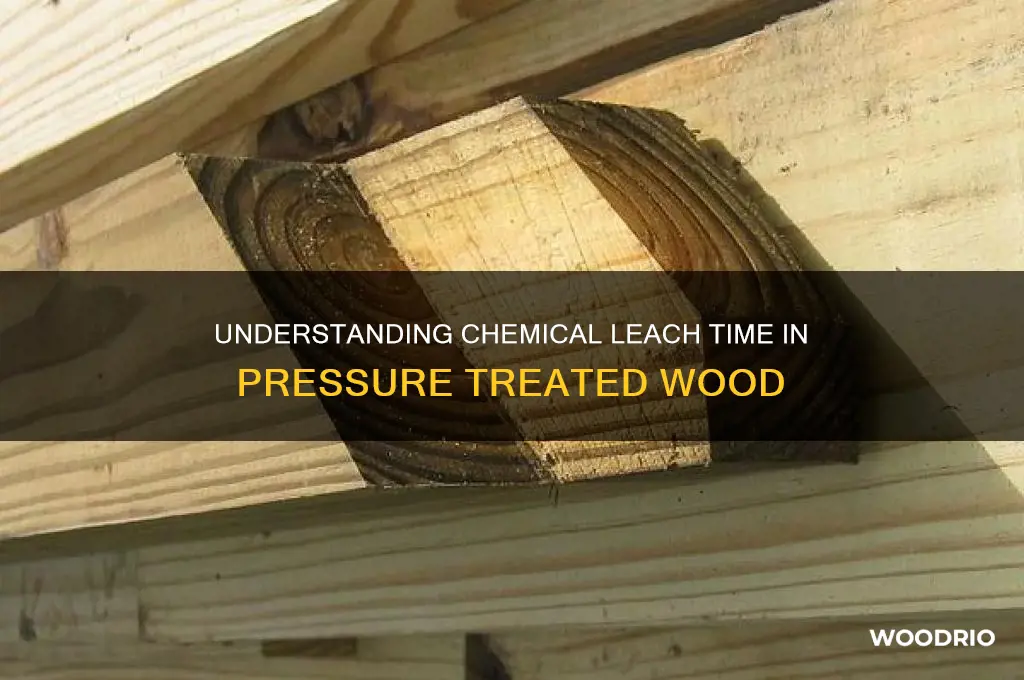

Pressure-treated wood is widely used in outdoor construction due to its durability and resistance to rot, insects, and decay. However, it is treated with chemicals like copper, chromium, and arsenic (CCA) or newer alternatives such as alkaline copper quaternary (ACQ) to achieve these properties. One common concern is how long these chemicals leach from the wood into the surrounding environment. Studies indicate that the leaching process is most active during the first few years after installation, gradually decreasing over time. Factors such as moisture, temperature, and exposure to elements influence the rate of leaching. While newer treatments like ACQ are considered less toxic and leach at slower rates, older CCA-treated wood can release arsenic for decades, raising environmental and health concerns. Understanding the leaching timeline is crucial for safe use and disposal of pressure-treated wood.

| Characteristics | Values |

|---|---|

| Leaching Duration | Varies; most leaching occurs within the first 2-5 years after treatment. |

| Primary Chemicals Leached | Arsenic, chromium, copper, and other preservatives (depending on treatment type). |

| Factors Affecting Leaching | Moisture exposure, temperature, soil pH, and wood type. |

| Environmental Impact | Can contaminate soil and water, especially in high-moisture areas. |

| Health Risks | Potential skin irritation, respiratory issues, or toxicity if ingested. |

| Reduction Over Time | Leaching significantly decreases after the initial years but may continue at lower rates for decades. |

| Modern Treatments | Newer treatments (e.g., ACQ, CA-B) leach less compared to older CCA-treated wood. |

| Regulatory Standards | Restricted use of CCA-treated wood for residential applications since 2003 in the U.S. |

| Mitigation Measures | Using barriers like liners, proper disposal, and avoiding use near water sources. |

| Detection Methods | Soil and water testing for chemical residues. |

Explore related products

What You'll Learn

- Leaching Timeline: How long does chemical release from treated wood persist after installation

- Factors Affecting Leaching: Does weather, soil type, or moisture impact chemical leaching rates

- Chemical Types: Which chemicals (e.g., CCA, ACQ) leach and at what levels

- Environmental Impact: How do leached chemicals affect soil, water, and nearby plants/animals

- Safety Precautions: What measures reduce exposure to leached chemicals from treated wood

Leaching Timeline: How long does chemical release from treated wood persist after installation?

