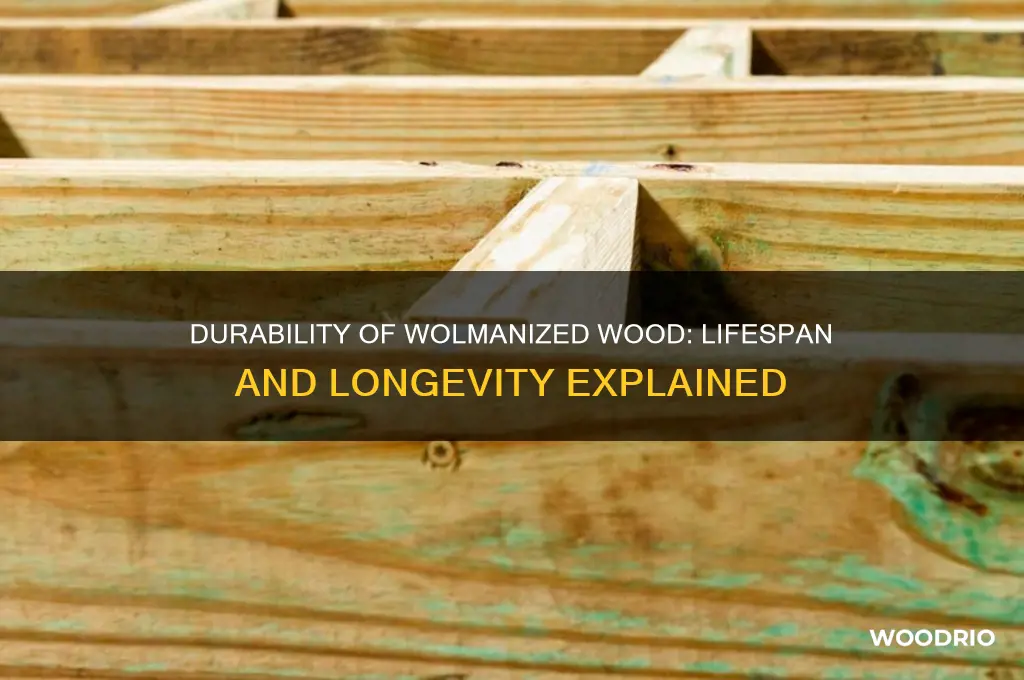

Wolmanized wood, treated with copper-based preservatives, is renowned for its durability and resistance to decay, insects, and fungal growth. When properly installed and maintained, Wolmanized wood can last anywhere from 20 to 40 years or more, depending on factors such as exposure to moisture, soil conditions, and climate. Its longevity makes it a popular choice for outdoor applications like decking, fencing, and structural supports. However, regular inspection and maintenance, such as sealing or staining, can further extend its lifespan, ensuring it remains a reliable and cost-effective material for various construction projects.

| Characteristics | Values |

|---|---|

| Expected Lifespan | 20-40 years (above ground); 40+ years (below ground or in contact with soil) |

| Resistance to Decay | Highly resistant to fungal decay and termite damage |

| Maintenance Required | Minimal; periodic cleaning and re-sealing recommended |

| Environmental Factors | Durability may vary based on exposure to moisture, sunlight, and climate conditions |

| Chemical Treatment | Treated with copper-based preservatives (e.g., ACQ, CA-B) |

| Safety Considerations | Safe for most applications but requires proper handling during installation |

| Common Uses | Decks, fences, playground equipment, outdoor structures, and landscaping |

| Biodegradability | Not biodegradable due to chemical treatment |

| Cost | Higher initial cost compared to untreated wood but lower long-term maintenance costs |

| Sustainability | Sourced from renewable timber; treatment extends wood lifespan, reducing replacement needs |

Explore related products

What You'll Learn

- Factors Affecting Durability: Climate, soil contact, and maintenance impact wolmanized wood lifespan significantly

- Expected Lifespan: Typically lasts 20-40 years with proper installation and care

