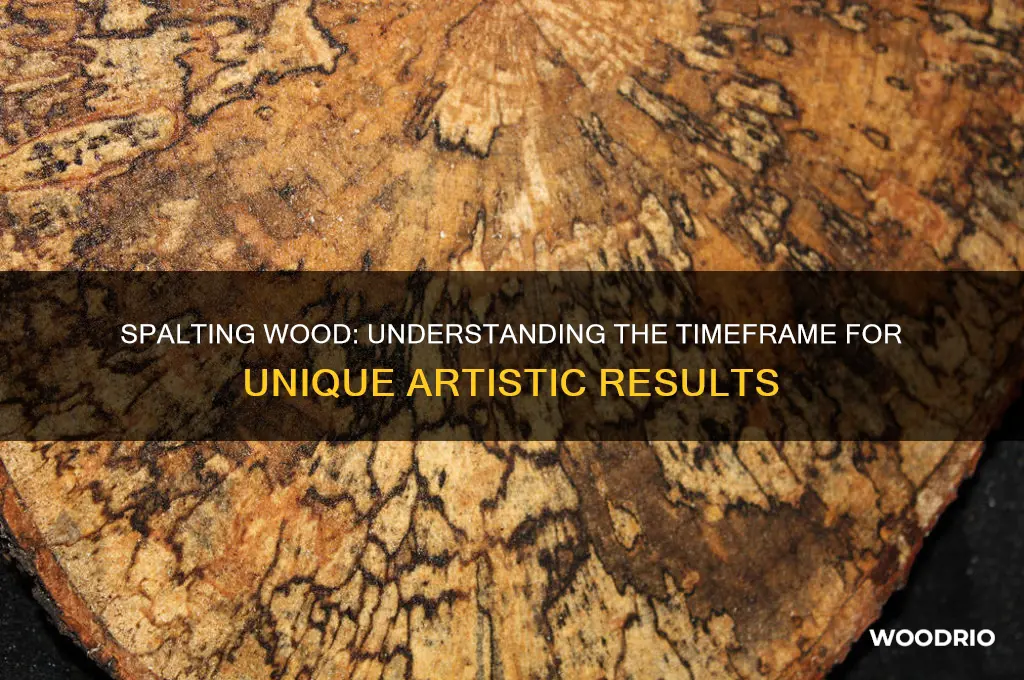

Spalting wood is a fascinating process that involves allowing fungi to colonize the wood, creating unique patterns and colors that are highly prized by woodworkers and artisans. The time it takes to spalt wood can vary significantly depending on several factors, including the type of wood, moisture levels, temperature, and the specific fungi present. Generally, the spalting process can take anywhere from a few weeks to several months. Softwoods like maple and birch tend to spalt more quickly, often within 4 to 8 weeks, while hardwoods such as oak or walnut may require 2 to 3 months or longer. Maintaining optimal conditions—such as keeping the wood damp but not waterlogged and storing it in a warm, humid environment—is crucial for successful spalting. Patience is key, as rushing the process can lead to uneven results or wood decay.

| Characteristics | Values |

|---|---|

| Time to Spalt Wood | 2 weeks to 4 months (depending on conditions) |

| Optimal Temperature Range | 60°F to 80°F (15°C to 27°C) |

| Optimal Humidity Range | 40% to 60% (higher humidity accelerates spalting) |

| Wood Species | Hardwoods (e.g., maple, birch, beech) are best for spalting |

| Fungal Growth Requirement | Presence of spalting fungi (e.g., Trichoderma, Xylobolus) |

| Oxygen Availability | Adequate airflow is necessary to prevent decay |

| Moisture Control | Wood should be consistently damp but not waterlogged |

| Color Development | Colors appear after 2-4 weeks, fully develop over 1-3 months |

| Risk of Over-Spalting | Wood may become too brittle or decayed if left too long |

| Post-Spalting Drying Time | 2-4 weeks in a dry environment to stabilize the wood |

| Common Uses of Spalted Wood | Furniture, decorative items, turned objects, and artwork |

| Preservation Methods | Kiln drying or sealing to stop fungal activity and preserve colors |

