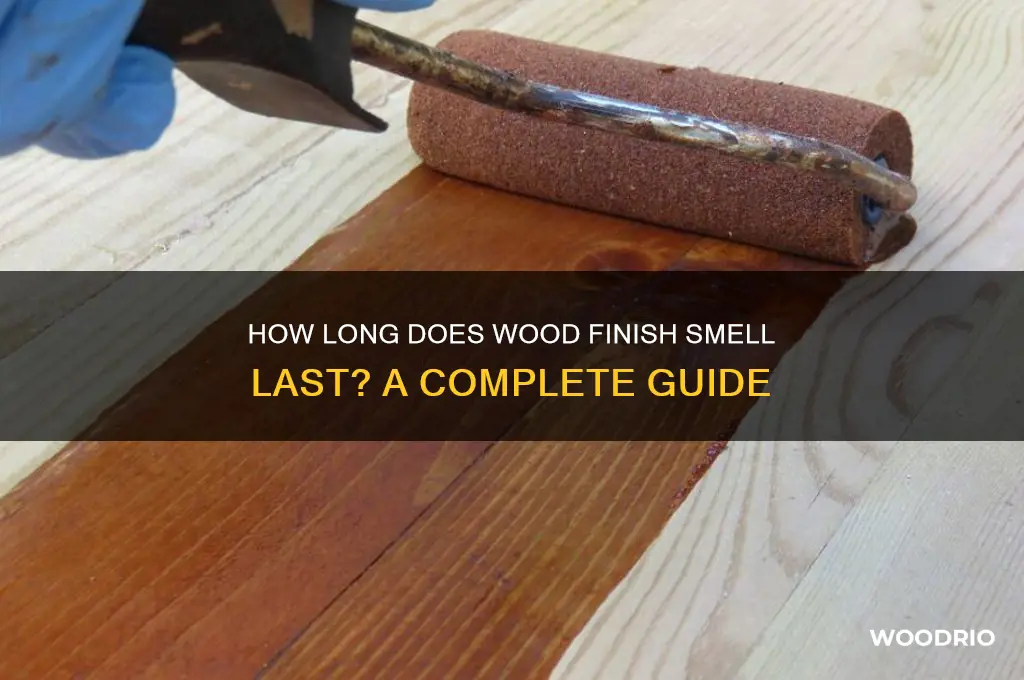

Wood finishes, such as stains, sealers, and varnishes, often emit a distinct odor during and after application, which can linger for varying durations depending on the type of product, environmental conditions, and ventilation. The smell is typically caused by volatile organic compounds (VOCs) present in the finish, which evaporate over time. Water-based finishes generally have a milder odor and dissipate more quickly, often within a few hours to a couple of days, while oil-based finishes can have a stronger, more persistent smell that may last several days to weeks. Proper ventilation, temperature, and humidity levels play a crucial role in how long the odor remains, with warmer and well-ventilated spaces accelerating the drying and off-gassing process. Understanding these factors can help homeowners and DIY enthusiasts manage expectations and ensure a more comfortable environment during and after wood finishing projects.

| Characteristics | Values |

|---|---|

| Type of Wood Finish | Oil-based, water-based, polyurethane, varnish, shellac, wax, etc. |

| Odor Duration (General) | 24 hours to several weeks depending on type and conditions |

| Oil-Based Finishes | 1–4 weeks |

| Water-Based Finishes | 24–72 hours |

| Polyurethane Finishes | 1–2 weeks |

| Varnish Finishes | 1–3 weeks |

| Shellac Finishes | 24–48 hours |

| Wax Finishes | 24–48 hours |

| Factors Affecting Odor Duration | Ventilation, humidity, temperature, thickness of application, and type |

| Ventilation Impact | Proper ventilation reduces odor duration significantly |

| Humidity Impact | Higher humidity prolongs drying and odor |

| Temperature Impact | Warmer temperatures speed up drying and reduce odor duration |

| Thickness of Application | Thicker coats take longer to cure and emit odor |

| Odor Elimination Tips | Use fans, air purifiers, open windows, or odor-neutralizing products |

| Health Considerations | Prolonged exposure to fumes may cause headaches or dizziness |

| Recommended Cure Time Before Use | Follow manufacturer guidelines (typically 72 hours to 1 week) |

Explore related products

What You'll Learn

Factors affecting wood finish odor duration

The duration of wood finish odor is influenced by several key factors, each playing a unique role in how long the smell lingers. Understanding these factors can help you manage expectations and take proactive steps to minimize odor persistence. For instance, the type of finish used—whether it’s oil-based, water-based, or a natural wax—directly impacts the off-gassing period. Oil-based finishes, such as polyurethane, typically emit odors for 2 to 7 days, while water-based options may dissipate within 24 to 48 hours due to their lower VOC (volatile organic compound) content.

