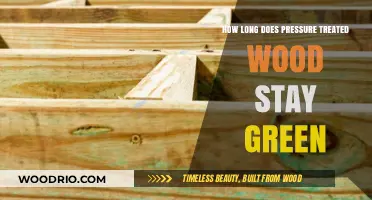

Rubber wood, derived from the Pará rubber tree (*Hevea brasiliensis*), is a popular and sustainable material widely used in furniture, flooring, and kitchenware due to its durability, affordability, and eco-friendly nature. Its longevity depends on various factors, including the quality of the wood, environmental conditions, and maintenance practices. When properly treated and cared for, rubber wood can last for decades, often rivaling the lifespan of harder woods like oak or maple. However, exposure to moisture, extreme temperatures, or pests can significantly reduce its durability. Understanding its lifespan and how to preserve it is essential for maximizing its value and ensuring it remains a reliable choice for both residential and commercial applications.

| Characteristics | Values |

|---|---|

| Durability | 10-15 years (with proper care), up to 25 years in optimal conditions |

| Resistance to Moisture | Moderate; not suitable for outdoor use without treatment |

| Resistance to Pests | Naturally resistant to termites and fungi |

| Hardness | Janka hardness rating of 980 lbf (softer than oak but harder than pine) |

| Maintenance Required | Regular sealing or oiling to prevent drying and cracking |

| Environmental Impact | Sustainable and eco-friendly, as it’s a byproduct of rubber production |

| Cost | Affordable compared to hardwoods like oak or maple |

| Common Uses | Furniture, kitchen utensils, flooring, and decorative items |

| Susceptibility to Scratches | Prone to scratches and dents due to its softer nature |

| Color and Grain | Light color with a fine, straight grain that darkens over time |

| Workability | Easy to work with, sands, stains, and finishes well |

| Weight | Lightweight compared to denser hardwoods |

| Stability | Less stable than some hardwoods; may warp or crack if exposed to extreme conditions |

| Fire Resistance | Low; burns relatively easily |

| Availability | Widely available due to its sustainable sourcing |

Explore related products

What You'll Learn

Rubber Wood Durability Factors

Rubber wood, derived from the Hevea brasiliensis tree, is a popular choice for furniture and cabinetry due to its sustainability and affordability. However, its durability hinges on several critical factors that determine how well it withstands time and use. Understanding these factors can help you maximize the lifespan of rubber wood products, ensuring they remain functional and aesthetically pleasing for years.

Moisture Management: The Achilles’ Heel

Rubber wood’s susceptibility to moisture is its most significant vulnerability. Prolonged exposure to humidity or water can cause warping, cracking, or mold growth. To mitigate this, maintain indoor humidity levels between 40–60% using dehumidifiers or humidifiers as needed. For outdoor use, apply a high-quality sealant every 6–12 months to create a protective barrier. Avoid placing rubber wood furniture in damp areas like basements or near windows prone to condensation.

Finish and Maintenance: The Protective Shield

The type and quality of finish applied to rubber wood dramatically influence its durability. Polyurethane, varnish, or oil-based finishes provide excellent protection against scratches, stains, and moisture. Reapply finishes every 2–3 years, or sooner if signs of wear appear. Regular cleaning with a soft, damp cloth and mild soap prevents dirt buildup, while avoiding harsh chemicals preserves the wood’s integrity.

Structural Integrity: Joinery and Construction

The way rubber wood is assembled plays a pivotal role in its longevity. Traditional joinery techniques like dovetail or mortise-and-tenon joints offer superior strength compared to staples or glue alone. Inspect furniture for loose joints or cracks, and repair them promptly to prevent further damage. Reinforcing high-stress areas, such as table legs or drawer bottoms, with metal brackets can extend the life of the piece.

Environmental Conditions: Beyond the Surface

Rubber wood’s durability is also affected by its environment. Direct sunlight can cause fading and drying, leading to brittleness over time. Use curtains or UV-protective coatings to shield furniture from harsh rays. Temperature fluctuations can stress the wood, so avoid placing it near heat sources like radiators or fireplaces. For outdoor applications, consider using rubber wood treated with preservatives to enhance resistance to weather and pests.

By addressing these durability factors—moisture, finish, construction, and environment—you can ensure rubber wood remains a reliable and long-lasting material. With proper care, rubber wood furniture can endure for decades, making it a smart investment for both homes and businesses.

Wood Piles in Salt Water: Durability and Lifespan Explained

You may want to see also

Explore related products

Indoor vs. Outdoor Lifespan

Rubberwood's durability diverges sharply between indoor and outdoor environments, primarily due to its susceptibility to moisture and UV exposure. Indoors, where humidity levels are controlled and sunlight is minimal, rubberwood can last 10–15 years or more with proper care. Its dense grain and natural oils provide moderate resistance to wear and tear, making it a popular choice for furniture like dining tables, chairs, and kitchen utensils. Regular maintenance, such as wiping with a damp cloth and applying wood polish every 3–6 months, can extend its lifespan significantly.

