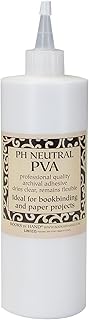

PVA (Polyvinyl Acetate) glue is a popular adhesive for woodworking projects due to its strong bonding capabilities and ease of use. When applying PVA glue to wood, one common question that arises is how long it takes to dry. The drying time of PVA glue on wood can vary depending on several factors, including the thickness of the glue layer, humidity levels, temperature, and the type of wood being used. Generally, PVA glue begins to set within 15 to 30 minutes under normal room conditions, but it can take anywhere from 1 to 24 hours to fully cure and reach maximum strength. Proper clamping and ensuring optimal environmental conditions can significantly influence the drying process, making it essential to plan accordingly for the best results in woodworking projects.

| Characteristics | Values |

|---|---|

| Initial Tack Time | 10-30 minutes (depending on humidity, temperature, and wood type) |

| Clamp Time | 30 minutes to 2 hours (for sufficient bond strength) |

| Full Cure Time | 24 hours (for maximum strength) |

| Drying Time in High Humidity | Longer (up to 48 hours) |

| Drying Time in Low Humidity | Shorter (as fast as 1-2 hours for initial set) |

| Temperature Impact | Faster drying at higher temperatures (e.g., 70°F/21°C or above) |

| Wood Type Impact | Dense woods (e.g., oak) may take longer than softwoods (e.g., pine) |

| Glue Thickness | Thicker applications take longer to dry |

| Ventilation Effect | Good airflow can speed up drying time |

| Bond Strength After 24 Hours | Typically reaches 80-90% of maximum strength |

| Water Resistance | Not fully waterproof; may take longer to dry in damp conditions |

| Accelerated Drying Methods | Using a hairdryer or warm environment can reduce drying time |

Explore related products

$9.78

What You'll Learn

Factors Affecting Drying Time

The drying time of PVA glue on wood is not a fixed constant but a variable influenced by several key factors. Understanding these can help you optimize your gluing process for efficiency and strength. One of the most significant factors is humidity. High humidity slows down evaporation, the primary mechanism by which PVA glue dries. In environments with relative humidity above 60%, drying times can double or even triple, extending from the typical 30 minutes to several hours. Conversely, low humidity accelerates drying but can lead to surface cracking if the glue dries too quickly.

Another critical factor is temperature. PVA glue dries faster at higher temperatures because heat increases molecular activity, speeding up the evaporation of water. At room temperature (20–25°C or 68–77°F), PVA glue typically dries to the touch within 30–60 minutes. However, at 30°C (86°F), this time can reduce to 15–30 minutes. For faster drying, consider using a hairdryer on a low setting or placing the glued piece in a warm, well-ventilated area. Avoid excessive heat, as temperatures above 50°C (122°F) can degrade the glue’s adhesive properties.

The thickness of the glue layer also plays a role. Thin, even applications dry faster than thick beads or clumps. Aim for a layer no thicker than 0.5 mm to ensure optimal drying. If you’re joining large surfaces, spread the glue evenly with a notched trowel or spatula to avoid pooling, which can prolong drying time and weaken the bond. For small joints, a thin, consistent coat applied with a brush or roller is ideal.

The type of wood and its moisture content can further affect drying time. Porous woods like pine absorb moisture more readily, potentially slowing drying as the wood competes with the glue for moisture evaporation. Dense woods like oak or maple dry faster because they absorb less water. Additionally, wood with high moisture content (above 12%) can dilute the glue, weakening its bond and extending drying time. Always use wood with a moisture content of 8–12% for best results.

Finally, air circulation is often overlooked but crucial. Stagnant air traps moisture, slowing evaporation. Ensure your workspace is well-ventilated, or use a fan to promote airflow around the glued area. This simple step can reduce drying time by up to 20%. However, avoid directing the fan too close to the glue, as this can cause uneven drying and surface imperfections. By controlling these factors—humidity, temperature, glue thickness, wood type, and air circulation—you can significantly influence the drying time of PVA glue on wood, ensuring a strong, durable bond.

Seasoning Fur Wood: Understanding the Time Required for Optimal Results

You may want to see also

Explore related products

Ideal Conditions for Quick Drying

The drying time of PVA glue on wood can be significantly reduced by creating an environment that promotes evaporation and curing. Temperature plays a pivotal role in this process. At room temperature (around 20-25°C or 68-77°F), PVA glue typically takes 30 minutes to 1 hour to set and 24 hours to fully cure. However, increasing the temperature to 30-35°C (86-95°F) can halve the setting time to 15-30 minutes, though full curing still requires a day. For projects needing quicker turnaround, a warm, well-ventilated workspace is essential. Avoid excessive heat, as temperatures above 40°C (104°F) can degrade the glue’s adhesive properties.