Pressure-treated wood, a staple in outdoor construction, undergoes a process where chemicals are forced into the wood fibers to enhance durability against rot, insects, and decay. One of the most common concerns is how long these chemicals leach from the wood after installation. The leaching timeline varies based on factors like the type of treatment, environmental conditions, and the wood’s intended use. For instance, chromated copper arsenate (CCA)-treated wood, once widely used, can leach arsenic and other heavy metals for decades, though its residential use has been restricted since 2003. Newer treatments, like alkaline copper quaternary (ACQ) and copper azole (CA-B), leach copper at a slower rate, typically peaking in the first 1–3 years and tapering off significantly after 5–10 years.

Environmental conditions play a critical role in accelerating or slowing leaching. Rainfall, humidity, and soil acidity can increase chemical release, particularly in the first year after installation. For example, a study found that ACQ-treated wood in high-rainfall areas released up to 50% of its copper within the first 12 months, compared to 30% in drier climates. To mitigate this, consider installing treated wood in areas with good drainage or using barriers like landscaping fabric to reduce soil contact. Regularly sealing the wood with a water-repellent finish can also minimize leaching by reducing moisture penetration.

The intended use of the wood also influences the leaching timeline. Decking and playground structures, which are frequently exposed to moisture and wear, may leach chemicals more rapidly than fence posts or retaining walls. For high-contact applications, such as picnic tables or garden beds, opt for non-leaching alternatives like naturally rot-resistant woods (e.g., cedar or redwood) or composite materials. If using treated wood, allow it to weather for at least 6 months before using it in areas where food is prepared or consumed, as this reduces surface chemical residues.

Understanding the leaching timeline is crucial for safety and environmental considerations. While newer treatments are less toxic than CCA, copper leaching can still impact soil and water quality, particularly in aquatic ecosystems. For example, copper concentrations from ACQ-treated wood can reach levels harmful to aquatic life within 1–2 years in poorly drained areas. To minimize ecological impact, avoid using treated wood near water bodies or in areas prone to runoff. Regularly testing soil and water near treated wood installations can help monitor chemical levels and ensure compliance with local regulations.

In summary, the chemical release from pressure-treated wood persists for varying durations, depending on the treatment type, environmental conditions, and application. While leaching is most significant in the first few years, it can continue at lower rates for decades. By selecting appropriate treatments, managing installation conditions, and considering alternative materials for high-risk uses, you can balance durability with safety and environmental responsibility. Always follow manufacturer guidelines and local regulations to ensure proper handling and disposal of treated wood.

Drying Fresh Milled Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Factors Affecting Leaching: Does weather, soil type, or moisture impact chemical leaching rates?

Pressure-treated wood, commonly used in outdoor structures, is infused with chemicals like copper azole or alkaline copper quaternary (ACQ) to resist decay and insects. However, these chemicals can leach into the surrounding environment over time, raising concerns about their impact on soil, water, and ecosystems. Understanding the factors that influence leaching rates—weather, soil type, and moisture—is crucial for minimizing environmental risks and ensuring the longevity of treated wood installations.

Weather plays a significant role in chemical leaching from pressure-treated wood. Rainfall, for instance, accelerates leaching by washing chemicals from the wood surface into the soil or nearby water bodies. A study by the U.S. Environmental Protection Agency (EPA) found that heavy rainfall can increase leaching rates by up to 50% compared to drier conditions. Temperature also matters; higher temperatures can increase the solubility of chemicals, making them more prone to leaching. For example, in regions with hot, humid climates, copper leaching from ACQ-treated wood can be 30% higher than in cooler, drier areas. To mitigate this, consider installing treated wood in shaded areas or using protective coatings to reduce direct exposure to rain and sunlight.

Soil type is another critical factor affecting leaching rates. Sandy soils, with larger particles and greater porosity, allow chemicals to move more freely, increasing leaching potential. In contrast, clay soils, with smaller particles and higher cation exchange capacity, can bind chemicals more effectively, reducing leaching. A field study in *Environmental Science & Technology* revealed that copper leaching in sandy soils was twice as high as in clay soils over a five-year period. If you’re working in sandy soil, create a barrier, such as a geotextile fabric or gravel layer, between the wood and soil to minimize chemical migration.