- Above-Ground Use: Lasts longer when not in direct soil contact, up to 40+ years

- Ground Contact: Shorter lifespan, 15-25 years, due to moisture and pests

- Maintenance Tips: Regular cleaning, sealing, and inspections extend wolmanized wood durability effectively

Factors Affecting Durability: Climate, soil contact, and maintenance impact wolmanized wood lifespan significantly

Wolmanized wood, treated with copper-based preservatives, boasts an impressive lifespan of 20 to 40 years in ideal conditions. However, this durability isn't set in stone. Three critical factors—climate, soil contact, and maintenance—play a pivotal role in determining how long your Wolmanized wood will stand the test of time.

Understanding these factors empowers you to make informed decisions, ensuring your investment in Wolmanized wood pays off for decades.

Climate's Crucial Role:

Imagine a sun-drenched desert versus a damp, humid rainforest. These contrasting climates wreak havoc on Wolmanized wood in different ways. In arid regions, intense UV radiation breaks down the wood's surface, leading to cracking and splintering. Conversely, constant moisture in humid climates creates a breeding ground for fungi and insects, accelerating decay. Extreme temperature fluctuations, common in many regions, cause the wood to expand and contract, weakening its structure over time.

While Wolmanized wood is designed to resist these elements, its longevity is significantly impacted by the severity and frequency of these climatic challenges.

Soil Contact: A Hidden Enemy:

Direct contact with soil is a silent killer for Wolmanized wood. Soil harbors moisture, insects, and microorganisms that can bypass the protective treatment and attack the wood from within. This is especially problematic for fence posts, deck supports, and other structures buried or partially buried in the ground. To mitigate this, consider using gravel or concrete bases to elevate the wood, minimizing direct soil contact. Additionally, ensure proper drainage around the wood to prevent water pooling and prolonged moisture exposure.

Maintenance: The Key to Longevity:

Think of Wolmanized wood like a well-oiled machine. Regular maintenance is essential to keep it functioning optimally. Inspect your wood structures annually for signs of wear and tear, such as cracks, splinters, or discoloration. Address any issues promptly, using appropriate wood sealants or preservatives to protect exposed areas. For added protection, consider applying a fresh coat of sealant every 2-3 years, especially in harsh climates. Remember, preventative maintenance is far less costly than replacing damaged wood.

Maximizing Lifespan: A Holistic Approach:

By understanding the interplay of climate, soil contact, and maintenance, you can significantly extend the lifespan of your Wolmanized wood. Choose the right type of Wolmanized wood for your specific climate and application. Implement strategies to minimize soil contact and moisture exposure. Finally, commit to a regular maintenance routine, treating your Wolmanized wood with the care it deserves. With these measures in place, you can enjoy the beauty and durability of Wolmanized wood for generations to come.

Wooden Bulkhead Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

Expected Lifespan: Typically lasts 20-40 years with proper installation and care

Wolmanized wood, a pressure-treated lumber, is renowned for its durability, but its lifespan hinges on meticulous installation and maintenance. Properly installed and cared for, this material can endure for 20 to 40 years, making it a reliable choice for outdoor structures like decks, fences, and playground equipment. The key to maximizing its longevity lies in understanding the treatment process and adhering to best practices during and after installation.

Installation Matters: The lifespan of Wolmanized wood begins with correct installation. Ensure the wood is not in direct contact with soil or water, as prolonged exposure can accelerate decay. Use corrosion-resistant fasteners, such as stainless steel or hot-dipped galvanized screws, to prevent rust and staining. Proper spacing between boards allows for adequate airflow, reducing moisture retention and the risk of rot. For ground-contact applications, opt for wood treated with higher chemical retention levels, typically labeled as .40 PCF (pounds per cubic foot), which offers enhanced protection against insects and fungi.

