Crafting a wooden bow is a meticulous process that varies significantly in duration depending on factors such as the maker’s skill level, the type of wood used, and the desired design complexity. For a beginner, the process can take anywhere from 10 to 20 hours, including selecting and preparing the wood, shaping the bow, and adding finishing touches like tillering and stringing. Experienced bowyers, however, may complete a bow in as little as 5 to 10 hours, as they are more efficient in their techniques and familiar with the nuances of working with different wood types. Additionally, traditional methods, which often involve hand tools and natural materials, can extend the timeline compared to modern techniques that incorporate power tools. Ultimately, the time required to make a wooden bow is a balance between craftsmanship, patience, and the desired quality of the final product.

| Characteristics | Values |

|---|---|

| Average Time for Beginners | 8–16 hours (spread over multiple sessions) |

| Time for Experienced Crafters | 4–8 hours (can be completed in 1–2 days) |

| Drying Time for Wood | 1–2 weeks (air drying for green wood to prevent cracking) |

| Tillering Process | 2–4 hours (adjusting the bow limbs for even bending) |

| Carving and Shaping | 3–6 hours (depends on wood type and tool proficiency) |

| Sanding and Finishing | 1–2 hours (smoothing and applying protective coatings) |

| String Notching and Final Touches | 30 minutes–1 hour |

| Factors Affecting Time | Wood type, tools used, skill level, bow design complexity, and drying conditions |

| Traditional vs. Modern Methods | Traditional methods may take longer due to hand tools and natural drying |

| Batch Production Time | Time reduces significantly (e.g., 2–3 hours per bow for experienced makers) |

Explore related products

$18.95

What You'll Learn

Selecting the Right Wood Type

The choice of wood is a critical factor in bow-making, influencing both the crafting time and the final product's performance. Different wood types offer unique characteristics, and understanding these properties is essential for any bowmaker. For instance, the density and flexibility of wood directly impact the bow's power and speed, with denser woods often requiring more time to shape and bend.

Analyzing Wood Properties:

Wood species vary significantly in their physical attributes. Hardwoods like hickory and oak are renowned for their strength and durability, making them ideal for powerful bows. However, their hardness can extend the crafting process, as they demand more effort to carve and shape. Softer woods, such as cedar or pine, are more forgiving and easier to work with, allowing for quicker initial shaping. Yet, they may lack the resilience needed for long-lasting bows. The key is to strike a balance between workability and the desired performance characteristics.

A Step-by-Step Selection Process:

- Identify the Bow's Purpose: Determine whether the bow is for target practice, hunting, or traditional archery. This decision will guide your wood choice. For example, a hunting bow requires wood that can withstand high tension and provide accuracy, while a traditional bow might prioritize aesthetics and cultural significance.

- Research Wood Options: Study the properties of various woods. Consider factors like grain pattern, density, and natural flexibility. Woods with straight, tight grains are generally preferred for their strength and predictability.

- Availability and Sustainability: Check the availability of the wood in your region. Locally sourced wood can reduce costs and environmental impact. Ensure the wood is sustainably harvested to support ethical practices.

- Test and Experiment: If possible, obtain samples of different woods and conduct bending tests. This hands-on approach provides valuable insights into how the wood responds to shaping and stress.

Cautions and Considerations:

- Moisture Content: Wood's moisture level is crucial. Green wood (freshly cut) is easier to bend but requires time to dry and stabilize. Seasoned wood is drier and more stable but may be more challenging to shape.

- Grain Orientation: Always work with the grain, not against it. Improper grain orientation can lead to weak spots and potential failure during the bow's use.

- Wood Defects: Inspect the wood for knots, cracks, or irregularities. These flaws can compromise the bow's integrity and should be avoided or carefully worked around.

In the art of bow-making, selecting the right wood is a blend of science and craftsmanship. It involves understanding the wood's natural qualities and matching them to the intended purpose of the bow. By carefully considering these factors, bowmakers can ensure a more efficient crafting process and a superior final product. This attention to detail is what separates a well-crafted bow from a mere wooden stick.

Tom Ford Oud Wood Longevity: Does This Fragrance Endure?

You may want to see also

Explore related products

Preparing and Shaping the Wood

The first step in crafting a wooden bow is selecting the right wood, a decision that significantly influences both the bow's performance and the time required for preparation. Hardwoods like Osage orange, yew, or hickory are preferred for their strength and flexibility, but their density demands patience. Softwoods, while easier to work with, may lack the resilience needed for a functional bow. Once the wood is chosen, it must be seasoned—a process that can take weeks to months, depending on the wood's moisture content. Rushing this step risks warping or cracking, so plan ahead.

