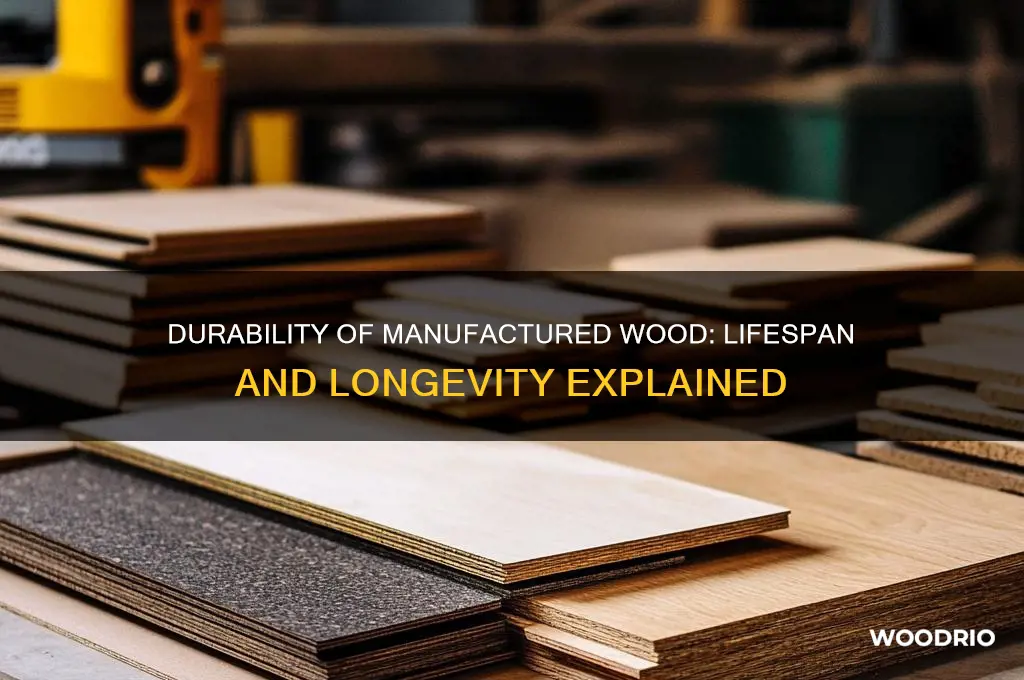

Manufactured wood, also known as engineered wood, is a popular alternative to solid wood due to its affordability, versatility, and sustainability. However, its durability and lifespan vary significantly depending on the type of manufactured wood, its intended use, and environmental factors. For instance, plywood and MDF (Medium-Density Fiberboard) can last anywhere from 10 to 50 years or more when properly maintained and protected from moisture, while particleboard may have a shorter lifespan of 5 to 15 years due to its susceptibility to water damage. Factors such as exposure to humidity, temperature fluctuations, and wear and tear also play a crucial role in determining how long manufactured wood will last. Understanding these variables is essential for choosing the right type of engineered wood for specific applications and ensuring its longevity.

| Characteristics | Values |

|---|---|

| Average Lifespan | 10–30 years (varies by type and conditions) |

| Factors Affecting Durability | Moisture exposure, quality of materials, installation, and maintenance |

| Moisture Resistance | Low to moderate (prone to swelling, warping, or delamination if wet) |

| Indoor Use Lifespan | 20–30 years (with proper care) |

| Outdoor Use Lifespan | 5–15 years (even for treated varieties like MDF or plywood) |

| Structural Integrity | Weaker than solid wood over time; prone to sagging or cracking |

| Maintenance Requirements | Regular sealing, painting, or varnishing to extend lifespan |

| Common Types | MDF, Plywood, Particle Board, OSB (each with varying durability) |

| Environmental Impact | Shorter lifespan compared to solid wood; often non-biodegradable |

| Cost-Effectiveness | Cheaper upfront but may require replacement sooner than solid wood |

Explore related products

What You'll Learn

- Factors Affecting Durability: Moisture, humidity, quality, usage, and maintenance impact manufactured wood lifespan significantly

- Types of Manufactured Wood: Plywood, MDF, particleboard, and OSB vary in longevity based on composition