Outdoors, however, rubberwood faces relentless challenges. Prolonged exposure to rain, humidity, and temperature fluctuations causes the wood to warp, crack, or rot within 2–5 years, even with protective treatments. UV rays from sunlight degrade its surface, leading to discoloration and brittleness. While sealing rubberwood with waterproof finishes like marine varnish or teak oil can delay deterioration, it’s not a permanent solution. For outdoor use, consider limiting rubberwood to covered areas or replacing it with more weather-resistant materials like teak or cedar.

The key to maximizing rubberwood’s lifespan lies in understanding its limitations. Indoors, its durability rivals that of oak or maple when shielded from excessive moisture and heat. Avoid placing rubberwood furniture near radiators, air vents, or in bathrooms, where humidity levels exceed 50%. Outdoors, even treated rubberwood should be stored indoors during harsh weather or winter months to prevent premature damage.

For those determined to use rubberwood outdoors, follow a strict maintenance regimen. Apply a high-quality sealant every 6–12 months, inspect for cracks or splinters regularly, and sand rough areas to prevent further splitting. Despite these efforts, outdoor rubberwood remains a short-term solution, ideal for decorative pieces rather than structural elements.

In summary, rubberwood thrives indoors with minimal upkeep but falters quickly outdoors. By aligning its use with its natural strengths and protecting it from environmental stressors, you can ensure it serves its purpose effectively, whether as a long-lasting indoor centerpiece or a temporary outdoor accent.

Wood Turtle Egg Hatching Timeline: What to Expect and When

You may want to see also

Explore related products

Maintenance Tips for Longevity

Rubberwood, known for its durability and eco-friendly appeal, can last for decades with proper care. However, its longevity hinges on consistent maintenance to protect it from environmental stressors and wear. Here’s how to ensure your rubberwood furniture or items remain in prime condition for years to come.

Prevent moisture damage by controlling humidity levels. Rubberwood is susceptible to warping and cracking when exposed to excessive moisture or drastic humidity fluctuations. Maintain indoor humidity between 40% and 60% using a dehumidifier or humidifier as needed. Wipe up spills immediately, and avoid placing rubberwood items near sinks, dishwashers, or exterior doors where moisture levels spike. For outdoor rubberwood pieces, apply a waterproof sealant annually and store them indoors during rainy seasons.

Shield rubberwood from direct sunlight to preserve its color. Prolonged exposure to UV rays can cause fading and discoloration. Position furniture away from windows or use curtains and blinds to filter sunlight during peak hours. If fading occurs, lightly sand the surface and reapply a wood stain or sealant to restore its original tone. For high-traffic areas, consider using UV-protective coatings designed for wooden surfaces.

Clean and polish regularly, but avoid harsh chemicals. Dust rubberwood weekly with a soft, dry microfiber cloth to prevent particle buildup. For deeper cleaning, use a damp cloth with a mild soap solution, ensuring the wood isn’t saturated. Avoid ammonia-based cleaners, which can strip the finish. Every 3–4 months, apply a high-quality wood polish or wax to maintain its luster and protect the surface from scratches. Test any new product on a small, inconspicuous area first.

Address scratches and wear promptly to prevent further damage. Minor scratches can be camouflaged with a matching wood marker or filler. For deeper scratches, lightly sand the area with 220-grit sandpaper, then refinish with a compatible sealant. If the damage is extensive, consult a professional for refinishing. Regularly inspect high-contact areas like table edges and chair arms, as these are prone to wear.

By implementing these targeted maintenance practices, you can significantly extend the lifespan of rubberwood items, ensuring they retain their beauty and functionality for generations. Consistency is key—small, routine efforts yield far greater results than sporadic, intensive care.

Linseed Oil Curing Time: How Long to Fully Cure Wood?

You may want to see also

Explore related products

Comparing Rubber Wood to Others

Rubber wood, derived from the Pará rubber tree (*Hevea brasiliensis*), is often praised for its durability and sustainability. But how does it stack up against other common woods like oak, pine, or teak? To understand its longevity, consider its density, resistance to wear, and environmental impact. Rubber wood’s medium density (around 540 kg/m³) makes it less hard than oak (700 kg/m³) but harder than pine (420 kg/m³). This places it in a sweet spot for furniture, offering durability without the brittleness of denser woods or the softness of lighter ones. However, unlike teak, which contains natural oils that resist decay, rubber wood requires sealing to prevent moisture damage.

