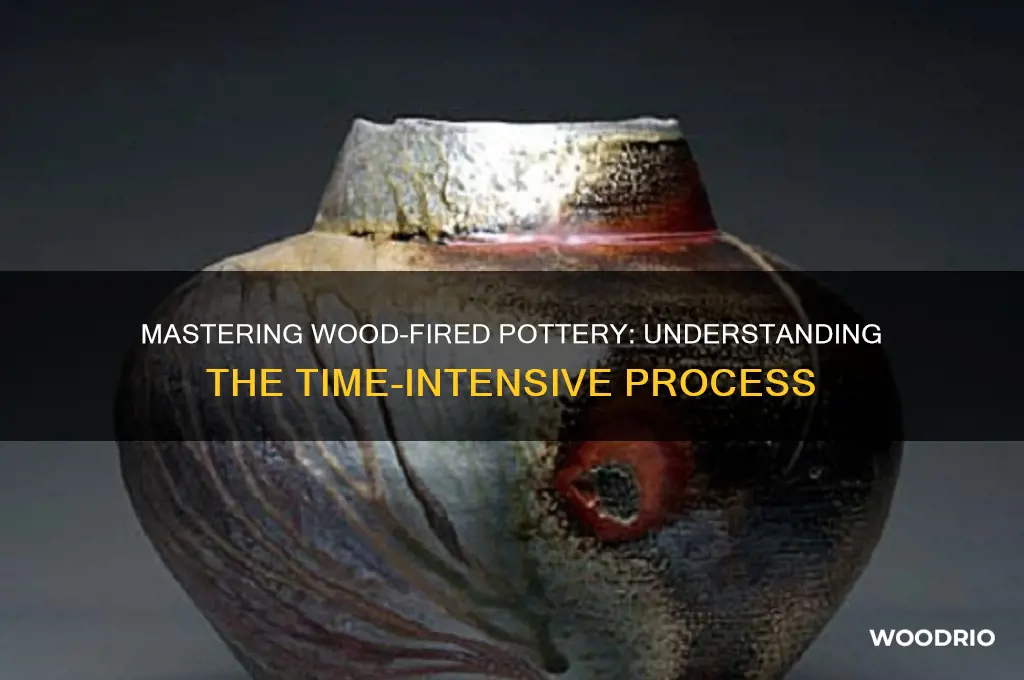

Wood firing pottery is a traditional and time-intensive process that involves heating a kiln with wood as the primary fuel source. The duration of this process can vary significantly depending on several factors, including the size of the kiln, the amount of pottery being fired, the desired temperature, and the specific techniques used by the potter. Typically, a wood firing cycle can range from 24 to 72 hours, with some larger or more complex firings extending even longer. During this time, the potter must continuously monitor and adjust the fire, adding wood at regular intervals to maintain the desired temperature, which often reaches between 2,200°F and 2,400°F (1,200°C to 1,315°C). The cooling period, which can take an additional 24 to 48 hours, is equally important, as it affects the final appearance and durability of the pottery. This labor-intensive method is prized for its unique, natural ash glazes and the unpredictable beauty it imparts to each piece, making the lengthy process a labor of love for many artisans.

| Characteristics | Values |

|---|---|

| Firing Duration | Typically 24 to 48 hours, depending on kiln size and desired effects. |

| Temperature Range | 1800°F to 2400°F (982°C to 1315°C). |

| Wood Consumption | Approximately 1 to 2 cords of wood per firing. |

| Labor Intensity | High; requires constant monitoring and stoking of the fire. |

| Cooling Time | 12 to 48 hours, depending on kiln size and insulation. |

| Total Process Time | 36 to 72 hours (firing + cooling). |

| Variability | Dependent on kiln design, wood type, and desired aesthetic outcomes. |

| Environmental Impact | Higher carbon footprint due to wood burning; sustainable wood sourcing recommended. |

| Skill Level Required | Advanced; requires experience in kiln management and firing techniques. |

| Post-Firing Inspection | Necessary to check for cracks, warping, or other defects. |

Explore related products

$32.62 $35

What You'll Learn

Preparing Clay for Firing

The journey of wood-fired pottery begins long before the flames kiss the clay. Preparing the clay for firing is a meticulous process that demands attention to detail, patience, and an understanding of the material's unique characteristics. This stage is crucial, as improperly prepared clay can lead to warping, cracking, or even complete failure during the firing process, which can last anywhere from 24 to 72 hours depending on the kiln size and desired effects.

