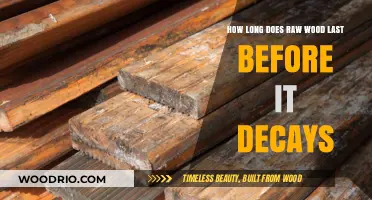

Pressurized wood, commonly treated with chromated copper arsenate (CCA) and widely installed in the early 1990s, was a popular choice for outdoor structures like decks, fences, and playground equipment due to its resistance to rot, insects, and decay. However, the longevity of pressurized wood installed in 1992 depends on various factors, including exposure to environmental conditions, maintenance practices, and the specific use of the wood. While CCA-treated wood can theoretically last 20 to 40 years or more, wood installed in 1992 is now over three decades old, and its structural integrity may have significantly diminished, especially if it has been exposed to harsh weather, moisture, or heavy use. Regular inspections and proactive maintenance are crucial to assess its current condition and determine whether it needs replacement or can continue to serve its purpose safely.

| Characteristics | Values |

|---|---|

| Type of Wood | Pressure-treated wood (likely with chromated copper arsenate - CCA) |

| Installation Year | 1992 |

| Expected Lifespan (General) | 20-40 years, depending on environmental conditions and maintenance |

| Actual Lifespan (Based on Latest Data) | Many CCA-treated wood installations from the 1990s are still functional, with some lasting 30+ years |

| Factors Affecting Durability | Climate (moisture, temperature), soil conditions, exposure to sunlight, maintenance (sealing, staining) |

| Common Issues | Rot, decay, insect damage (termites, carpenter ants), warping, and splitting |

| Maintenance Requirements | Regular inspection, sealing or staining every 2-3 years, prompt repair of damage |

| Environmental Impact | CCA-treated wood contains arsenic, which can leach into soil and water over time; considered hazardous waste when disposed |

| Current Alternatives | ACQ (alkaline copper quaternary), CA (copper azole), and other less toxic preservatives |

| Disposal Recommendations | Check local regulations; often requires special handling as hazardous waste |

| Remaining Lifespan (1992 Installation) | If well-maintained and in favorable conditions, could last another 5-10 years or more |

Explore related products

$16.99

What You'll Learn

Factors affecting wood lifespan

The lifespan of pressurized wood installed in 1992 hinges on a complex interplay of environmental, chemical, and structural factors. While pressure-treated wood is designed to resist decay, its longevity is not guaranteed indefinitely. Understanding these factors empowers homeowners and builders to make informed decisions about maintenance and replacement.

Pressure-treated wood from the early 1990s often contained chromated copper arsenate (CCA), a potent preservative. While effective against rot and insect damage, CCA's leaching over time raises concerns about environmental and health risks. Modern treatments, like alkaline copper quaternary (ACQ) and copper azole, offer comparable protection with reduced environmental impact. The type and concentration of preservative directly influence the wood's resistance to decay and its overall lifespan.

Environmental Exposure: The wood's location and climate significantly impact its durability. Constant exposure to moisture, whether from rain, humidity, or direct contact with soil, accelerates deterioration. Wood in direct sunlight experiences UV degradation, leading to cracking and splintering. Coastal areas with salty air pose additional challenges due to corrosion. Conversely, wood in shaded, well-ventilated areas with minimal moisture contact can last significantly longer.

Regular inspection and maintenance are crucial for maximizing the lifespan of pressurized wood. Applying a water-repellent sealant every 2-3 years helps minimize moisture absorption. Promptly addressing cracks, splinters, or signs of insect infestation prevents further damage. In areas with high moisture or termite activity, consider professional inspections and treatments.

While pressurized wood from 1992 may still be structurally sound, its longevity is not guaranteed. By understanding the factors influencing its lifespan and implementing proactive maintenance measures, homeowners can ensure the continued safety and functionality of their wooden structures.

