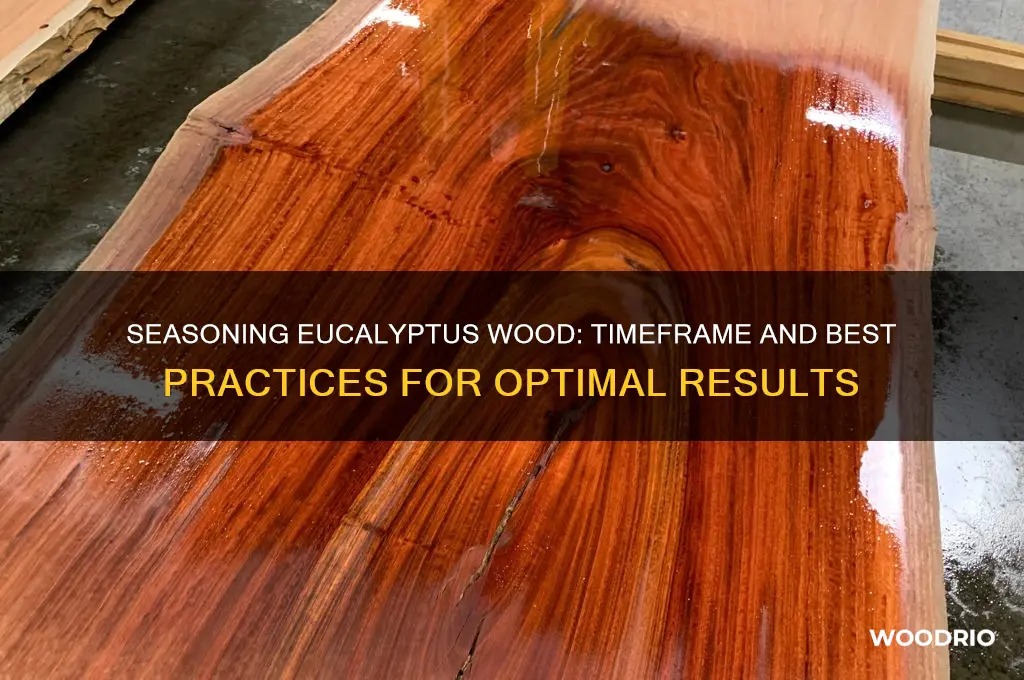

Seasoning eucalyptus wood is a crucial process that involves drying the wood to reduce its moisture content, ensuring it becomes stable and suitable for various applications such as furniture, flooring, or construction. The time required to season eucalyptus wood can vary significantly depending on several factors, including the initial moisture content, the thickness of the wood, the climate conditions, and the seasoning method used. Typically, air-drying eucalyptus wood can take anywhere from 6 months to 2 years, while kiln-drying, a faster method, can reduce this time to just a few weeks. Proper seasoning is essential to prevent warping, cracking, or shrinking once the wood is in use, making it a vital step in wood preparation.

| Characteristics | Values |

|---|---|

| Seasoning Time (Air Drying) | 6 months to 2 years, depending on climate, thickness, and moisture content |

| Moisture Content Reduction Goal | Below 12-15% for optimal use in woodworking or construction |

| Factors Affecting Seasoning Time | Climate (humidity, temperature), wood thickness, initial moisture content |

| Kiln Drying Time | 2-4 weeks, significantly faster than air drying |

| Wood Density | High density (affects drying rate, typically slower) |

| Common Uses After Seasoning | Furniture, flooring, construction, outdoor structures |

| Shrinkage and Warping Risk | Moderate to high; proper stacking and ventilation are crucial |

| Recommended Stacking Method | Stickers placed between layers to allow air circulation |

| Optimal Seasoning Environment | Well-ventilated, covered area with controlled humidity and temperature |

| Initial Moisture Content | Typically 50-100% when freshly cut |

Explore related products

What You'll Learn

Ideal Conditions for Seasoning

Eucalyptus wood, prized for its durability and rich grain, demands careful seasoning to unlock its full potential. The process, which can span from several months to over a year, hinges on creating ideal conditions that balance moisture release and structural integrity.

