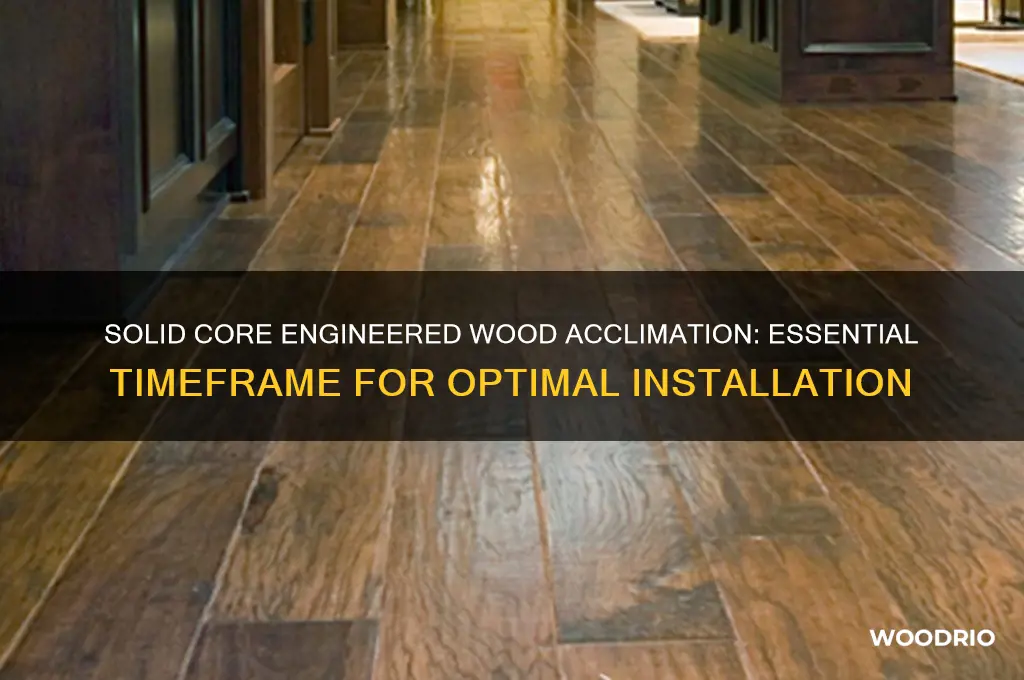

Solid core engineered wood flooring is a popular choice for homeowners due to its durability, stability, and aesthetic appeal. However, before installation, it is crucial to allow the flooring to acclimate to its new environment. Acclimation is the process of letting the wood adjust to the temperature and humidity levels of the space where it will be installed, ensuring it expands or contracts appropriately and minimizing the risk of gaps, warping, or buckling after installation. The acclimation period for solid core engineered wood typically ranges from 48 to 72 hours, depending on the manufacturer’s recommendations and the specific conditions of the installation area. During this time, the flooring should be stored in the room where it will be installed, with the packaging unopened, to allow it to equilibrate with the ambient conditions. Proper acclimation is essential for the long-term performance and appearance of the flooring, making it a critical step in the installation process.

| Characteristics | Values |

|---|---|

| Acclimation Time | 48-72 hours (2-3 days) |

| Ideal Humidity Range | 30%-50% relative humidity |

| Temperature Range | 60°F-80°F (15°C-27°C) |

| Storage Before Installation | Store in the installation room, unopened, for the acclimation period |

| Stacking Method | Stack boxes horizontally, supported every 2 feet (0.6 meters) |

| Moisture Content | Should match the environment where it will be installed (typically 6%-9%) |

| Expansion Gap | Leave a 1/2 inch (12 mm) gap around the perimeter for expansion |

| Subfloor Requirements | Subfloor must be clean, dry, and level |

| Manufacturer Guidelines | Always follow specific instructions provided by the manufacturer |

| Seasonal Considerations | Longer acclimation may be needed in extreme humidity or temperature |

| Inspection After Acclimation | Check for warping, cupping, or gaps before installation |

Explore related products

What You'll Learn

- Ideal acclimation duration for solid core engineered wood in different humidity conditions

- Factors affecting acclimation time, such as room temperature and wood moisture content

- How to properly store solid core engineered wood during the acclimation process?

