Creating a wood mold is a meticulous process that varies significantly in duration depending on factors such as the complexity of the design, the type of wood used, and the skill level of the craftsman. Simple molds for basic shapes may take only a few hours to complete, while intricate designs requiring precise detailing and multiple components can span several days or even weeks. Additionally, the time needed for drying, sanding, and finishing the wood must be factored in, as these steps are crucial for ensuring durability and accuracy. Thus, the timeline for making a wood mold can range from a single day to several weeks, making it essential to plan carefully and allocate sufficient time for each stage of the process.

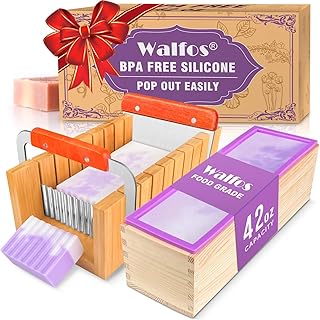

Explore related products

What You'll Learn

- Preparation Time: Gathering materials, planning design, and preparing wood for mold creation

- Carving Process: Time spent shaping wood to desired mold specifications accurately

- Sanding & Finishing: Smoothing surfaces and applying finishes for durability and precision

- Drying & Curing: Allowing wood to dry completely to prevent warping or cracking

- Assembly & Testing: Combining parts, testing fit, and making final adjustments for functionality

Preparation Time: Gathering materials, planning design, and preparing wood for mold creation

The preparation phase of creating a wood mold is often the most time-consuming yet crucial step, setting the foundation for the entire project. Gathering materials alone can take anywhere from a few hours to several days, depending on the complexity of the mold and the availability of resources. For instance, sourcing rare or specialized wood types like mahogany or walnut may require additional time, especially if ordering online or visiting multiple suppliers. Basic materials such as pine or plywood are more readily available but still demand careful selection to ensure they meet the project’s structural and aesthetic requirements. A pro tip: always purchase 10–20% extra wood to account for mistakes or unexpected defects.

Planning the design is where creativity meets precision, and this stage can span from a few hours to a week or more. Sketching the mold’s dimensions, considering the object it will shape, and deciding on joinery techniques are critical steps. Digital tools like CAD software can streamline this process, but hand-drawn plans remain a viable option for simpler designs. For beginners, starting with a small-scale prototype can save time and materials in the long run. Caution: rushing this phase often leads to costly errors during construction, so allocate ample time for revisions and consultations if needed.

Preparing the wood is a hands-on process that typically takes 1–3 days, depending on the wood’s condition and the tools available. Begin by cutting the wood to rough dimensions using a table saw or circular saw, ensuring accuracy within 1/16 of an inch. Next, sanding is essential to achieve a smooth surface, especially if the mold will be used for delicate materials like resin or concrete. A belt sander speeds up this process, but hand sanding with progressively finer grits (80 to 220) ensures precision. If the wood is warped or damp, allow an extra day for acclimatization or drying to prevent later distortion.

Comparing DIY preparation to professional services highlights the trade-offs between time and cost. While hiring a carpenter or woodworker can reduce preparation time by 50–70%, it significantly increases expenses. For example, a professional might charge $50–$100 per hour, whereas DIY costs are primarily material-based. However, professionals often bring expertise that minimizes errors, making this a worthwhile investment for complex or high-stakes projects. Ultimately, the choice depends on your budget, timeline, and skill level.

In conclusion, preparation time for a wood mold varies widely but is a non-negotiable investment. By meticulously gathering materials, refining the design, and properly preparing the wood, you set the stage for a successful mold creation. Whether you’re a hobbyist or a professional, understanding these steps ensures efficiency and quality, turning what could be a daunting task into a manageable and rewarding process.

Perfect Wooden Kabob Sticks: Soaking Time for Safe Grilling

You may want to see also

Explore related products

Carving Process: Time spent shaping wood to desired mold specifications accurately

The carving process is a meticulous dance between the artisan’s hand and the wood’s grain, where precision dictates time. Unlike machine-driven methods, hand-carving a wood mold to exact specifications requires patience and skill. For a small, simple mold—say, a 6-inch by 4-inch block with basic contours—an experienced carver might spend 2–4 hours. However, intricate designs with sharp angles, curves, or detailed patterns can extend this to 10–20 hours or more. The key variable? Complexity. A mold for a custom furniture joint, for instance, demands far more attention than one for a basic candle holder.

To streamline the carving process, start by selecting the right wood. Softwoods like pine or basswood are ideal for beginners due to their forgiving grain, while hardwoods like oak or maple require sharper tools and more force, adding time. Sketch your design directly onto the wood or use a template for accuracy. Begin with rough cuts using a chisel or knife to remove excess material, then refine with finer tools like gouges and rasps. Sanding is non-negotiable—allocate at least 30 minutes to an hour for this step, depending on the mold’s size and finish requirements. A practical tip: work in layers, carving gradually rather than attempting deep cuts, to avoid splintering or mistakes that double your time.

