Laser etching wood is a precise and efficient process, but the time it takes can vary significantly depending on several factors. These include the type and thickness of the wood, the complexity of the design, the power and speed settings of the laser machine, and the desired depth of the etch. Generally, simpler designs on softer woods like pine or birch can be completed in just a few minutes, while intricate patterns or deeper engravings on harder woods like oak or walnut may take anywhere from 15 minutes to over an hour. Understanding these variables is key to estimating the time required for a specific laser etching project.

| Characteristics | Values |

|---|---|

| Laser Power | Higher power (e.g., 50W+) reduces etching time significantly. |

| Wood Type | Softer woods (e.g., pine, balsa) etch faster than harder woods (e.g., oak, walnut). |

| Design Complexity | Simple designs take minutes; intricate designs can take hours. |

| Depth of Etch | Surface etching is faster; deeper engraving increases time. |

| Laser Speed | Faster speeds (e.g., 500 mm/s) reduce time but may sacrifice precision. |

| Typical Time Range | 5–30 minutes for small, simple designs; 1–4+ hours for large, complex designs. |

| Machine Quality | Industrial-grade lasers are faster than hobbyist models. |

| Focus and Calibration | Properly calibrated lasers reduce errors and save time. |

| Post-Processing | Additional time may be needed for sanding or finishing. |

| Material Thickness | Thicker wood requires more time for deeper engraving. |

| Cooling and Maintenance | Regular maintenance ensures consistent etching speed. |

Explore related products

What You'll Learn

- Factors Affecting Etching Time: Material density, laser power, design complexity, and desired depth impact etching duration

- Laser Power Settings: Higher power speeds up etching but may compromise precision or wood quality

- Design Complexity: Intricate patterns take longer than simple designs due to more laser movements

- Wood Type Influence: Hardwoods like oak etch slower than softwoods like pine or balsa

- Desired Depth Control: Deeper etchings require multiple passes, increasing overall processing time significantly

Factors Affecting Etching Time: Material density, laser power, design complexity, and desired depth impact etching duration

Laser etching wood is a precise art, but the time it takes isn’t fixed. Four key factors dictate how long your project will sit under the laser: material density, laser power, design complexity, and desired depth. Understanding these variables allows you to predict etching duration and optimize your workflow.

Material density acts as a natural brake on etching speed. Denser woods like walnut or maple absorb more laser energy, requiring slower passes or higher power to achieve the same result as softer woods like pine or balsa. Think of it as carving through marble versus soapstone – the harder the material, the more deliberate your approach must be. For instance, etching a detailed design into a hardwood cutting board might take 20-30 minutes, while a similar pattern on a softwood plaque could be completed in half the time.

Laser power is your accelerator pedal. Higher wattage lasers cut and engrave faster, but precision suffers. A 40W laser can zip through a simple design in minutes, while a 10W laser might take 10-15 minutes for the same task. The key is finding the sweet spot where power meets precision – too much power can scorch the wood, while too little results in shallow, faint lines.

Design complexity introduces a wild card. Intricate patterns with fine lines and tight curves demand slower speeds to maintain detail. A minimalist logo with bold lines might etch in seconds, while a photorealistic portrait could take an hour or more. Vector designs, with their clean lines and defined paths, generally etch faster than raster images, which require the laser to trace every pixel.

Desired depth is the final arbiter of time. A surface-level engraving for a decorative piece takes far less time than a deep, 3D-effect carving. Achieving a 0.1mm depth might be done in a single pass, while a 2mm engraving could require multiple passes with varying power settings. Remember, deeper engravings not only take longer but also require more material, so plan your design accordingly.

Bleaching Wood: Understanding the Timeframe for a Perfect Finish

You may want to see also

Explore related products

Laser Power Settings: Higher power speeds up etching but may compromise precision or wood quality

Laser power settings are a critical factor in determining the speed and quality of wood etching. Increasing the power can significantly reduce etching time, but this comes with trade-offs. For instance, a 40W laser operating at 100% power might etch a simple design into birch wood in 2-3 minutes, while the same design at 50% power could take 5-7 minutes. However, the higher power setting may char the wood edges or produce a less precise finish, especially on intricate patterns. This balance between speed and quality is essential for achieving the desired outcome.

When adjusting laser power, consider the wood type and thickness, as these variables influence how the material reacts to heat. Softer woods like pine or cedar may burn more easily at higher power settings, while harder woods like oak or walnut can withstand greater intensity without compromising quality. For example, etching a detailed logo onto a ¼-inch oak plank might require a 60W laser at 70% power to maintain sharpness, whereas a 30W laser at 90% power could suffice for a simpler design on the same material. Always test on scrap wood to fine-tune settings before committing to the final piece.

Precision is another casualty of high-power settings, particularly in intricate designs. A laser operating at maximum power may melt or vaporize wood too quickly, causing details to blur or disappear. For fine lines or small text, reducing power to 40-60% and increasing the number of passes can yield better results. For example, a 50W laser at 50% power with two passes might produce sharper 1mm lettering than a single pass at 80% power. This approach takes longer but ensures the design retains its clarity.

