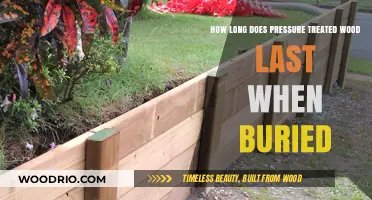

Pressure-treated wood is a popular choice for outdoor construction projects due to its enhanced durability and resistance to rot, decay, and insect damage. One common question among homeowners and builders is, How long does pressure-treated wood stay green? The green color of this wood comes from the chemical preservatives used during the treatment process, which typically include copper-based compounds. Initially, the green hue is noticeable, but over time, the wood will naturally weather and fade to a silvery-gray or brown color, depending on exposure to sunlight, moisture, and environmental conditions. This color change does not affect the wood’s structural integrity or protective qualities, and the preservatives remain effective for decades, often lasting 20 to 40 years or more, depending on the specific treatment and usage. To maintain the green appearance, some homeowners choose to apply stains or sealants, though this is purely cosmetic and not necessary for the wood’s longevity.

| Characteristics | Values |

|---|---|

| Initial Green Color Duration | Typically lasts 6 months to 1 year |

| Factors Affecting Green Color Retention | Exposure to sunlight, moisture, and environmental conditions |

| Weathering Process | Gradual fading to a natural wood tone (grayish or brown) |

| Chemical Composition | Contains water-soluble dyes and preservatives (e.g., CCA, ACQ, CA-B) |

| UV Resistance | Limited; UV rays accelerate color fading |

| Maintenance Requirements | Periodic cleaning and sealant application can extend green color |

| Environmental Impact | Leaching of chemicals over time, especially in older treatments |

| Alternative Options | Stain or paint can be applied to maintain or change color |

| Longevity of Wood Structure | 15-20 years or more, regardless of color, with proper care |

| Common Uses | Decks, fences, outdoor structures, and landscaping |

Explore related products

What You'll Learn

Initial Green Color Duration

Pressure-treated wood's initial green hue typically lasts 6 to 12 months, depending on environmental factors and maintenance. This color comes from a copper-based preservative, which also protects the wood from rot, insects, and decay. During this period, the wood undergoes a natural weathering process, gradually fading to a silvery-gray or brown shade. Understanding this timeline helps homeowners and builders plan for aesthetic changes and potential staining or sealing treatments.

Analyzing the factors influencing this duration reveals that sunlight exposure is the primary culprit. UV rays break down the chemical compounds responsible for the green tint, accelerating the fading process. In regions with intense sunlight, the green color may disappear within 6 months, while shaded areas can retain it for up to a year. Moisture levels also play a role; wood in damp environments tends to fade more slowly due to reduced UV penetration.

To prolong the initial green color, consider applying a UV-resistant sealant or stain specifically designed for pressure-treated wood. This not only preserves the hue but also enhances the wood’s durability. For best results, apply the sealant within the first month of installation, ensuring the wood is clean and dry. Reapply every 1-2 years to maintain both color and protection. Avoid using oil-based products, as they can trap moisture and lead to premature deterioration.

Comparing pressure-treated wood to alternatives like cedar or redwood highlights its unique color dynamics. While cedar naturally weathers to a gray tone over 1-2 years, pressure-treated wood’s green phase is shorter and more predictable. This makes it ideal for projects where a temporary green aesthetic is desired, such as garden borders or outdoor structures. However, for long-term color consistency, combining pressure-treated wood with periodic staining is key.

In practical terms, if you’re installing a deck or fence, plan for the green color to be a temporary feature. Embrace the natural weathering process or take proactive steps to alter it. For instance, if you prefer a consistent brown tone, apply a semi-transparent stain after the green fades. Alternatively, let the wood age naturally for a rustic, weathered look. Either way, the initial green phase is a fleeting but functional stage in the life of pressure-treated wood.

Polyurethane Application Tips: Ideal Timing Between Coats for Guitar Wood

You may want to see also

Explore related products

Factors Affecting Color Fading

Pressure-treated wood's vibrant green hue is a temporary feature, and understanding the factors that influence its color fading is key to managing expectations and maintenance. The primary culprit behind this transformation is the wood's exposure to ultraviolet (UV) radiation from sunlight. UV rays break down the chemical bonds in the wood's surface, causing the green pigment to degrade over time. This process is accelerated in regions with intense sunlight, such as desert climates or areas with high altitudes, where UV exposure is more direct and prolonged. For instance, pressure-treated wood in Arizona may fade significantly within 6 to 12 months, while the same wood in the Pacific Northwest could retain its color for 2 to 3 years due to reduced sunlight intensity.