Comparing hand-carving to power tools reveals a trade-off between speed and control. A router or CNC machine can shape a mold in minutes, but achieving the same level of detail and tactile precision as hand-carving is rare. For example, a CNC-cut mold might take 30 minutes to produce but lack the subtle nuances of a hand-carved piece. Hand-carving, while slower, allows for real-time adjustments and a unique, artisanal touch. If time is a constraint, consider hybrid methods: use power tools for rough shaping, then finish by hand for accuracy.

Persuasively, the time spent carving is an investment in quality. A well-crafted wood mold not only serves its functional purpose but also becomes a testament to craftsmanship. For professionals, this attention to detail can differentiate their work in competitive markets. For hobbyists, it’s a meditative practice that builds skill and satisfaction. To maximize efficiency, plan your carving sessions in blocks of 2–3 hours, as fatigue can lead to errors. Keep tools sharp—a dull blade triples effort and time. Finally, embrace imperfections; they add character and remind us that hand-carving is as much an art as it is a science.

Understanding Wood Joist Span Lengths for Safe and Effective Construction

You may want to see also

Explore related products

Sanding & Finishing: Smoothing surfaces and applying finishes for durability and precision

Sanding and finishing are the final, transformative steps in creating a wood mold, turning a rough, functional piece into a durable, precise tool. The time required for this phase depends on the mold’s complexity, the wood’s grain, and the desired finish quality. For a small, simple mold, sanding and finishing might take 2–4 hours, while larger, intricate molds can demand 8–12 hours or more. The key is patience—rushing this stage compromises both aesthetics and longevity.

Begin with coarse-grit sandpaper (80–120 grit) to remove tool marks and imperfections, working in the direction of the grain to avoid scratches. Progress to medium grit (150–220) to smooth the surface further, and finish with fine grit (320–400) for a polished feel. Each grit stage should be thorough but efficient; spending too long with coarse grit can create deeper scratches that are harder to remove. For curved or detailed areas, use sanding blocks or folded sandpaper to maintain control and precision.

Applying finishes is both art and science. Choose a finish based on the mold’s purpose: tung oil or Danish oil for natural, breathable protection, or polyurethane for high durability. Apply thin, even coats with a brush or cloth, allowing each layer to dry completely (typically 4–6 hours, depending on humidity). Lightly sand between coats with 400-grit paper to ensure adhesion and smoothness. Two to three coats are usually sufficient, but critical molds may require more. Proper ventilation is essential, especially with oil-based finishes, to avoid fumes and ensure even drying.

The precision of your sanding and finishing directly impacts the mold’s performance. A smooth, evenly finished surface ensures better material release and reduces wear over time. For example, a mold used for casting resin requires a glass-like finish to prevent bubbles or imperfections in the final product. Conversely, a mold for clay might prioritize durability over absolute smoothness. Tailor your approach to the end use, balancing time investment with functional needs.

In conclusion, sanding and finishing are not mere afterthoughts but critical steps that define a wood mold’s quality and lifespan. While time-consuming, they are non-negotiable for achieving professional results. By methodically progressing through grits, choosing the right finish, and applying it meticulously, you ensure a mold that is both functional and enduring. This phase may extend the overall project timeline, but the payoff is a tool that performs flawlessly, time after time.

Wood vs. Metal: Which Material Offers Superior Longevity?

You may want to see also

Explore related products

Drying & Curing: Allowing wood to dry completely to prevent warping or cracking

Wood's moisture content is a critical factor in mold-making, as it directly influences the material's stability and dimensional accuracy. Freshly cut timber, often referred to as 'green wood,' contains a high percentage of moisture, typically ranging from 30% to 200% of its dry weight, depending on the species. This moisture needs to be carefully managed to ensure the wood's integrity during the mold-making process. The drying and curing stage is a crucial step, requiring patience and precision to achieve optimal results.

The Science of Drying:

Drying wood is a delicate balance between removing moisture and maintaining the material's structural integrity. The process involves allowing the wood to reach equilibrium with its environment, ensuring it neither gains nor loses moisture excessively. This equilibrium moisture content (EMC) varies depending on the surrounding humidity and temperature. For instance, in a typical indoor environment with 40-60% relative humidity, the EMC for wood is around 8-12%. Achieving this balance is essential to prevent future warping or cracking.