Environmental conditions significantly affect how quickly wood finish odors dissipate. Temperature and humidity are critical variables; warmer temperatures and higher humidity accelerate curing and evaporation, reducing odor duration. For example, maintaining a room temperature of 70°F (21°C) with 50% humidity can cut drying time by up to 30% compared to cooler, drier conditions. Proper ventilation is equally essential—opening windows, using fans, or employing air purifiers with activated carbon filters can expedite the process. In poorly ventilated spaces, odors may persist for weeks, whereas well-ventilated areas often see a reduction within days.

The application method and thickness of the finish layer also play a role. Over-application or uneven coats can prolong curing time, trapping solvents and extending the odor release period. Professionals recommend applying thin, even coats, allowing each layer to dry fully before adding another. For example, two thin coats of polyurethane may cure and lose their odor within 3 days, while a single thick coat could take up to a week. Sanding between coats ensures better adhesion and reduces the risk of prolonged off-gassing.

Lastly, the specific chemicals in the finish and their VOC levels are determining factors. Finishes labeled "low-VOC" or "zero-VOC" are formulated to minimize odor and health risks, often dissipating within 1 to 3 days. Conversely, high-VOC finishes, common in traditional oil-based products, can emit odors for 5 to 14 days or longer. Always check product labels for VOC content and follow manufacturer guidelines for application and curing. For sensitive individuals, opting for eco-friendly finishes or allowing extended curing time in a well-ventilated area is advisable.

By considering these factors—finish type, environmental conditions, application technique, and chemical composition—you can better predict and control the duration of wood finish odors. Practical steps like choosing low-VOC products, maintaining optimal temperature and humidity, and ensuring proper ventilation can significantly reduce odor persistence, making the finishing process more manageable and less intrusive.

Curing Green Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

$16.99

Types of finishes and their smell longevity

The duration of a wood finish's odor varies significantly depending on the type of finish used, with factors like ventilation, humidity, and application thickness playing critical roles. Oil-based finishes, such as polyurethane or varnish, typically emit a strong solvent smell that can linger for 2–4 weeks in poorly ventilated spaces. Water-based finishes, on the other hand, dry faster and have a milder odor that dissipates within 24–72 hours. Natural oils like linseed or tung oil retain a faint, earthy scent for 1–2 weeks but are often preferred for their non-toxic nature. Understanding these differences helps in choosing the right finish for your project and managing expectations for odor persistence.

For those seeking a quick turnaround, shellac is an excellent option. This alcohol-based finish dries rapidly, with its alcohol scent disappearing within 8–12 hours. However, shellac is less durable than other finishes, making it ideal for low-traffic areas or temporary applications. Lacquer, another fast-drying finish, emits a potent smell that can last 3–5 days, though proper ventilation can significantly reduce this timeframe. Both finishes are popular in professional settings due to their speed, but their strong initial odor requires careful planning for indoor use.

If odor longevity is a primary concern, consider wax or hemp oil finishes. Wax, applied in thin layers, has a mild, pleasant scent that fades within 24–48 hours. Hemp oil, known for its eco-friendly properties, leaves a subtle nutty aroma that lingers for 3–5 days. These finishes are ideal for furniture or surfaces where chemical smells are undesirable. However, their durability is lower compared to polyurethane or varnish, so they require more frequent reapplication.

To minimize odor persistence, follow these practical tips: apply finishes in thin, even coats to avoid trapping moisture, maintain optimal room temperature (65–75°F) for faster curing, and use fans or dehumidifiers to improve air circulation. For oil-based finishes, consider adding a small amount of odor-neutralizing additive to the product before application. Always test the finish in a small, well-ventilated area to gauge its smell and drying time before committing to a larger project. By matching the finish to your needs and environment, you can balance durability, aesthetics, and odor management effectively.