Humidity levels are another critical factor. PVA glue dries through evaporation of water, so low humidity (below 50%) accelerates drying. In high-humidity environments (above 70%), drying time can double. To combat this, use a dehumidifier or work in a climate-controlled space. If outdoor conditions are unavoidable, schedule gluing during drier parts of the day, such as early morning or late afternoon. Adding a small fan to direct airflow over the glued area can also enhance evaporation without disturbing the bond.

The application technique directly impacts drying speed. Thin, even layers of PVA glue dry faster than thick beads. Use a brush or roller to spread the glue uniformly, ensuring no excess pools on the surface. For edge gluing or joinery, clamp the pieces tightly to squeeze out excess glue, which reduces drying time and improves bond strength. Wipe away any squeezed-out glue immediately to prevent it from hardening and becoming difficult to remove.

Preparation of the wood surface can also expedite drying. Ensure the wood is clean, dry, and free of dust or oils, as contaminants can hinder adhesion and prolong drying. Lightly sanding the surface before gluing increases surface area, allowing the glue to bond more effectively. If time is critical, pre-warm the wood to room temperature or slightly above, as cold wood can slow the curing process.

Finally, consider the type of PVA glue used. Standard white PVA glues dry slower than specialized formulations like aliphatic resin or fast-drying variants. Fast-drying PVA glues can set in as little as 5-10 minutes and cure within 12 hours, making them ideal for time-sensitive projects. Always follow manufacturer instructions for optimal application and drying conditions, as formulations vary. By combining these strategies—temperature control, humidity management, proper application, surface preparation, and glue selection—you can achieve quick and reliable drying of PVA glue on wood.

Cedar Wood Durability: How Long Does It Last Outdoors?

You may want to see also

Explore related products

Drying Time for Thick vs. Thin Layers

The thickness of PVA glue application on wood directly influences drying time, a critical factor for project timelines and bond strength. Thin layers, typically less than 1mm, dry to the touch within 20–30 minutes under standard conditions (20°C and 50% humidity). Full curing, however, takes 12–24 hours, as moisture evaporates and polymers cross-link. Thick layers, exceeding 2mm, can remain tacky for 2–4 hours and require 24–48 hours for complete curing. Excess glue acts as an insulator, trapping moisture and slowing evaporation, which delays drying and weakens the bond if not managed properly.

To optimize drying, consider the application method. For thin layers, use a brush or roller to spread glue evenly, ensuring maximum wood contact without excess. Thick layers, often unavoidable in gap-filling or joint reinforcement, benefit from clamping pressure to expel air and excess adhesive. A practical tip: mix PVA with a small amount of water (10–15% by volume) for thin applications to enhance penetration and reduce surface drying time. For thick layers, apply heat gently (e.g., a hairdryer on low setting) to accelerate moisture evaporation, but avoid overheating, which can degrade the glue’s properties.

Comparing the two, thin layers are ideal for precision work like veneering or laminating, where quick tack and strong bonding are essential. Thick layers, while slower to dry, are better suited for structural repairs or filling voids, provided adequate clamping and curing time. A cautionary note: over-application of thick layers can lead to shrinkage cracks or weak spots, so always apply the minimum necessary to achieve the desired bond.

In real-world scenarios, environmental factors exacerbate the difference in drying times. High humidity or cold temperatures can double drying times for both thin and thick layers, while warm, dry conditions expedite the process. For instance, a thin layer might dry in 10–15 minutes at 30°C and 20% humidity, whereas a thick layer could take 6–8 hours under the same conditions. Always test drying times on scrap wood before committing to a project, especially when working with thick applications or in non-ideal environments.

Ultimately, understanding the drying dynamics of PVA glue on wood empowers crafters and woodworkers to choose the right application thickness for their needs. Thin layers offer speed and precision, while thick layers provide gap-filling strength—but patience is key. By balancing application technique, environmental control, and curing time, you can achieve durable, professional results regardless of the layer thickness.

Vinyl vs. Wood Fences: Which Material Offers Longer Durability?

You may want to see also

Explore related products

Accelerating PVA Glue Drying Process

PVA glue typically takes 30 minutes to 2 hours to dry on wood, depending on factors like humidity, temperature, and glue thickness. However, when time is of the essence, accelerating the drying process becomes crucial. One effective method is to increase the ambient temperature. PVA glue dries faster in warmer conditions because heat accelerates the evaporation of water, a key component of the glue. Aim for a temperature range of 70°F to 90°F (21°C to 32°C) for optimal results. Using a hairdryer on a low setting or placing the glued wood near a heater can expedite drying without damaging the wood or glue bond.

