Seasoning wood indoors is a process that involves drying firewood to reduce its moisture content, making it more efficient for burning. The time it takes to season wood indoors can vary significantly depending on several factors, including the type of wood, the initial moisture level, the indoor environment, and the methods used to accelerate drying. Softwoods like pine typically season faster, often within 6 to 12 months, while hardwoods like oak may require 12 to 24 months or more. Indoor seasoning is generally slower than outdoor methods due to controlled humidity and temperature, but it offers the advantage of protecting the wood from rain and pests. Proper stacking, adequate ventilation, and maintaining a consistent environment are key to expediting the process.

| Characteristics | Values |

|---|---|

| Ideal Seasoning Time Indoors | 6 months to 1 year (varies based on wood type and conditions) |

| Wood Type (Softwood) | Seasons faster (e.g., pine: 6–9 months) |

| Wood Type (Hardwood) | Takes longer (e.g., oak: 9–12 months) |

| Moisture Content Goal | 20% or less for optimal burning efficiency |

| Indoor Storage Conditions | Well-ventilated, dry area with protection from rain and snow |

| Stacking Method | Split and stacked in a single row with air gaps for airflow |

| Initial Moisture Content | Freshly cut wood: 30–50% moisture content |

| Accelerating Factors | Splitting logs, using a kiln, or storing in a warm, dry environment |

| Signs of Seasoned Wood | Cracked ends, lighter weight, and a dull grayish color |

| Tools for Monitoring | Moisture meter to check wood moisture levels |

| Safety Considerations | Avoid stacking near heat sources or flammable materials |

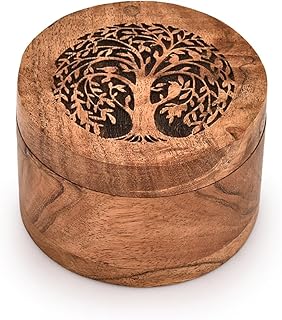

Explore related products

What You'll Learn

Ideal Wood Types for Indoor Seasoning

The process of seasoning wood indoors is as much about the type of wood as it is about time and technique. Not all wood species are created equal when it comes to drying efficiency and end-use suitability. Hardwoods like oak, maple, and hickory are popular choices for indoor seasoning due to their density and durability. These woods typically take longer to season—anywhere from 6 months to 2 years—but the result is a stable, long-lasting material ideal for furniture, flooring, or firewood. Softwoods, such as pine or cedar, dry faster, often within 3 to 6 months, but they are more prone to warping and cracking, making them better suited for projects where structural integrity is less critical.

Selecting the right wood type begins with understanding its moisture content and fiber structure. Woods with lower natural moisture levels, like ash or cherry, season more predictably indoors. For instance, ash wood, with its straight grain and moderate density, can be seasoned in 6 to 12 months, making it a practical choice for woodworking enthusiasts. Cherry, though denser, also seasons relatively quickly due to its fine, uniform texture. Both woods are excellent for indoor projects requiring dimensional stability, such as cabinetry or decorative panels.

If you’re seasoning wood for firewood, the species matters even more. Hardwoods like beech or birch are ideal because they burn hotter and longer than softwoods. Beech, for example, takes about 1 to 2 years to season properly but provides a high heat output, making it worth the wait. Birch, on the other hand, seasons slightly faster—around 6 to 12 months—and is prized for its clean burn and pleasant aroma. Avoid using resinous softwoods like spruce or fir for indoor firewood, as they can produce excessive smoke and creosote buildup in chimneys.

For those prioritizing sustainability, consider locally sourced woods with shorter seasoning times. Poplar, a fast-growing hardwood, seasons in 6 to 12 months and is an eco-friendly option for indoor projects. Similarly, basswood, known for its ease of carving, dries within the same timeframe and is perfect for artistic endeavors. Both woods are less dense than oak or maple but offer the advantage of quicker turnaround, reducing the environmental impact of transportation and storage.

Finally, proper storage is key to successful indoor seasoning, regardless of wood type. Stack wood in a dry, well-ventilated area, ensuring airflow between pieces. Use stickers (small pieces of wood) to separate layers and prevent moisture buildup. Monitor humidity levels—ideally below 60%—to avoid mold or rot. For firewood, split logs into 4-inch diameters to expedite drying. By pairing the right wood species with thoughtful preparation, you can optimize the seasoning process and achieve high-quality results tailored to your indoor needs.