After seasoning, the wood is roughly shaped to the bow's outline, a task that can be done with a bandsaw or handsaw. This initial shaping is deceptively simple but requires precision to avoid removing too much material. The goal is to create a blank that’s slightly thicker than the final bow, allowing room for refinement. This stage typically takes 1–2 hours for an experienced bowyer, but beginners may spend twice as long, especially when working with harder woods.

Next comes the meticulous task of tillering, where the bow is gradually shaped to achieve the desired curve and flexibility. This involves removing wood from the belly (the side facing the archer) while ensuring the back remains smooth and intact. Tillering is both art and science, requiring frequent bending tests to assess progress. A mistake here can render the wood unusable, so it’s a slow, deliberate process. Expect to spend 3–6 hours on tillering, with harder woods demanding more time and attention.

Throughout shaping, the wood must be kept dry and stable to prevent twisting or splitting. Working in a controlled environment—ideally a workshop with consistent humidity—is crucial. Hand tools like drawknives, rasps, and spokeshaves are preferred for their precision, though power tools can expedite rough shaping. However, over-reliance on power tools increases the risk of errors, particularly during tillering.

In summary, preparing and shaping the wood for a wooden bow is a time-intensive process that balances skill, patience, and material properties. From seasoning to tillering, each step requires careful consideration to ensure the final product is both functional and durable. While the total time can range from 5–10 hours (excluding seasoning), the investment pays off in a bow that performs reliably and stands the test of time.

Firewood Drying Time: Uncovering the Truth Behind the Process

You may want to see also

Explore related products

Tillering Process Explained

The tillering process is the heart of crafting a wooden bow, where the bow's limbs are shaped to bend uniformly, ensuring both power and balance. This stage demands precision and patience, as it directly influences the bow's performance and longevity. Unlike rough shaping, tillering requires constant evaluation and adjustment, making it the most time-consuming phase of bow making. For beginners, this process can take anywhere from 4 to 8 hours, while experienced bowyers may complete it in 2 to 4 hours, depending on the wood type and desired draw weight.

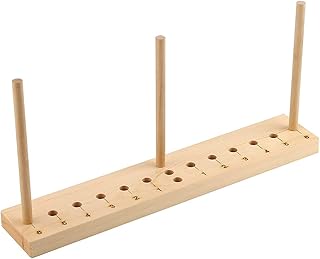

To begin tillering, secure the bow in a tiller jig or use a simple method like clamping it to a workbench with the string attached. Apply gradual pressure to the string, mimicking the draw of an arrow, and observe how the limbs bend. The goal is to achieve even flexion along the entire length of both limbs, avoiding flat spots or excessive bending in any one area. Use a sharp knife or drawknife to remove wood from areas that are stiff, working in small increments to prevent over-removal. A common mistake is rushing this process, leading to uneven limbs that compromise the bow's efficiency and safety.

One practical tip is to mark the limbs with a pencil or chalk to highlight areas needing adjustment. This visual guide helps maintain consistency and prevents overworking specific sections. Additionally, regularly flex the bow by hand to feel for stiffness or resistance, as this tactile feedback complements visual inspection. For those using harder woods like hickory or yew, expect a slower tillering process due to the wood's density, whereas softer woods like cedar may require more caution to avoid over-thinning.

The tillering process is as much art as it is science, requiring intuition developed through practice. Advanced bowyers often use a tillering stick—a tool with graduated marks—to measure limb deflection accurately. This ensures symmetry and helps achieve the desired brace height (the distance between the string and the bow’s belly at rest). While this step may seem tedious, it is crucial for creating a bow that shoots smoothly and consistently. Skipping or rushing tillering can result in a bow that either breaks under tension or fails to deliver adequate power.

In conclusion, the tillering process is where a wooden bow transforms from a rough-shaped stave into a functional tool. Its duration varies widely based on skill level, wood type, and desired specifications, but its importance cannot be overstated. By focusing on gradual adjustments, using visual and tactile feedback, and employing tools like a tillering stick, even novice bowyers can achieve a well-balanced bow. Mastery of this phase not only ensures a safe and effective bow but also deepens the craftsman’s understanding of the material and the physics of archery.

Perfectly Crispy Chicken of the Woods: Frying Time Guide

You may want to see also

Explore related products

Finishing and Sanding Techniques

The final stages of crafting a wooden bow—finishing and sanding—demand precision and patience, often consuming 20–40% of the total project time. While shaping the bow might take hours, refining its surface and applying finishes can span days, depending on the desired quality and complexity. This phase is where the bow transitions from a rough, functional tool to a polished, durable masterpiece.

Steps to Master Sanding: Begin with coarse-grit sandpaper (80–120 grit) to remove tool marks and imperfections, working along the wood grain. Progress to medium grit (150–220) for smoothing, and finish with fine grit (320–400) for a glass-like surface. Use folded sandpaper or sanding blocks for even pressure, especially on curves. For hard-to-reach areas, wrap sandpaper around dowels or use specialized sanding tools. Always sand in the direction of the grain to avoid scratches or tear-out.