- Indoor vs. Outdoor Use: Indoor use extends life; outdoor exposure reduces durability due to weather

- Maintenance Tips: Regular cleaning, sealing, and avoiding water damage prolong manufactured wood life

- Average Lifespan: Typically lasts 10–30 years, depending on type, use, and care

Factors Affecting Durability: Moisture, humidity, quality, usage, and maintenance impact manufactured wood lifespan significantly

Manufactured wood, despite its engineered nature, is not immune to the ravages of moisture and humidity. These elements can infiltrate the wood’s layers, causing swelling, warping, or even delamination over time. For instance, particleboard and MDF (medium-density fiberboard) are particularly vulnerable in bathrooms or kitchens, where humidity levels often exceed 60%. To mitigate this, consider using moisture-resistant variants like marine-grade plywood or sealing edges with waterproof coatings. A dehumidifier in high-moisture areas can also extend the lifespan of manufactured wood by maintaining relative humidity below 50%.

Quality plays a pivotal role in determining how well manufactured wood withstands the test of time. Low-grade materials often contain higher resin content, which can degrade faster under stress or temperature fluctuations. Premium options, such as high-density HDF (high-density fiberboard), offer better structural integrity and resistance to wear. When selecting manufactured wood, inspect the resin-to-wood ratio and opt for products with formaldehyde emissions below 0.05 ppm (parts per million) to ensure durability and safety. Investing in higher-quality materials upfront can save costs on replacements later.

Usage patterns dictate the wear and tear on manufactured wood, directly influencing its longevity. High-traffic areas like floors or countertops made from laminate or engineered wood will degrade faster than those in low-use spaces. For example, laminate flooring in a busy kitchen may show signs of wear within 5–10 years, while the same material in a guest bedroom could last 15–20 years. To prolong life, use protective measures such as felt pads under furniture legs, rugs in heavy-traffic zones, and avoiding dragging sharp objects across surfaces.

Maintenance is the unsung hero of manufactured wood durability. Regular cleaning with a damp (not wet) cloth and mild detergent prevents dirt buildup, which can scratch surfaces over time. Avoid abrasive cleaners or excessive water, as these can strip protective finishes. For veneered pieces, refinishing every 5–7 years can restore appearance and protect against damage. Additionally, inspect for cracks or chips periodically, as these can allow moisture to penetrate and accelerate deterioration. Proper care can double the lifespan of manufactured wood, making it a cost-effective choice when maintained diligently.

In summary, the durability of manufactured wood hinges on a delicate balance of environmental conditions, material quality, usage intensity, and maintenance practices. By controlling moisture, choosing premium products, adapting usage habits, and implementing routine care, you can maximize its lifespan. While manufactured wood may not match the longevity of solid hardwood, strategic management ensures it remains a viable and long-lasting option for various applications.

Understanding the Lifespan of Wood Bison in the Wild

You may want to see also

Explore related products

Types of Manufactured Wood: Plywood, MDF, particleboard, and OSB vary in longevity based on composition

Manufactured wood products dominate construction and furniture industries, but their lifespans differ dramatically based on composition. Plywood, composed of thin wood veneers glued in alternating grain directions, typically lasts 30 to 50 years in structural applications. Its layered structure resists warping and splitting, making it ideal for flooring, roofing, and wall sheathing. However, exposure to moisture without proper sealing can reduce its lifespan to under a decade. For longevity, apply a waterproof sealant and avoid prolonged contact with water.

MDF (Medium-Density Fiberboard), made from wood fibers bonded with resin, offers a smooth surface perfect for painting and detailing but is highly susceptible to moisture. Indoors, MDF can last 20 to 30 years, but in humid environments like bathrooms or kitchens, it may degrade within 5 years. To maximize durability, use MDF only in dry areas and seal edges with paint or sealant. Its affordability and consistency make it a favorite for cabinetry and decorative trim, but it’s not suited for structural use.

Particleboard, the least durable of the group, consists of wood chips and resin pressed into sheets. Its lifespan ranges from 5 to 15 years, primarily due to its tendency to swell and disintegrate when exposed to moisture. Despite its fragility, particleboard is widely used in temporary furniture and low-cost shelving. For extended use, apply a moisture barrier and avoid placing it in areas prone to spills or humidity. Its low cost makes it practical for short-term applications but impractical for long-term structural needs.