Explore related products

What You'll Learn

Understanding Wood Spalting Process

Wood spalting is a natural process where fungi colonize wood, breaking down its cells and creating unique patterns and colors. This transformation doesn’t happen overnight; it’s a delicate interplay of moisture, temperature, and time. Typically, spalting takes 2 to 12 weeks under controlled conditions, though it can occur faster or slower depending on environmental factors. For instance, a humid environment with temperatures between 60°F and 80°F accelerates fungal growth, while drier or colder conditions slow it down. Understanding this timeline is crucial for woodworkers aiming to harness spalting’s aesthetic appeal without compromising the wood’s structural integrity.

To initiate spalting, wood must be kept at a moisture content of 40% to 60%, a range where fungi thrive but wood decay is minimized. This can be achieved by misting the wood periodically or storing it in a sealed container with damp sponges. White rot and brown rot fungi are the primary agents of spalting, each producing distinct effects: white rot fungi create light-colored zones, while brown rot fungi result in darker, more contrasting patterns. Experimenting with different fungal species or wood types (such as maple or birch) can yield varied results, but patience is key—rushing the process risks over-spalting, which weakens the wood.

A common misconception is that spalting ruins wood, but when managed correctly, it enhances its beauty without significant loss of strength. However, prolonged exposure to spalting fungi can lead to advanced decay, especially if moisture levels exceed 60%. To prevent this, monitor the wood weekly, checking for signs of excessive softening or darkening. If the wood feels spongy or emits a musty odor, it’s time to halt the process by drying the wood to below 20% moisture content. This balance between art and science is what makes spalting both challenging and rewarding.

For those new to spalting, start with small batches of wood to refine your technique. Use a moisture meter to track humidity levels and keep detailed notes on temperature, fungal activity, and visual changes. Advanced practitioners often inoculate wood with specific fungi strains to achieve predictable results, but this requires sterile techniques to avoid contamination. Whether you’re a hobbyist or professional, understanding the spalting process transforms it from a gamble into a controlled craft, allowing you to create stunning, one-of-a-kind pieces with confidence.

Wood Glue Bonding Time: How Long Does It Take?

You may want to see also

Explore related products

Factors Affecting Spalting Time

Spalting, the process by which fungi colonize wood, creating unique patterns and colors, is as much art as it is science. The time it takes for wood to spalt varies dramatically, influenced by a constellation of factors that can either accelerate or hinder the process. Understanding these variables allows woodworkers and artisans to manipulate conditions, achieving desired results within a predictable timeframe.

Key among these factors is moisture content. Spalting fungi thrive in environments with a moisture content between 30% and 60%. Wood stored in a humid environment, such as a sealed container with damp paper towels or a controlled humidity chamber, will spalt faster than wood left to air-dry. For instance, placing hardwoods like maple or beech in a plastic bag with a moisture source can reduce spalting time from months to weeks. However, exceeding 60% moisture risks promoting decay fungi, which can ruin the wood’s structural integrity.

Temperature plays a pivotal role as well, acting as a catalyst for fungal activity. Optimal spalting occurs between 70°F and 85°F (21°C to 29°C). Cooler temperatures slow fungal growth, while higher temperatures can stress or kill the fungi. For example, wood stored in a heated garage during winter may take twice as long to spalt compared to wood kept in a warm, controlled environment. Experimenting with temperature gradients—such as using heating pads or insulated boxes—can fine-tune spalting speed, though consistency is key to avoiding uneven results.

The wood species itself is a non-negotiable factor. Hardwoods like maple, birch, and beech are prime candidates for spalting due to their dense structure and natural resistance to full decay. Softwoods, such as pine or cedar, often decompose too quickly, leaving little time for aesthetic spalting to occur. Additionally, the age and condition of the wood matter: freshly cut, green wood spalts faster than seasoned wood, as the former retains more moisture and nutrients for fungal growth.