Another practical approach involves reducing humidity, as moisture in the air slows down the drying process. Dehumidifiers or air conditioners can create a drier environment, particularly useful in workshops or areas with high humidity. For smaller projects, placing the glued wood in an oven set to a low temperature (around 150°F or 65°C) for 10–15 minutes can significantly speed up drying. However, this method requires caution to avoid overheating, which can weaken the bond or damage the wood. Always monitor the process closely to prevent accidents.

Applying thin, even layers of PVA glue is a simple yet effective technique to accelerate drying. Thick globs of glue take longer to dry and can create uneven bonds. Use a brush or roller to spread the glue uniformly, ensuring complete coverage without excess. Additionally, clamping the wood pieces together firmly reduces gaps and allows the glue to dry more efficiently. This method not only speeds up drying but also enhances the strength of the bond.

For those seeking a chemical solution, adding a PVA glue accelerator to the mix can drastically reduce drying time. These accelerators, often containing compounds like ammonium chloride or aluminum sulfate, react with the glue to speed up curing. Follow the manufacturer’s instructions carefully, as overuse can compromise the bond’s integrity. Typically, adding 1–2% accelerator by weight of the glue is sufficient for most applications. This method is ideal for professionals or hobbyists working on time-sensitive projects.

Lastly, combining multiple techniques can yield the best results. For instance, applying a thin layer of glue, clamping the wood, and using a fan to circulate warm air creates an optimal drying environment. Experimenting with these methods allows users to tailor the process to their specific needs, ensuring strong, durable bonds in minimal time. Whether for DIY projects or professional woodworking, accelerating PVA glue drying is both an art and a science, requiring attention to detail and a bit of creativity.

Wood Casket Durability: Lifespan in the Ground Explained

You may want to see also

Explore related products

$11.43 $12.07

Testing if PVA Glue is Fully Dry

PVA glue, a staple in woodworking, typically takes 1-2 hours to dry to the touch and 24 hours to fully cure, depending on factors like humidity, temperature, and wood porosity. However, relying solely on time can be misleading. To ensure your project is ready for the next step, testing the glue’s dryness is essential. Here’s how to do it accurately.

Step 1: The Touch Test

Gently press the glued area with your fingertip. If the surface feels hard and resists indentation, the glue is likely dry to the touch. However, this doesn’t confirm full curing. For a more precise test, press firmly but briefly—if no glue oozes out or the surface remains unchanged, it’s a good initial indicator. Avoid this method if the wood is delicate or the joint is critical, as pressure could weaken the bond.

Step 2: The Sound Test

Tap the glued joint lightly with a wooden or plastic tool. A clear, sharp sound indicates the glue has dried and the bond is strong. A dull or hollow sound suggests the glue is still soft or the bond is incomplete. This method is particularly useful for larger pieces where visual inspection is difficult.

Step 3: The Visual and Flex Test

Inspect the joint for any visible gaps or glue residue. If the bond looks seamless, gently flex the joint. Apply minimal pressure to test its strength. If the joint holds without shifting or cracking, the glue is likely fully cured. Be cautious with this test on delicate or intricate pieces, as excessive force could damage the wood.

Cautions and Takeaway

While these tests are reliable, always err on the side of caution. If in doubt, allow additional drying time, especially in humid or cold conditions. Rushing the process can compromise the bond’s integrity. For critical projects, follow the manufacturer’s guidelines and consider using a hairdryer on low heat to expedite drying, but avoid overheating, which can weaken the glue. By combining these tests, you’ll ensure your PVA glue is fully dry and your woodwork is ready for finishing or use.

Understanding the Lifespan of Cottonwood Trees: A Comprehensive Guide

You may want to see also

Frequently asked questions

PVA glue usually takes 1-2 hours to dry to the touch on wood, but it requires 24 hours for a full cure and maximum strength.

Yes, high humidity or low temperatures can slow down the drying process, while warm and dry conditions can speed it up.

Yes, you can use a fan, heater, or place the project in a warm, dry area to accelerate drying, but avoid excessive heat as it may weaken the bond.

![[8.5 oz] Book Binding Glue, PH Neutral PVA Glue, Strong & Permanent Bond Bookbinding Adhesive Repair, Acid-Free, Dries Clear & Flexible for Book Repair, Framing, Collages, Paper Crafts and Art](https://m.media-amazon.com/images/I/61dmUQk5pKL._AC_UL320_.jpg)