Another critical factor is moisture exposure, which can exacerbate color fading through a process known as "weathering." When water penetrates the wood's surface, it can carry away pigments and accelerate the breakdown of the wood's protective chemicals. This is particularly evident in humid environments or areas with frequent rainfall. For example, a deck in Florida’s humid climate will likely fade faster than one in arid New Mexico, even with similar sun exposure. To mitigate this, homeowners can apply water-repellent sealants, which not only reduce moisture absorption but also provide a barrier against UV rays, effectively slowing down the fading process.

The type and quality of the pressure treatment chemicals also play a significant role. Modern pressure-treated wood often uses copper azole or alkaline copper quaternary (ACQ) preservatives, which are less prone to rapid color loss compared to older chromated copper arsenate (CCA) treatments. However, even with advanced preservatives, the green pigment is typically a dye added for aesthetic purposes and is not integral to the wood’s protection. Manufacturers may use different dye concentrations, with some adding up to 0.5% pigment by weight, which can influence how long the green color lasts. Consumers should inquire about dye specifications when purchasing to better predict fading timelines.

Lastly, physical wear and tear, such as foot traffic, cleaning methods, and environmental debris, can hasten color loss. High-traffic areas like deck stairs or playground surfaces will naturally fade faster due to abrasion. Pressure washing, while effective for cleaning, can strip away surface pigments if done too aggressively. Experts recommend using a fan-tip nozzle and maintaining a distance of at least 12 inches from the wood surface to minimize damage. Regularly sweeping away leaves, dirt, and other debris can also prevent staining and reduce the need for harsh cleaning methods, thereby preserving the wood’s color for longer.

In summary, while pressure-treated wood’s green color is not permanent, its fading rate can be managed through strategic interventions. By considering factors like UV exposure, moisture, chemical composition, and physical wear, homeowners can extend the wood’s aesthetic appeal. Practical steps such as applying sealants, choosing higher-quality treatments, and adopting gentle maintenance practices can significantly slow down color fading, ensuring the wood remains visually appealing for years to come.

Concrete vs. Wood Posts: Durability and Lifespan Comparison Guide

You may want to see also

Explore related products

Chemical Treatment Impact on Green

Pressure-treated wood's green hue is a direct result of the chemical preservatives used during the treatment process. The most common chemicals, such as chromated copper arsenate (CCA) and alkaline copper quaternary (ACQ), contain copper compounds that react with the wood's natural tannins, producing the distinctive green color. This reaction is not merely aesthetic; it indicates the presence of protective chemicals that safeguard the wood against rot, insects, and fungal decay. However, the intensity and longevity of this green shade vary depending on the specific treatment formula and application method.

The chemical dosage during treatment plays a critical role in how long the wood remains green. For instance, ACQ treatments typically use a copper retention level of 0.15 to 0.40 pounds per cubic foot (PCF), while CCA treatments (now restricted for residential use) ranged from 0.25 to 0.60 PCF. Higher dosages can prolong the green color but may also increase the risk of chemical leaching, especially in outdoor applications. Manufacturers often balance these factors to ensure both durability and environmental safety, though the green hue inevitably fades over time due to UV exposure and weathering.

To maximize the green appearance of pressure-treated wood, consider these practical steps: first, choose a treatment type known for its color retention, such as ACQ or copper azole (CA-B). Second, apply a UV-resistant sealant or stain immediately after installation to slow color degradation. Third, avoid placing the wood in areas with prolonged sun exposure, as UV rays accelerate fading. For example, using pressure-treated wood for shaded structures like pergolas or fences can extend the green lifespan by several years compared to direct sunlight applications.

A comparative analysis reveals that while CCA-treated wood retains its green color longer initially, its use has declined due to arsenic-related health concerns. ACQ-treated wood, though greener in environmental impact, tends to fade more quickly but remains a safer alternative for residential projects. Newer treatments like micronized copper azole (MCA) strike a balance, offering moderate color retention and reduced leaching. Understanding these trade-offs allows homeowners and builders to select the best option for their specific needs, whether prioritizing longevity, safety, or aesthetics.

Finally, the green color of pressure-treated wood is not permanent, typically fading to a natural brown or gray within 6 to 12 months, depending on exposure conditions. This transformation does not indicate a loss of protection, as the chemicals remain effective for decades. For those who prefer the green appearance, periodic reapplication of a green-tinted wood preservative or stain can restore the color without compromising the wood's structural integrity. This approach combines functionality with aesthetic appeal, ensuring the wood remains both durable and visually pleasing.