Optimal Environment: The Goldilocks Zone

Seasoning eucalyptus thrives in a controlled environment where humidity hovers between 50–70% and temperatures remain steady at 60–80°F (15–27°C). This "Goldilocks zone" prevents rapid drying, which causes cracking, and avoids excessive moisture retention. Storing wood in a well-ventilated shed or under a breathable tarp ensures gradual moisture loss without exposing it to harsh weather.

Stacking Strategy: Airflow is Key

Proper stacking accelerates seasoning by maximizing airflow. Arrange eucalyptus planks in a staggered pile, leaving 1–2 inches between boards. Elevate the stack on stickers (small wooden strips) to prevent ground moisture absorption. For larger batches, consider a crisscross pattern to promote even drying. Rotate the stack monthly to ensure uniform moisture loss, especially in thicker cuts.

Timeframe Expectations: Patience Pays Off

While some woods season in 6–12 months, eucalyptus often requires 12–18 months due to its dense grain. Thicker pieces (over 2 inches) may need up to 2 years. Monitor progress with a moisture meter; aim for 12–15% moisture content, the sweet spot for stability. Rushing the process risks internal stresses, compromising the wood’s strength and appearance.

Cautions: What to Avoid

Direct sunlight and extreme temperatures are seasoning’s foes. Prolonged sun exposure can warp or discolor the wood, while frost accelerates cracking. Avoid stacking near heat sources or in damp areas. For expedited drying, kiln-drying is an option, but it requires precise control to prevent damage. Always prioritize slow, natural seasoning for the best results.

By mastering these conditions, you transform raw eucalyptus into a material ready for craftsmanship, ensuring longevity and beauty in every project.

Killing Dry Wood: Understanding the Timeframe for Effective Treatment

You may want to see also

Explore related products

Air-Drying vs. Kiln-Drying Methods

Eucalyptus wood, prized for its durability and rich grain, requires careful seasoning to prevent warping, cracking, or insect infestation. Two primary methods dominate this process: air-drying and kiln-drying. Each has distinct advantages, limitations, and timelines that woodworkers and builders must weigh based on their project needs.

Air-drying, the traditional method, relies on natural conditions to gradually reduce moisture content. Stacks of eucalyptus logs or planks are arranged in well-ventilated areas, often with stickers (spacers) between layers to promote airflow. This process typically takes 6–24 months, depending on climate, wood thickness, and initial moisture level. In arid regions with consistent sunlight, seasoning may accelerate, while humid environments prolong drying. For instance, a 2-inch thick eucalyptus board might reach 12–15% moisture content (ideal for furniture) in 12 months under optimal conditions. However, air-drying demands patience and space, making it less feasible for commercial operations or time-sensitive projects.

Kiln-drying, in contrast, employs controlled heat and humidity to expedite seasoning. Eucalyptus wood is placed in a kiln, where temperature and airflow are precisely regulated to draw out moisture. This method reduces drying time to 3–14 days, depending on kiln settings and wood thickness. For example, a kiln operating at 120°F (49°C) can season 1-inch eucalyptus planks in 3–5 days, while thicker cuts may require up to 2 weeks. Kiln-drying ensures uniformity and minimizes defects like checking or honeycombing, making it ideal for high-quality applications like flooring or cabinetry. However, the energy costs and specialized equipment make it more expensive than air-drying.

Choosing between methods hinges on project scale, budget, and timeline. Air-drying suits hobbyists or small-scale operations willing to invest time for cost savings. Kiln-drying, while pricier, offers speed and consistency, critical for commercial production or urgent projects. For instance, a furniture maker crafting a custom eucalyptus table might opt for kiln-dried wood to meet a client deadline, while a DIY enthusiast building a garden bench could air-dry their own planks over several seasons.

Practical tips for both methods include monitoring moisture levels with a wood moisture meter, ensuring proper stacking or kiln loading to prevent distortion, and acclimating seasoned wood to its final environment before use. Whether prioritizing tradition or technology, understanding these methods empowers woodworkers to harness eucalyptus’s full potential.