OSB (Oriented Strand Board), made from compressed wood strands, rivals plywood in strength and is commonly used in sheathing and subflooring. With proper installation and moisture protection, OSB can last 30 to 60 years. Its rough texture and susceptibility to edge swelling require careful handling and sealing. Unlike MDF or particleboard, OSB performs well in exterior applications when treated with a water-resistant coating. Its durability and cost-effectiveness make it a staple in residential and commercial construction.

Understanding these differences allows for informed material selection based on application and environment. Plywood and OSB excel in structural roles, MDF shines in dry, decorative uses, and particleboard serves best in temporary or low-moisture settings. By matching the material to its intended use and applying appropriate protective measures, you can maximize longevity and avoid premature failure. Always consider moisture exposure, load requirements, and aesthetic needs when choosing among these manufactured wood types.

When Do Baby Wood Ducks Take Flight? A Timeline Guide

You may want to see also

Explore related products

Indoor vs. Outdoor Use: Indoor use extends life; outdoor exposure reduces durability due to weather

Manufactured wood, when used indoors, can last for decades, often outperforming its outdoor counterparts by a significant margin. The controlled environment of interiors shields it from the primary culprits of deterioration: moisture, temperature fluctuations, and UV radiation. For instance, laminate flooring, a common indoor application, can endure up to 25 years with proper care, while the same material exposed to outdoor conditions might degrade within 5–10 years. This stark contrast underscores the importance of matching the material to its intended environment.

Outdoor use of manufactured wood demands a different approach. Weather-resistant treatments, such as sealants and UV inhibitors, become essential to mitigate the effects of exposure. Even with these precautions, the lifespan is inherently shorter. For example, composite decking, designed specifically for outdoor use, typically lasts 15–20 years, compared to 30+ years for indoor engineered wood products. Regular maintenance, including resealing every 2–3 years and prompt cleaning after harsh weather, can help maximize durability but cannot fully replicate the protective benefits of indoor use.

The science behind this disparity lies in the material’s composition and its interaction with environmental factors. Manufactured wood often contains adhesives and binders that, while stable indoors, can break down under prolonged exposure to moisture and heat. For outdoor applications, selecting products with higher resin content or those specifically formulated for exterior use is critical. However, even these specialized options cannot match the longevity of indoor-only variants, making placement a key determinant of lifespan.

Practical considerations further highlight the indoor-outdoor divide. Indoor manufactured wood can be installed in areas with consistent humidity levels, ideally between 30–50%, to prevent warping or delamination. In contrast, outdoor installations require strategic placement, such as under partial shade or with proper drainage, to reduce weather impact. While indoor use offers a "set it and forget it" advantage, outdoor applications necessitate ongoing vigilance and intervention to preserve functionality and appearance.

Ultimately, the choice between indoor and outdoor use of manufactured wood hinges on balancing desired lifespan with intended application. For long-term, low-maintenance solutions, prioritize indoor use wherever possible. When outdoor use is unavoidable, invest in high-quality, weather-resistant products and commit to a rigorous maintenance schedule. Understanding these dynamics ensures that manufactured wood performs optimally, whether it’s underfoot in a living room or exposed to the elements on a patio.

Perfect Grilling: Soaking Wooden Skewers for Safe, Tasty Results

You may want to see also

Explore related products

$44.99 $59.99

Maintenance Tips: Regular cleaning, sealing, and avoiding water damage prolong manufactured wood life

Manufactured wood, when properly maintained, can rival the longevity of solid wood, often lasting 20 to 30 years or more. However, its lifespan hinges on consistent care, particularly in cleaning, sealing, and water damage prevention. Dust and debris accumulate over time, acting like sandpaper that gradually wears down the surface. Regular cleaning with a soft, damp cloth removes these abrasives, preserving the wood’s finish and structural integrity. Avoid harsh chemicals or abrasive scrubbers, as they can strip protective layers and expose the wood to moisture and decay.

