Drying wood chips is a crucial process that affects their usability and quality, whether for fuel, mulch, or other applications. The time it takes to dry wood chips depends on several factors, including the initial moisture content, chip size, environmental conditions such as temperature and humidity, and the drying method used. Typically, air-drying wood chips in a well-ventilated area can take anywhere from a few weeks to several months, while mechanical drying methods, such as using kilns or dryers, can significantly reduce this time to just a few days. Understanding these variables is essential for optimizing the drying process and ensuring the wood chips meet the desired moisture levels for their intended use.

| Characteristics | Values |

|---|---|

| Drying Time (Air Drying) | 6 months to 2 years, depending on wood type, moisture content, and climate conditions |

| Drying Time (Kiln Drying) | 2–14 days, depending on kiln efficiency, wood thickness, and moisture level |

| Moisture Content Reduction Goal | Typically from 40–60% (freshly cut) to 15–20% for optimal use |

| Factors Affecting Drying Time | Wood species, initial moisture content, chip size, humidity, temperature, airflow |

| Optimal Conditions for Air Drying | Sunny, well-ventilated area with low humidity and consistent airflow |

| Optimal Conditions for Kiln Drying | Controlled temperature (100–200°F), humidity, and airflow in a kiln |

| Common Wood Chip Uses | Biomass fuel, mulch, animal bedding, smoking chips, landscaping |

| Signs of Properly Dried Wood Chips | Lightweight, brittle, and grayish color; no mold or mildew |

| Environmental Impact | Air drying is energy-efficient; kiln drying uses more energy but is faster |

| Cost Considerations | Air drying is cheaper; kiln drying is more expensive but saves time |

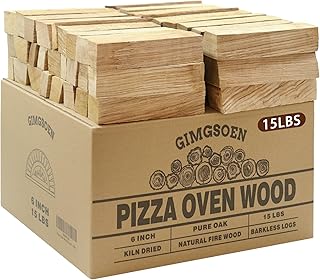

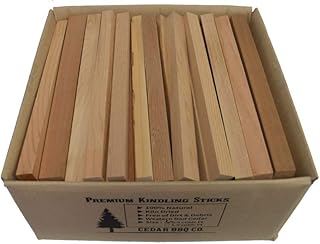

Explore related products

What You'll Learn

Factors Affecting Drying Time

Wood chip drying times vary widely, influenced by a combination of environmental and material factors. Understanding these elements is crucial for optimizing the process, whether for industrial use or personal projects. The moisture content of fresh wood chips typically ranges from 40% to 60%, and reducing this to 20% or less is essential for efficient combustion or storage. The drying duration can span from a few days to several weeks, depending on how these factors interact.

Environmental Conditions: The Unseen Hands Shaping Drying Speed

Temperature and humidity are the primary environmental drivers. Wood chips dry fastest in temperatures above 85°F (29°C), as heat accelerates moisture evaporation. Conversely, high humidity levels (above 60%) slow drying by saturating the air, reducing its capacity to absorb moisture. For example, wood chips left in a sunny, arid climate may dry in 3–5 days, while those in a damp, cool environment could take 2–3 weeks. To expedite drying, consider using a greenhouse or a covered area with ventilation to control these conditions.

Material Characteristics: Intrinsic Traits That Dictate Drying Dynamics

The type and size of wood chips significantly impact drying time. Softwoods like pine dry faster than hardwoods like oak due to their lower density and higher resin content, which aids moisture release. Chip size matters too: smaller pieces (1–2 inches) expose more surface area, drying in 1–2 weeks, while larger chunks (4–6 inches) may take 3–4 weeks. For uniform drying, ensure chips are spread thinly, no more than 6 inches deep, to prevent internal moisture retention.

Airflow: The Silent Accelerator

Proper airflow is non-negotiable for efficient drying. Stagnant air prolongs the process by trapping moisture around the chips. To enhance airflow, use raised beds or mesh screens to allow air circulation from below. Turning the pile every 2–3 days further exposes damp areas, reducing drying time by up to 40%. In industrial settings, forced air systems or fans can cut drying times in half, making this a worthwhile investment for large-scale operations.

Practical Tips for Optimal Drying

For home users, start by splitting logs into chips during dry, sunny weather to minimize initial moisture. Store chips in a single layer on a breathable surface, like a pallet or gravel pad, to prevent ground moisture absorption. If time is critical, cover the pile with a tarp to shield from rain while allowing airflow through the sides. Regularly monitor moisture levels using a wood moisture meter, aiming for 20% or less before use. These steps ensure wood chips are ready for their intended purpose without unnecessary delays.

Spook Wood Growth Timeline: Understanding the Development of This Unique Tree

You may want to see also

Explore related products

Optimal Drying Conditions

Wood chips dry at different rates depending on factors like moisture content, chip size, and environmental conditions. Achieving optimal drying conditions accelerates this process while preserving the wood’s quality. For instance, freshly cut wood chips with a moisture content of 50-60% can take anywhere from a few days to several weeks to dry naturally. However, controlled drying methods reduce this time significantly, often to 3-7 days, depending on the setup.

