Satin wood finish is a popular choice for enhancing the appearance and durability of wooden surfaces, offering a smooth, low-sheen look that complements various styles. One common question among DIY enthusiasts and professionals alike is how long it takes for satin wood finish to cure fully. The curing time can vary depending on factors such as the specific product used, humidity levels, temperature, and ventilation. Generally, satin wood finishes can be dry to the touch within 2 to 4 hours, but achieving a full cure typically takes between 24 to 48 hours. For optimal results, it’s essential to follow the manufacturer’s guidelines and allow sufficient time for the finish to harden completely before subjecting the surface to heavy use or additional coats.

| Characteristics | Values |

|---|---|

| Cure Time (Light Traffic) | 24-48 hours |

| Full Cure Time | 7-14 days (varies by brand, temperature, and humidity) |

| Recoat Time | 2-4 hours (light sanding recommended between coats) |

| Drying Time (Touch Dry) | 2-4 hours |

| Factors Affecting Cure Time | Temperature, humidity, wood type, thickness of application |

| Optimal Conditions | 70°F (21°C) and 50% humidity |

| Accelerating Cure Time | Use of fans, heaters, or low-VOC products |

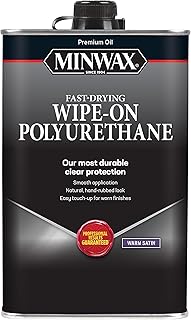

| Common Brands | Minwax, Varathane, Deft (cure times may vary slightly by manufacturer) |

| Finish Type | Satin (semi-gloss with a smooth, low-sheen appearance) |

| Recommended Uses | Furniture, cabinetry, trim, and interior woodwork |

Explore related products

$22.97

What You'll Learn

- Ideal Curing Conditions: Temperature, humidity, and ventilation impact satin wood finish curing time significantly

- Drying vs. Curing: Drying takes hours; full curing requires days to weeks for durability

- Coat Application Time: Allow 2-4 hours between coats for proper adhesion and finish

- Light Use Timing: Safe for light use after 24-48 hours, but avoid heavy contact

- Full Cure Duration: Satin wood finish fully cures in 7-14 days under optimal conditions

Ideal Curing Conditions: Temperature, humidity, and ventilation impact satin wood finish curing time significantly

Satin wood finish curing is a delicate dance influenced by environmental factors, primarily temperature, humidity, and ventilation. These elements can either accelerate or hinder the process, affecting the final quality of the finish. Understanding their roles is crucial for achieving optimal results.

Temperature plays a pivotal role in the curing process. Ideal conditions typically range between 70°F and 80°F (21°C and 27°C). At this range, the chemical reactions necessary for curing occur at a steady pace. Lower temperatures, below 60°F (15°C), can significantly slow down curing, often doubling or tripling the time required. Conversely, higher temperatures, above 90°F (32°C), can cause the finish to dry too quickly, leading to imperfections like bubbling or cracking. For instance, a satin wood finish applied in a 75°F (24°C) room with controlled conditions may cure fully within 24 to 48 hours, whereas the same finish in a 50°F (10°C) garage could take up to 72 hours or more.

Humidity levels are equally critical. Relative humidity should ideally be kept between 50% and 70%. High humidity, above 70%, can prevent proper evaporation of solvents, leading to a tacky or uneven finish. Low humidity, below 50%, can cause the finish to dry too rapidly, resulting in a brittle surface. For example, in a humid environment, using a dehumidifier can help maintain optimal conditions, while in dry climates, a humidifier or damp cloth placed nearby can add necessary moisture. Monitoring humidity with a hygrometer ensures the environment remains within the ideal range.

Ventilation is often overlooked but is essential for curing. Proper airflow helps dissipate fumes and ensures even drying. Inadequate ventilation can trap solvents, prolonging curing time and potentially causing a cloudy finish. A well-ventilated space, such as a room with open windows or a fan circulating air, promotes faster and more uniform curing. For enclosed spaces, using an exhaust fan or air mover can significantly improve conditions. However, avoid drafts directly on the drying surface, as they can cause dust to settle or the finish to dry unevenly.

Practical tips for achieving ideal curing conditions include planning the finishing process during mild weather, using space heaters or coolers to regulate temperature, and employing humidifiers or dehumidifiers as needed. Additionally, applying thin, even coats of finish and allowing sufficient drying time between coats can mitigate issues caused by suboptimal conditions. For professional results, consider using a dedicated finishing room or tent with controlled temperature, humidity, and ventilation.