Moisture levels in the environment directly impact leaching dynamics. Prolonged exposure to moisture, whether from rainfall, humidity, or groundwater, increases the likelihood of chemicals dissolving and leaching from the wood. For example, pressure-treated wood used in waterfront structures or areas with poor drainage can leach chemicals at rates 40% higher than in well-drained sites. To reduce moisture-related leaching, ensure proper site drainage, elevate wood structures where possible, and avoid using treated wood in direct contact with water bodies.

Practical tips for minimizing leaching include selecting the right treatment type for your climate and soil conditions. For instance, ACQ-treated wood is less prone to leaching in acidic soils compared to copper chromated arsenate (CCA)-treated wood. Additionally, follow manufacturer guidelines for installation, such as maintaining a 6-inch clearance between treated wood and soil or using corrosion-resistant fasteners to prevent chemical release. Regularly inspect treated wood structures for signs of wear or damage, as cracks and splinters can expose fresh wood surfaces, increasing leaching potential.

By considering these factors—weather, soil type, and moisture—you can make informed decisions to reduce chemical leaching from pressure-treated wood, protecting both your project and the environment. While leaching is inevitable to some degree, strategic planning and maintenance can significantly minimize its impact.

Durability of Wood Log Joints: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Chemical Types: Which chemicals (e.g., CCA, ACQ) leach and at what levels?

Pressure-treated wood, a staple in outdoor construction, relies on chemical preservatives to resist rot, insects, and decay. However, these chemicals can leach into the surrounding environment over time, raising concerns about their impact on soil, water, and human health. Understanding which chemicals leach and at what levels is crucial for informed decision-making.

Chromated Copper Arsenate (CCA): Once the most common preservative, CCA contains arsenic, chromium, and copper. Studies show that CCA-treated wood can leach arsenic at levels ranging from 0.5 to 5 parts per million (ppm) in the first few years after installation, gradually decreasing over time. Arsenic leaching is influenced by factors like moisture, pH, and wood-to-soil contact. While CCA is no longer used in residential settings due to health risks, older structures may still pose concerns, especially in playgrounds or gardens where children play.

Alkaline Copper Quaternary (ACQ): ACQ, a popular CCA alternative, uses copper and a quaternary ammonium compound. Copper leaching from ACQ-treated wood typically ranges from 1 to 10 ppm, with higher levels observed in the first year. Unlike arsenic, copper is less toxic but can still harm aquatic life if it accumulates in water bodies. To minimize leaching, avoid placing ACQ-treated wood in direct contact with water sources and use barriers like gravel or plastic sheeting.

Copper Azole (CA-B and CA-C): These preservatives combine copper with organic compounds like azoles. Leaching rates for copper from CA-treated wood are similar to ACQ, around 1 to 10 ppm, with azole compounds leaching at lower levels (0.1 to 1 ppm). While less toxic than arsenic, copper accumulation remains a concern, particularly in acidic soils where solubility increases. Regularly inspect CA-treated wood for signs of wear and reapply sealants to reduce leaching.

Sodium Borates: Used in interior applications, sodium borates leach more readily in wet conditions, with borate concentrations reaching up to 50 ppm in the first year. While borates are less toxic than heavy metals, prolonged exposure can harm plants and beneficial soil microorganisms. Limit the use of borate-treated wood in areas prone to moisture and consider using non-toxic alternatives for raised garden beds or compost bins.

Practical Tips: To mitigate chemical leaching, choose preservatives based on the application, seal treated wood with water-repellent coatings, and avoid cutting or sanding pressure-treated wood, as this exposes fresh surfaces to leaching. Regularly test soil and water near treated wood structures, especially in sensitive environments like gardens or near water bodies. By understanding the leaching behavior of different chemicals, you can balance durability with environmental and health considerations.

Understanding Wood Furniture Off-Gassing: Duration and Health Considerations

You may want to see also

Explore related products

Environmental Impact: How do leached chemicals affect soil, water, and nearby plants/animals?

Pressure-treated wood, commonly used in outdoor structures like decks and fences, releases chemicals such as arsenic, chromium, and copper into the environment over time. These leached substances can significantly alter soil chemistry, particularly by increasing pH levels and reducing nutrient availability for plants. For instance, arsenic, a known carcinogen, binds to soil particles, limiting its mobility but posing long-term risks to soil health. Studies show that soils near treated wood structures can accumulate arsenic at concentrations up to 100 mg/kg, far exceeding natural levels. This contamination not only disrupts microbial activity but also hinders the growth of essential soil organisms, creating a cascade of ecological imbalances.