Cautions in Finishing: Avoid over-sanding, which can alter the bow’s thickness and compromise its strength. Test the draw regularly during sanding to ensure structural integrity. When applying finishes like linseed oil, tung oil, or varnish, work in thin, even coats, allowing ample drying time between applications (typically 24–48 hours). Too much finish can make the bow slippery or add unnecessary weight.

Comparative Techniques: Natural oils like linseed penetrate the wood, enhancing its grain and providing a matte finish, while varnishes create a harder, glossier surface. For traditional bows, consider a simple wax coating for a rustic look. Modern archers might prefer epoxy finishes for added durability. The choice depends on the bow’s intended use—indoor target shooting may favor aesthetics, while outdoor hunting requires weather resistance.

Practical Tips for Efficiency: Use a tack cloth to remove dust between sanding stages, ensuring a clean surface for finishing. Apply finishes in a well-ventilated area, and use gloves to avoid skin irritation. For intricate carvings or inlays, mask off areas with tape before sanding or finishing. Finally, allow the bow to cure fully (7–14 days) before use, as rushed finishes can crack or peel under tension.

Mastering finishing and sanding techniques not only enhances the bow’s appearance but also protects it from moisture, wear, and environmental damage. While time-consuming, this phase is where craftsmanship truly shines, turning a functional tool into a work of art.

Durability of Wood Frame Homes in Coastal Florida's Harsh Climate

You may want to see also

Explore related products

$11.38 $12.4

Final Assembly and Stringing Steps

The final assembly and stringing of a wooden bow is a delicate process that can make or break the functionality and longevity of the weapon. It's not just about tying a string to the bow; it's about ensuring the string is seated correctly, the brace height is optimal, and the overall structure is balanced. This stage typically takes 1-2 hours for experienced bowyers, but can take longer for beginners who need to fine-tune their technique. The process involves attaching the string to the bow's nocks, adjusting the string's tension, and checking the bow's bend and recoil.

Instructive guidance is crucial at this stage. Start by applying a small amount of bowstring wax to the string's serving to reduce friction and wear. Then, attach the string to the bow's nocks, ensuring the string is seated properly in the grooves. A common mistake is to overtighten the string, which can cause the bow to twist or warp. To avoid this, use a bow stringer tool to apply even tension as you attach the string. For traditional bows, a brace height of 7-8 inches (17.8-20.3 cm) is typical, but this can vary depending on the bow's design and intended use.

Comparing different stringing methods can help illustrate the importance of this step. For instance, the "step-by-step" method involves attaching the string one end at a time, while the "twist and loop" method uses a continuous loop to secure the string. Each approach has its advantages and disadvantages, with the former being more straightforward but requiring more precision, and the latter being more forgiving but potentially less secure. Ultimately, the choice of method will depend on the bowyer's preference and the specific requirements of the bow.

As a persuasive argument for taking the time to get this step right, consider the potential consequences of a poorly strung bow. A string that's too tight can cause the bow to crack or break, while a string that's too loose can result in poor arrow flight and reduced accuracy. Moreover, an improperly seated string can cause the bow to twist or bend unevenly, leading to long-term damage and reduced performance. By investing time and care into the final assembly and stringing steps, bowyers can ensure their wooden bows are not only functional but also safe and reliable.

Descriptive details can further illustrate the intricacies of this process. Imagine the bow's limbs bending smoothly as the string is attached, the wood fibers compressing and recoiling with each adjustment. The sound of the string settling into place, the feel of the bow's balance shifting as the tension is fine-tuned – these sensory cues provide valuable feedback for the bowyer, allowing them to make informed adjustments and ensure the final product is of the highest quality. By paying attention to these details, bowyers can create wooden bows that are not only beautiful but also exceptional performers, capable of delivering accurate and powerful shots.

Wood Decay Timeline: Factors Affecting Decomposition and Breakdown Process

You may want to see also

Frequently asked questions

For a beginner, making a wooden bow can take anywhere from 8 to 20 hours, depending on skill level, tools, and the complexity of the design.

Factors include the type of wood, the bow's design, the crafter's experience, the tools available, and the desired finish or embellishments.

Yes, an experienced crafter with the right tools and prepared materials can complete a simple wooden bow in a single day, though rushing may compromise quality.

A traditional longbow typically takes 15–30 hours due to its length, curvature, and precision requirements, compared to 8–12 hours for a simpler, shorter bow.

Yes, if starting with green wood, drying and seasoning can add weeks to months to the process, though using pre-seasoned wood eliminates this step.