In summary, mastering the ideal curing conditions for satin wood finish requires attention to temperature, humidity, and ventilation. By maintaining a temperature between 70°F and 80°F, humidity between 50% and 70%, and ensuring proper airflow, you can significantly reduce curing time and enhance the finish’s durability and appearance. These specifics transform a potentially frustrating process into a predictable and rewarding one.

Air Drying Elm Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Drying vs. Curing: Drying takes hours; full curing requires days to weeks for durability

Satin wood finishes, like many coatings, undergo two distinct phases: drying and curing. Drying is the initial evaporation of solvents, a process that typically takes 2-6 hours depending on humidity, temperature, and airflow. During this time, the surface becomes dry to the touch, but the finish is still soft and vulnerable. Curing, however, is a chemical process where the finish hardens fully, achieving maximum durability. This stage can take 7-21 days, with some finishes requiring up to 30 days for complete curing. Understanding this difference is crucial for avoiding premature wear or damage.

To illustrate, imagine applying a satin finish to a dining table. After 4 hours, the surface may feel dry, tempting you to place objects on it. But without allowing the full curing period, heat from a coffee mug or scratches from utensils could mar the finish. Manufacturers often recommend waiting 72 hours before light use and 2 weeks before heavy use. Accelerating drying with fans or heat can speed up the first phase but won’t shorten curing time, which relies on chemical reactions.

Practical tips can help optimize both processes. Maintain a temperature of 70-75°F (21-24°C) and humidity around 50% for ideal conditions. Avoid high humidity, which slows drying, or low humidity, which can cause cracking. Light sanding between coats (if applicable) ensures better adhesion, but always follow product-specific instructions. For example, oil-based finishes cure slower than water-based ones, so plan accordingly.

Comparing drying and curing highlights their distinct roles. Drying is about convenience—when you can handle the piece. Curing is about longevity—when the finish reaches its full protective potential. Think of drying as the first act and curing as the finale. Skipping the finale means the finish won’t perform as intended, especially in high-traffic areas like floors or countertops.

In conclusion, patience is key when working with satin wood finishes. While drying times are short, curing demands a longer commitment. Treat the finish gently during the curing phase, avoiding harsh chemicals, heavy objects, or excessive moisture. By respecting these timelines, you ensure a durable, beautiful result that stands the test of time.

Minwax Wood Filler Drying Time: Quick Guide for Perfect Results

You may want to see also

Explore related products

Coat Application Time: Allow 2-4 hours between coats for proper adhesion and finish

Applying multiple coats of satin wood finish is a delicate balance of patience and precision. Rushing the process by layering coats too quickly can lead to a host of issues: uneven drying, bubbling, or a tacky surface that never fully cures. The recommended 2-4 hour window between coats isn't arbitrary – it's the sweet spot for allowing the solvents in the finish to evaporate while the resins bond properly to the wood and each subsequent layer.

Skipping this waiting period can trap moisture between coats, leading to adhesion failure and a finish that peels or cracks over time.

Think of each coat as a thin, protective film. Allowing adequate drying time ensures these films bond together seamlessly, creating a strong, durable finish. Imagine trying to glue two pieces of paper together while the glue is still wet – they'll slip and slide, never forming a strong bond. The same principle applies to wood finish.

Rushing the process might save you a few hours upfront, but it could cost you days of sanding and reapplication down the line.

For optimal results, consider environmental factors. Humidity and temperature play a significant role in drying time. In humid conditions, err on the side of caution and allow closer to 4 hours between coats. Cooler temperatures will also slow drying, so plan accordingly. If you're unsure, a simple touch test can be helpful: lightly touch the surface with your fingertip. If it feels tacky or leaves an imprint, it's not ready for another coat.

Remember, patience is key to achieving a beautiful, long-lasting satin wood finish.

Detoxing Your Body with Rae Wood: Understanding the Timeline

You may want to see also

Explore related products

Light Use Timing: Safe for light use after 24-48 hours, but avoid heavy contact

Satin wood finishes are prized for their smooth, low-sheen appearance, but their durability depends on proper curing. While full cure times can stretch to weeks, light use can often begin much sooner. The 24-48 hour mark is a critical window for satin finishes, offering a balance between practicality and protection.

Understanding this timeframe allows you to reintroduce furniture to your space without compromising the finish's integrity.