- Signs that solid core engineered wood has fully acclimated to its environment

- Consequences of installing solid core engineered wood without proper acclimation

Ideal acclimation duration for solid core engineered wood in different humidity conditions

Solid core engineered wood, a popular choice for flooring and interior design, requires careful acclimation to ensure stability and longevity. The duration of this process hinges significantly on humidity levels, which dictate how the wood expands or contracts. In low humidity environments (below 30% relative humidity), the wood tends to release moisture, leading to shrinkage and potential gaps. Conversely, in high humidity conditions (above 60% relative humidity), the wood absorbs moisture, causing swelling and possible warping. Understanding these dynamics is crucial for determining the ideal acclimation period.

In dry climates, where humidity typically falls below 40%, solid core engineered wood should acclimate for 7 to 10 days. During this time, the wood adjusts to the indoor environment, minimizing the risk of shrinkage after installation. To expedite the process, use a humidifier to maintain indoor humidity between 40% and 60%. Additionally, store the wood in the room where it will be installed, ensuring it lies flat and is evenly distributed. Avoid stacking bundles too high, as this can restrict airflow and hinder acclimation.

For humid climates, where relative humidity often exceeds 60%, the acclimation period extends to 10 to 14 days. Here, the goal is to prevent the wood from absorbing excess moisture, which can lead to cupping or crowning. A dehumidifier can help maintain optimal humidity levels, while proper ventilation ensures consistent air circulation. If the wood feels damp or shows signs of swelling during acclimation, extend the period by a few days to allow for thorough adjustment.

In moderate humidity conditions (40% to 60%), solid core engineered wood typically requires 5 to 7 days to acclimate. This is considered the ideal range for wood stability, as the material neither loses nor gains significant moisture. However, even in these conditions, monitor the wood for any signs of movement and adjust the acclimation period accordingly. Using a hygrometer to measure humidity levels can provide precise data, ensuring the wood is ready for installation.

Regardless of humidity, consistency is key during acclimation. Fluctuations in temperature or humidity can disrupt the process, so maintain a stable indoor environment. For example, avoid running heating or cooling systems excessively, as this can dry out or moisten the air too quickly. By tailoring the acclimation duration to specific humidity conditions and following these practical steps, you can ensure solid core engineered wood performs optimally for years to come.

Boiling Mopani Wood: Perfect Timing for Aquarium Safe Use

You may want to see also

Explore related products

Factors affecting acclimation time, such as room temperature and wood moisture content

Solid core engineered wood requires acclimation to prevent warping, gapping, or buckling after installation. The time needed for this process hinges on two critical factors: room temperature and wood moisture content. These elements interact dynamically, influencing how quickly the wood adjusts to its new environment. Understanding their roles allows for precise control over acclimation, ensuring a seamless and durable installation.

Room temperature acts as a catalyst for moisture exchange between the wood and its surroundings. At 60°F to 80°F (15°C to 27°C), the ideal range for acclimation, moisture equilibrates efficiently. Lower temperatures slow this process, extending acclimation time by up to 50%. For instance, wood stored in a 50°F (10°C) basement may require 14 days instead of the typical 7. Conversely, higher temperatures can accelerate moisture loss, but extreme heat (above 90°F or 32°C) risks drying the wood too rapidly, leading to cracks. Humidity levels, closely tied to temperature, also play a role: 30% to 50% relative humidity is optimal, as it minimizes stress on the wood fibers.

Wood moisture content (MC) at the time of delivery is equally pivotal. Solid core engineered wood should ideally arrive with an MC matching the expected in-use conditions, typically 6% to 9% for interior environments. If the MC exceeds 12%, acclimation may take 2–3 weeks, as excess moisture gradually dissipates. A moisture meter can verify MC levels, ensuring the wood is ready for installation. For example, wood with an MC of 8% in a room at 70°F (21°C) and 40% humidity typically acclimates within 5–7 days, while wood at 12% MC may need twice as long.