The Drying Process: A Delicate Balance

Clay must be thoroughly dried before firing to eliminate all moisture, a step often overlooked by beginners. Air-drying is the most common method, but it requires careful management. Place your pottery in a well-ventilated area, away from direct sunlight or heat sources, which can cause uneven drying. For larger pieces, aim for a drying period of 7–10 days, while smaller items may only need 3–5 days. A simple test to check dryness is to tap the clay; a clear, ringing sound indicates it’s ready, while a dull thud suggests residual moisture.

Bisque Firing: The First Bake

Before wood firing, most potters perform a bisque firing, a low-temperature bake (typically 900°C to 1000°C) that hardens the clay without fully vitrifying it. This step drives out remaining water and prepares the piece for glazing or direct wood firing. Bisque firing usually takes 8–12 hours, including ramp-up and cooling time. Skipping this step risks structural instability during the intense heat of wood firing, which can reach temperatures of 1200°C or higher.

Surface Preparation: Enhancing the Final Look

The way you prepare the clay’s surface before firing dramatically affects the final aesthetic. For wood firing, consider applying slips, engobes, or resists to create patterns that interact with the ash and flame. For example, a thin layer of iron oxide slip can deepen the color where ash lands, while wax resist techniques leave unglazed areas for unique contrasts. Ensure all surface treatments are fully dry before firing, as moisture can cause bubbling or uneven effects.

Cautions and Troubleshooting

Even with careful preparation, issues can arise. Hairline cracks, known as "silt cracks," may appear during drying if the clay shrinks too quickly. To prevent this, cover pieces with plastic or damp cloth to slow moisture loss. Additionally, avoid stacking or handling wet clay excessively, as this can distort shapes. If you notice warping during bisque firing, adjust your drying techniques for future pieces, ensuring even moisture loss across the entire form.

By mastering the preparation of clay for firing, potters set the stage for successful wood firing, where the interplay of heat, ash, and clay transforms raw material into enduring art. This foundational step, though time-consuming, is indispensable for achieving the rich, unpredictable beauty that defines wood-fired pottery.

Elmer's Wood Filler Drying Time: Quick Guide for DIY Enthusiasts

You may want to see also

Explore related products

$21.95 $23.95

Loading the Kiln Properly

Loading a kiln for wood firing is an art as much as a science, demanding precision and foresight. Each piece must be placed with care to ensure even heat distribution and prevent damage. Start by arranging larger, more robust items at the bottom, where temperatures are highest, and position delicate or smaller pieces toward the top. This stratified approach minimizes the risk of cracking or warping due to uneven heating. Use kiln shelves or stilts to elevate pieces, allowing air and heat to circulate freely. Remember, overcrowding restricts airflow, leading to inconsistent firing, so leave adequate space between items.

The orientation of each piece matters more than you might think. Handles, spouts, and other protruding elements should face inward or upward to avoid catching on neighboring items or the kiln walls. This reduces the likelihood of breakage during the firing process. For pieces with intricate designs or glazes, ensure they are not touching other items to prevent sticking or smudging. A well-organized kiln not only protects your work but also optimizes fuel efficiency, as proper airflow allows the wood to burn more completely.

One often overlooked aspect of kiln loading is the use of wadding or kiln wash. Wadding, small pads of ceramic fiber, is placed between pieces or between a piece and the kiln shelf to prevent sticking. Kiln wash, a refractory mixture applied to shelves, serves a similar purpose. Both are essential for preserving the integrity of your work, especially when using glazes that tend to run or fuse. Apply these materials sparingly but strategically, focusing on points of contact between pieces and surfaces.