Analytical Insight: Optimal drying conditions hinge on balancing temperature, airflow, and humidity. Temperatures between 120°F and 140°F (49°C and 60°C) are ideal for efficient drying without causing thermal degradation. Airflow should be consistent, with a minimum of 500 cubic feet per minute (CFM) per ton of wood chips to ensure even moisture removal. Humidity levels below 50% are preferable, as higher humidity slows evaporation. For example, a kiln-drying setup with these parameters can reduce moisture content from 50% to 20% in 48-72 hours.

Instructive Steps: To create optimal drying conditions, start by spreading wood chips in a single layer on a well-ventilated surface, such as a raised bed or wire mesh. Position the chips in direct sunlight if possible, as solar heat accelerates drying. If using a kiln or dehydrator, preheat the unit to 130°F (54°C) before loading the chips. Rotate or stir the chips every 12 hours to ensure uniform drying. For outdoor drying, cover the chips with a breathable tarp during rain or high humidity to prevent reabsorption of moisture.

Comparative Perspective: Natural air-drying is cost-effective but slow, often taking 2-4 weeks, while kiln-drying is faster but requires equipment investment. Solar drying offers a middle ground, combining affordability with efficiency, especially in sunny climates. For small-scale operations, a DIY solar dehydrator made from plywood, clear plastic, and a fan can reduce drying time to 3-5 days. In contrast, industrial operations may use biomass dryers, which integrate heat recovery systems to dry chips in under 24 hours.

Practical Tips: Monitor moisture levels using a wood moisture meter, aiming for 15-20% for most applications. Avoid over-drying, as wood below 10% moisture becomes brittle. For outdoor drying, choose a south-facing location to maximize sun exposure. If using a kiln, maintain a consistent temperature and airflow to prevent case-hardening, where the exterior dries too quickly, trapping moisture inside. Finally, store dried chips in a dry, covered area to prevent rehydration, ensuring they remain usable for fuel, mulch, or other purposes.

Durability of Manufactured Wood Desks: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Methods for Faster Drying

Drying wood chips efficiently is crucial for various applications, from biomass fuel to landscaping mulch. The natural drying process can take weeks or even months, depending on environmental conditions. However, several methods can significantly accelerate this timeline, ensuring wood chips are ready for use in a fraction of the time.

Solar Drying: Harnessing the Power of the Sun

One of the most cost-effective and eco-friendly methods is solar drying. By spreading wood chips in thin layers on a flat, sunny surface, you maximize exposure to sunlight and air circulation. For optimal results, use a dark tarp or mesh screen to retain heat and prevent moisture absorption from the ground. Stir the chips daily to ensure even drying. This method can reduce drying time from months to as little as 3–7 days, depending on weather conditions. Pairing solar drying with a greenhouse or clear plastic cover can further enhance efficiency by trapping heat and protecting chips from dew or rain.

Mechanical Drying: Investing in Technology

For larger-scale operations, mechanical dryers offer a reliable solution. Rotary drum dryers, for instance, use heated air to evaporate moisture as the chips tumble inside a rotating cylinder. These systems can dry wood chips in 24–48 hours, but they require significant energy input. Alternatively, fluidized bed dryers suspend chips on a stream of hot air, achieving drying times as short as 10–15 minutes per batch. While expensive to install, these technologies are ideal for commercial applications where time and consistency are critical.

Chemical Treatment: Accelerating Moisture Release

Applying chemical agents like calcium chloride or potassium acetate can expedite drying by drawing moisture out of wood cells. Mix 1–2% of the chemical (by weight) with the wood chips and allow it to penetrate for 24 hours before air-drying. This method is particularly effective in humid climates but requires careful handling due to the corrosive nature of these substances. Always wear protective gear and ensure proper ventilation during application.

Ventilated Storage: Balancing Airflow and Protection

Proper storage can dramatically speed up drying while preventing reabsorption of moisture. Store wood chips in a well-ventilated shed or under a roof with open sides to allow cross-ventilation. Elevate the pile on pallets or a slatted floor to promote airflow from below. Avoid compacting the chips, as this restricts air movement. With adequate ventilation, wood chips can dry in 1–2 weeks, even in moderately humid conditions.

Each method has its advantages and trade-offs, from the simplicity of solar drying to the efficiency of mechanical systems. By selecting the right approach based on scale, budget, and environmental factors, you can drastically reduce drying times and optimize the usability of wood chips.

OSB Wood Soaking Time: Factors Affecting Absorption and Durability

You may want to see also

Explore related products

Moisture Content Measurement

Wood chips, fresh from the chipper, can hold moisture levels upwards of 50%, making them unsuitable for many applications like fuel or mulch. Drying time varies wildly—from days to weeks—depending on factors like wood type, chip size, and drying method. But how do you know when they're truly dry? Enter moisture content measurement, the critical step that ensures your wood chips are ready for use.