Practical steps can mitigate delays. Store the wood flat in the installation room, allowing air circulation around all surfaces. Avoid stacking more than 20 cartons high to prevent compression. Use a dehumidifier if humidity exceeds 55%, or a space heater in cooler rooms, ensuring temperatures stay within the 60°F to 80°F range. Regularly monitor MC with a meter, aiming for consistency within 2% of the target. By addressing both temperature and moisture content, acclimation becomes a predictable, manageable process, safeguarding the wood’s integrity for years to come.

White Fir Wood Drying Time: A Comprehensive Guide to Proper Seasoning

You may want to see also

Explore related products

How to properly store solid core engineered wood during the acclimation process

Solid core engineered wood requires careful storage during acclimation to prevent warping, cupping, or moisture damage. This process typically takes 3–5 days, but can extend to 2 weeks depending on humidity, temperature, and the wood’s moisture content. Proper storage ensures the wood adjusts to its environment, mimicking its final installation conditions.

Location matters. Store the wood in the room where it will be installed, as this allows it to acclimate to the specific humidity and temperature of that space. If that’s not possible, choose an area with similar environmental conditions—ideally, an indoor space with stable temperature (60–80°F) and humidity (30–50%). Avoid basements, garages, or outdoor areas where conditions fluctuate drastically.

Stacking and spacing are critical. Lay the planks flat, with a smooth, dry surface underneath. Use stickers—small, evenly spaced supports—between layers to promote airflow. Stack no more than 5–7 bundles high to prevent crushing or uneven pressure. Leave a 4–6 inch gap between the stack and walls to allow air circulation on all sides.

Protect from moisture and direct sunlight. Cover the wood with a breathable material like a tarp or plastic sheeting, ensuring it’s not airtight. Avoid placing it directly on concrete floors, as moisture can wick up from the ground. If using a vapor barrier, ensure it doesn’t trap condensation. Keep the wood away from windows or vents where sunlight or drafts could cause uneven drying.

Monitor conditions regularly. Use a hygrometer to check the room’s humidity and a moisture meter to verify the wood’s moisture content aligns with the manufacturer’s recommendations (typically 6–9% for interior use). Adjust storage conditions if the wood feels damp or if humidity exceeds 55%. Patience is key—rushing the acclimation process risks long-term damage.

By following these steps, you ensure the wood stabilizes properly, setting the stage for a flawless installation and lasting performance.

Danish Oil Durability: How Long Does It Protect Wood Surfaces?

You may want to see also

Explore related products

Signs that solid core engineered wood has fully acclimated to its environment

Solid core engineered wood, a popular choice for flooring and other applications, requires a critical acclimation period to adjust to its new environment. But how do you know when it’s truly ready for installation? The process isn’t just about waiting a set number of days—it’s about observing specific signs that indicate the wood has reached equilibrium with its surroundings. Here’s what to look for.

Stability in Moisture Content

One of the most reliable indicators of full acclimation is stability in moisture content. Engineered wood expands or contracts based on humidity levels, so fluctuations in moisture content signal ongoing adjustment. Use a moisture meter to measure the wood’s moisture level daily. Once the readings remain consistent for at least 3–5 days, typically within 2–4% of the ambient moisture level in the room, the wood has likely acclimated. For example, if the room’s relative humidity is 50%, the wood’s moisture content should stabilize around 8–10%.

Absence of Gaps or Cupping

Visually inspect the planks for gaps or cupping, which occur when the wood is still adjusting to humidity levels. Lay the planks out in the room where they’ll be installed, stacking them in a staggered pattern with spacers to allow air circulation. After a week, check for any visible changes in shape or spacing. Fully acclimated wood will maintain its dimensions without warping, curling, or pulling apart at the edges. If gaps or cupping persist, give it more time.

Consistent Expansion or Contraction

Engineered wood naturally expands in high humidity and contracts in low humidity. To test this, measure the width of several planks at the start of the acclimation period and remeasure after 7–14 days. If the measurements remain unchanged, the wood has likely reached equilibrium. For instance, if a plank initially measures 5 inches wide and stays the same after two weeks, it’s a strong sign of acclimation. Keep in mind that minor fluctuations (less than 1/16 inch) are normal.