Finally, consider the firing timeline when loading the kiln. Wood firing typically takes 24 to 48 hours, during which the kiln’s temperature rises gradually and then cools slowly. This extended process means that pieces must be stable and secure to withstand prolonged exposure to heat. Double-check that all items are balanced and that no sharp edges or unstable forms could shift during firing. A well-loaded kiln not only ensures the success of your pieces but also enhances the overall efficiency and safety of the wood-firing process.

Effective Wood Stripping: Optimal Time to Leave Stripping Agents On

You may want to see also

Explore related products

Firing Temperature and Duration

Wood-firing pottery is an art that hinges on precision, particularly in managing firing temperature and duration. The ideal temperature range for wood-fired kilns typically falls between 1,000°C (1,832°F) and 1,300°C (2,372°F), depending on the desired effects and clay body. Lower temperatures, around 1,000°C, produce earthy, matte finishes, while higher temperatures, nearing 1,300°C, yield glossy surfaces and vibrant ash glazes. Achieving these temperatures requires careful monitoring, as fluctuations can alter the final piece dramatically.

The duration of firing varies widely, often spanning 24 to 72 hours, depending on kiln size, wood type, and desired aesthetic. Shorter firings, around 24 hours, are suitable for smaller kilns and simpler designs, while longer firings, up to 72 hours, are reserved for larger pieces or complex ash effects. The firing process is divided into stages: preheating, bisque firing, and final reduction. Preheating gradually raises the temperature to avoid thermal shock, while the reduction phase, typically at peak temperature, enhances color and texture by controlling oxygen levels.

Mastering wood-firing requires understanding the interplay between temperature and time. For instance, rapid temperature increases during the reduction phase can intensify ash glazes, but too much heat too quickly risks cracking or warping. Conversely, slow, controlled cooling over 8 to 12 hours ensures the clay vitrifies properly without stress. Experienced potters often use pyrometric cones to gauge heatwork, ensuring consistency across firings.

Practical tips include using hardwoods like oak or maple for sustained heat and avoiding softwoods that burn too quickly. Regularly stoking the kiln maintains even temperatures, while strategically placing pieces within the kiln maximizes exposure to ash and flame. Beginners should start with shorter firings at lower temperatures, gradually experimenting with longer durations and higher heat as skill improves.

In essence, firing temperature and duration are the backbone of wood-fired pottery, dictating not only the piece’s durability but also its aesthetic appeal. Balancing these elements requires patience, observation, and a willingness to learn from each firing. With practice, potters can harness the unpredictable beauty of wood-firing, turning technical constraints into artistic opportunities.

Ash Wood Drying Time: Factors Affecting the Process and Duration

You may want to see also

Explore related products

$13.99

Cooling Process After Firing

The cooling process after firing wood-fired pottery is a critical phase that can make or break the final piece. Unlike electric or gas kilns, wood-fired kilns operate at unpredictable temperatures, often reaching upwards of 2300°F (1260°C). Rapid cooling at these extremes can cause thermal shock, leading to cracks or even shattering. To prevent this, potters employ a slow, controlled cooling process known as "annealing." This typically takes 12 to 24 hours, depending on the kiln size and firing duration. During this time, the kiln is gradually sealed off from oxygen, reducing the temperature by 100°F (38°C) per hour or less. Patience here is non-negotiable—rushing the cool-down risks undoing hours of meticulous work.

Instructive in nature, the cooling process demands precision and foresight. After the final wood load is burned, the kiln vents are closed to starve the fire of oxygen, a step known as "damping down." This slows the cooling rate and allows the pottery to acclimate to lower temperatures. For larger kilns, such as anagama or noborigama styles, the process can extend to 48 hours or more. Potters often monitor the kiln’s exterior temperature with infrared thermometers, ensuring it drops below 200°F (93°C) before opening. A common mistake is opening the kiln too soon, exposing the pottery to ambient air and causing uneven contraction. To avoid this, some potters use a "spy hole" to peek inside once temperatures are safe, ensuring the pieces are stable before unloading.