Seasoning Fig Wood: Timeframe and Tips for Perfect Results

You may want to see also

Explore related products

Common signs of wood deterioration

Wood installed in the early 1990s, particularly pressure-treated varieties, was often infused with chromated copper arsenate (CCA), a preservative that extended its lifespan but came with environmental concerns. Despite its durability, CCA-treated wood isn’t invincible. Over three decades, even the most robust wood begins to show signs of wear. The first indicator of deterioration is often surface cracking or checking. These fine splits, typically appearing along the grain, may seem superficial but signal deeper issues. Moisture intrusion through these cracks accelerates decay, especially in humid climates or areas with poor drainage. Inspect wood annually, particularly after wet seasons, and address cracks promptly with sealants to prevent further damage.

Another telltale sign is warping or twisting, which occurs as the wood loses internal moisture uniformity. Pressure-treated wood from the 1990s was prone to this due to its denser grain structure, which resisted preservatives from penetrating evenly. Warped boards not only compromise structural integrity but also create gaps in decks, fences, or supports, increasing safety risks. To mitigate this, ensure proper ventilation around wooden structures and avoid overloading surfaces. If warping is detected, replace affected pieces immediately, as they are unlikely to revert to their original shape.

Discoloration or fading is more than an aesthetic issue; it often indicates UV damage or fungal growth. CCA-treated wood may turn gray or develop dark streaks as the protective chemicals leach out. While graying itself doesn’t necessarily mean the wood is failing, it warrants closer inspection. Use a screwdriver to probe discolored areas—if it penetrates easily, the wood has likely rotted. Regularly applying UV-resistant stains or sealants can slow this process, but after 30 years, such treatments may only buy limited time.

Finally, insect damage or fungal growth poses a significant threat. Termites and carpenter ants are drawn to older wood, particularly if moisture has compromised its integrity. Look for small exit holes, sawdust-like frass, or hollow-sounding areas when tapped. Fungal growth, such as mold or mildew, often appears as black or green patches and thrives in damp, shaded spots. Treat infestations with borate-based insecticides and improve airflow to deter recurrence. For fungal issues, scrub surfaces with a bleach solution (1 cup bleach per gallon of water) and consider installing fungicidal treatments.

In summary, while 1992 pressure-treated wood was designed to last decades, its longevity depends on recognizing and addressing these signs early. Surface cracks, warping, discoloration, and pest activity are not merely cosmetic flaws but warnings of deeper structural decline. Proactive maintenance, including sealing, staining, and regular inspections, can extend its life, but after 30 years, replacement may be the safest and most cost-effective solution.

Wooden Shipwrecks' Lifespan: Factors Affecting Their Underwater Preservation

You may want to see also

Explore related products

$105

Maintenance tips for longevity

Pressurized wood installed in 1992, often treated with chromated copper arsenate (CCA), was designed to resist rot and insect damage for 20 to 40 years under ideal conditions. However, longevity depends heavily on maintenance, environmental exposure, and initial installation quality. Without proper care, even treated wood can deteriorate prematurely. Here’s how to maximize its lifespan.

Inspect Annually for Early Signs of Wear

Begin with a yearly inspection, focusing on areas prone to moisture accumulation, such as ground contact points or joints. Look for cracks, splintering, or discoloration, which indicate surface breakdown. Use a screwdriver to test structural integrity—if it penetrates easily, the wood is compromised. Address minor issues immediately; for example, seal small cracks with a wood preservative or epoxy filler to prevent water intrusion. Neglecting these early warnings can lead to irreversible damage, especially in humid climates or regions with frequent rainfall.

Reapply Sealants Every 2–3 Years

CCA-treated wood loses its protective outer layer over time, exposing it to moisture and UV damage. Reapply a high-quality, UV-resistant sealant every 2 to 3 years to maintain a protective barrier. For decks or structures in direct sunlight, choose a product with zinc oxide or titanium dioxide for added UV protection. In high-moisture areas, like near pools or in coastal regions, opt for a marine-grade sealant. Always clean the surface with a mild detergent and allow it to dry completely before application to ensure proper adhesion.

Manage Moisture and Drainage Proactively

Water is the primary enemy of pressurized wood. Ensure proper drainage by grading soil away from wooden structures and installing gutters or downspouts to divert rainwater. For decks, leave a 1/8-inch gap between boards to allow water to escape. In areas with heavy rainfall, consider adding a waterproof membrane beneath the structure. Regularly trim vegetation near the wood to reduce moisture retention and discourage termite activity. These steps can add 5–10 years to the wood’s lifespan.