Practical tips for optimizing power settings include starting with the manufacturer’s recommended values for your laser and wood type, then adjusting incrementally. For instance, if a 30W laser suggests 60% power for birch, try 50% and 70% on test pieces to observe the differences. Additionally, use a lower power setting for the first pass to outline the design, then increase power for subsequent passes to deepen the etch without sacrificing precision. This layered approach combines speed and detail, making it ideal for complex projects.

In conclusion, while higher laser power settings expedite wood etching, they demand careful consideration to avoid quality and precision losses. By understanding the interplay between power, wood type, and design complexity, you can tailor settings to achieve optimal results. Experimentation and testing remain key to mastering this balance, ensuring each project meets both time and quality standards.

Outdoor Firewood Storage: How Long Does It Last and Stay Usable?

You may want to see also

Explore related products

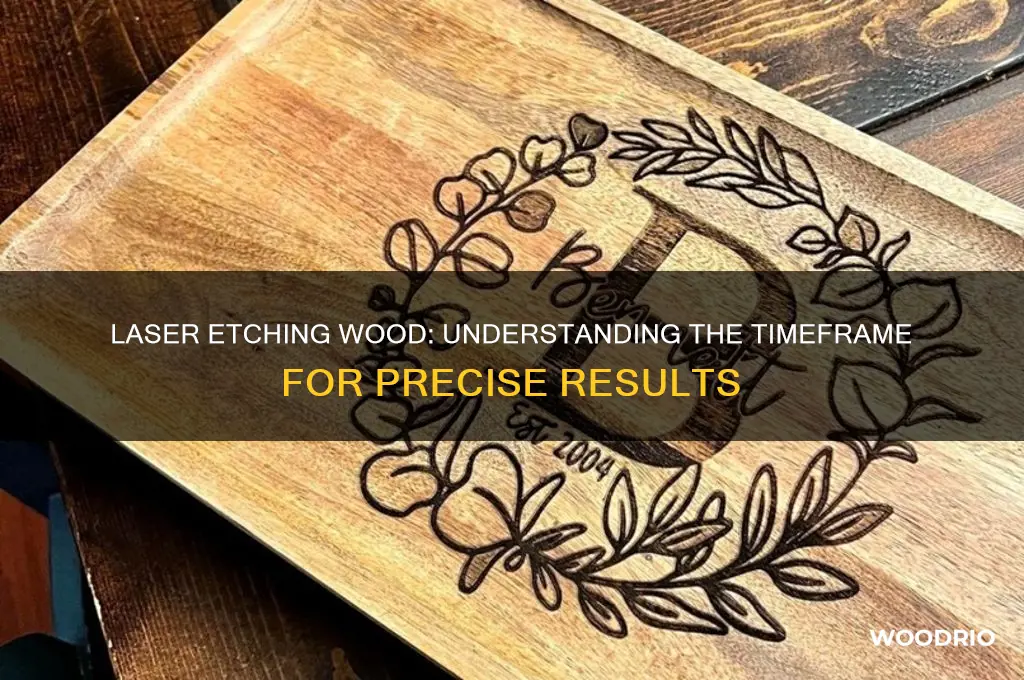

Design Complexity: Intricate patterns take longer than simple designs due to more laser movements

Laser etching time on wood is directly proportional to the complexity of the design. A simple geometric shape, like a square or circle, might take mere seconds to etch, as the laser only needs to trace a few lines. However, intricate patterns with fine details, such as filigree or photorealistic images, can take significantly longer. This is because the laser must make numerous precise movements to recreate the complexity of the design.

Consider a floral pattern with delicate petals and swirling vines. Each petal edge, each vine tendril, requires the laser to move along a specific path, adjusting speed and intensity to achieve the desired depth and shading. This intricate dance of the laser head translates to longer etching times. For instance, a simple monogram might take 30 seconds, while a detailed floral border around the same monogram could extend the process to several minutes.

Pro Tip: When designing for laser etching, remember that simplicity often translates to faster production times and potentially lower costs.

The relationship between design complexity and etching time isn't linear. Doubling the number of lines in a design doesn't necessarily double the etching time. Factors like laser speed, power settings, and material thickness also play a role. However, the underlying principle remains: more intricate designs demand more laser movements, leading to longer processing times.

Caution: Extremely intricate designs with very fine details may push the limits of laser etching technology, potentially resulting in blurred or incomplete results.

Understanding this relationship allows for informed design choices. If time is a constraint, opting for simpler designs can significantly reduce production time. Conversely, if intricate detail is paramount, factoring in the extended etching time is crucial for project planning and budgeting.

Understanding Morning Woods Duration: How Long Does It Typically Last?

You may want to see also

Explore related products

Wood Type Influence: Hardwoods like oak etch slower than softwoods like pine or balsa

The density of wood significantly impacts laser etching speed, with hardwoods like oak requiring more time than softwoods like pine or balsa. This is because hardwoods have a tighter grain structure and higher density, which resists the laser's energy more effectively. For example, etching a detailed design on a piece of oak might take 10-15 minutes, whereas the same design on pine could be completed in 5-7 minutes. Understanding this difference is crucial for planning projects and managing time efficiently.