Time and Techniques:

The time required for wood to dry adequately can vary significantly, ranging from several weeks to over a year. This duration depends on various factors, including the wood species, initial moisture content, thickness of the wood, and the drying method employed. Air drying, a common technique, involves stacking wood with stickers (spacers) to allow air circulation and gradually reducing moisture content. This method can take 1-2 years for thicker pieces. Kiln drying, on the other hand, is a faster process, using controlled heat and humidity to accelerate moisture removal, often completing the drying process in days or weeks.

Practical Considerations:

For mold-making, it's essential to source wood that has been properly dried and cured. Buying kiln-dried lumber from reputable suppliers ensures a more consistent moisture content, typically around 6-8%. However, even with kiln-dried wood, acclimating it to the workshop environment for a few weeks is advisable to minimize any residual moisture movement. For those air-drying their own wood, regular moisture content checks using a moisture meter are crucial. Aim for a moisture content below 12% for most woodworking projects, including mold-making.

Cautions and Best Practices:

Rushing the drying process can lead to disastrous results. Rapid drying may cause checking (surface cracks), honeycombing (internal cracks), or warping. These defects can render the wood unsuitable for precise mold-making. Additionally, different wood species have varying drying rates and tendencies to warp or crack. For instance, oak is known for its slow drying time and susceptibility to surface checks, while maple dries relatively quickly and evenly. Understanding these species-specific characteristics is vital for successful mold construction. Properly dried and cured wood ensures a stable foundation for your mold, preventing dimensional changes that could affect the final product's quality.

Maximizing Lifespan: How Long Do Wood Burners Typically Last?

You may want to see also

Explore related products

Assembly & Testing: Combining parts, testing fit, and making final adjustments for functionality

The assembly phase of creating a wood mold is where individual components transform from separate pieces into a functional unit. This stage demands precision and patience, as the fit of each part directly impacts the mold’s performance. Begin by aligning the pre-cut wooden sections according to your design blueprint. Use clamps to hold pieces together temporarily, ensuring they are flush and level. Avoid over-tightening clamps, as this can warp the wood, especially if it’s a softer species like pine or cedar. For harder woods like oak or maple, consider pre-drilling pilot holes to prevent splitting when screws or dowels are inserted.

Testing fit is a critical step that cannot be rushed. Dry-fit all components before applying any adhesive or fasteners. Check for gaps, misalignments, or uneven surfaces using a straightedge or caliper. Pay special attention to corners and joints, as these areas are prone to discrepancies. If discrepancies are found, sand or trim the offending pieces incrementally—removing too much material at once is irreversible. For complex molds with interlocking parts, test the movement of sliding or rotating components to ensure smooth operation. This iterative process can take anywhere from 30 minutes to several hours, depending on the mold’s complexity and the woodworker’s skill level.

Final adjustments for functionality often involve refining the mold’s interior surfaces. Sand the cavity to achieve the desired smoothness, starting with coarse-grit sandpaper (80–120 grit) and progressing to finer grits (220–400 grit) for a polished finish. Apply a thin coat of sealant or wax to protect the wood from moisture and prolong the mold’s lifespan, especially if it will be used for casting materials like concrete or resin. Test the mold with a sample material to identify any remaining imperfections. Common issues include air bubbles, uneven curing, or material sticking to the wood. Address these by adjusting the mold’s surface treatment or modifying the casting process.

A persuasive argument for thorough assembly and testing is the long-term savings in time and materials. Skipping or rushing this phase often leads to costly rework or mold failure. For example, a misaligned joint can cause leaks, ruining batches of cast material and wasting hours of effort. Conversely, a well-assembled and tested mold can produce hundreds of consistent, high-quality casts with minimal maintenance. Invest time upfront to ensure each part fits perfectly, and you’ll reap the benefits in efficiency and reliability.

In conclusion, assembly and testing are not mere steps but a meticulous process that defines the mold’s success. Approach this phase with a blend of precision, adaptability, and foresight. By combining parts carefully, testing fit rigorously, and making final adjustments thoughtfully, you ensure the mold functions as intended. This stage, though time-consuming, is the linchpin of the entire project, turning raw wood into a tool capable of shaping your vision into reality.

Cedar Wood Moth Protection: Durability and Longevity Explained

You may want to see also

Frequently asked questions

For a simple wood mold, such as one for casting small objects, it typically takes 2 to 4 hours, depending on the complexity and tools available.

Factors include the size and complexity of the mold, the type of wood used, the tools and skills of the maker, and whether additional finishing or detailing is required.

Larger or intricate wood molds can take anywhere from 1 to 3 days, as they require more precise measurements, cutting, and sanding.

Yes, if wood glue or sealant is used, drying time can add several hours to a day, depending on the product and environmental conditions.

Yes, using CNC machines or other advanced tools can significantly reduce the time, often completing the mold in a fraction of the time compared to hand-carving, typically within a few hours.