Comparatively, the cooling process in wood firing differs significantly from electric or gas kilns, which often cool in 6 to 8 hours with automated controls. Wood firing’s manual, hands-on approach requires intuition and experience. For instance, in a traditional Japanese *anagama* kiln, the cooling process is as much an art as the firing itself. The potter must read the kiln’s behavior—observing smoke color, ash patterns, and temperature gradients—to determine the optimal cooling rate. This contrasts with the precision of digital kiln controllers, where timing is predetermined. The trade-off? Wood-fired pieces often exhibit unique surface effects, such as flashing or ash glazes, that emerge during this extended cool-down.

Descriptively, the cooling phase is a quiet, almost meditative period after the chaos of firing. The kiln, once a roaring inferno, now hums with residual heat, its walls radiating warmth like a dying ember. Inside, the pottery undergoes a final transformation as the clay and glaze molecules settle into their permanent structure. This is when the magic happens—colors deepen, textures emerge, and the piece’s character is fully realized. For the potter, this waiting period is both agonizing and exhilarating, a reminder that craftsmanship is as much about restraint as action.

Persuasively, investing time in the cooling process is essential for achieving professional-quality results. Skipping or rushing this step can turn a masterpiece into debris. For hobbyists, understanding this phase is key to avoiding costly mistakes. Practical tips include covering the kiln with insulating blankets to slow heat loss and using a kiln sitter or pyrometer to monitor internal temperatures. For those new to wood firing, partnering with an experienced potter during the first few firings can provide invaluable guidance. Ultimately, the cooling process is a testament to the adage that good things come to those who wait—especially in the world of wood-fired pottery.

Formaldehyde in Wood: Durability and Longevity Explained

You may want to see also

Explore related products

Post-Firing Inspection Tips

Wood-fired pottery emerges from the kiln transformed, its surface a testament to the dance of flame and clay. But the journey isn't over. Post-firing inspection is crucial, a meticulous process that separates the masterpieces from the misfires.

Begin with a cool-headed assessment. Allow the kiln to cool completely, a process that can take anywhere from 12 to 24 hours depending on the size and type of kiln. Rushing this step risks thermal shock, cracking your precious creations.

Inspect for structural integrity first. Gently tap each piece with a wooden or plastic tool, listening for a clear, resonant sound. A dull thud or a crackling noise indicates potential weakness or hidden fractures. Visually scan for warping, cracks, or uneven shrinkage, paying close attention to handles, spouts, and other vulnerable areas.

Surface examination demands a keen eye. Wood firing creates unique effects, from subtle ash deposits to dramatic flashing and carbon trapping. While these are often desirable, ensure they enhance the piece's aesthetic rather than detracting from it. Look for blistering, pitting, or excessive soot buildup, which may indicate firing inconsistencies or glaze application issues.

Functionality is paramount for utilitarian pieces. Test the fit of lids, the stability of bases, and the smoothness of interiors. Pour water into vessels to check for leaks, and ensure handles are securely attached and comfortable to grip. Remember, a beautiful piece that doesn't function well is merely a decoration.

Document your findings. Note any imperfections, no matter how minor, for future reference. This record helps you refine your techniques, identify recurring issues, and track the evolution of your craft. Embrace the learning process – even "failed" pieces offer valuable lessons for future firings.

OSB Wood Soaking Time: Factors Affecting Absorption and Durability

You may want to see also

Frequently asked questions

The firing process for wood-fired pottery typically takes between 12 to 48 hours, depending on the size of the kiln, the amount of pottery being fired, and the desired temperature and effects.

Cooling down can take anywhere from 12 to 48 hours, or even longer for larger kilns. It’s crucial to allow the pottery to cool slowly to avoid thermal shock and cracking.

Preparation can take several days to a week, including loading the kiln, stacking the pottery, and preparing the wood. Proper planning ensures an efficient and successful firing.

From preparation to cooling, the entire wood-firing process can take 3 to 7 days, depending on the scale of the operation and the specific techniques used.