To optimize etching speed, consider the wood’s hardness and adjust laser settings accordingly. Softwoods, with their looser grain and lower density, absorb and disperse laser energy more quickly, allowing for faster etching and higher detail resolution. Hardwoods, on the other hand, demand lower laser speeds and higher power settings to achieve comparable results. For instance, a 40W laser might etch pine at 100% power and 20% speed, while oak may require 100% power and 10% speed to prevent burning or incomplete etching.

Practical tips for working with different wood types include testing on scrap pieces to fine-tune settings and using vector engraving for precise lines on hardwoods. Softwoods like balsa, being extremely lightweight, may char easily, so reducing power by 10-20% can help maintain clarity. For hardwoods, increasing the number of passes can improve depth without compromising the material’s integrity. Always ensure proper ventilation, as hardwoods tend to produce more smoke and residue during etching.

Comparing the two, softwoods are ideal for quick, detailed projects, while hardwoods offer durability and a premium finish at the cost of longer processing times. For example, a pine sign might be etched and ready for use in under 15 minutes, whereas an oak plaque could take 30-45 minutes to achieve the same level of detail. Choosing the right wood type based on project requirements balances speed, aesthetics, and functionality.

In conclusion, the type of wood directly influences laser etching time, with hardwoods etching slower than softwoods due to their density and grain structure. By adjusting laser settings and selecting the appropriate wood type, you can achieve efficient, high-quality results tailored to your project’s needs. Whether prioritizing speed with pine or durability with oak, understanding these differences ensures successful outcomes in laser wood etching.

Cherry Wood Aging: How Long Until It Reaches Its Darkest Hue?

You may want to see also

Explore related products

Desired Depth Control: Deeper etchings require multiple passes, increasing overall processing time significantly

Achieving the desired depth in laser etching wood is a delicate balance between precision and patience. The depth of the etch directly correlates with the number of passes the laser makes over the material. For instance, a shallow engraving, such as a surface-level design, might only require a single pass at a moderate power setting (e.g., 30-40 watts) and a speed of 1000-1500 mm/min. However, deeper etchings, like those needed for 3D effects or functional inlays, demand multiple passes. Each additional pass increases the processing time significantly, often doubling or tripling the duration for each layer of depth. For example, a 2mm deep etch might require 3-4 passes, each taking 5-7 minutes, resulting in a total processing time of 15-28 minutes, excluding setup and cooling periods.

To optimize time without sacrificing quality, consider adjusting laser settings between passes. For the first pass, use higher speed (1200 mm/min) and lower power (35 watts) to remove material quickly but roughly. Subsequent passes should decrease speed (800 mm/min) and increase power (45 watts) to refine the edges and deepen the etch. This tiered approach ensures that each pass contributes meaningfully to the final depth while minimizing redundant work. Additionally, using a focus lens with a shorter focal length can enhance precision, reducing the need for extra passes in some cases.

A common misconception is that increasing laser power alone can achieve deeper etchings in a single pass. While higher power settings (e.g., 60 watts) can cut through wood faster, they often result in charring, loss of detail, or uneven surfaces. Multiple passes at moderate power settings (40-50 watts) not only maintain the integrity of the design but also allow for better heat dissipation, reducing the risk of material damage. For intricate designs, a test run on a scrap piece of wood is essential to calibrate the number of passes and settings before committing to the final piece.

Comparatively, other methods like CNC routing or hand carving offer depth control but lack the precision and repeatability of laser etching. Laser etching’s advantage lies in its ability to achieve consistent depth across complex designs, but this precision comes at the cost of time. For projects requiring depths greater than 3mm, consider whether the aesthetic or functional benefit justifies the extended processing time. In some cases, combining laser etching with other techniques (e.g., laser etching for detail and CNC for depth) can strike a balance between time efficiency and desired outcome.

Finally, practical tips can streamline the process. Ensure the wood is properly secured and aligned to avoid repositioning errors between passes, which can add unnecessary time. Use a cooling system or air assist to prevent overheating, especially during multiple passes. For large-scale projects, break the design into sections and process them sequentially, allowing the laser to focus on smaller areas at a time. By understanding the relationship between depth, passes, and settings, you can plan more effectively, ensuring that the final result meets your vision without unnecessary delays.

Curing Murtle Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Frequently asked questions

The time to laser etch wood depends on factors like the design complexity, wood type, and laser machine settings. Simple designs may take a few minutes, while intricate patterns can take 30 minutes to several hours.

Yes, harder or denser woods like oak or walnut typically take longer to etch compared to softer woods like pine or balsa. The wood’s grain and moisture content also influence etching speed.

Yes, using a higher-powered laser or optimizing settings like speed and power can reduce etching time for larger projects. However, this may affect the precision and depth of the etch.

More intricate designs with fine details or deep engraving require more passes and slower speeds, increasing the overall etching time. Simpler designs with fewer details are faster to complete.