Tactile and Auditory Cues

Sometimes, your senses can provide valuable clues. Run your hand over the surface of the wood—fully acclimated planks will feel smooth and uniform, without rough patches or raised edges. Additionally, tap the planks lightly with a mallet or your knuckles. A consistent, solid sound indicates stability, while a hollow or uneven tone suggests the wood is still adjusting. These sensory checks are particularly useful when combined with more precise measurements.

Alignment with Manufacturer Guidelines

Always refer to the manufacturer’s recommendations for acclimation time, which typically range from 3–14 days depending on the product and environmental conditions. However, don’t rely solely on the calendar—use the signs above to confirm readiness. For instance, if the manufacturer suggests 7 days but the wood still shows gaps or moisture fluctuations, extend the acclimation period. Conversely, if all signs point to stability before the recommended time, proceed with caution and double-check measurements.

By observing these signs—stable moisture content, absence of physical distortions, consistent dimensions, sensory cues, and alignment with guidelines—you can confidently determine when solid core engineered wood has fully acclimated. Rushing this process risks long-term issues like buckling or gaps, so patience and attention to detail are key.

Seasoning Cherry Wood: Optimal Time for Perfect Flavor and Results

You may want to see also

Explore related products

Consequences of installing solid core engineered wood without proper acclimation

Solid core engineered wood, a popular choice for flooring, requires a critical step often overlooked: acclimation. This process allows the wood to adjust to the environment’s humidity and temperature, preventing future issues. Skipping or rushing acclimation can lead to costly and unsightly consequences, undermining the very benefits that make engineered wood appealing.

Warping and Gapping: The Immediate Eyesores

Without proper acclimation, solid core engineered wood is prone to warping and gapping. The wood’s moisture content must align with the installation site’s conditions. If installed in a drier environment than it was stored, the planks shrink, creating gaps between boards. Conversely, in a more humid setting, the wood expands, leading to buckling or cupping. These issues not only detract from the floor’s appearance but also compromise its structural integrity, requiring extensive repairs or replacement.

Adhesive Failure: A Hidden Hazard

Engineered wood often relies on adhesives for installation. Improper acclimation disrupts the bond between the wood and subfloor. When the wood expands or contracts post-installation, the adhesive may fail, causing planks to loosen or detach. This not only poses a safety risk but also necessitates reinstallation, doubling labor costs and downtime. Manufacturers typically recommend acclimating for 48–72 hours, but high humidity or low temperatures may require up to a week.

Voided Warranties: A Costly Oversight

Most engineered wood warranties explicitly require proper acclimation. Ignoring this step voids the warranty, leaving homeowners financially responsible for any defects or damages. For instance, a 25-year residential warranty from a leading brand becomes null if acclimation guidelines aren’t followed. Always check the manufacturer’s instructions, which often specify maintaining room temperatures between 60°F and 80°F and humidity levels between 30% and 50% during acclimation.

Long-Term Degradation: Beyond Surface-Level Issues

The consequences of skipping acclimation extend beyond immediate defects. Over time, unacclimated wood is more susceptible to wear, delamination, and moisture damage. For example, in kitchens or bathrooms, where humidity fluctuates, improperly acclimated floors may develop soft spots or mold beneath the surface. This not only shortens the floor’s lifespan but also poses health risks, requiring complete removal and remediation.

In summary, acclimation is not an optional step but a necessity for solid core engineered wood. By allowing 3–7 days for adjustment, maintaining optimal environmental conditions, and adhering to manufacturer guidelines, homeowners can avoid the pitfalls of warping, adhesive failure, warranty voids, and long-term degradation. Patience during installation pays off in durability and aesthetics.

How Long Does a 1/4 Cord of Wood Typically Last?

You may want to see also

Frequently asked questions

Solid core engineered wood typically needs to acclimate for 48 to 72 hours in the room where it will be installed to adjust to the humidity and temperature conditions.

Yes, in more humid or dry climates, acclimation may take longer, up to 5–7 days, to ensure the wood properly adjusts to the environment.

No, skipping acclimation can lead to warping, gapping, or buckling after installation, as the wood needs time to stabilize in its new environment.

Store the wood in the room where it will be installed, with the packaging unopened, in a flat, horizontal position, and maintain consistent temperature and humidity levels.

Improper acclimation can result in dimensional changes, such as expansion or contraction, leading to installation issues or long-term damage to the flooring.