Without accurate measurement, you risk using under-dried chips that can mold, attract pests, or burn inefficiently.

Methods of Measurement:

Two primary methods dominate the scene: oven-drying and moisture meters. The oven-drying method, while time-consuming, is the gold standard. It involves weighing a sample, drying it in an oven at 105°C (221°F) until it reaches a constant weight, then calculating the moisture loss. This method is precise but requires specialized equipment and patience. Moisture meters, on the other hand, offer a quicker, albeit less precise, solution. These handheld devices use electrical resistance or capacitance to estimate moisture content. While convenient, they require calibration and can be influenced by factors like temperature and wood density.

Target Moisture Levels:

The ideal moisture content for wood chips depends on their intended use. For firewood, aim for 20% or less to ensure efficient burning and minimize creosote buildup. Mulch typically requires moisture levels below 30% to prevent mold and fungal growth. Biomass fuel pellets demand even lower moisture content, often below 10%, for optimal combustion.

Practical Tips for Accurate Measurement:

- Sample Size Matters: For oven-drying, use a representative sample of at least 100 grams. For moisture meters, take multiple readings from different locations within the chip pile to account for variations.

- Calibration is Key: Regularly calibrate your moisture meter using a known dry wood sample to ensure accurate readings.

- Consider Wood Type: Different wood species have varying densities and moisture absorption rates. Consult species-specific guidelines for optimal drying times and target moisture levels.

The Takeaway: Moisture content measurement isn't just a technicality; it's a crucial step in ensuring the quality and safety of your dried wood chips. Whether you opt for the precision of oven-drying or the convenience of a moisture meter, understanding the principles and best practices will empower you to achieve the desired moisture levels for your specific application.

Maine Winter Wood Supply: How Long Does a Cord Last?

You may want to see also

Explore related products

Storage Tips for Dry Chips

Drying wood chips is a process that can take anywhere from a few days to several weeks, depending on factors like wood type, moisture content, and environmental conditions. Once dried, proper storage is crucial to maintain their quality and usability. Improper storage can lead to reabsorption of moisture, mold growth, or pest infestations, rendering the chips unusable. Here’s how to store dry wood chips effectively.

Choose the Right Container: Airtight containers are ideal for storing dry wood chips, as they prevent moisture from seeping in and pests from entering. Plastic bins with secure lids or heavy-duty bags with zip closures work well. For larger quantities, consider using food-grade barrels or drums. Avoid containers with cracks or gaps, as these can compromise the chips' dryness. If using bags, ensure they are stored off the ground on pallets or shelves to prevent moisture absorption from the floor.

Control Humidity and Temperature: Dry wood chips should be stored in a cool, dry place with consistent humidity levels below 50%. High humidity can cause the chips to reabsorb moisture, while extreme temperature fluctuations can degrade their quality. A climate-controlled shed, garage, or basement is ideal. If these spaces are unavailable, use desiccant packs or a dehumidifier to maintain optimal conditions. Avoid storing chips near heat sources, such as furnaces or water heaters, as this can accelerate drying and cause brittleness.

Organize for Accessibility: Store wood chips in labeled containers with the date of drying clearly marked. This helps you rotate stock and use older chips first. Stack containers neatly to maximize space and ensure easy access. For bulk storage, consider using labeled bins or sections to differentiate between chip types (e.g., hardwood vs. softwood). Proper organization not only saves time but also prevents unnecessary exposure to air when retrieving chips.

Monitor for Pests and Mold: Regularly inspect stored wood chips for signs of pests, such as beetles or termites, or mold growth. Even dry chips can become infested if stored in unsanitary conditions. To deter pests, place bay leaves or cedar blocks in storage containers. If mold is detected, remove the affected chips immediately and improve ventilation in the storage area. For added protection, treat storage spaces with natural repellents like diatomaceous earth or essential oils.

Long-Term Storage Considerations: For extended storage periods, consider vacuum-sealing wood chips to eliminate air exposure and preserve dryness. If storing outdoors, use weatherproof containers and cover them with tarps to protect against rain or snow. Periodically check the chips for moisture content, especially after rainy seasons. Re-dry chips if necessary before use to ensure optimal performance in applications like smoking, mulching, or fuel.

By following these storage tips, you can ensure that your dry wood chips remain in prime condition, ready for use whenever needed. Proper storage not only extends their lifespan but also enhances their functionality, whether for culinary, gardening, or heating purposes.

Petrifying Wood: Understanding the Timeframe for Fossilization Process

You may want to see also

Frequently asked questions

Drying wood chips naturally in the sun can take anywhere from 2 to 6 weeks, depending on factors like humidity, temperature, and airflow.

Using a kiln, wood chips can dry in 24 to 72 hours, depending on the kiln's efficiency and the moisture content of the wood chips.

In a well-ventilated indoor space, wood chips can take 1 to 3 weeks to dry, depending on environmental conditions and the initial moisture level.