Maintenance is Key: Even with proper installation, Wolmanized wood requires regular maintenance to reach its full potential. Inspect the wood annually for signs of wear, such as cracks, splinters, or discoloration. Clean the surface with a mild detergent and water to remove dirt, mildew, and algae. Every 2–3 years, apply a water-repellent sealant or stain to protect against UV damage and moisture infiltration. Avoid using paints or solid-color stains that can trap moisture, leading to premature deterioration.

Environmental Factors: The surrounding environment plays a significant role in the wood’s lifespan. In regions with high humidity, frequent rainfall, or extreme temperature fluctuations, Wolmanized wood may require more frequent maintenance. For example, in coastal areas, saltwater exposure can accelerate corrosion of fasteners and degrade the wood’s surface. In such cases, consider using additional protective measures, like installing a barrier between the wood and the ground or applying a marine-grade sealant.

Comparative Advantage: Compared to untreated wood, which typically lasts 5–10 years in outdoor applications, Wolmanized wood’s 20–40 year lifespan offers a substantial return on investment. However, it falls short of alternatives like composite materials or cedar, which can last 50+ years with minimal maintenance. For those seeking a balance between cost and durability, Wolmanized wood remains a practical choice, provided its care requirements are diligently followed. By investing time in proper installation and routine upkeep, homeowners can ensure this material stands the test of time.

Durability of Wooden Planter Boxes: Lifespan and Maintenance Tips

You may want to see also

Explore related products

$34.17

Above-Ground Use: Lasts longer when not in direct soil contact, up to 40+ years

Wolmanized wood, when used above ground, can outlast its in-ground counterparts by decades, often enduring for 40 years or more. This extended lifespan is primarily due to reduced exposure to moisture and soil-dwelling organisms that accelerate decay. For instance, a deck or fence post made from Wolmanized lumber will face fewer threats from rot and insect damage compared to a buried support beam, which is constantly in contact with damp soil.

To maximize the longevity of Wolmanized wood in above-ground applications, follow these steps: first, ensure proper installation by using corrosion-resistant fasteners like stainless steel or hot-dipped galvanized nails. Second, apply a UV-protective sealant or stain every 2–3 years to shield the wood from sun damage, which can cause surface degradation over time. Third, maintain adequate ventilation around the wood to prevent moisture buildup, especially in humid climates.

A comparative analysis highlights the advantage of above-ground use: while Wolmanized wood in direct soil contact typically lasts 15–25 years, above-ground structures can easily surpass 40 years with minimal maintenance. For example, a pergola or playground structure built with Wolmanized lumber will require far less frequent replacement than a retaining wall or fence post buried in the ground. This makes above-ground applications a cost-effective choice for long-term projects.

Practical tips for homeowners include avoiding direct contact with concrete or metal surfaces, as these can trap moisture against the wood. Instead, use plastic or rubber spacers to create a barrier. Additionally, inspect above-ground structures annually for signs of wear, such as cracks or splintering, and address issues promptly to prevent further damage. By adhering to these guidelines, you can ensure Wolmanized wood reaches its full potential lifespan in above-ground settings.

Elder Scrolls Wood Elves Lifespan: Unveiling Their Mystical Longevity Secrets

You may want to see also

Explore related products

Ground Contact: Shorter lifespan, 15-25 years, due to moisture and pests

Wolmanized wood, a type of pressure-treated lumber, is renowned for its durability, but its lifespan varies significantly based on its application. When used in ground contact, this material faces a unique set of challenges that curtail its longevity to 15–25 years. This reduced lifespan is primarily attributed to two relentless adversaries: moisture and pests. Understanding these factors is crucial for anyone considering Wolmanized wood for projects where it will be in direct contact with the earth.

Moisture is the silent saboteur of ground-contact Wolmanized wood. Despite the chemical treatment, prolonged exposure to soil moisture accelerates the breakdown of the wood’s protective barrier. Over time, waterlogged conditions foster fungal growth, which can compromise the wood’s structural integrity. For instance, in regions with high humidity or frequent rainfall, the lower end of the lifespan spectrum (15 years) is more likely. To mitigate this, ensure proper drainage around the wood and consider elevating structures slightly above ground level where feasible.