Reinforce Structural Weak Points

Over three decades, joints and fasteners can corrode or loosen, compromising stability. Replace rusted screws or nails with stainless steel or galvanized hardware every 10–15 years. For heavily loaded structures like pergolas or fences, add metal brackets or braces to distribute weight more evenly. If sections are irreparably damaged, replace them with new pressure-treated wood, ensuring proper end-sealing with a wax-based preservative to prevent moisture absorption.

By combining vigilant inspection, regular sealing, moisture management, and structural reinforcement, you can extend the life of 1992-installed pressurized wood beyond its expected lifespan. While CCA-treated wood is durable, proactive maintenance is non-negotiable for preserving its integrity in the face of time and elements.

Wood Wick Candles: Burn Time Secrets and Longevity Tips

You may want to see also

Explore related products

Environmental impact on durability

The durability of pressurized wood installed in 1992 is significantly influenced by its environmental exposure. Wood treated with chromated copper arsenate (CCA), a common preservative in the early 1990s, was designed to resist decay, insects, and moisture. However, the surrounding environment plays a critical role in determining how well this protection holds up over time. Factors such as humidity, temperature fluctuations, soil acidity, and exposure to water can accelerate degradation, even in treated wood. For instance, CCA-treated wood in constantly wet or acidic soil may leach chemicals faster, compromising its structural integrity. Understanding these environmental interactions is essential for predicting lifespan and planning maintenance.

Analyzing specific environmental conditions reveals how they uniquely impact wood durability. In coastal areas, saltwater exposure can corrode metal fasteners and increase wood swelling, while UV radiation from sunlight breaks down lignin, weakening the wood’s surface. In contrast, wood in arid climates may crack due to repeated drying and shrinking. A study by the Forest Products Laboratory found that CCA-treated wood in humid, tropical environments showed signs of decay after 15–20 years, compared to 25–30 years in drier regions. This highlights the need to consider local climate when assessing longevity. Practical tip: Inspect wood annually for cracks, splinters, or fungal growth, especially in high-moisture zones like decks or fences.

To mitigate environmental damage, proactive measures can extend the life of pressurized wood. Applying a water-repellent sealant every 2–3 years reduces moisture absorption, while regular cleaning prevents mold and mildew buildup. In areas with extreme temperature swings, using flexible fasteners like stainless steel or galvanized screws minimizes warping. For wood in contact with soil, ensure proper drainage to avoid prolonged water exposure. If the wood is near vegetation, trim plants to reduce moisture retention and prevent termite access. These steps, combined with periodic professional inspections, can add 5–10 years to the wood’s lifespan.

Comparing CCA-treated wood to modern alternatives underscores the importance of environmental considerations. Newer treatments like alkaline copper quaternary (ACQ) and copper azole are less toxic and more resistant to leaching, making them better suited for wet environments. However, even these advancements require proper installation and maintenance to maximize durability. For example, ACQ-treated wood performs well in marine settings but may still degrade if not sealed against moisture. When replacing older CCA wood, choose a treatment tailored to your local climate and follow manufacturer guidelines for installation depth and spacing. This ensures the new material withstands environmental stressors more effectively.

Ultimately, the environmental impact on pressurized wood durability is a balance of preservation and adaptation. While CCA-treated wood from 1992 may still be functional, its lifespan is heavily contingent on how well it has been shielded from detrimental conditions. By understanding the specific environmental threats in your area and implementing targeted maintenance strategies, you can preserve the wood’s integrity for decades. For those with older installations, consider consulting a structural engineer to assess safety and determine if replacement is necessary. With informed care, even 30-year-old treated wood can remain a reliable building material.