Sealing is the unsung hero of manufactured wood maintenance. A high-quality sealant acts as a barrier against moisture, UV rays, and temperature fluctuations, which can cause warping, cracking, or delamination. Apply a sealant every 1–2 years, depending on exposure to elements. For outdoor furniture or flooring, use a marine-grade sealant for added durability. Indoor pieces benefit from a polyurethane or wax-based sealant, which enhances shine while protecting against spills and stains. Always sand lightly before reapplication to ensure proper adhesion.

Water damage is the arch-nemesis of manufactured wood, as it penetrates layers, causing swelling, mold, or structural failure. To avoid this, promptly wipe up spills and ensure the wood is never left in standing water. In high-moisture areas like kitchens or bathrooms, install waterproof barriers or use water-resistant manufactured wood varieties. For outdoor installations, elevate furniture on stands or use gravel bases to improve drainage. During rainy seasons, cover exposed pieces or store them indoors to minimize water exposure.

A proactive approach to maintenance not only extends the life of manufactured wood but also maintains its aesthetic appeal. Inspect surfaces quarterly for signs of wear, such as peeling sealant or water stains, and address issues immediately. For example, if you notice a crack in the sealant, reseal the area before moisture seeps in. Similarly, if a piece is frequently exposed to sunlight, rotate it periodically to prevent uneven fading. By integrating these practices into your routine, you ensure manufactured wood remains functional and beautiful for decades.

Bretton Woods Monetary System: Duration and Impact on Global Economy

You may want to see also

Explore related products

Average Lifespan: Typically lasts 10–30 years, depending on type, use, and care

Manufactured wood, a versatile and cost-effective alternative to solid wood, boasts a lifespan that varies widely—typically ranging from 10 to 30 years. This durability hinges on three critical factors: the type of manufactured wood, its application, and the level of care it receives. For instance, particleboard, often used in furniture, may degrade faster in humid environments due to its susceptibility to moisture. In contrast, medium-density fiberboard (MDF) can last closer to 20 years when properly sealed and maintained. Understanding these variables is key to maximizing the longevity of your investment.

To extend the life of manufactured wood, consider its intended use. High-traffic areas like kitchen cabinets or flooring demand materials designed for durability, such as laminate or plywood. For example, laminate flooring, when installed correctly and maintained with regular cleaning, can endure up to 25 years. Conversely, using particleboard for heavy-duty applications will likely result in premature wear and tear. Always match the material to the demand of its environment to avoid costly replacements.

Proper care is equally vital. Manufactured wood is prone to damage from moisture, heat, and scratches. To mitigate this, apply waterproof sealants to surfaces exposed to water, such as bathroom vanities. Use coasters and felt pads to protect furniture from scratches and heat damage. For outdoor applications, opt for treated or weather-resistant varieties like oriented strand board (OSB) with wax coatings. These simple precautions can add years to the material’s lifespan.

Finally, recognize that not all manufactured wood is created equal. Higher-quality products, though more expensive upfront, often outlast cheaper alternatives. For instance, premium MDF with enhanced resins can resist warping and cracking better than standard versions. Investing in better materials and adhering to manufacturer guidelines for installation and maintenance can significantly extend the product’s life, ensuring it remains functional and aesthetically pleasing for decades.

Cynthia Woods Mitchell Pavilion Concert Length: What to Expect

You may want to see also

Frequently asked questions

Manufactured wood, such as MDF, plywood, or particleboard, typically lasts 10 to 30 years, depending on the quality, usage, and environmental conditions.

No, manufactured wood generally does not last as long as solid wood. Solid wood can last for decades or even centuries, while manufactured wood is more prone to wear, moisture damage, and degradation over time.

The lifespan of manufactured wood is affected by factors like exposure to moisture, humidity, temperature fluctuations, quality of materials, and the type of adhesive used in its construction.

Yes, minor damage to manufactured wood can often be repaired with wood filler or glue. However, refinishing is limited compared to solid wood, as sanding can damage the thin veneer or laminate surface.

Manufactured wood is not ideal for outdoor use unless specifically treated for exterior conditions. Even then, it typically lasts only 5 to 10 years outdoors due to exposure to weather elements.