Finally, the type and presence of spalting fungi cannot be overlooked. White rot, brown rot, and zone line fungi each produce distinct patterns and colors, but their colonization rates differ. Introducing specific fungal cultures, available from specialty suppliers, can expedite the process. For instance, *Trametes versicolor* (turkey tail fungus) is known for its rapid white rot spalting, often visible within 2–4 weeks under ideal conditions. However, relying on naturally occurring fungi in the environment may extend spalting time to 3–6 months, depending on local microbial populations.

In practice, spalting is a delicate balance of control and patience. By manipulating moisture, temperature, wood selection, and fungal presence, artisans can shorten spalting time from months to weeks. Yet, rushing the process risks sacrificing the wood’s integrity or the depth of its patterns. The takeaway? Spalting is a craft that rewards precision, experimentation, and respect for the natural processes at play.

Durability of Wooden Bows: Lifespan, Care, and Longevity Tips

You may want to see also

Best Wood Types for Spalting

Spalting thrives on specific wood characteristics, and hardwoods with high starch content and open grain structures are prime candidates. Beech, maple, and birch excel due to their abundant starch reserves, which fungi readily consume, creating striking patterns. Their porous structures allow moisture and fungi to penetrate easily, accelerating the spalting process. While softer woods like pine can spalt, their lower starch content and denser grain often yield less dramatic results.

Beech, with its fine, even texture and high starch content, is a spalting superstar. Its ability to absorb moisture without warping makes it ideal for controlled spalting environments. Maple, particularly soft maple, offers a beautiful contrast between its light sapwood and darker heartwood, enhanced by spalting's zonate patterns. Birch, known for its strength and workability, develops intricate spiderweb-like lines during spalting, adding a unique dimension to its already appealing grain.

For optimal spalting, prioritize freshly cut wood, ideally within a week of felling. This ensures the wood retains its starch reserves and hasn't begun to dry out, hindering fungal growth. Maintain a moisture content of 30-50% – enough to support fungal activity without causing rot. Temperature plays a crucial role; aim for a range of 60-80°F (15-27°C), ideal for fungal metabolism.

Avoid over-saturating the wood, as excessive moisture can lead to decay rather than spalting. Regularly monitor the wood's progress, checking for desired coloration and patterns. Once the desired level of spalting is achieved, kiln-dry the wood to halt the process and prevent further fungal activity. Remember, spalting is a delicate balance between encouraging fungal growth and preserving the wood's structural integrity.

Wood Duck Egg Hatching Timeline: Incubation Period Explained

You may want to see also

Accelerating Spalting Techniques

Spalting, the process of encouraging fungi to create unique patterns in wood, typically takes weeks to months under natural conditions. However, woodworkers and artisans often seek to accelerate this process to meet project deadlines or experiment with designs. By manipulating environmental factors and introducing specific fungi, spalting can be expedited significantly, reducing the timeline from months to just a few weeks.

Controlling Humidity and Temperature: One of the most effective ways to accelerate spalting is by maintaining optimal conditions for fungal growth. Fungi thrive in environments with 40–60% humidity and temperatures between 70–85°F (21–29°C). Using a humidity-controlled chamber or a simple setup with a humidifier and thermometer can shorten spalting time by up to 50%. For example, placing wood in a sealed container with damp sphagnum moss and monitoring the temperature can create an ideal microclimate for rapid fungal colonization.

Inoculating with Specific Fungi: Instead of relying on ambient fungi, introducing known spalting species like *Trametes versicolor* or *Ceriporiopsis subvermispora* can expedite the process. These fungi can be purchased as spore suspensions or cultured from existing spalted wood. Applying a spore solution directly to the wood surface, followed by maintaining high humidity, can produce visible spalting patterns within 2–3 weeks. Caution: Ensure proper ventilation and wear protective gear when handling fungal cultures to avoid respiratory issues.