When comparing maintenance, rubber wood demands more care than teak or cedar, which are naturally rot-resistant. For instance, outdoor rubber wood furniture must be treated with a waterproof sealant annually to avoid warping or cracking. In contrast, oak and maple, while harder, are more prone to scratches and require frequent polishing. Pine, though softer, is easier to repair but less durable overall. If you’re choosing wood for high-traffic areas, rubber wood’s balance of hardness and workability makes it a practical choice, but it’s not maintenance-free.

From a sustainability perspective, rubber wood outshines many competitors. Harvested from trees that have already served their latex-producing lifespan, it minimizes waste and reduces the need for deforestation. Teak, while durable, often comes from unsustainable logging practices. Pine, though fast-growing, is less durable and requires frequent replacement. For eco-conscious consumers, rubber wood’s lifecycle—from latex production to furniture—offers a unique advantage. However, its sustainability depends on ethical sourcing, so look for FSC-certified products.

In terms of cost, rubber wood is a budget-friendly alternative to hardwoods like walnut or mahogany, which can be prohibitively expensive. It’s also more affordable than teak, which is priced for its longevity and natural resistance. While pine is cheaper, its shorter lifespan often means higher long-term costs. For those seeking a balance of affordability and durability, rubber wood is a smart choice, especially for indoor furniture. Pair it with proper care—like avoiding direct sunlight and using coasters—to maximize its lifespan, which can easily reach 10–15 years with minimal wear.

Finally, consider the aesthetic and functional differences. Rubber wood’s light color and subtle grain make it versatile for staining or painting, unlike darker woods like walnut that limit customization. However, it lacks the prestige of exotic woods like rosewood or the rustic charm of reclaimed pine. For modern or minimalist designs, rubber wood’s clean look is ideal. Pair it with metal accents for a contemporary feel or keep it natural for a Scandinavian vibe. While it may not be the longest-lasting wood available, its combination of durability, sustainability, and affordability makes it a strong contender in the right applications.

Redwood Growth Timeline: Understanding the Slow Journey of Giants

You may want to see also

Explore related products

$10.95

Signs of Rubber Wood Aging

Rubber wood, known for its durability and eco-friendly appeal, typically lasts 10 to 15 years under normal indoor conditions. However, its lifespan can vary based on factors like exposure to moisture, sunlight, and wear. Recognizing the signs of aging in rubber wood is crucial for timely maintenance or replacement. Here’s how to identify when this material begins to show its age.

One of the earliest signs of rubber wood aging is surface discoloration. Over time, the wood may darken or develop uneven patches due to prolonged exposure to sunlight or air. This is particularly noticeable in furniture placed near windows or under direct light. While some may appreciate the patina as a natural aging process, others might view it as a signal to refinish or protect the surface with UV-resistant coatings. Regularly rotating furniture or using curtains to block harsh sunlight can slow this process.

Another indicator of aging is structural weakening, often manifested as cracks or splits in the wood. Rubber wood, though dense, is not immune to changes in humidity. Fluctuations in moisture levels can cause the wood to expand and contract, leading to stress fractures. These cracks are more likely to appear in areas subjected to heavy use, such as table legs or chair arms. Inspecting these high-stress points periodically and maintaining consistent indoor humidity (ideally between 40-60%) can mitigate this issue.

Warping is a more severe sign of rubber wood aging, typically occurring when the wood has been exposed to prolonged moisture. This is common in kitchen or bathroom furniture, where water spills or high humidity are frequent. Warped surfaces not only detract from the aesthetic appeal but also compromise functionality. To prevent warping, promptly wipe up spills and consider using waterproof sealants on surfaces prone to moisture exposure.

Finally, listen for telltale sounds of aging, such as creaking or groaning when the furniture is moved or used. These noises often indicate that joints are loosening due to wear and tear. Reinforcing joints with wood glue or screws can extend the life of the piece, but persistent issues may require professional repair. Regularly tightening hardware and avoiding excessive weight on the furniture can also help maintain its integrity.

By staying vigilant for these signs—discoloration, cracks, warping, and unusual sounds—you can address aging in rubber wood before it becomes irreversible. Proper care not only preserves the material’s longevity but also ensures it remains functional and visually appealing for years to come.

Lepage Wood Glue Drying Time: Quick Guide for Woodworkers

You may want to see also

Frequently asked questions

Rubber wood can last 15–20 years or more in furniture when properly cared for, depending on usage and environmental conditions.

Rubber wood is less durable than hardwoods like oak or maple but can still last a long time with proper maintenance and protection.

Excessive moisture can cause rubber wood to warp, crack, or rot, significantly reducing its lifespan. It’s important to keep it dry and avoid humid environments.

Rubber wood is not suitable for outdoor use as it lacks natural weather resistance. It is best used indoors to ensure longevity.

To extend its lifespan, regularly clean the wood, apply protective finishes like sealant or varnish, avoid direct sunlight, and maintain a stable indoor environment.