Building a wooden house from scratch is a complex and time-consuming process that involves several stages, from planning and design to construction and finishing. The timeline can vary significantly depending on factors such as the size of the house, the complexity of the design, local building codes, weather conditions, and the availability of materials and labor. On average, constructing a wooden house from scratch can take anywhere from 6 months to over a year. The initial phase, including obtaining permits and finalizing designs, can take 1-3 months, followed by site preparation and foundation work, which typically lasts 1-2 months. Framing and roofing usually take 1-2 months, while interior work, including electrical, plumbing, insulation, and drywall, can span 2-4 months. Finally, exterior finishes, landscaping, and final inspections may add another 1-2 months. Proper planning and coordination among contractors are essential to streamline the process and minimize delays.

| Characteristics | Values |

|---|---|

| Average Time to Build a Wood House | 6 to 12 months (depending on size, complexity, and location) |

| Foundation Preparation | 1 to 2 months |

| Framing Construction | 1 to 3 months |

| Roofing Installation | 1 to 2 weeks |

| Exterior Finishing (Siding, Windows) | 2 to 4 weeks |

| Interior Finishing (Insulation, Drywall, Flooring) | 2 to 3 months |

| Plumbing and Electrical Work | 2 to 4 weeks |

| Final Inspections and Permits | 1 to 2 weeks (varies by locality) |

| Weather Impact | Can add 1 to 3 months (depending on climate and season) |

| Labor Availability | Delays possible if skilled labor is scarce |

| Custom Features | Adds 1 to 3 months (e.g., custom cabinetry, unique designs) |

| Pre-Construction Planning | 1 to 3 months (design, permits, material sourcing) |

| Total Estimated Time | 9 to 18 months (from planning to completion) |

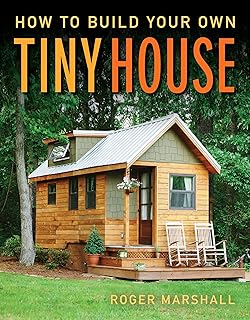

Explore related products

$24.48

What You'll Learn

- Planning & Design: Blueprint creation, permits, and layout considerations for a wooden house

- Material Sourcing: Selecting and purchasing wood, tools, and construction supplies

- Foundation Building: Preparing the site, pouring concrete, and setting the base

- Framing & Assembly: Constructing walls, roof, and structural components of the house

- Finishing Touches: Adding insulation, plumbing, electrical work, and interior/exterior details

Planning & Design: Blueprint creation, permits, and layout considerations for a wooden house

Building a wooden house from scratch is a complex process, and the planning and design phase is where the foundation for success is laid. Blueprint creation is the first critical step, as it translates your vision into a detailed, scalable plan. This involves drafting floor plans, elevations, and structural details, ensuring every beam, joist, and wall is accounted for. Modern software like AutoCAD or SketchUp can expedite this process, but even with tools, expect to spend 2–4 weeks refining designs to meet functional and aesthetic goals. Collaborating with an architect or structural engineer is essential to ensure the blueprint complies with building codes and maximizes the material efficiency of wood.

Securing permits is the next hurdle, and its timeline varies widely by location. In rural areas with fewer regulations, permits might be approved in 2–4 weeks, while urban or environmentally sensitive zones could take 2–6 months. Research local zoning laws, fire codes, and environmental restrictions early. Prepare a comprehensive submission package, including blueprints, site plans, and environmental impact assessments, to avoid delays. Engaging a local consultant familiar with regional requirements can streamline this process, saving time and frustration.

Layout considerations are where practicality meets creativity. Start by prioritizing natural light and ventilation, leveraging wood’s insulating properties to reduce energy costs. Incorporate open floor plans to enhance space flow, but balance this with structural integrity—wooden houses require strategic load-bearing walls. Consider future needs, such as aging-in-place features or expansion possibilities, to ensure the design remains relevant. For example, pre-wiring for smart home systems or adding extra foundation supports for future additions can add long-term value.

A common oversight is underestimating the impact of site-specific factors. Slope, soil type, and climate influence foundation design and material choice. For instance, in humid climates, incorporate moisture barriers and ventilation to prevent wood rot. In seismic zones, reinforce joints and connections to enhance stability. These considerations add layers of complexity to the blueprint but are crucial for durability. Allocate 3–6 weeks for site analysis and adjustments to the design, ensuring the house is tailored to its environment.

Finally, balance ambition with realism. While a custom wooden house offers endless possibilities, every additional feature—like a loft, wraparound porch, or vaulted ceilings—extends the timeline and budget. Prioritize must-haves over nice-to-haves, and be prepared to make trade-offs. A well-planned design phase, though time-consuming, can prevent costly mid-construction changes. With thorough blueprinting, proactive permit management, and thoughtful layout decisions, this phase typically spans 3–6 months, setting the stage for a smoother build.

