process.

Understanding the Lifespan of Wood-Boring Bees: A Comprehensive Guide

You may want to see also

Explore related products

Finishing Touches: Adding gates, staining, or sealing extends the project by 1-2 days

Installing a wood fence is a substantial project, but the real transformation often lies in the finishing touches. Adding gates, staining, or sealing not only enhances durability and aesthetics but also extends the timeline by 1-2 days. These steps are essential for longevity, yet they require careful planning and execution to avoid delays.

Steps to Efficiently Add Finishing Touches:

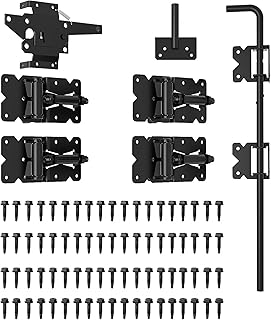

- Gates Installation: Allocate half a day for this task. Measure and mark gate posts precisely, ensuring they’re plumb and aligned. Use galvanized hardware to prevent rust. If installing double gates, allow extra time for hinge adjustments and latch alignment.

- Staining or Sealing: Plan a full day for this process, including drying time. Clean the wood thoroughly to remove dust or debris. Apply stain or sealant evenly with a brush or sprayer, following the manufacturer’s instructions. For example, oil-based stains typically require 24-48 hours to dry, while water-based options dry in 2-4 hours.

Cautions to Avoid Common Pitfalls:

- Avoid staining or sealing in direct sunlight or high humidity, as this can lead to uneven drying or bubbling.

- Ensure gates are fully functional before staining to prevent damage to hinges or latches.

- Test stain or sealant on a small section first to confirm color and finish.

Comparative Analysis: While skipping these steps saves time, the trade-off is significant. Unsealed wood fences can warp, crack, or fade within a year, doubling maintenance costs. Gates without proper hardware may sag or malfunction, requiring repairs sooner than expected.

Practical Tips for Success:

- Stain or seal the fence panels before installation if possible to save time.

- Use a wood conditioner before staining to ensure even absorption, especially on dense woods like cedar.

- Schedule finishing touches on days with moderate temperatures (50-85°F) for optimal results.

Petrifying Wood: Understanding the Timeframe for Fossilization Process

You may want to see also

Frequently asked questions

On average, installing a wood fence takes 1 to 3 days for a standard residential property, depending on the length of the fence and the complexity of the terrain.

Yes, the size of the fence significantly affects installation time. Larger fences can take 2 to 5 days or more, while smaller sections may only take a day.

Yes, weather conditions like rain, high winds, or extreme temperatures can delay installation, potentially adding days or even weeks to the timeline.

Yes, more intricate designs or using harder wood types can increase installation time, as they require additional labor and precision.