Wooden Swing Durability: Timeframe for Wear and Tear Explained

You may want to see also

Explore related products

Moisture Content Goals

Eucalyptus wood, prized for its durability and aesthetic appeal, requires careful seasoning to achieve optimal moisture content for long-term use. The goal is to reduce the wood’s moisture level to 12–15%, aligning with the average humidity of its intended environment. This range minimizes warping, cracking, and susceptibility to pests, ensuring the wood’s structural integrity. Failing to meet this target can lead to costly repairs or replacements, making moisture content management a critical step in the seasoning process.

Achieving the desired moisture content in eucalyptus wood is a balance of time, technique, and environmental factors. Air drying, the most common method, typically takes 6–12 months, depending on climate conditions. In humid regions, this timeline may extend to 18 months or more, as excess moisture in the air slows evaporation. Kiln drying, a faster alternative, can reduce seasoning time to 2–4 weeks but requires precise temperature and humidity control to avoid case-hardening or internal stresses. Monitoring moisture levels with a wood moisture meter is essential to determine when the wood has reached its goal.

Comparatively, eucalyptus wood seasons faster than denser hardwoods like oak or maple due to its naturally lower density and more open cell structure. However, its rapid drying can lead to surface checking if not managed properly. To mitigate this, stack eucalyptus wood with stickers (spacers) between boards to promote airflow, and cover the pile to protect it from rain while allowing ventilation. Regularly rotating the stack ensures even drying and prevents moisture pockets from forming.

For those seeking a hands-on approach, here’s a practical tip: seal the ends of eucalyptus logs or boards with a moisture-resistant sealant immediately after cutting. This prevents rapid moisture loss from the ends, which dry faster than the sides, reducing the risk of splits. Additionally, store the wood in a shaded, well-ventilated area to avoid direct sunlight, which can cause uneven drying. Patience is key—rushing the process by exposing the wood to heat or wind can compromise its quality.

Ultimately, the moisture content goal for eucalyptus wood is not just a number but a benchmark for usability and longevity. Whether for furniture, flooring, or construction, achieving 12–15% moisture content ensures the wood performs as expected in its final application. By understanding the factors influencing drying time and employing strategic techniques, woodworkers and enthusiasts can transform raw eucalyptus into a stable, reliable material ready for any project.

Why Wood Prices Remain High: Causes, Trends, and Future Outlook

You may want to see also

Explore related products

Timeframe for Eucalyptus Wood

Eucalyptus wood, prized for its durability and aesthetic appeal, requires careful seasoning to achieve optimal performance. The timeframe for seasoning eucalyptus wood typically ranges from 6 to 12 months, depending on factors like climate, moisture content, and the thickness of the wood. In drier, warmer regions, the process can be expedited, while humid environments may extend the duration. Proper seasoning is critical to prevent warping, cracking, or decay, ensuring the wood’s longevity in applications like furniture, flooring, or construction.

To accelerate seasoning, stack eucalyptus wood in a well-ventilated area, ensuring air circulation between pieces. Use stickers (small spacers) between layers to promote even drying. For thicker cuts (over 2 inches), extend the seasoning period to 12 months or more, as denser wood retains moisture longer. Monitor the wood’s moisture content with a moisture meter, aiming for a level between 10-15% for indoor use or 12-18% for outdoor applications. Kiln-drying can reduce seasoning time to 2-4 weeks, but this method requires specialized equipment and may alter the wood’s natural properties.

Comparatively, eucalyptus seasons faster than hardwoods like oak or maple due to its lower density and natural oils, which aid in moisture expulsion. However, it’s more prone to checking (surface cracks) if dried too quickly. To mitigate this, cover the ends of the wood with sealant or wax to slow moisture loss from these areas. Additionally, avoid direct sunlight during seasoning, as it can cause uneven drying and discoloration.

For DIY enthusiasts, patience is key. Rushing the process can compromise the wood’s structural integrity. If time is a constraint, consider purchasing pre-seasoned eucalyptus, which has already undergone controlled drying. Alternatively, blend seasoned and unseasoned wood in projects, using the drier pieces to stabilize moisture-rich ones. Always acclimate eucalyptus to its intended environment for at least 2 weeks before use to minimize post-installation movement.