Granville T. Woods: Revolutionizing Long-Distance Communication with Innovative Inventions

You may want to see also

Explore related products

$12.88 $16.99

Material Sourcing: Selecting and purchasing wood, tools, and construction supplies

Building a wooden house from scratch demands meticulous material sourcing, a phase that significantly influences both timeline and quality. The first step is identifying the right type of wood, balancing durability, cost, and sustainability. Hardwoods like oak or maple offer strength but are pricier, while softwoods like pine or cedar are cost-effective and easier to work with. For structural elements, pressure-treated lumber is essential to prevent rot and insect damage, especially in humid climates. Research local suppliers or lumberyards that offer bulk discounts and delivery services, as transporting heavy timber can delay construction if not planned properly.

Tools are the backbone of any construction project, and investing in high-quality equipment pays off in efficiency and precision. Essential tools include a circular saw, nail gun, drill, and measuring tape. For specialized tasks, consider renting equipment like a table saw or planer instead of purchasing to save costs. Safety gear, such as gloves, goggles, and dust masks, is non-negotiable and should be sourced alongside tools. Online platforms like Amazon or Home Depot often provide tool kits tailored for woodworking projects, offering convenience and potential savings.

Construction supplies, from nails and screws to insulation and sealants, require careful selection to ensure compatibility with wood and environmental conditions. Galvanized nails are recommended to prevent rust, while exterior-grade screws provide added stability. Insulation materials like fiberglass or foam boards should meet local building codes for energy efficiency. Sealants and stains protect the wood from moisture and UV damage, extending the house’s lifespan. Bulk purchasing from wholesale suppliers or negotiating with local vendors can reduce costs, but always verify product quality to avoid compromises.

A strategic approach to material sourcing involves creating a detailed inventory list, cross-referencing it with project blueprints, and prioritizing purchases based on construction phases. For instance, foundation materials like concrete and anchors should be sourced first, followed by framing lumber and roofing supplies. This phased approach minimizes storage challenges and reduces the risk of material degradation. Additionally, consider eco-friendly options like reclaimed wood or recycled insulation to align with sustainable building practices, though these may require additional research and sourcing time.

Finally, anticipate delays in material availability, especially for specialty items or during peak construction seasons. Building a buffer of 2–4 weeks into the sourcing timeline allows for unexpected shortages or shipping delays. Establishing relationships with suppliers can expedite orders and provide access to expert advice. By combining thorough research, strategic planning, and flexibility, material sourcing becomes a streamlined process that sets the foundation for a successful wooden house build.

Understanding Rick of Wood: Size, Measurement, and Practical Uses

You may want to see also

Explore related products

Foundation Building: Preparing the site, pouring concrete, and setting the base

The foundation is the backbone of any wooden house, and its construction demands precision, patience, and planning. Before the first board is laid, the site must be meticulously prepared. This involves clearing the land of debris, vegetation, and any obstructions, followed by grading to ensure proper drainage. Soil testing is crucial to determine its load-bearing capacity, as poor soil can lead to settling or structural failure. Depending on the site’s condition, this phase can take anywhere from a few days to several weeks, especially if additional measures like soil compaction or retaining walls are required.

Pouring the concrete for the foundation is a critical step that requires careful execution. After excavation and the placement of footings, forms are constructed to hold the concrete in place. The concrete mix, typically a ratio of 1:2:4 (cement:sand:gravel), must be poured evenly and cured properly to achieve maximum strength. Weather conditions play a significant role here; ideal temperatures range between 50°F and 90°F, as extreme heat or cold can affect curing time and quality. This stage usually takes 3–7 days, including curing, but delays can occur if weather or material shortages intervene.

Setting the base involves installing anchor bolts and ensuring the foundation is level and plumb. This step is often overlooked but is vital for the structural integrity of the wooden house. A laser level or water level can be used to achieve precision, and adjustments are made using shims or additional concrete. Once the base is set, a moisture barrier and insulation may be added to protect against water damage and improve energy efficiency. This phase typically takes 1–2 days but can extend if complex adjustments are needed.

Comparatively, while the framing and roofing of a wooden house can proceed quickly, the foundation building process is slower and more labor-intensive. It accounts for approximately 20–30% of the total construction timeline, which for a small to medium-sized house can range from 3 to 6 months. Skipping or rushing this phase can lead to costly repairs or even structural failure down the line. Therefore, investing time and resources in a robust foundation is not just a step—it’s a necessity.

In conclusion, foundation building is a multifaceted process that requires careful planning, skilled labor, and attention to detail. From site preparation to setting the base, each step is interdependent and critical to the overall success of the project. While it may seem time-consuming, the longevity and stability of the wooden house depend entirely on this foundational work. Patience in this phase pays dividends in the form of a durable, safe, and long-lasting home.