How Long Can Bacteria Survive on Wood Surfaces?

You may want to see also

Explore related products

Ventilation impact on curing time and smell

Proper ventilation is critical when applying wood finish, as it directly influences both curing time and the persistence of odors. Without adequate airflow, solvents in the finish remain trapped, slowing evaporation and prolonging the drying process. For oil-based finishes, which rely on oxidation to cure, stagnant air can hinder polymerization, leaving the surface tacky for days or even weeks. Water-based finishes, while faster-drying, still require ventilation to dissipate moisture and prevent a lingering chemical smell. A well-ventilated workspace accelerates solvent release, ensuring the finish cures uniformly and reducing the time you’ll need to avoid the treated surface.

To maximize ventilation, follow these steps: open windows and doors to create cross-flow, use fans to direct air outward, and consider an exhaust system if working indoors. For larger projects, such as flooring or furniture, aim for a minimum airflow rate of 10 air changes per hour (ACH) in the workspace. This can be achieved with a combination of natural ventilation and mechanical assistance. If using a fan, position it to blow air away from the finish, not across it, to avoid dust contamination. For confined spaces, a portable air scrubber with a HEPA filter can remove airborne particles while maintaining airflow.

The impact of ventilation on smell is equally significant. Volatile organic compounds (VOCs), common in wood finishes, are the primary source of odors. Without ventilation, these compounds accumulate, creating a strong, unpleasant smell that can persist for weeks. For example, polyurethane finishes, which contain high levels of VOCs, may emit a sharp odor for up to 14 days in poorly ventilated areas. In contrast, a well-ventilated space can reduce this timeframe to 2–3 days. To mitigate odors, avoid working in enclosed areas like basements or garages without proper airflow, and consider using low-VOC or water-based finishes, which produce fewer fumes.

A comparative analysis reveals that ventilation not only speeds up curing but also improves the quality of the finish. Inadequate airflow can lead to a cloudy or uneven surface as solvents fail to escape properly. For instance, a study comparing oil-based finishes in ventilated vs. non-ventilated environments found that the former cured 40% faster and exhibited a smoother, more consistent appearance. Similarly, water-based finishes in well-ventilated spaces showed reduced blistering and bubbling, common issues when moisture is trapped. This highlights the dual benefit of ventilation: it enhances both the aesthetic and functional outcomes of wood finishing.

Finally, consider the long-term implications of ventilation on health and safety. Prolonged exposure to VOCs, even at low concentrations, can cause headaches, dizziness, and respiratory issues. For professionals or hobbyists working regularly with wood finishes, investing in a dedicated ventilation system is a prudent measure. Even for one-off projects, simple precautions like wearing a respirator and ensuring continuous airflow can significantly reduce health risks. By prioritizing ventilation, you not only expedite curing and minimize odors but also create a safer environment for yourself and others.

Durability of Wood Arrows: Lifespan, Care, and Longevity Tips

You may want to see also

Explore related products

Temperature and humidity effects on odor dissipation

Temperature and humidity play a pivotal role in how quickly wood finish odors dissipate, acting as silent accelerators or inhibitors of the process. Higher temperatures increase molecular activity, causing the volatile organic compounds (VOCs) in wood finishes to evaporate more rapidly. For instance, a room maintained at 75°F (24°C) will see odors fade faster than one kept at 60°F (15°C), assuming all other factors are equal. This principle is why professionals often recommend warming a space to expedite curing and odor reduction. However, extreme heat can also cause finishes to dry too quickly, trapping residual odors beneath the surface, so moderation is key.

Humidity, on the other hand, complicates the equation by slowing evaporation. In environments with relative humidity above 60%, moisture in the air competes with VOCs for space, hindering their escape. This is particularly noticeable in water-based finishes, which rely on water evaporation to cure. For example, a basement with 70% humidity may retain wood finish odors for weeks longer than a well-ventilated, dry attic. To counteract this, using dehumidifiers or ensuring proper airflow can significantly speed up odor dissipation in humid conditions.

Practical steps to leverage temperature and humidity include maintaining a consistent room temperature between 70°F and 75°F (21°C to 24°C) and keeping humidity below 50%. Opening windows during mild weather or using fans to circulate air can further enhance evaporation. For oil-based finishes, which emit stronger odors, pairing warmth with low humidity is especially effective. Conversely, in cold or damp climates, consider using space heaters or dehumidifiers to create an optimal drying environment.