Transforming Wood Chips into Mulch: Timing and Process Explained

You may want to see also

Explore related products

Optimal Indoor Humidity Levels for Wood

Wood seasoning indoors is a delicate balance, heavily influenced by humidity levels. The ideal moisture content for seasoned wood is 15-20%, mirroring the average indoor humidity range of 30-50%. This correlation isn’t coincidental; maintaining this humidity range prevents wood from absorbing excess moisture or drying out excessively, both of which can lead to warping, cracking, or mold growth. A hygrometer is an essential tool here—place it near the wood stack to monitor conditions and adjust ventilation or dehumidifiers as needed.

Achieving optimal humidity requires proactive management. In humid climates, use a dehumidifier to keep levels below 50%, ensuring wood doesn’t reabsorb moisture. In dry environments, a humidifier can prevent wood from losing moisture too quickly, which can cause checks (surface cracks). For best results, stack wood loosely to allow air circulation, and store it away from walls to avoid trapped moisture. Aim for gradual seasoning, as rapid drying under low humidity can compromise wood integrity.

Comparing indoor seasoning to outdoor methods highlights the importance of humidity control. Outdoors, wood is exposed to fluctuating conditions, often taking 6–24 months to season. Indoors, with stable humidity, this process can be reduced to 3–6 months. However, consistency is key. Fluctuations of more than 10% in humidity can stall progress or damage the wood. For example, a sudden drop from 50% to 30% humidity can cause wood to shrink and crack, while a rise to 70% can reintroduce moisture, prolonging seasoning time.

Practical tips can further optimize indoor seasoning. If using a basement or garage, ensure these spaces are well-ventilated to prevent stagnant air. Cover the wood pile with a breathable material like a tarp to protect it from dust while allowing airflow. Rotate the stack periodically to expose all pieces evenly to the controlled environment. For those in extreme climates, consider a dedicated storage area with a humidity control system, especially if working with high-value hardwoods like oak or maple, which are more sensitive to moisture changes.

Ultimately, mastering indoor wood seasoning hinges on maintaining 30-50% humidity. This range ensures wood dries evenly without stress, preserving its structural integrity. While the process demands vigilance, the payoff is significant: high-quality, ready-to-use wood in a fraction of the time it takes outdoors. Whether for firewood, woodworking, or restoration, understanding and controlling humidity is the linchpin of successful indoor seasoning.

Woodchucks' Lifespan: Understanding How Long These Groundhogs Live

You may want to see also

Explore related products

Required Time for Softwood Seasoning

Softwood, such as pine or spruce, typically requires less time to season indoors compared to hardwoods due to its lower density and moisture content. On average, softwood can be seasoned in 6 to 12 months, depending on factors like humidity, airflow, and initial moisture levels. This timeframe is significantly shorter than the 1 to 2 years often needed for denser hardwoods like oak or maple. For optimal results, softwood should be split into smaller pieces, stacked in a well-ventilated area, and protected from rain while still allowing air circulation.

The seasoning process for softwood involves reducing its moisture content from around 50% to below 20%, making it suitable for burning or woodworking. To expedite this, ensure the wood is stored in a dry, indoor space with consistent airflow. A moisture meter can be a valuable tool to monitor progress, as softwood is ready for use when it reaches 15–20% moisture content. Avoid overcrowding the stack, as this can trap moisture and prolong drying time.

Comparatively, softwood’s faster seasoning time makes it a practical choice for those needing wood quickly, such as for winter firewood or small DIY projects. However, its lower density means it burns faster and produces less heat than hardwood, so it’s essential to balance the benefits of quicker seasoning with the intended use. For indoor seasoning, softwood’s lighter weight also makes it easier to handle and rearrange during the drying process.

A key caution when seasoning softwood indoors is managing resin and sap, which can be more prevalent in species like pine. Resin can attract pests or create sticky messes, so consider storing softwood on a tarp or elevated surface to protect floors. Additionally, ensure the wood is not placed near heat sources, as this can cause uneven drying or cracking. With proper care, softwood can be efficiently seasoned indoors, providing a reliable resource in a relatively short timeframe.

Wood County Ohio Probate Records Retention: How Long Are They Kept?

You may want to see also

Explore related products

Required Time for Hardwood Seasoning

Hardwood seasoning indoors is a meticulous process that hinges on moisture content reduction, typically requiring 6 to 12 months for optimal results. This timeframe varies based on wood species, initial moisture levels, and environmental conditions. Dense hardwoods like oak or hickory take longer to season than softer varieties like pine due to their lower permeability. For instance, oak with an initial moisture content of 50% may need a full year to reach the ideal 12-20% range, while pine might achieve this in 6 months. Monitoring moisture levels with a wood moisture meter is essential to avoid under-seasoning, which can lead to warping or mold.