Danish Oil Drying Time: How Long to Cure Wood Perfectly

You may want to see also

Explore related products

Weathering and Sun Exposure Effects

Pressure-treated wood's vibrant green hue is a temporary feature, and understanding the role of weathering and sun exposure is key to managing its transformation. The green color comes from the copper-based preservatives used in the treatment process, which are essential for protecting the wood from rot, insects, and fungal decay. However, this green pigment is not designed to last indefinitely. Exposure to sunlight, particularly ultraviolet (UV) rays, accelerates the fading process, causing the wood to turn a silvery-gray over time. This natural weathering is a cosmetic change and does not diminish the wood’s structural integrity or protective qualities.

To slow the fading process, consider applying a UV-resistant sealant or stain specifically designed for pressure-treated wood. These products not only help retain the green color for a longer period but also provide an additional layer of protection against moisture and wear. For best results, apply the sealant within the first few weeks after installation, ensuring the wood is clean and dry. Reapply every 1–2 years, depending on exposure levels—wood in direct sunlight will require more frequent maintenance than shaded areas.

Comparatively, untreated wood weathers much faster and is more susceptible to damage, while pressure-treated wood maintains its structural benefits even as it fades. The green color typically lasts 1–3 years before noticeable changes occur, though this timeline varies based on climate and exposure. In regions with intense sunlight, such as the southwestern United States, fading may occur within the first year. Conversely, in cooler, shaded environments, the green hue can persist for up to 5 years.

For those seeking to preserve the green appearance, strategic placement can make a difference. Positioning structures like decks or fences in shaded areas or using overhead coverings can significantly reduce sun exposure. Additionally, incorporating landscaping elements, such as trees or awnings, provides natural protection. If fading is unavoidable, embrace the transition to gray as a natural aesthetic, or periodically refinish the wood to restore its original color.

In summary, while pressure-treated wood’s green color is fleeting, its durability remains unaffected by weathering and sun exposure. By understanding the factors at play and taking proactive measures, you can either prolong the green hue or gracefully accept its evolution into a weathered finish. The choice ultimately depends on your aesthetic preferences and maintenance willingness.

Drying Fresh Wood: Essential Tips for Optimal Curing Time

You may want to see also

Explore related products

$16.44

Maintenance Tips to Preserve Green Hue

Pressure-treated wood typically retains its green hue for 6 to 12 months, depending on exposure to sunlight, moisture, and environmental conditions. Once the initial color fades, the wood turns to a silvery-gray patina unless proactive maintenance steps are taken. Preserving the green hue requires a combination of protective treatments and regular upkeep to counteract natural weathering processes.

Step 1: Apply a Wood Sealant with UV Protection

Within the first month of installation, coat the wood with a high-quality sealant containing UV inhibitors. Products like Thompson’s WaterSeal Advanced or Olympic Elite Woodland Oil penetrate the surface to block ultraviolet rays, the primary cause of color degradation. Reapply every 6–12 months, especially in regions with intense sunlight. For best results, clean the wood with a mild detergent solution and allow it to dry completely before application.

Step 2: Use a Semi-Transparent Stain with Green Pigments

After the initial sealant application, enhance and lock in the green hue with a semi-transparent stain. Brands like Cabot Semi-Solid Stain or Ready Seal offer green-tinted options that blend with the wood’s natural tone. Apply in thin, even coats using a brush or sprayer, ensuring full coverage. Reapply annually or biennially, depending on wear. Avoid solid-color stains, as they obscure the wood grain and require more frequent maintenance.

Step 3: Minimize Moisture Exposure

Moisture accelerates color loss and wood deterioration. Ensure proper drainage around structures like decks or fences to prevent standing water. Trim vegetation at least 12 inches away from the wood to improve airflow and reduce humidity. For horizontal surfaces, consider installing a water-repellent barrier beneath the wood to prevent ground moisture absorption.

Step 4: Regular Cleaning and Inspection

Dirt, mildew, and algae dull the wood’s color and promote decay. Clean the surface quarterly with a mixture of oxygen bleach (1 cup per gallon of water) and a stiff-bristle brush. Rinse thoroughly and allow to dry before reapplying sealant or stain. Inspect for cracks, splinters, or mold, addressing issues promptly to maintain the wood’s integrity and appearance.

By combining these strategies, you can extend the green hue of pressure-treated wood for 3–5 years, significantly longer than untreated wood. While no method guarantees indefinite color retention, consistent maintenance ensures the wood remains vibrant and structurally sound, blending functionality with aesthetic appeal.

Durability of Wood Dock Pilings: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

Pressure treated wood typically stays green for 6 months to 2 years, depending on the treatment type and environmental exposure.

Yes, the green color on pressure treated wood will naturally fade due to sunlight, weather, and aging, usually within 1 to 3 years.

Yes, you can accelerate the fading process by exposing the wood to sunlight, washing it with soapy water, or using a wood cleaner designed to remove surface treatments.