In aquatic ecosystems, leached chemicals from pressure-treated wood can be particularly devastating. Copper, often used in modern treatments, is highly toxic to fish and aquatic invertebrates even at low concentrations (as little as 2-5 parts per billion). When rainwater carries these chemicals into nearby water bodies, it can cause acute toxicity in fish, leading to population declines. For example, a study in the Pacific Northwest found that runoff from treated wood decks contributed to copper levels in streams that exceeded EPA aquatic life criteria by 30%. Amphibians, such as frogs and salamanders, are also vulnerable, as their permeable skin absorbs contaminants directly from water, leading to developmental abnormalities and reduced survival rates.

Plants near pressure-treated wood structures often exhibit stunted growth and leaf discoloration due to chemical uptake from the soil. Arsenic, in particular, interferes with photosynthesis by inhibiting enzyme function, while copper can accumulate in plant tissues, causing toxicity. Gardeners and landscapers should maintain a buffer zone of at least 3 feet between treated wood and edible plants to minimize contamination risks. For example, tomatoes grown within 2 feet of treated wood have been found to contain arsenic levels up to 0.2 mg/kg, approaching the FDA’s limit for drinking water. Mulching and using physical barriers can further reduce chemical migration into plant root zones.

Wildlife exposure to leached chemicals occurs through ingestion of contaminated soil, water, or plants. Small mammals, such as rodents, may accumulate arsenic in their tissues, which then biomagnifies as predators consume them. Birds nesting in structures made of treated wood can experience reduced reproductive success, with studies showing thinner eggshells and lower hatch rates in areas with high chemical leaching. To mitigate these risks, consider using alternative materials like naturally rot-resistant wood (e.g., cedar or redwood) or composite lumber for outdoor projects. If pressure-treated wood is necessary, seal all cut ends and surfaces with a non-toxic sealant to minimize chemical release.

Long-term environmental monitoring is essential to understand the cumulative effects of leached chemicals from pressure-treated wood. Homeowners and builders can play a role by choosing environmentally friendly alternatives and adopting best practices, such as proper disposal of treated wood scraps and avoiding use near water sources. Regulatory agencies should also update guidelines to reflect current research, such as reducing allowable copper concentrations in treated wood products. By taking proactive steps, we can minimize the ecological footprint of these widely used materials and protect soil, water, and wildlife for future generations.

Durability of Kiln Dried Wood: Outdoor Lifespan and Preservation Tips

You may want to see also

Explore related products

Safety Precautions: What measures reduce exposure to leached chemicals from treated wood?

Pressure-treated wood, while durable and widely used, releases chemicals like arsenic, chromium, and copper over time, posing risks through skin contact, inhalation, or ingestion. To minimize exposure, prioritize physical barriers and mindful handling. Wear gloves, long sleeves, and a dust mask when cutting, sanding, or drilling treated wood to prevent skin absorption and inhalation of particles. After handling, wash hands thoroughly with soap and water, and launder contaminated clothing separately to avoid cross-contamination.

For outdoor structures like decks or playgrounds, consider sealing the wood with a non-toxic, water-repellent sealant annually. This reduces chemical leaching by minimizing moisture penetration, which accelerates the release of preservatives. Avoid using treated wood for raised garden beds or surfaces where food is prepared, as chemicals can migrate into soil or come into direct contact with consumables. Opt for naturally rot-resistant woods like cedar or redwood in these applications instead.

In high-traffic areas, such as children’s play structures, install a physical barrier like rubber mats or gravel beneath the wood to limit direct contact with soil and reduce the risk of chemical transfer. Regularly inspect and maintain these structures, replacing worn or damaged boards promptly. For added safety, ensure play areas are well-ventilated to disperse any airborne particles, and discourage children from putting hands or objects in their mouths after touching treated wood.

Finally, dispose of treated wood scraps responsibly. Never burn pressure-treated wood, as this releases toxic fumes into the air. Instead, check local regulations for designated disposal sites or recycling programs. By combining these measures—protective gear, sealing, barriers, and proper disposal—you can significantly reduce exposure to leached chemicals and safely enjoy the benefits of treated wood.

Transforming Wood Chips into Mulch: Timing and Process Explained

You may want to see also

Frequently asked questions

Pressure treated wood typically leaches chemicals for 3 to 5 years after installation, depending on the type of treatment and environmental conditions.

While the chemicals leached from pressure treated wood are generally considered safe in small amounts, prolonged exposure or ingestion can pose health risks. It’s best to avoid direct contact with the wood during the initial leaching period.

Yes, sealing the wood with a water-repellent sealant or allowing it to weather naturally can minimize chemical leaching. Proper installation and maintenance also help reduce exposure.