Pre-Treating Wood for Faster Absorption: Wood density and moisture content play a critical role in spalting speed. Pre-treating wood by soaking it in a 10% hydrogen peroxide solution for 24 hours can open up cell walls, allowing fungi to penetrate more quickly. Alternatively, lightly sanding the wood surface or creating small incisions can provide entry points for fungal spores. These techniques, combined with controlled conditions, can reduce spalting time to as little as 10–14 days for softer woods like maple or birch.

Comparing Accelerated vs. Natural Spalting: While accelerated spalting offers speed and control, it may yield slightly different patterns compared to natural processes. Accelerated techniques often produce more uniform and vibrant colors due to the controlled introduction of specific fungi. However, natural spalting can result in more organic, unpredictable designs. For projects requiring consistency, acceleration is ideal; for those valuing uniqueness, a hybrid approach—starting with inoculation and finishing naturally—may be preferable.

By combining these techniques, woodworkers can significantly reduce spalting time without sacrificing the aesthetic appeal of the wood. Experimentation with different fungi, humidity levels, and wood species will further refine the process, making accelerated spalting a valuable skill for both hobbyists and professionals.

Benjamin Banneker's Wooden Watch: Its Functionality and Lifespan Explored

You may want to see also

Signs Spalting is Complete

Spalting is a natural process where fungi colonize wood, creating unique patterns and colors. Knowing when it’s complete is crucial to prevent over-spalting, which can weaken the wood. The first sign of completion is the stabilization of color and pattern development. Once the fungi have ceased spreading and the wood’s appearance no longer changes, spalting is likely finished. This typically occurs after 4 to 8 weeks, depending on humidity, temperature, and wood species. For example, maple often shows vibrant black lines and zones of color within this timeframe, while beech may take slightly longer due to its denser grain.

Another indicator is the wood’s texture and structural integrity. Spalting should enhance the wood’s aesthetic without compromising its strength. If the wood feels excessively soft or crumbly, it’s a sign of over-spalting. To test, press a fingernail gently into the surface—minor give is acceptable, but deep indentation suggests the process has gone too far. Ideally, the wood should retain its hardness while showcasing the spalting patterns. For hardwoods like oak or walnut, a moisture meter reading between 12% and 15% indicates the wood is dry and stable, signaling the spalting process is complete.

Odor is a less obvious but equally important sign. Freshly spalted wood often has a mild, earthy scent due to fungal activity. Once spalting is complete, this smell diminishes significantly. If the wood still has a strong, pungent odor, the fungi may still be active, and the process isn’t finished. Air-drying the wood in a well-ventilated area for an additional week can help dissipate any lingering smells and ensure the spalting is fully stabilized.

Finally, visual cues like fungal fruiting bodies (mushrooms or bracket fungi) appearing on the wood’s surface indicate advanced spalting. While these growths can be removed, their presence suggests the fungi are still active. To halt the process, submerge the wood in a 1:10 solution of vinegar and water for 24 hours to kill the fungi, then dry it thoroughly. This step ensures the spalting is complete and prevents further degradation. Always wear gloves and a mask when handling spalted wood to avoid fungal spores.

In summary, spalting completion is marked by stabilized colors, intact structural integrity, reduced odor, and the absence of active fungal growth. Monitoring these signs ensures the wood is both visually stunning and functional. While the process typically takes 4 to 8 weeks, factors like wood species and environmental conditions can influence timing. By recognizing these cues, woodworkers can achieve the perfect balance between art and preservation.

Wood Duck Egg Incubation: Duration and Nesting Habits Explained

You may want to see also

Frequently asked questions

Spalting time varies depending on conditions, but it typically takes 2 to 8 weeks for noticeable spalting to occur.

Factors include wood moisture content (ideally 20-30%), temperature (60-90°F or 15-32°C), and the presence of fungi, which are essential for spalting.

Yes, by maintaining optimal conditions: keeping the wood damp, ensuring proper airflow, and using wood species prone to spalting, such as maple or beech.

Yes, if left too long, the wood can become too weak or decayed. Monitor the process and stabilize the wood once the desired spalting effect is achieved.