Pests, particularly termites and carpenter ants, pose another significant threat. While Wolmanized wood is treated with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ), these chemicals are not foolproof against persistent infestations. Termites, for example, can still tunnel through the wood, creating pathways for moisture and further decay. Regular inspections and the application of additional pest deterrents, such as termiticide barriers, can help extend the wood’s life.

Comparatively, Wolmanized wood used above ground can last 30–40 years, highlighting the stark difference in lifespan based on application. This disparity underscores the importance of selecting the right type of treated wood for your project. For ground-contact applications, opt for wood rated specifically for this purpose, as it typically contains higher concentrations of preservatives. Additionally, consider using gravel or concrete bases to minimize direct soil contact.

In practice, maximizing the lifespan of ground-contact Wolmanized wood requires proactive maintenance. Annually inspect the wood for signs of moisture damage, such as warping or discoloration, and address issues promptly. For pest control, consult with a professional to establish a preventive treatment plan. While 15–25 years may seem limited, with proper care, this material can still provide reliable performance for decades in even the most demanding environments.

How Long Does Wet Rot Take to Destroy Wood?

You may want to see also

Explore related products

Maintenance Tips: Regular cleaning, sealing, and inspections extend wolmanized wood durability effectively

Wolmanized wood, treated with copper-based preservatives, boasts a lifespan of 20 to 40 years, significantly outperforming untreated alternatives. However, this impressive durability isn't automatic; it hinges on proactive maintenance. Regular cleaning, sealing, and inspections are the trifecta that safeguards your investment, ensuring Wolmanized wood reaches its full potential.

Neglecting these practices leaves wood vulnerable to moisture infiltration, UV damage, and the relentless assault of fungi and insects. Think of it like a car: regular oil changes and tune-ups prevent breakdowns, while ignoring maintenance leads to costly repairs.

Cleaning: Dirt, debris, and organic matter act as sponges, trapping moisture against the wood's surface. This creates the perfect breeding ground for rot and decay. Aim to clean Wolmanized wood surfaces at least twice a year, more frequently in areas prone to dirt accumulation or leaf litter. Use a mild detergent solution and a soft-bristle brush, avoiding harsh chemicals or pressure washing, which can damage the protective coating.

Rinse thoroughly with clean water and allow the wood to dry completely before proceeding to sealing.

Sealing: Think of sealant as sunscreen for your Wolmanized wood. It acts as a barrier against UV rays, moisture, and temperature fluctuations, preventing cracking, warping, and fading. Choose a high-quality, water-repellent sealant specifically formulated for pressure-treated wood. Apply a generous coat, following the manufacturer's instructions for drying times and reapplication frequency, typically every 2-3 years.

Inspections: Early detection is key to preventing minor issues from becoming major problems. Conduct thorough inspections at least annually, looking for signs of cracking, splintering, discoloration, or insect activity. Pay close attention to areas where water tends to pool, such as joints and crevices. Address any issues promptly, whether it's a simple touch-up with sealant or more extensive repairs.

By incorporating these maintenance practices into your routine, you'll significantly extend the lifespan of your Wolmanized wood, ensuring it remains a beautiful and functional part of your outdoor space for decades to come. Remember, a little preventative care goes a long way in preserving the value and longevity of your investment.

Cedar vs Pressure Treated Wood: Which Lasts Longer Outdoors?

You may want to see also

Frequently asked questions

Wolmanized wood, treated with Wolmanized preservatives, can last 20 to 40 years or more, depending on environmental conditions, maintenance, and usage.

Yes, Wolmanized wood lasts significantly longer than untreated wood, which typically deteriorates within 5 to 10 years due to rot, insects, and weathering.

The lifespan of Wolmanized wood is influenced by exposure to moisture, soil contact, climate, and proper installation. Regular maintenance, such as sealing or staining, can further extend its durability.