The indoor seasoning process demands controlled conditions to mimic the slow drying of outdoor seasoning. Maintain a consistent temperature between 60°F and 80°F (15°C and 27°C) and humidity below 60% to facilitate even drying. Stack wood in a single row with spacers to allow airflow, and ensure the storage area is well-ventilated but protected from direct heat sources, which can cause uneven drying. For expedited results, consider using a dehumidifier or fans, but avoid rushing the process, as rapid drying increases the risk of cracks.

Comparing indoor and outdoor seasoning highlights the trade-offs. Outdoor seasoning is faster for hardwoods in dry climates but exposes wood to weather extremes, increasing the risk of splitting. Indoor seasoning, while slower, offers greater control and protection, making it ideal for high-quality hardwoods intended for furniture or flooring. For example, a craftsman seasoning walnut for a custom table would prioritize indoor methods to preserve the wood’s integrity, even if it means waiting longer.

Practical tips can streamline the indoor seasoning process. Start by splitting hardwood logs into 1- to 2-inch thicknesses to increase surface area for moisture escape. Apply a sealant to the ends of logs to minimize end grain absorption, which accounts for 90% of moisture loss. Regularly rotate the stack to ensure uniform drying, and store wood away from walls to prevent moisture absorption. Patience is key; rushing hardwood seasoning compromises its stability and longevity, undermining the effort invested in the process.

Sourwood Lifespan: Understanding the Longevity of This Unique Tree Species

You may want to see also

Explore related products

$86.99

Proper Stacking Techniques for Indoor Wood Drying

Stacking wood indoors for seasoning isn’t just about piling logs in a corner; it’s a precise art that accelerates drying while conserving space. Proper stacking maximizes airflow, the single most critical factor in reducing seasoning time from months to weeks. Wood stacked haphazardly retains moisture, leading to mold, rot, or insect infestations. A well-organized stack, however, allows air to circulate evenly, drawing out moisture through the end grain, where wood releases water most efficiently.

Begin by selecting a dry, well-ventilated area with a concrete or raised wooden floor to prevent ground moisture absorption. Use a base layer of 2x4s or pallets to elevate the wood, ensuring air circulates beneath. Stack logs in a crisscross or linear pattern, leaving 1–2 inches between pieces to promote airflow. Avoid tight packing, as this traps humidity. For stability, alternate layers in a staggered brick pattern, ensuring each row is level. Keep the stack no taller than 4 feet to prevent toppling and maintain even drying.

While stacking, consider the wood’s moisture content. Freshly cut wood can take 6–12 months to season outdoors but dries significantly faster indoors with proper techniques. Kiln-dried wood, for comparison, achieves 15–20% moisture content in days, but indoor air-drying aims for 20–25% over 3–6 months. Use a moisture meter to monitor progress, aiming for levels below 20% for optimal burning efficiency.

One common mistake is neglecting the end grain. Wood releases 80% of its moisture through the cut ends, so ensure these faces are exposed. If stacking against a wall, leave a 2-inch gap to prevent moisture transfer. Cover the top loosely with a tarp or breathable fabric to protect from dust and debris while allowing air exchange. Avoid plastic sheeting, as it traps moisture and fosters mold.

Finally, patience is key. Even with ideal stacking, indoor seasoning time varies based on humidity, temperature, and wood density. Hardwoods like oak or hickory take longer than softwoods like pine. Regularly rotate logs to ensure uniform drying, and store wood away from heat sources to prevent uneven moisture loss. Proper stacking isn’t just about organization—it’s a strategic method to transform raw wood into a clean-burning fuel source, saving time and energy in the long run.

Wooden Boat Swelling Time: Factors Affecting Absorption and Expansion Process

You may want to see also

Frequently asked questions

Seasoning wood indoors typically takes 6 to 12 months, depending on factors like wood type, moisture content, and environmental conditions such as humidity and airflow.

Yes, you can speed up seasoning by splitting wood into smaller pieces, storing it in a dry, well-ventilated area, and using fans to improve airflow. However, it still requires at least 3 to 6 months for proper seasoning.

Fully seasoned wood feels lighter, has cracks at the ends, and makes a hollow sound when two pieces are knocked together. A moisture meter can also confirm it’s below 20% moisture content.