Basement Wood Swelling: Duration and Effective Remedies Explained

You may want to see also

Explore related products

Framing & Assembly: Constructing walls, roof, and structural components of the house

The framing and assembly phase is the backbone of your wooden house, transforming piles of lumber into a recognizable structure. This stage demands precision, as every wall, roof truss, and joint contributes to the overall stability and safety of the building.

Steps to Efficient Framing:

- Layout and Marking: Begin by laying out the floor plan on the foundation, marking wall positions with chalk lines. Use a laser level to ensure accuracy, especially for plumb walls and square corners.

- Wall Construction: Pre-assemble walls on the ground, starting with bottom plates, studs (typically 16 or 24 inches on center), and top plates. Secure with nails or screws, ensuring each wall is straight and square.

- Raising Walls: With a team, lift each wall into place, securing it temporarily with braces. Use a nail gun for speed and consistency when fastening walls to the sole plate and each other.

- Roof Framing: Build roof trusses or rafters off-site if possible, then hoist them into position. Ensure proper bracing and alignment before sheathing the roof with plywood or OSB.

Cautions and Best Practices:

- Always double-check measurements; a 1/8-inch error can compound over multiple studs.

- Use hurricane ties or metal connectors for critical joints, especially in high-wind or seismic zones.

- Avoid overloading walls with sheathing until the roof is framed, as this can compromise stability.

Time Investment: For a small to medium-sized house (1,500–2,500 sq. ft.), framing typically takes 2–4 weeks with a skilled crew of 3–5 workers. DIY builders should allocate 4–8 weeks, factoring in learning curves and weather delays.

Takeaway: Framing is not just about speed but precision. A well-executed frame ensures the house stands strong for decades, while shortcuts can lead to costly repairs or safety hazards. Invest time in planning and double-checking measurements—it’s the foundation of your foundation.

Untreated Wood Outdoors: Lifespan, Durability, and Weather Resistance Explained

You may want to see also

Explore related products

Finishing Touches: Adding insulation, plumbing, electrical work, and interior/exterior details

Insulation is the unsung hero of any wooden house, transforming a mere structure into a comfortable, energy-efficient home. Proper insulation not only regulates indoor temperature but also reduces noise and prevents moisture buildup. For a wood house, rigid foam or spray foam insulation is often preferred due to its high R-value and ability to fit snugly between studs. Installation typically takes 2–4 days for a 2,000-square-foot home, depending on the complexity of the layout. Pro tip: Seal gaps around windows and doors with expanding foam to maximize efficiency. Without adequate insulation, even the most beautifully crafted wood house will fall short in functionality.

Plumbing and electrical work are the veins and nerves of your home, and their installation demands precision and compliance with local codes. Plumbing involves laying pipes for water supply, drainage, and possibly a septic system if you’re off-grid. This phase can take 1–2 weeks, including rough-in and final hookups. Electrical work, which includes wiring outlets, switches, and lighting, typically follows plumbing and takes another 1–2 weeks. Hiring licensed professionals is non-negotiable here—DIY mistakes can lead to costly repairs or safety hazards. For example, improper grounding in electrical systems can cause fires, while leaky pipes can rot wooden structures.

Interior and exterior details are where your wood house gains personality and durability. Inside, choose finishes like hardwood floors, tongue-and-groove paneling, or reclaimed wood accents to highlight the material’s natural beauty. Exterior details, such as siding, trim, and roofing, should balance aesthetics with weather resistance. Cedar or redwood siding, for instance, offers natural rot resistance but requires staining every 2–3 years. This phase can take 2–4 weeks, depending on the level of customization. A well-executed exterior not only protects the structure but also enhances curb appeal, ensuring your wood house stands out for decades.

The timeline for these finishing touches varies, but they collectively account for 4–8 weeks in a typical wood house build. While it’s tempting to rush through these stages, cutting corners here undermines the entire project. Insulation, plumbing, electrical work, and detailing are investments in longevity and livability. For instance, spending extra time on waterproofing exterior joints can prevent costly repairs later. Similarly, thoughtful interior design can make a small space feel expansive. These final steps are where a house becomes a home—functional, safe, and uniquely yours.

Durability of Wood Post Mailboxes: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

Building a small wooden house from scratch typically takes 3 to 6 months, depending on factors like size, design complexity, weather conditions, and availability of materials and labor.

Delays can occur due to adverse weather, supply chain issues, permit approvals, changes in design, or labor shortages, potentially extending the timeline by several weeks or months.

Yes, using pre-fabricated materials can significantly reduce construction time, often allowing a wooden house to be completed in 1 to 3 months, as much of the work is done off-site in a controlled environment.