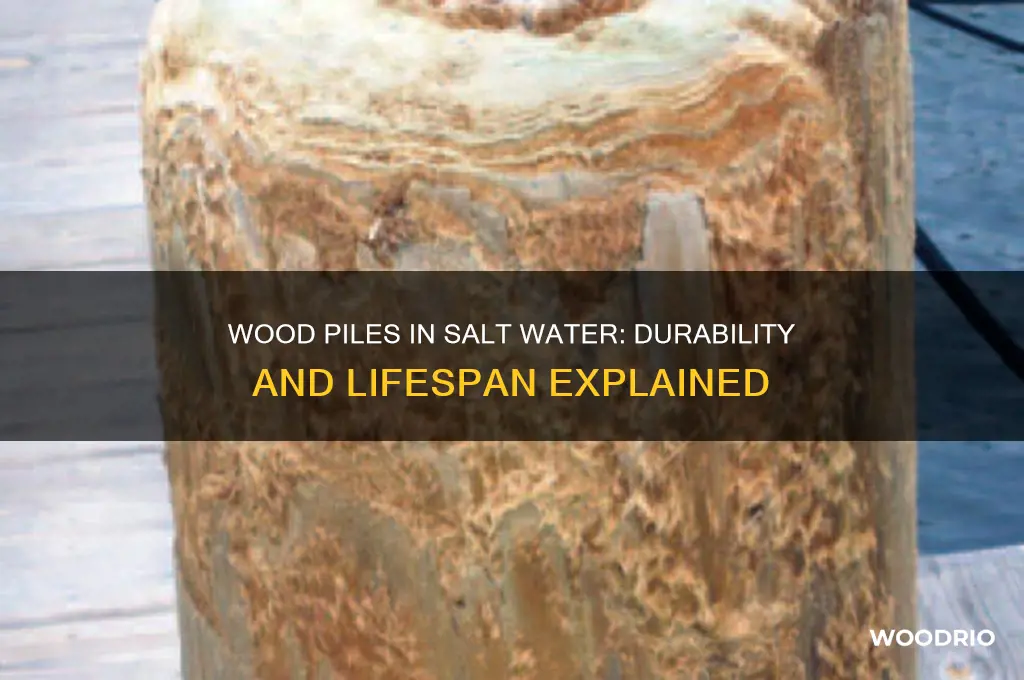

Wood piles submerged in salt water face a unique set of challenges that significantly impact their longevity. Salt water is highly corrosive and accelerates the degradation of wood through processes like chloride-induced corrosion and marine borer activity. Additionally, the constant exposure to moisture prevents the wood from drying out, promoting fungal decay and rot. While treated wood, such as creosote-coated or pressure-treated varieties, can last anywhere from 20 to 40 years in salt water, untreated wood typically deteriorates much faster, often within 5 to 10 years. Factors like water depth, tidal movement, and the presence of marine organisms further influence the lifespan of wood piles in such environments. Understanding these dynamics is crucial for designing and maintaining structures like piers, docks, and seawalls in coastal areas.

| Characteristics | Values |

|---|---|

| Type of Wood | Hardwoods (e.g., oak, teak) last longer than softwoods (e.g., pine, cedar) due to higher natural resistance to decay. |

| Treatment | Untreated wood: 5–10 years; Creosote-treated wood: 20–40 years; Pressure-treated wood (CCA, ACQ): 30–50+ years. |

| Water Depth | Deeper water (submerged) reduces oxygen exposure, slowing decay; shallow water accelerates deterioration due to alternating wet/dry conditions. |

| Water Flow | High-flow areas (e.g., tidal zones) increase abrasion and wear, reducing lifespan compared to still water. |

| Marine Borers | Presence of organisms like teredo worms significantly shortens lifespan, especially for untreated wood. |

| Temperature | Warmer saltwater accelerates biological activity and decay; colder water slows it down. |

| Salinity | Higher salinity increases corrosion and biological activity, reducing lifespan compared to brackish water. |

| Maintenance | Regular inspection and repair can extend lifespan; neglect accelerates deterioration. |

| Typical Lifespan Range | Untreated: 5–10 years; Treated: 20–50+ years (varies by treatment and conditions). |

| Environmental Factors | Pollution, UV exposure, and sediment buildup can further impact durability. |

Explore related products

$13.05 $14.77

What You'll Learn

- Type of Wood: Hardwoods vs. softwoods and their resistance to saltwater degradation over time

- Saltwater Exposure: Duration and frequency of exposure to saltwater affecting wood pile lifespan