A comparative analysis reveals that while temperature directly influences evaporation rates, humidity acts as a passive barrier. For instance, a wood finish applied in a dry, warm environment might lose its odor within 3–5 days, whereas the same finish in a cool, damp space could take 2–3 weeks. This underscores the importance of controlling both factors simultaneously for efficient odor dissipation. Ignoring humidity in favor of heat alone can lead to prolonged curing times and lingering smells, particularly in water-based finishes.

In conclusion, understanding the interplay between temperature and humidity allows for strategic manipulation of drying conditions. By creating a warm, dry environment, homeowners and professionals can minimize the time wood finish odors persist. This not only improves indoor air quality but also ensures finishes cure properly, avoiding issues like tackiness or uneven drying. Whether refinishing furniture or flooring, mastering these environmental factors is a practical, cost-effective way to achieve faster, more reliable results.

How Long Do Wood Ticks Stay Attached to Humans?

You may want to see also

Explore related products

Comparing oil-based vs. water-based finish smells

The smell of wood finish can linger, but the duration and intensity vary significantly between oil-based and water-based products. Oil-based finishes, such as polyurethane or varnish, are known for their strong, solvent-like odor that can persist for weeks. These finishes contain volatile organic compounds (VOCs), which evaporate slowly, releasing fumes that can be overwhelming in poorly ventilated spaces. In contrast, water-based finishes emit a milder, more fleeting scent, often described as slightly sweet or ammonia-like, that typically dissipates within 24 to 48 hours.

From a practical standpoint, choosing between oil-based and water-based finishes often hinges on your tolerance for smell and the project timeline. If you’re refinishing furniture in a well-ventilated garage, the longer-lasting odor of oil-based finishes might be manageable. However, for indoor projects like kitchen cabinets or flooring, water-based finishes are preferable due to their quicker drying time and reduced odor. For example, applying a water-based polyurethane in a bedroom allows you to reoccupy the space within a day or two, whereas an oil-based counterpart could require up to a week for the smell to become tolerable.

Analyzing the chemical composition provides insight into these differences. Oil-based finishes rely on petroleum-derived solvents, which release VOCs as they cure, contributing to their potent smell. Water-based finishes, on the other hand, use water as the primary carrier, with minimal VOC content. This not only reduces odor but also makes them a healthier option, especially for individuals with chemical sensitivities or respiratory issues. Manufacturers often label water-based products as "low-VOC" or "VOC-compliant," adhering to environmental regulations that limit harmful emissions.

A comparative study of user experiences highlights the trade-offs. Oil-based finishes are praised for their durability and rich, amber hue, but users frequently complain about the lingering smell and the need for extensive ventilation. Water-based finishes, while less odoriferous, may require additional coats to achieve the same level of protection and can raise the wood grain, necessitating extra sanding. For instance, a professional woodworker might opt for oil-based finishes for high-traffic areas like staircases, accepting the prolonged odor for superior longevity, while a DIY enthusiast refinishing a nursery crib would prioritize the quick-drying, low-odor benefits of a water-based product.

In conclusion, the choice between oil-based and water-based finishes ultimately depends on your project requirements and personal preferences. If odor is a primary concern, water-based finishes offer a faster, more pleasant experience, though they may demand additional effort for optimal results. Oil-based finishes, despite their stronger smell, remain a top choice for projects where durability and aesthetic appeal are paramount. Always follow manufacturer guidelines for application and ventilation, and consider using respirators or masks when working with oil-based products to minimize exposure to harmful fumes.

Drying Wood: Understanding the Timeframe for Perfectly Seasoned Lumber

You may want to see also

Frequently asked questions

The smell of wood finish usually lasts 1–3 days for water-based finishes and 3–7 days for oil-based finishes, depending on ventilation and humidity.

Yes, increasing ventilation by opening windows, using fans, or running air purifiers can significantly reduce the smell faster.

While the smell itself is not usually harmful, prolonged exposure to wood finish fumes can irritate the eyes, nose, and throat, especially for those with sensitivities.

Yes, oil-based finishes tend to have a stronger and longer-lasting smell compared to water-based finishes, which are generally milder and dissipate quicker.