Imagine a freshly refinished dining table. After 24 hours, the satin finish has dried to the touch, but it's still vulnerable. Light use, such as placing a tablecloth or setting down a vase, is generally safe. However, avoid dragging heavy objects across the surface or placing hot dishes directly on the wood. These actions can mar the finish, leaving scratches or heat marks that detract from its beauty.

Think of it like a freshly painted wall – you wouldn't lean a ladder against it immediately after painting.

The 24-48 hour window is a period of gradual hardening. During this time, the finish is transitioning from a liquid to a solid state. While it may feel dry, the chemical curing process continues beneath the surface. This is why heavy contact, which can exert pressure and cause indentations, should be avoided. Think of it as a delicate pastry cooling – it needs time to set properly before it can withstand handling.

For optimal results, aim for the full 48 hours before subjecting the finished piece to more substantial use.

To ensure the longevity of your satin wood finish, consider these practical tips:

- Plan Ahead: If you're refinishing furniture for a specific event, factor in the 24-48 hour light use period.

- Use Coasters and Placemats: Protect surfaces from scratches and heat damage, especially during this initial curing phase.

- Avoid Harsh Chemicals: Steer clear of abrasive cleaners or solvents that can damage the finish.

- Be Patient: While it's tempting to use your newly finished piece immediately, allowing for proper curing will ensure its beauty and durability for years to come.

Exploring the Lifespan of Wood Elves in Dungeons & Dragons

You may want to see also

Explore related products

$13.97 $17.99

Full Cure Duration: Satin wood finish fully cures in 7-14 days under optimal conditions

Satin wood finish, a popular choice for its smooth, low-sheen appearance, requires patience for optimal results. While it may feel dry to the touch within hours, achieving a full cure—where the finish reaches maximum hardness and durability—takes significantly longer. Under ideal conditions, this process spans 7 to 14 days.

Understanding the Cure Process

The curing of satin wood finish is a chemical reaction where solvents evaporate and binders harden. Optimal conditions—temperatures between 70–75°F (21–24°C) and humidity levels around 50%—accelerate this process. Lower temperatures or higher humidity can extend curing time, as the chemical reactions slow down. For instance, in a cool, damp basement, curing may take closer to 14 days or even longer.

Practical Tips for Faster Curing

To ensure a full cure within the 7–14 day window, control the environment. Use a dehumidifier if humidity exceeds 60%, and maintain consistent warmth with a space heater if temperatures drop below 65°F (18°C). Avoid placing finished pieces in direct sunlight, as this can cause uneven drying and potential discoloration. Additionally, ensure proper ventilation to aid solvent evaporation without introducing dust or debris.

Why Full Cure Matters

Rushing the curing process can compromise the finish’s durability. A fully cured satin wood finish is more resistant to scratches, stains, and wear. For high-traffic items like tabletops or cabinets, waiting the full 14 days ensures the finish can withstand daily use. Premature use of the piece may result in fingerprints, smudges, or damage that requires reapplication.

Testing for Full Cure

To confirm the finish is fully cured, perform a simple test. Press a fingernail gently into an inconspicuous area. If no indentation remains, the finish is cured. Alternatively, place a drop of water on the surface; if it beads up and wipes away cleanly, the cure is complete. This method ensures you’re not relying solely on time but on the finish’s actual readiness.

By respecting the 7–14 day curing window and optimizing conditions, you’ll achieve a satin wood finish that not only looks elegant but also stands the test of time. Patience in this step is the key to a professional, long-lasting result.

Playground Wood Chips Lifespan: Durability, Maintenance, and Replacement Guide

You may want to see also

Frequently asked questions

Satin wood finish usually takes 24 to 48 hours to cure enough for light use, but full curing can take 7 to 14 days, depending on humidity, temperature, and thickness of application.

A: Yes, you can speed up curing by ensuring good ventilation, maintaining a warm temperature (around 70°F or 21°C), and using a fan to circulate air, but avoid excessive heat, which can cause bubbling or uneven drying.

A: Yes, satin wood finish is generally safe to touch after 24 hours, but it may still feel slightly tacky. Avoid heavy use or placing objects on it until fully cured (7–14 days).

A: Satin wood finish is fully cured when it feels hard, smooth, and no longer tacky to the touch. Test a small area with your fingernail—if no imprint is left, it’s fully cured.

![12.25 Oz Clear Wood Finish Satin [Set of 6]](https://m.media-amazon.com/images/I/71A10edQXrL._AC_UL320_.jpg)