- Preservative Treatments: Effectiveness of treatments like creosote or CCA in saltwater environments

- Environmental Factors: Impact of temperature, tides, and marine life on wood pile durability

- Maintenance Practices: Regular inspections and repairs to extend wood pile longevity in saltwater

Type of Wood: Hardwoods vs. softwoods and their resistance to saltwater degradation over time

The durability of wood in saltwater environments hinges largely on whether it’s a hardwood or softwood. Hardwoods, derived from deciduous trees, generally boast denser cell structures and higher natural oils, making them more resistant to decay. Softwoods, from coniferous trees, tend to be less dense and more susceptible to degradation, though exceptions exist. This fundamental difference in composition dictates their lifespan when submerged in saltwater, a harsh environment that accelerates rot, warping, and insect damage.

Consider the practical implications for marine construction. Teak, a dense hardwood, is a staple in boatbuilding due to its natural oils that repel water and resist rot. It can last 40–50 years in saltwater with minimal treatment. In contrast, pine, a common softwood, deteriorates within 5–10 years without preservatives. However, pressure-treated softwoods, infused with chemicals like chromated copper arsenate (CCA), can rival hardwoods in longevity, lasting 20–30 years. The key takeaway: while hardwoods inherently resist saltwater better, treated softwoods offer a cost-effective alternative.

For those seeking eco-friendly options, untreated softwoods like cedar or redwood provide moderate resistance due to their natural tannins and resins. Cedar, for instance, can endure 15–20 years in saltwater, though its lifespan shortens in high-splash zones. Hardwoods like ipe or oak, with their extreme density, outperform even treated softwoods but come at a premium. The choice depends on budget, environmental impact, and desired lifespan.

Maintenance plays a critical role in extending wood life in saltwater. Regular inspections for cracks, fungal growth, or borer holes are essential. Applying marine-grade sealants or paints every 1–2 years can add 5–10 years to a wood pile’s life. For hardwoods, periodic oiling with teak or linseed oil replenishes natural defenses. Softwoods benefit from reapplication of preservatives every 3–5 years. Proper installation, such as elevating wood piles to reduce constant water contact, also significantly prolongs durability.

In summary, hardwoods naturally outlast softwoods in saltwater due to their density and oils, but treated softwoods bridge the gap with chemical assistance. Cedar and redwood offer mid-range durability for eco-conscious projects. Regardless of type, proactive maintenance is non-negotiable. By understanding these distinctions and taking preventive measures, you can maximize the lifespan of wood piles in saltwater environments, balancing cost, performance, and sustainability.

Sealing Dried Wood: Optimal Timing for Durable and Long-Lasting Results

You may want to see also

Explore related products

$19.38 $20.91

Saltwater Exposure: Duration and frequency of exposure to saltwater affecting wood pile lifespan

Wood piles submerged in saltwater face a relentless assault from both physical and chemical forces. Prolonged immersion accelerates decay as salt acts as a catalyst for corrosion, while constant moisture prevents the wood from drying, fostering fungal growth. Even intermittent exposure, such as tidal fluctuations, can be detrimental, as the wetting and drying cycles cause the wood to expand and contract, leading to structural weakening. Understanding the duration and frequency of saltwater contact is crucial for predicting and mitigating damage.

Consider the scenario of a wooden pier pilings exposed to saltwater. If the pilings are fully submerged, their lifespan can be as short as 5 to 10 years, depending on the wood species and water conditions. Tropical hardwoods like greenheart or ekki may endure longer, up to 20–30 years, due to their natural resistance to decay. In contrast, softwoods like pine or fir, without treatment, can fail within 2–5 years. Partial exposure, where pilings are only submerged during high tide, extends lifespan but still poses risks. For instance, a piling exposed to saltwater for 6 hours daily may last 10–15 years, while one exposed for 2 hours daily could endure 15–20 years.

To maximize wood pile lifespan in saltwater environments, strategic measures are essential. Pressure-treating wood with preservatives like chromated copper arsenate (CCA) can significantly enhance durability, adding 5–10 years to its life. Applying protective coatings, such as epoxy or marine paint, creates a barrier against moisture and salt penetration. Additionally, designing structures to minimize water retention—such as incorporating drainage holes or using elevated platforms—reduces the frequency of exposure. For example, a wood pile with a 12-inch clearance above the high tide line can experience up to 50% less saltwater contact, doubling its lifespan.