In conclusion, seasoning eucalyptus wood is a balance of time, technique, and environmental factors. Whether air-drying or kiln-drying, the goal is consistent moisture reduction to enhance durability. By understanding the wood’s unique properties and following best practices, craftsmen and builders can harness eucalyptus’s full potential for their projects.

Understanding Cord of Wood Measurements: Length, Volume, and Stacking Tips

You may want to see also

Explore related products

Factors Affecting Seasoning Speed

Eucalyptus wood, prized for its durability and rich grain, requires careful seasoning to prevent warping, cracking, or decay. The time this process takes isn’t fixed—it hinges on several interrelated factors that dictate how quickly moisture escapes the wood fibers. Understanding these variables allows for more precise control over the seasoning timeline, ensuring the wood is ready for use in optimal condition.

Moisture Content at Harvest: The initial moisture level of freshly cut eucalyptus directly influences seasoning speed. Wood harvested during wet seasons or from particularly dense stands can contain upwards of 100% moisture content (relative to its dry weight). Such high levels necessitate longer drying periods—often 12–18 months—compared to wood cut during drier periods, which may season in 6–9 months. A moisture meter reading above 25% indicates wood that’s far from seasoned, while readings below 12% signal readiness for use.

Environmental Conditions: Climate plays a pivotal role in seasoning eucalyptus. In arid regions with low humidity (below 40%) and consistent temperatures (60–80°F), air-drying can proceed rapidly, sometimes halving the typical timeline. Conversely, humid climates or areas with fluctuating temperatures slow the process, as moisture evaporates less efficiently. Stacking wood in a well-ventilated shed with raised platforms and spaced layers can mitigate these effects, but geographic limitations remain a dominant factor.

Wood Thickness and Density: Thicker eucalyptus planks or beams retain moisture longer than thinner pieces due to reduced surface-area-to-volume ratios. A 4-inch thick board, for instance, may take twice as long to season as a 2-inch board under identical conditions. Additionally, eucalyptus species vary in density—*Eucalyptus grandis* seasons faster than the denser *Eucalyptus microcorys*. Kiln-drying can accelerate this process for thicker pieces, reducing time from months to weeks, but at the risk of stress cracks if not carefully monitored.

Seasoning Method: Air-drying, the most common method, relies on natural conditions and is cost-effective but slower. Kiln-drying, while expensive, can season eucalyptus in 2–4 weeks by controlling temperature (120–140°F) and humidity. Solar drying, using greenhouses to trap heat, offers a middle ground, reducing time by 30–50% compared to air-drying. Each method has trade-offs: kilns risk overheating, solar drying depends on consistent sunlight, and air-drying demands patience.

Stacking and Sticker Placement: Proper stacking accelerates seasoning by maximizing airflow. Stickers—spacers placed between wood layers—should be 1–2 inches thick and made of dry, non-resinous wood to prevent staining. Rows should be aligned with prevailing winds or vents, and stacks should be covered to protect from rain while allowing airflow. Poorly stacked wood can trap moisture, extending seasoning by months. Regularly rotating pieces ensures even drying, particularly in thicker batches.

By manipulating these factors—whether through strategic harvesting, controlled environments, or methodical stacking—the seasoning of eucalyptus wood can be tailored to meet specific timelines and quality standards. Each decision impacts not only speed but also the wood’s final stability and appearance, making informed choices critical for optimal results.

Gorilla Wood Glue Setting Time: Quick Guide for Perfect Bonding

You may want to see also

Frequently asked questions

Seasoning eucalyptus wood typically takes 6 to 12 months, depending on climate conditions and the thickness of the wood.

Yes, in a dry and warm climate, eucalyptus wood can season faster, often within 6 months, compared to humid or cold environments.

For basic use, eucalyptus wood should be seasoned for at least 3 months, though longer seasoning ensures better stability and durability.

Yes, thicker pieces of eucalyptus wood take longer to season, often requiring closer to 12 months, while thinner pieces may be ready in 6 months.