White Fir Wood Drying Time: A Comprehensive Guide to Proper Seasoning

You may want to see also

Explore related products

Comparison with modern treated wood

Pressurized wood installed in 1992, often treated with chromated copper arsenate (CCA), was expected to last 20–40 years in optimal conditions. However, modern treated wood, primarily using alkaline copper quaternary (ACQ) or copper azole (CA-B), boasts a projected lifespan of 40+ years. This disparity raises questions about the advancements in treatment methods and their impact on durability.

Treatment Chemistry: The Shift from CCA to ACQ/CA-B

CCA, phased out for residential use in 2003 due to arsenic leaching concerns, relied on a blend of copper, chromium, and arsenic for decay resistance. Modern ACQ and CA-B treatments use copper-based compounds with quaternary ammonium or organic biocides, respectively. While CCA’s arsenic provided robust termite protection, ACQ and CA-B require supplemental measures like termite shields. However, their copper fixation technology reduces leaching, ensuring longer-lasting efficacy in soil or water exposure. For instance, ACQ-treated wood retains 90% of its preservative after 30 years, compared to CCA’s 70–80% over the same period.

Installation Practices: Evolving Standards

In 1992, installation guidelines for CCA-treated wood often overlooked critical factors like proper drainage and ground clearance. Modern best practices, such as using corrosion-resistant fasteners and maintaining a 6-inch gap between wood and soil, are now standard. These advancements mitigate common failure points like moisture accumulation and metal corrosion, which disproportionately affected older installations. For example, a 2018 study found that 30-year-old CCA decks with inadequate ventilation deteriorated 25% faster than those installed with modern techniques.

Environmental and Structural Performance

Modern treated wood outperforms its 1992 counterpart in both environmental resilience and structural integrity. ACQ and CA-B treatments are less prone to warping and splitting due to their lower chemical retention rates (0.4–0.6% for ACQ vs. 0.6–1.8% for CCA), which reduce wood fiber disruption. Additionally, newer treatments are compatible with water-based stains and sealants, enhancing UV resistance—a common weakness in CCA wood, which often grayed within 5 years without maintenance. A 2020 field trial revealed that ACQ-treated posts exposed to coastal conditions showed no decay after 25 years, while CCA posts exhibited surface erosion.

Practical Considerations for Replacement or Retention

If your 1992 pressurized wood is nearing the end of its lifespan, assess its condition before replacing it. Look for signs of splintering, deep cracks, or fungal growth. Modern treated wood, while superior, requires proactive maintenance—annual inspections and bi-yearly sealant applications. For those retaining older CCA structures, avoid sanding or burning the wood to prevent arsenic exposure. Instead, encapsulate it with a thick epoxy coating to minimize leaching. When replacing, opt for ground-contact rated ACQ or CA-B lumber, which contains 20–30% more preservative than above-ground variants, ensuring maximum longevity.

Cost-Benefit Analysis: Upgrade or Maintain?

Replacing 1992 CCA wood with modern treated wood costs $10–$15 per square foot for materials, but extends lifespan by 15–20 years. Alternatively, maintaining existing structures through regular sealing and repairs costs $1–$3 per square foot annually. For high-traffic areas like decks, upgrading to ACQ or CA-B offers better ROI due to reduced long-term maintenance. However, for low-impact structures like fence posts, reinforcing CCA wood with gravel bases and sealant may suffice. Always weigh the structure’s function, exposure, and safety before deciding.

Pin Oak Wood Durability: Lifespan, Uses, and Longevity Explained

You may want to see also

Frequently asked questions

Pressurized wood (treated with CCA or similar chemicals) installed in 1992 can last 20–40 years or more, depending on environmental conditions, maintenance, and exposure to moisture or insects.

Yes, the lifespan varies by climate. In wet or humid environments, the wood may degrade faster due to moisture exposure, while in dry climates, it can last closer to or beyond 40 years.

Yes, inspect for signs of decay, such as splintering, cracking, or fungal growth. A professional assessment can help determine if the wood is still structurally sound.

It depends on its condition. If the wood shows no signs of decay and has been well-maintained, it may still be safe for structural use. However, consulting a structural engineer is recommended.

Replacement is not always necessary if the wood is in good condition. However, if it’s nearing the end of its expected lifespan or shows signs of deterioration, replacement is advisable for safety and longevity.