Comparing freshwater and saltwater environments highlights the severity of saltwater’s impact. While freshwater can cause wood to decay over 20–40 years, saltwater exposure reduces this timeframe by 50–75% due to its corrosive properties. The frequency of exposure compounds this effect; wood piles in areas with frequent tidal changes or wave action degrade faster than those in calmer waters. For instance, pilings in a sheltered bay may outlast those in an open coastal area by 5–10 years, even with similar submersion durations.

In practical terms, monitoring and maintenance are key to prolonging wood pile lifespan in saltwater. Regular inspections for signs of decay, such as cracking, splintering, or fungal growth, allow for timely interventions. Replacing compromised sections before structural failure occurs can extend the overall life of the installation. For high-risk areas, consider alternative materials like composite lumber or galvanized steel, which offer greater resistance to saltwater degradation. By balancing exposure duration, frequency, and protective measures, it’s possible to optimize wood pile performance in even the harshest marine environments.

Composite vs. Wood Fences: Which Lasts Longer in Your Yard?

You may want to see also

Explore related products

Preservative Treatments: Effectiveness of treatments like creosote or CCA in saltwater environments

Wood exposed to saltwater faces relentless degradation from moisture, marine borers, and fungi. Preservative treatments like creosote and chromated copper arsenate (CCA) aim to extend its lifespan, but their effectiveness varies significantly in such harsh conditions. Creosote, a tar-based distillate, penetrates wood deeply, forming a toxic barrier against organisms. However, its oily nature can leach into water, raising environmental concerns. CCA, a water-soluble compound, fixes copper, chromium, and arsenic into the wood’s cellular structure, providing robust protection against decay and insects. While both treatments offer benefits, their performance in saltwater hinges on application method, wood species, and environmental factors.

To maximize the effectiveness of creosote, apply it under pressure to ensure deep penetration, typically at a retention level of 6–10 pounds per cubic foot. This process, known as pressure treatment, forces the preservative into the wood’s fibers, enhancing durability. For CCA, retention levels range from 0.4 to 0.6 pounds per cubic foot for above-ground use, but higher concentrations are recommended for saltwater exposure. Post-treatment, allow the wood to dry thoroughly to prevent surface leaching. Despite these measures, creosote-treated wood may still degrade faster in saltwater due to its organic composition, while CCA-treated wood retains its integrity longer, thanks to its inorganic components.

Environmental considerations cannot be overlooked. Creosote’s toxicity poses risks to marine life, limiting its use in ecologically sensitive areas. CCA, while effective, has faced scrutiny due to arsenic leaching, leading to restrictions in some regions. Alternatives like alkaline copper quaternary (ACQ) and copper azole offer safer options but may not match CCA’s longevity in saltwater. When selecting a treatment, weigh the wood’s intended use, environmental impact, and expected lifespan.

In practice, combining preservative treatments with proper design can further extend wood piles’ lifespan in saltwater. Elevate the wood above the waterline where possible, use sacrificial caps, and inspect regularly for signs of degradation. For critical structures, CCA remains the gold standard, but its use requires careful handling and compliance with regulations. Creosote, though effective, is best reserved for less sensitive applications. Ultimately, no treatment guarantees indefinite protection, but informed choices can significantly delay the inevitable effects of saltwater exposure.

Understanding the Lifespan of Chemicals in Pressure-Treated Wood

You may want to see also

Explore related products

Environmental Factors: Impact of temperature, tides, and marine life on wood pile durability

Wood piles submerged in salt water face a relentless assault from environmental factors that accelerate degradation. Temperature fluctuations, tidal movements, and marine life activity collectively determine their lifespan, often reducing it to a fraction of what it would be on land. Understanding these dynamics is crucial for anyone relying on wood structures in marine environments.

Temperature extremes act as a double-edged sword. In tropical regions, where water temperatures consistently exceed 25°C (77°F), wood-boring organisms like teredo worms thrive, tunneling through piles at rates up to 1.5 cm per month. Conversely, in colder waters below 10°C (50°F), microbial activity slows, but freeze-thaw cycles in brackish zones can cause wood to crack, increasing surface area for salt penetration. For optimal durability, consider using pressure-treated wood with preservatives like chromated copper arsenate (CCA), which can extend lifespan by 5–10 years in temperate climates.

Tidal forces introduce mechanical stress and chemical erosion. In intertidal zones, where piles are alternately submerged and exposed, the wet-dry cycle accelerates surface degradation. Salt crystals form during evaporation, exerting up to 200 psi of pressure on wood fibers, leading to spalling. To mitigate this, apply marine-grade sealants with UV inhibitors every 12–18 months, particularly on piles in areas with a tidal range exceeding 2 meters.

Marine life poses both direct and indirect threats. Barnacles and mussels encrust surfaces, adding weight and creating micro-abrasions, while shipworms bore into untreated wood, reducing structural integrity by up to 40% within 3 years. In high-biodiversity regions like coral reefs, biofouling communities can double maintenance needs. Installing protective wraps or using naturally resistant species like black locust can reduce biological damage, though the latter typically lasts only 5–7 years in salt water.

Practical takeaways for maximizing durability:

- Material selection: Opt for hardwoods like greenheart or treated softwoods with a minimum 0.6% CCA retention level.

- Design considerations: Elevate piles 30–50 cm above the mean high tide line to minimize intertidal exposure.

- Maintenance schedule: Inspect annually for borer holes or sealant cracks, and reapply treatments after severe storms or temperature shifts.

By addressing these environmental factors systematically, wood piles in salt water can be engineered to last 15–20 years, balancing functionality with the realities of marine conditions.

Wood Glue Setting Time: How Long Does It Take to Dry?

You may want to see also

Explore related products

Maintenance Practices: Regular inspections and repairs to extend wood pile longevity in saltwater

Wood piles submerged in saltwater face relentless degradation from marine borers, fungi, and electrochemical reactions. Without intervention, untreated timber can deteriorate within 5–10 years, while treated piles may last 20–40 years. Regular maintenance, however, can significantly extend this lifespan by addressing vulnerabilities before they escalate. Inspections should focus on visible damage, such as cracks, splintering, or borehole patterns, while repairs must prioritize replacing compromised sections and reinforcing structural integrity.

Inspection Protocols: A Proactive Approach

Begin with quarterly visual inspections, increasing frequency to monthly in high-traffic or turbulent areas. Use a sharp tool to probe for softness, a sign of internal decay. Submerge a waterproof camera for underwater assessments, identifying hidden damage caused by shipworms or barnacle encrustations. Document findings with photographs and notes, tracking deterioration trends over time. For piles supporting critical structures, consider annual professional surveys using ultrasonic testing to detect voids or delamination.

Repair Strategies: Precision and Timeliness

Minor damage, like surface cracks or small boreholes, can be treated with epoxy injections or marine-grade wood fillers. For moderate decay, splice in new timber sections, ensuring treated wood matches the existing pile’s preservative type (e.g., creosote or CCA). Severe damage may require pile jackets—fiberglass or steel encasements that shield against further borer activity. Always clean surfaces before repairs, removing biofouling and debris to ensure adhesives or wraps bond effectively.

Preventive Measures: Beyond Repairs

Complement repairs with preventive treatments. Apply antifouling coatings annually to deter marine growth, reducing physical stress and borer access. Install sacrificial anodes (zinc or aluminum) near piles to mitigate galvanic corrosion if metal components are present. For new installations, consider wrapping pile bases in geotextile fabric to minimize sediment buildup, which can trap moisture and accelerate decay.

Cost-Benefit Analysis: Longevity vs. Expense

While maintenance demands upfront investment, the alternative—premature replacement—costs 2–3 times more. A well-maintained pile can outlast its untreated counterpart by 50–100%, delaying capital expenditures. Budget for maintenance at 10–15% of initial installation costs annually, allocating funds for inspections, materials, and labor. Prioritize high-risk piles first, such as those in fast-flowing currents or near boat traffic, to maximize resource efficiency.

By integrating systematic inspections, targeted repairs, and preventive measures, wood piles in saltwater environments can defy their typical lifespan projections. This approach not only preserves structural integrity but also ensures safety and sustainability, turning maintenance from a chore into a strategic asset.

Galvanized Ties Near Wood: Lifespan and Durability Explained

You may want to see also

Frequently asked questions

Wood piles in salt water generally last between 25 to 40 years, depending on the type of wood, environmental conditions, and maintenance.

Yes, hardwoods like oak or greenheart are more resistant to saltwater degradation and can last longer than softer woods like pine, which may deteriorate faster.

Yes, treating wood piles with preservatives like creosote or copper-based chemicals can significantly extend their lifespan by protecting against marine borers and rot.

Factors like exposure to tidal movement, marine borers, pollutants, and lack of maintenance can accelerate the deterioration of wood piles in salt water.

Yes, alternatives include concrete, steel, and composite materials, which are more durable in saltwater but often come with higher initial costs.